Any electric floor must be checked for malfunctions during the installation stage. As soon as the heating elements are laid, you need to connect the power supply and observe the operation. If all systems function smoothly and without failures, then you can begin pouring the screed or laying the topcoat. For non-professionals, it is better to entrust the installation of heated electric floors to specialists, since improper handling of electrical appliances can lead to big problems.

Checking the resistance of a heated floor

All manufacturers declare the high reliability of electric heating systems, provide a guarantee, and indicate on the product a service life of up to 20 years. If everything is done correctly at the installation stage, then the warm floor will actually last for decades. But, there are also non-standard situations when the heated floor does not heat. What to do in this case? There are several reasons for this situation:

- thermostat malfunction;

- The heated floor temperature sensor does not work;

- Damage to floor heating wires. Cable diagram for heated floors

Heated floor malfunctions

A malfunction of the infrared heated floor system is an unlikely but possible event.

Most often, the reason for this is an error made during installation. In this article we will look at ways to detect the cause of a malfunction. First of all, it is necessary to determine the faulty element. The main elements that may be incorrectly connected or fail are the heating element itself, the connecting wires, the thermostat and temperature measurement sensors.

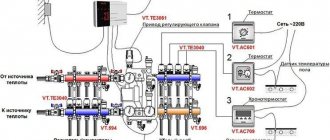

Main elements of a film heated floor heating system

Make sure the thermostat is receiving power and is set to the correct settings. If power is supplied but there is no effect, the next step is to check that the wires are connected correctly to the thermostat. Refer to the owner's manual or contact markings on the back of the thermostat to make sure all contacts are connected correctly. If everything is in order here, then we move on to checking the heating elements themselves.

In most cases, the heating film fails due to improper installation. This could be an error in connecting the wires to the film, their break during installation, or an incorrectly calculated cross-section.

There are two ways to check the health of the heating film.

Resistance measurement

The first method is to measure the resistance of the floor and compare it with that indicated in the passport. The resistance value can be calculated using the formula R=U/P. When using several heating elements, you can check the resistance of each individually.

Signs of a malfunctioning film heated floor:

- If the meter reading is zero, there is most likely a short circuit in the system.

- If the device reading is infinity, the heating element in the system may break.

In any case, if the measured resistance does not match the specification, the cause of the malfunction lies in the film. It is necessary to check the integrity of the wires and the correct connection to the heating elements.

Connecting the heating film

The second method is to connect power to the heated floor directly, bypassing the thermostat. If the film starts to heat up, then the problem is with the thermostat. Otherwise, it is necessary to check the film and the wires connected to it.

Attention!

All work is performed with the power supply turned off! Contacts on the thermostat may differ; refer to the operating instructions and markings on the thermostat.

Connecting the film to the network without a thermostat for a long time can lead to its failure. If, when connecting the heating film, the machine directly knocks out, there may be a short circuit or a malfunction of the machine; in this case, it is necessary to measure the resistance of the heated floor; it should not tend to zero.

How to check the functionality of the thermostat

Malfunctions of the thermostat can be associated both with the device itself and with the remote temperature sensor.

When the thermostat fails, most often the relay or capacitor is to blame. Considering the cost of repairing it, it is more advisable to purchase a new thermostat. To check the functionality of the thermostat you must:

- set the thermostat to the minimum temperature,

- apply voltage to the thermostat and measure it (should be 220 V),

- move the toggle switch to the ON position,

- Set the thermostat to the maximum temperature. When the temperature rises, a click is heard from a working thermostat (the relay switches). The voltage at the load contacts (wires going to the heating elements) should be 220 V.

- when the thermostat is set to the minimum temperature, the relay is activated again, cutting off the voltage supply to the load contacts.

Checking the temperature sensor

To check the serviceability of the floor temperature sensor, you need to measure its resistance using a multimeter. Each sensor has a declared factory resistance indicated in the passport. As the temperature sensor heats up, its resistance decreases. If the resistance differs by more than 5 kOhm, or is equal to 0, then the sensor is faulty and requires replacement.

Note

In programmable thermostats, if the temperature sensor is faulty, a corresponding message is displayed on the panel.

Checking when a fault occurs

During the operation of the heated floor, deviations from the normal operating mode may occur. Let us consider the main manifestations of system dysfunction.

No heating over the entire floor area

In this case, you need to start checking for a break from the “head”, that is, make sure that power is supplied to the system. If the mains voltage indicator does not light up, you need to check the machine on the panel. After this, you can check whether voltage is supplied to the input of the temperature controller. The presence of voltage at the input and its absence at the output indicates a malfunction in the thermostat itself. The reason may be either in the regulator itself, or in the temperature sensor, which can be checked by measuring its resistance. If you apply voltage to the heated floor directly, without a thermostat, you can test the cable for serviceability.

A situation may arise when the circuit breaker in the panel that supplies the heated floor is turned off by the protection. This indicates a short circuit. To localize the short circuit, we check the resistance between the phase and neutral wires supplying the heated floor. Before ringing the cable, remove the voltage. Disconnect the power wires from the temperature controller. We measure the “phase-zero” resistance in the area from the panel to the thermostat. If the device shows zero resistance, the wiring in this area is damaged; if the resistance is high, we continue the search. Disconnect the underfloor heating cable from the temperature regulator. We take measurements at the regulator input. If a short circuit is detected during the test, then the damage is located inside the thermostat. If not, all that remains is the underfloor heating cable itself. You can check this by measuring the resistance between the cable cores. In this case, you cannot do without opening the floor surface.

What to do when voltage is supplied to the heating elements, but heating does not occur? In this case, the cable must be tested, that is, checked for integrity (or for break, if you like). Having set the multimeter to resistance measurement mode, we take measurements between the cable cores. A resistance value close to infinity indicates a conductor break.

The video below clearly shows how to check an electric heated floor with a multimeter by measuring the resistance of the heating cable:

The heating temperature of the heated floor is not adjustable

If the heating elements over the entire floor area warm up, but the temperature does not change when the setpoint set by the regulator is changed, it is necessary to check the system, determining one of two possible options:

- malfunction in the temperature regulator circuits;

- The temperature sensor is faulty.

In this case, the temperature regulator must be dismantled, disconnecting all wires from it and sent for repair. How to check the temperature controller for a heated floor is shown in the video:

If you suspect a sensor, you should check its resistance. To do this, the sensor wires are disconnected from the regulator and the resistance between them is measured. A conclusion about the serviceability of the heated floor temperature sensor can be made by checking the value of its electrical resistance and comparing it with the passport data. As a last resort, you can do without a multimeter. Since this element cannot be repaired anyway, you can proceed as follows. Buy a known-good sensor, place it on the heated floor, and connect it to the regulator. If you ensure good contact of the sensor with the floor, the system should work if the regulator is working. After this, you can install the new sensor in place. This will require opening up the floor surface.

Answers from experts

Sergey Popov:

In no case. The foreman is clearly scamming you. The heated floor heats up immediately. If the floor is electric, then the circuit break or the regulator does not work.

Agonda:

Warm floors come in different varieties. The electric one immediately starts to heat up. Water longer. In our large area (the entire first floor, approximately 100 sq. m.), the water heated floor was turned on for the first time and heated up for 24 hours. And that's a lot. Is your foreman a fraud or an incompetent. Most likely he screwed up, now he’s thinking about how to get rid of it and leave. I don’t want to fix it at my own expense...

Evolutionary:

Well, he turned it down about moisture. What kind of flooring do you have (cable or mat)? If the cable is in a tie, it can really take a long time to heat up. And check: you can disconnect the wires of the floor itself from the thermostat and measure the resistance with a tester or by email. to the counter. Turn off all email. appliances, and then turn on the electric floor. The counter should start spinning.

Andrey:

The foreman claims that to check the correctness of the work you need to wait a month, he says that there is still moisture under the tiles and it interferes with heating... you need to trust people, we don’t live in the forest, support this holy man and tell him what’s stopping you from not only heating, but also paying for all his work, he himself suggested waiting a month, so meet this absolutely honest man halfway... .

Winds:

I support Andrey. Offer to either fix the problem or get money when the floor works.

Any electrical appliance generates heat if it works, regardless of humidity. And if the foreman himself said that he laid the cable on a damp base or laminate on a wet base, demand money from him for damaged materials - a violation of technology

Dmitry Ostankov:

You need to check two indicators: 1) the resistance of the heating core of the mat (using a multimeter). It must correspond to what is specified in the product passport. permissible deviations: +10% / -5% from the specified indicator. The multimeter terminals are connected to the heating core terminals at both ends. 2) insulation resistance (using a megohmmeter). Between the heating leads at both ends of the mat, the megohmmeter should show “0”, i.e. K/Z. , since these wires are closed. Between any of the cores and the screen, the device should show “infinity” - “8” on the side. This is the main indicator. It indicates the integrity of the mat's insulation. This indicator is especially important after filling. And don’t believe electricians who only checked the resistance with a Chinese tester and say that everything is fine.

Andrey Volkov:

They check it in the store in front of you when you buy it. - They look at the resistance with a device. And it’s better to roll it up in a screed

And glue the tiles on a flat surface - under the comb, so that there are no voids under it

Alexander Bakushev:

You can turn it on for a few seconds, if it gets warmer, it means it’s working!

Stas Shabanov:

Check with a tester, it should show 60-70 Ohms..

Functionality check upon purchase and after installation

The first check is carried out when purchasing the system. You need to ask the seller to demonstrate the operation of the device. If the attached documentation indicates the resistance values of the mats, it is advisable to check their actual values with a multimeter or tester. You can also check the insulation resistance. This can be done using a multimeter in high resistance mode, or a megohmmeter.

After installing the heating elements, before laying the tiles and before pouring the screed, you need to connect the electric heated floor to the power supply and observe its operation for a while in different modes. You should make sure that the thermostat, temperature sensor are working properly and that the heating cable is intact. With a working system, all sections of the cable should be heated evenly, the temperature of the heating elements should change in accordance with the setting of the thermostat.

If there is such a possibility, it is most convenient to check the uniformity of heating of the elements with a thermal imager, on the screen of which you can see whether each section of the floor is working or not. This device produces an image that is created by infrared rays, as shown in the photo below:

At this stage, if any malfunction is detected during testing, it is better not to look for the cause and not try to eliminate it. You need to take advantage of the warranty and replace the system.

HEATED FLOOR POWER PER SQUARE METER

Regardless of mats or cables, heated floors are usually selected so that for each square meter of heated surface there is an average of 150 W of electrical power. Depending on the purpose of the room and the purpose of installation, this value may vary:

- from 100 – 130 W, when it is enough just to make the temperature of the coating on the surface comfortable, for example, floor tiles in the bathroom or kitchen;

- from 130-180 W, when it is necessary to supplement the main heating system, it is used most often. It can heat up the floor covering quite strongly, thereby additionally warming the room during cold periods;

- from 180 – 250 W, when the heated floor is used as the main source of heating, or is a full part in the overall heating system for places where it is especially cold, such as a balcony;

- On average, the power of a linear meter of heating cable for a heated floor is 10 - 20 W/m.p.;

Thus, after measuring the resistance, you must estimate the approximate installation area and begin calculations:

Example: Let's say you have a corridor in an apartment in which about 6 square meters are heated. Having measured the resistance of the heating cable with a multimeter, you got a result of 55 Ohms. It remains to calculate how much this is enough for such an area:

First of all, we determine the total power:

P=U2/R= 220 2/55 = 880 W

Then the power of 1 square meter:

Psq.m.=880/6 = 146.7 W/sq.m. – which, taking into account the error, corresponds to the standard, most common electric floor heating power. If the calculated value is too low or high, then you will understand that it is the heating cable that is the cause of the malfunction - and you will be able to repair it.

As you can see, measuring the resistance of the heating cable of an electric heated floor is the main diagnostic method. Heating mats or cables, after they are installed in screed or tile adhesive, cannot be removed or inspected without complete dismantling. And measuring its resistance with a multimeter in everyday life is accessible to everyone and is not an impossible task. Once you know that the floor conductors are not broken, do not short, and have sufficient heating power, you can continue to look for the cause of the malfunction in other components.

Where do leaks come from in the heating system?

The most common cause of leaks in metal pipes is corrosion. Steel, even treated with special coatings, rusts. Only the speed of the process differs. It depends on the operating conditions of each specific system.

Heating pipe rupture

Metal is affected by temperature changes, moisture, and water hammer. Impurities in the coolant may contain aggressive chemicals and abrasives that accelerate corrosion. The places where system elements rust most quickly begin to leak. As a rule, these are connections, joints, seams.

Polymer materials do not rust, but this does not mean that they do not leak. Sooner or later, metal-plastic pipes may leak. Most often this happens if they are chosen incorrectly. Some home owners save money and buy cold water pipes. This is a big mistake, because... leads to deformations and breakthroughs in the system.

Homeowners who choose low-quality products for heating often suffer. Cheap polymer pipes swell, burst, and leak. If this happens, you have to replace the damaged sections. Imaginary savings result in additional costs of money, effort and nerves.

Metal-plastic pipes, which are specially designed for heating systems, are least at risk of leaks. They are designed to withstand high coolant temperatures, do not deform and can last for several decades.

Metal-plastic pipe repair

Method of testing heated floors for performance

To determine the malfunction of the heating system, two methods can be used: visual and the method of measuring basic parameters. And if in the first case the consumer can only rely on external signs (blackening, insulation melts, etc.), then the second option gives a more accurate assessment of the damage to the system.

Checking underfloor heating heaters using a multimeter

The first step is to make sure that there is supply voltage at the thermostat terminals. To do this, by moving the multimeter to the position for measuring alternating voltage, you need to make sure that there is a network. You must first remove the protective cover from the temperature controller.

The next step is to measure the resistance of the heating cable (film). To do this, the entire system should be de-energized and, moving the multimeter to the resistance measurement position, attach the probes of the device to the terminals of the heating elements (after having disconnected them from the thermostat terminals).

Resistance values may vary depending on the power of the device. Well, in order to accurately determine the correctness of the measurements (knowing the power of your heated floor), you can use the following relationship:

P=U2/R,

And then, by substituting the available values, you can determine the correctness of the measurements.

For example, if the multimeter showed a resistance value of 100 Ohms, then the power of your heated floor according to the given formula will be P=2202/50=480W.

By the way, if there are no passport data for a heated floor, then the average power of the heaters can be taken in the ratio of 150 W per 1 square meter of floor area.

By comparing the measurement results with the existing characteristics, you can find out about the quality of the heater. If the measurement results differ significantly from the passport data (more than 10 - 15%), then we can talk about damage to the heating element.

Exceeding resistance – short circuit;

Reduced (zero) resistance values – cable break.

Of course, further repair of the heated floor will require the involvement of specialists for the dismantling and subsequent installation of heating elements.

Checking the thermistor

In the case where the heaters are intact, the next thing you should pay attention to is the thermistor. Its integrity can also be checked using a multimeter

However, it should be understood that the electrical resistance value for a given element can vary significantly depending on the ambient temperature. And the same sensor will show 20 kOhm or more at t= +5⁰С and 5 kOhm at t= +35⁰С. You should pay attention to this point and additionally check the process of resistance change when the temperature sensor warms up.

As mentioned above, replacing a thermistor is a very simple undertaking. And if necessary, the consumer will be able to perform this procedure independently.

Checking insulation with a multimeter

In 99% of cases, ordinary users do not have a megohmmeter. Therefore, such a test in certain situations can at least show something.

Set the switch wheel to the maximum division (2000 kOhm).

Connect one of the probes to the working core, the other to the braid or yellow-green core. If there is damage and a short circuit on the heating cable, the readings will be zero or only a few ohms.

The same test can be carried out in the “call” mode. If there is a short circuit, the multimeter will beep.

During such a test, a working, serviceable cable should show the value “infinity” (the number “1” in the left field of the display or the inscription OL).

If at least some numbers are displayed on the display, then this is a reason to seriously think about the further operation of the cable. With such insulation under mains voltage, there will definitely be a current leakage on it.

Think for yourself, if some battery in a tester with a constant voltage of max 9V is capable of what is called “breaking through” the insulation and showing such a result, then what will happen with a change of 220V?

When the heating is connected through an RCD (as required by the rules), then the RCD should definitely turn off and work.

After checking one working core, do the same procedure with the second. To save time, you can initially hook two at once.

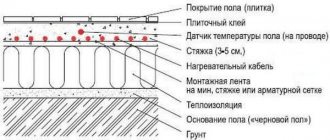

Cable designs and placement

According to the principle of operation, the cable in a heated floor design can be:

- self-regulating;

- resistive.

The self-regulating cable in operating mode changes its resistance with temperature changes. The resistance value of a resistive cable does not depend on temperature. If the cable installation work is carried out in compliance with all requirements and recommendations, then the cable will not be damaged by temperature. The main requirement for cable laying is maintaining a certain length. If the cable turns out to be long during installation, it must not be shortened, as this will cause a change in current characteristics and heating, which will lead to destruction of the insulation. In practice, 2 types of heating cables are most often used:

- single two-wire;

- 2 single-core with parallel arrangement.

A single two-core cable is a mesh of wire, plugged on one side. Mount such a cable in a concrete screed. The selection of the mesh is carried out strictly according to the area of the room, free of plumbing and furniture, since it cannot be cut.

The parallel arrangement of 2 separate cable cores is also mounted in a screed, but differs from the previous cable in that its length can be changed without fear of insulation.

A film floor based on infrared heating differs from cable structures in that it is a chain of active resistances. The advantage of film is its small thickness and the possibility of use with almost all floor coverings. It is allowed to change the area of the film, but only according to special markings.

How to lay film floors under laminate

How to properly lay laminate flooring with your own hands

Most often, film floors are laid under laminate.

The algorithm of actions is similar to that which should be performed when laying cables:

- forgive isolon,

- the joints are taped;

- nail a damper tape around the perimeter;

- The underfloor heating strips are cut into the required lengths and placed on top of the insulation.

- a silver or copper bus runs along the edges of the film; at the cut site it must be insulated with a bitumen adhesive plate;

- The contacts of the supply metal wires are connected to the busbars and crimped with pliers.

All contacts must be covered with bitumen sticky insulator. All protruding parts of the contacts are hidden in cut-out recesses in the heat insulator.

A temperature sensor is installed and also hidden in a cut-out recess in the isolon. In order to cut recesses in the heat insulator, use a regular knife.

This entire procedure must be done carefully and diligently, without leaving exposed wires.

The heating film is covered with plastic film on top. You can lay laminate flooring.

Important. When laying laminate on a heating film, no foamed polyethylene layer is required

If, instead of laminate, you need to lay linoleum or carpet on top, then you need to lay 1 cm thick plywood on top of the film. It is not recommended to use thick plywood, so as not to waste extra energy on heating it.

What should be the resistance of an electric heated floor?

Warm floors are most often produced in the form of heating cables or mats:

Heating mats are a heating cable laid in a certain way and fixed in this position. In addition to the fact that this option has much simpler installation, it has a fixed power per square meter, which does not change.

But the power of a square meter of floor made with a regular cable can vary greatly, depending on how it is placed on the surface, with what density, how many turns are made and the distance between them.

If you know what power the kit is by measuring its resistance, it will not be difficult for you to check its serviceability and efficiency:

It is enough to use Ohm’s law, namely the following formula:

P=U2/R, where P, Watt – power; U, Volt – network voltage, usually 220 Volts are taken into account; R, Ohm - Resistance;

Example: Thus, knowing that a heating mat with a total power of 800 W is poured into the screed, and the multimeter showed a resistance of about 60 Ohms, you can check how much the actual indicators correspond to the declared ones:

P = 220 2/60 = 806.7 W - which is very close to the nominal value, which means the floor is working.

If you do not know the power of the installed electric heating system, you only roughly understand the surface area that it heats and where it is installed, diagnostics should be carried out as follows:

Checking when a fault occurs

During the operation of the heated floor, deviations from the normal operating mode may occur. Let us consider the main manifestations of system dysfunction.

No heating over the entire floor area

In this case, you need to start checking for a break from the “head”, that is, make sure that power is supplied to the system. If the mains voltage indicator does not light up, you need to check the machine on the panel. After this, you can check whether voltage is supplied to the input of the temperature controller. The presence of voltage at the input and its absence at the output indicates a malfunction in the thermostat itself. The reason may be either in the regulator itself, or in the temperature sensor, which can be checked by measuring its resistance. If you apply voltage to the heated floor directly, without a thermostat, you can test the cable for serviceability.

A situation may arise when the circuit breaker in the panel that supplies the heated floor is turned off by the protection. This indicates a short circuit. To localize the short circuit, we check the resistance between the phase and neutral wires supplying the heated floor. Before ringing the cable, remove the voltage. Disconnect the power wires from the temperature controller. We measure the “phase-zero” resistance in the area from the panel to the thermostat. If the device shows zero resistance, the wiring in this area is damaged; if the resistance is high, we continue the search. Disconnect the underfloor heating cable from the temperature regulator. We take measurements at the regulator input. If a short circuit is detected during the test, then the damage is located inside the thermostat. If not, all that remains is the underfloor heating cable itself. You can check this by measuring the resistance between the cable cores. In this case, you cannot do without opening the floor surface.

What to do when voltage is supplied to the heating elements, but heating does not occur? In this case, the cable must be tested, that is, checked for integrity (or for break, if you like). Having set the multimeter to resistance measurement mode, we take measurements between the cable cores. A resistance value close to infinity indicates a conductor break.

The video below clearly shows how to check an electric heated floor with a multimeter by measuring the resistance of the heating cable:

https://youtube.com/watch?v=f9lTMSrwI-4

https://youtube.com/watch?v=f9lTMSrwI-4

The heating temperature of the heated floor is not adjustable

If the heating elements over the entire floor area warm up, but the temperature does not change when the setpoint set by the regulator is changed, it is necessary to check the system, determining one of two possible options:

- malfunction in the temperature regulator circuits;

- The temperature sensor is faulty.

In this case, the temperature regulator must be dismantled, disconnecting all wires from it and sent for repair. How to check the temperature controller for a heated floor is shown in the video:

If you suspect a sensor, you should check its resistance. To do this, the sensor wires are disconnected from the regulator and the resistance between them is measured. A conclusion about the serviceability of the heated floor temperature sensor can be made by checking the value of its electrical resistance and comparing it with the passport data. As a last resort, you can do without a multimeter. Since this element cannot be repaired anyway, you can proceed as follows. Buy a known-good sensor, place it on the heated floor, and connect it to the regulator. If you ensure good contact of the sensor with the floor, the system should work if the regulator is working. After this, you can install the new sensor in place. This will require opening up the floor surface.

too much resistance

Posted by shatl, February 28, 2015 in Warm floor (electric)

Create an account

Register in our community. It's very simple!

Already have an account? Sign in.

Or login using one of these services

Google recommends

Our recommendations

What is it for?

Phoenix posted a topic in Tools and Equipment, January 15, topic

I suggest warming up for those who are interested.

Does anyone have any guesses as to what this is for?)

birch suvel

Sano published a blog post in Slab Furniture, January 23, blog post

This is the cut of birch we brought to the workshop, while we are preliminary planning to make a coffee table.

The preparation of such material itself was not the easiest thing, not only was it found in the forest, it was also difficult to remove, then the suvel was cut into pieces, but after that it was cooked using a special technology for a couple of weeks, and then dried for a couple of years.

In general, this is a whole epic, and due to the fact that so much has been done just for the blank and based on the size, the price of such material is already becoming very high. And this is not the table itself.

You need to approach the work thoughtfully and make a smooth tabletop with minimal loss in the thickness of the workpiece.

Ceilings yin and yang

Ramon published a topic in Our works, December 12, 2008, topic

One of our first works supported the oriental theme with a sakura branch

Table made of slabs. Swallows Hoffmann

Sano published a blog post in Slab Furniture, Sunday at 20:28, blog post

I make a table to order, the tabletop is made from slabs of elm or otherwise elm.

In one of the slabs there is a fairly extensive and sometimes through crack. I cleaned it and also filled it with epoxy resin, it will seal the crack and also level the surface of the countertop.

As an additional blocking from the opening of the crack, Hoffman swallows are embedded, which not only enhance, but also create a decorative effect.

Some will say that they spoil the appearance, and they should have been placed on the back side of the countertop. But the fact of the matter is that you can’t put them there because of the features of the countertop.

I personally like these swallows and besides, their presence was approved by the customer of the table.

They were made from scraps of the same tabletop, two dark swallows lay on the light half, and one light one was cut into the dark half of the tabletop.

A short excursion into where this furniture element came from. For me, this Homphan did not invent anything, but simply took what has been used for centuries in carpentry and other art. In fact, this is the same dovetail connection.

Let's leave this to the author's conscience; besides, the name swallow or Hofmann's butterfly stuck to this type of connection, just as, for example, all copying machines are called Xerox.

In 1985, while still a student at Harvard University, Thomas Hoffmann developed a system for joining parts made of wood and chipboard materials (MDF and chipboard), which was named “Hoffmann Swallow” and was soon adopted throughout the woodworking industry.

Connection diagrams in apartments

What is the way out of the situation?

In city apartments, you can connect water heated floors according to several proposed schemes:

- Scheme A using a two-way valve connected to a thermostat. It regulates the flow of water. You can also install balancing valves. In this way, the temperature level will be regulated by just pressure. In this case, the pressure is controlled by the bypass valve.

- Scheme B involves the use of a bypass, which is a jumper between the combs. Here you can do without a bypass valve.

- Scheme B provides for the installation of a three-way valve on the return line. It will redirect the cooled water to the supply, leveling the desired temperature. The simplest but reliable scheme.

- Scheme D is the same as B, only a three-way valve is placed at the input. It dilutes the hot water with cooled water from the return before heading to the circulation pump.

- Scheme D. A four-way mixing valve is needed here. Can be installed with either manual or automated control.

- Scheme E. One of the most complex and expensive, since it is necessary to purchase a pressure gauge, an air vent and a valve that will regulate the pressure. But that's not all. A membrane expansion tank is needed to compensate for water hammer. In addition, the coolant is fed using a block equipped with a filter, check valve and valve.

Common problems with heated floors

The reason for the breakdown of the heated floor may be improper installation of equipment, or failure of individual elements of the system.

Thermostat

As mentioned above, it is responsible for maintaining the floor temperature in a given range. It is also a switching link on which all underfloor heating circuits are assembled (power, load, temperature control).

And if all connections are made according to the diagram, then the reason for the malfunction of the thermostat lies in its elemental base. Of course, you can try to restore the specified block. But as practice shows, most often repairing a thermostat comes down to replacing it.

temperature sensor

It is an easily replaceable element due to the fact that it is located in a corrugation (laid in the floor screed). The durability of this element directly depends on the quality of the materials from which it is made, as well as on the correct location of it relative to the heating cable (see the manufacturer’s recommendations).

Heating cable

A fairly reliable element of the system, which most often fails due to improper installation. Moreover, the most “problematic area” of the heating cable is the coupling (through which the power is supplied)

Therefore, when doing self-repair, you should first pay attention to this particular unit.

By the way, the method for choosing a heating cable for a heated floor can be found here.

How to find a break in a cable with a multimeter?

For a resistive heating cable, such a break in 90% of cases is observed at one of the couplings:

- at the initial

Where it is spliced with the power cable.

- or at the end

How to find out which clutch is at fault? To do this, you will need a multimeter with a capacitance measurement function.

Moreover, the accuracy of measurements and specific numbers do not matter. It is important by what order of magnitude they differ from each other.

Attach one probe to the working core and the other to the braid. Then to another core and again to the braid.

If the measurement values on one core differ several times from the values on the other, then there is a break in the initial coupling.

If the indicators are approximately equal, then there is a break at the end coupling.

How to check the functionality of the thermostat

Let's look at an example of how you can check whether the thermostat is working using an ordinary light bulb.

Step 1. The thermostat is connected to the network in compliance with all rules. That is, the phase wire is connected to terminal L, and the zero wire is connected to terminal N. A temperature sensor and a regular light bulb screwed into the socket are also connected. It will serve as a load indicator.

Step 2. The thermostat connected to the network is turned on using a toggle switch.

Step 3. The lever responsible for increasing the temperature is set to maximum.

Step 4. If the thermostat is working properly, the light will light up.

Step 5. Using this circuit, you can also check the temperature sensor. To do this, take it in your hand, and the temperature regulator is set to the average value.

Step 6. The temperature control is turned again to higher values. The light will come on again. But when the sensor heats up to the temperature of the human body, it will go out.

Step 7. After this, the system can be left alone. After some time, the light will light up again when the temperature sensor cools down and sends a signal to the thermostat.

Two options

To understand how to properly make a heated floor, and whether you can handle it yourself, you need to get acquainted with their structure. Let's consider two options for heated floors - water heated floors and electric heating systems. Each of their options has the right to life, the final choice is up to the consumer.

There are many subtleties and nuances that need to be taken into account when choosing which system is better:

- Electrical systems will be more expensive during operation, but their installation will not be difficult and the devices and devices themselves are much cheaper. Now you can choose electric floors of various modifications. Installing electronic thermostats will significantly reduce energy consumption, especially in cases where family members spend most of their time at work or traveling. A big plus of installing warm electric floors is that you can use temperature sensors to set different temperatures in individual rooms. For example, you can make the nursery warmer than the family room.

- Water floors are difficult to install, and even the simplest equipment for it will be more expensive than high-quality electric ones, but they will pay for themselves during operation. The difficulty of installation lies in the fact that you need to select suitable pipes, which are not as easy to install as it seems, since they must be a solid coil. Water floors made from high-quality pipes, in compliance with all conditions, are considered very durable and reliable. The savings are that water floors can be connected to an existing heating unit. As a rule, this is a gas boiler, and this fuel is considered the cheapest. On the other hand, to install a gas unit, considerable funds are needed. Therefore, with a small house area and warm winters, you can get by with electric heated floors.

To choose a convenient option, you need to know how to properly install an electric heated floor and how to install a water one.

Thermostat repair

It's no secret that sometimes thermostats fail, and at the most inopportune moment. There are several reasons for this sad event. The most common is incorrect installation: an error in the connection diagram (such as mixing up wires and terminals, too much load), painting the installed thermostat, installing the thermostat in a damp room. With such errors, the thermostat either immediately fails or its service life is significantly reduced. Trust the installation of the thermostat only to a professional electrician.

The second reason is related to the design features of thermostats. The fact is that basically their power supplies are built according to a transformerless circuit with a ballast capacitor (almost all regulators from such companies as: OJ Electronics, Eberle, Raychem, some DEVI), or according to a key stabilizer circuit such as, for example, Devireg D530, Devireg D535 , Veria B45, Veria T45.

Such thermostats are sensitive to impulse noise in the power supply network, which occurs when devices such as a welding transformer, hammer drill or electric lawn mower are turned on near the controller, which often happens in country houses. In such conditions, it is better to use regulators with transformer power supplies that do not allow impulse noise to pass through (for example, the Busch Jaeger NTC100 regulator).

If your regulator fails, do not rush to throw it away. In most cases, the regulator can be repaired.

Our company provides warranty repairs of thermostats purchased through our network of stores or through our dealers, as well as non-warranty repairs of any regulators.

The cost of such repairs is fixed - 1000 rubles.

Warm floor doesn't work! What to do?

A typical customer case! You have decided to install a heated floor in your home, and the builders who are doing the renovations say, “They have been laying floors since early childhood. More than 1000 heated floors have already been installed and everyone is happy. What should I put there?” You, as a person who sincerely trusts your builders, are afraid to show doubts about their professionalism and entrust them with the work of installing heated floors. From this moment the headache begins! The builders finished the repairs and left for their homeland. The old tiles have been laid, the cold weather has set in, but the warm floor is not working! Let's start looking for the cause of the problem.

How to properly install underfloor heating

If you have chosen a “warm floor” heating installation with a type of cable heating elements, then first you need to calculate the installation step of the electric heated floor. The following formula is used for this:

H = S × 100 / L,

here: H is the laying step in centimeters;

S is the surface area that will be used for installation;

L is the length of the heating wire.

Installation of floor heating

The length of the electrical cable depends on the power needed to heat the room.

Having decided how much of this electrical wire is needed and how much area will be covered by the heating system, you can begin installation.

The laying technology consists of several stages. First, you will need to make small recesses in the surface of the base to accommodate the temperature sensor, as well as the location of the wires to connect the thermostat.

To improve the contact of the base with the poured concrete screed, the dry and cleaned surface should be coated with a deep penetration primer.

The prepared base must be covered with roofing felt or polyethylene film, and some heat-insulating fiber of the required thickness with a protective film must be laid on top. It is necessary to protect the thermal insulation material from the influence of alkaline components of the concrete mixture.

To do this, use mounting tape, laying it in accordance with the calculated step size. To securely connect it to the base, dowels or other devices are chosen.

What kind of pipes can there be?

To choose the right pipes for a water floor system, you need to know what properties the materials from which they are made have, and what to especially pay attention to.

Important points when choosing pipes:

- Pipes must be solid along their entire length, without seams. And it doesn’t matter whether the seams are welded or soldered.

- Polypropylene or rigid steel pipes are not suitable, since they cannot be laid on the floor in a single contour. Adapters and fittings are not used for concrete screed; they are not designed for this due to their performance characteristics.

- Elastic pipes that are not subject to scale formation and do not react with oxygen are suitable for water heated floors. The technical characteristics of such pipes should indicate that they can be installed under a concrete screed in a heated floor system.

- The pipes must withstand a pressure of 8 to 10 bar. This is a very important condition when choosing them. Otherwise, there is a possibility that the heated floors will break through the system.

- The average cross-section of the pipes should be from 16 to 20 mm. A thinner diameter will reduce heat transfer, and for a thicker one you need to heat a very large volume of coolant. This will increase fuel consumption.

- Copper pipes are considered the best for water floors. They combine very high heat transfer and are durable. However, very expensive in price.

- For a long time, metal-plastic was the optimal choice. But good metal-plastic pipes are not cheap now. And it is highly undesirable to install poor quality pipes into heated floors, because remodeling the system will be very expensive. If you buy metal-plastic pipes, then you need to buy them from a well-known manufacturer that has proven itself in the market, at a retail outlet that you can trust.

Advice. When choosing metal-plastic, there is one trick: you need to look for pipes that have an oxygen barrier. The fact is that metal-plastic pipes are made of aluminum, which becomes brittle with constant contact with oxygen.

There are a lot of new products on the market made from cross-linked polyethylene, made using high technology. Pipes marked “PE-Ha” and having a protective layer “EVON” are ideal for heated floors. Consumers have already appreciated their quality.

Corrugated stainless steel pipe is another great new product. But quite expensive.

Important. When choosing pipes, you need to take into account that the circuit is laid correctly only when it is solid

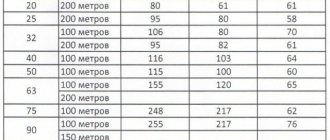

In this case, the length of one circuit should be no more than 80 meters. When this length is not enough, then you need to lay two contour lines.