The heating system of multi-storey buildings is quite complex, and can only work normally if all the necessary requirements are met, which necessarily include maintaining normal operating pressure. The value of this parameter directly determines the full circulation of the coolant, and as a result, the quality of the required heat transfer. And what is also very important, normal pressure is the key to the durability and reliability of the entire heating system as a whole, reducing the likelihood of emergency situations.

Working pressure in the heating system - how to check the norm, reasons for the decrease and increase

So, working pressure in the heating system - how to check the norm, reasons for the decrease and increase? This question often arises among apartment owners in several cases. Most often, the reason is unsatisfactory heating of the home, that is, a decrease in the temperature of the coolant. It is important to have an understanding of this parameter and, if necessary, carry out repair work on the intra-apartment circuit or completely replace it. In this regard, it is worth considering aspects directly related to current norms and standards. It will also be useful to become familiar with the causes of possible deviations and ways to eliminate them.

Pressure drop during heating correct functioning of the system

Often, the normal functioning of the hydraulic water supply system, plumbing equipment, devices and components, comfortable bathing and other hygiene procedures depend on optimal pressure. Most people believe that the system works by simply supplying liquid, you just have to open the tap. In reality, this system represents a rather complex communications system with its own technical parameters and characteristics. For example, voltage drops during heating are a very common occurrence, sometimes pipes even explode.

Where and at what approximate cost is it sold, what else should I consider when purchasing?

You can buy pressure gauges in stores that specialize in heating and water supply. Prices depend on the manufacturer and model. The simplest ones cost around 300-500 rubles.

We should not forget about the adapters that will be required if the thread diameter is different. They cost about 100-150 rubles.

There are models with connecting tubes . Their price can reach several thousand rubles. But usually they are installed only on the equipment itself.

To avoid buying a broken pressure gauge, you need to carefully inspect it. Firstly, the case must be undamaged. Secondly, the needle must be at zero. In addition, you should pay attention to the year of manufacture.

Some people cannot tell the difference between a water and an air pressure gauge. Indeed, outwardly they are absolutely identical, but in structure the difference is huge. Therefore, before purchasing, it is better to check with the seller for what purposes the device is used .

The influence of water pressure on system operation

When purchasing the appropriate plumbing equipment or household appliances connected to the water supply system, you need to familiarize yourself with their technical characteristics in advance. One of the parameters is the optimal pressure level at which the devices will operate normally and no drop will be observed.

If a difference occurs in the heating, then problems with heating the room begin. This indicator for washing machines and dishwashers is considered to be a pressure of 2 atmospheres. However, for automatic bathtubs and watering equipment for a vegetable garden or garden, this value is already 4 atmospheres.

The minimum water pressure for autonomous water supply networks in private homes should be at least 1.5 - 2 atmospheres. It is necessary to take into account that several water consumption objects can be connected to the water supply source at the same time.

Also, creating the necessary water pressure is especially important for private homeowners in case of a fire hazard.

Briefly about the main thing

Normal pressure in the heating system contributes to comfortable living. Ensuring that the pressure gauge needle shows the normal pressure value in the gas boiler is the responsibility of every owner of a house with a heating boiler.

Of course, how much pressure should be in a gas boiler is different for specific systems, since the type of system, equipment features, number of floors of the room - all this affects the value of the normal operating pressure in the heating design.

What pressure value is considered normal?

A stable amount of atmospheres in the main helps to reduce the level of heat loss and ensure that the circulating coolant has almost the same temperature to which it was heated by the boiler.

It is necessary to talk about what the pressure should be, taking into account what kind of heating system we are talking about. Options:

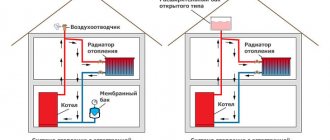

Pressure in the heating system of a private house. With the open heating method, the expansion tank is the communicating link between the system and the atmosphere. Even with the participation of a circulation pump, the number of atmospheres in the tank will be equal to atmospheric pressure, and the pressure gauge will show 0 Bar.

Pressure in the system of a multi-storey building. A characteristic feature of heating systems in multi-storey buildings is high static pressure. The higher the height of the house, the greater the number of atmospheres: in a 9-story building - 5-7 Atm, in 12-story buildings and higher - 7-10 Atm, while the pressure in the supply line is 12 Atm. Therefore, it is necessary to have powerful pumps with a dry rotor.

Heating scheme for a multi-storey building

Pressure in a closed heating system. The situation with a closed highway is somewhat more complicated. In this case, the static component is artificially increased to increase the efficiency of the equipment, as well as to prevent air penetration. The required pressure in the heating system of a private house is calculated by multiplying by 0.1 the difference between the highest and lowest points in meters. This is an indicator of static pressure. By adding 1.5 Bar to it, we get the required value.

Thus, the pressure in the heating system in a private house when installing a closed circuit should be within 1.5-2 atmospheres. An indicator outside the range is considered critical, and when mark 3 is reached, there is a high probability of an accident (depressurization of the main line, failure of units).

Yes, high pressure can improve the operation of the equipment, but the technical characteristics of the installed boiler should be taken into account. Some models can withstand 3 Bar, but most are designed for 2, and in some cases 1.6 Bar

It is important, when setting up the equipment, to achieve a reading in a cold system that is 0.5 Bar lower than the value stated in the passport. This will prevent the pressure relief valve from constantly tripping.

It is important to remember that measuring the water pressure in the heating system or trying to regulate it in a single apartment is pointless. The only thing that depends on the owners of the living space is the choice of batteries and the diameter of the pipes in the pipeline

For example, cast iron is not recommended, as they can only withstand 6 bar. And the use of pipes of larger diameter will lead to a decrease in pressure in the entire heating system of the house. When moving into an apartment with old heating, it is better to immediately replace all possible elements.

Another parameter that affects the amount of pressure in any heating line is the coolant temperature. A certain amount of cold water is pumped into the mounted and closed circuit, which ensures minimum pressure. After heating, the substance will expand and the number of atmospheres will increase. Therefore, by adjusting the water heating temperature, you can control the pressure in the circuit. Today, companies involved in heating equipment offer the use of equipment with hydraulic accumulators (expansion tank). They prevent the pressure from increasing, accumulating energy within themselves. As a rule, they come into operation when the level of 2 atmospheres is reached.

Temperature and pressure distribution in an apartment building

It is important to regularly check the accumulator in order to empty it on time. It would also be useful to install a safety valve, which can be activated at a pressure of 3 atm and a full tank to avoid an accident

Pressure increase due to expansion tank

Reasons for increased pressure in the heating circuit due to problems with the expansion tank:

- Small expansion tank volume. When heated to 85-90 °C, water adds about 4% in volume. If a small tank is selected, the coolant expands when heated and fills the container. There is a complete release of air through the valve. With further heating, the tank can no longer compensate for the thermal increase in the volume of water, as a result, the pressure in the system rises. The volume of the expansion tank must be at least 10% of the total coolant volume in the circuit if a gas boiler is installed, and at least 20% if the boiler is solid fuel. The volume of the tank can be taken approximately according to the boiler power: for 1 kW there are approximately 15 liters of water. But it is better to calculate the volume of a separate circuit (based on heating surfaces);

- Damage to the rubber membrane of the tank. In this case, the water will completely fill the container, and the pressure gauge will show a drop in pressure in the system. But, if you open the make-up valve and add water, then when the coolant heats up, the pressure in the heating circuit will become significantly higher than the operating one. To solve the problem, you will need to replace the tank if the membrane is diaphragm type, or replace the membrane if it is balloon type;

- The pressure in the expansion tank is too high or too low. Malfunctions in the expansion tank are one of the main reasons for increased pressure in a closed system. You can check the pressure and pump it up if necessary using an ordinary car pump. Before checking, you need to drain the water from the heating system - the needle on the system pressure gauge should be at zero. If there are shut-off valves and a drain on the water pipeline to the expansion tank, then it is enough to drain the water only from the tank. Then air is released through the nipple, which is located on the side opposite to the water supply. If the boiler operates at a pressure of 2 bar, then the pressure gauge on the pump should show 1.6 bar. You need to open the water shut-off valve and add the volume of water drained from the expansion tank through the make-up tap. This adjustment method works for both tanks with bottom and top water supply;

- The tank is located immediately after the circulation pump. This leads to the fact that the pressure rises sharply, and almost immediately it is released, and pressure surges are observed. This situation can provoke hydraulic shocks in the circuit. To solve this problem in a closed heating circuit, the expansion tank is installed on the return pipe - in a laminar flow zone with a minimum coolant temperature. The pump crashes into the return line after the tank, in front of the boiler.

Features of open and closed heating systems

According to the design of the heating system in private houses, there can be:

- open - it is assumed that there is an expansion tank and a natural type of circulation of the coolant: when heated, it rises up, and as it cools down, it goes down;

- closed - the heating circuit is isolated from the external environment, and the coolant moves thanks to the circulation pump.

For the successful operation of open-type heating, it is necessary that the boiler be located at the lowest point, and the expansion tank at the highest. In this case, the cross-section of the pipes leaving the boiler must be larger than those entering on the return circuit. This system is used mainly in small one-story houses.

Closed type heating is much more common. In this case, the working pressure in the heating of a private closed house should be at the level of one and a half to two atmospheres, provided that the building is small and there are few batteries. If a private house has many rooms or has several floors, an additional circulation pump will be needed.

If the heating system is filled with water for the first time, air may enter the circuit. Once it is removed, the pressure in the system will drop slightly. It will need to be raised a little more, without, however, bringing it to the working value. As the water warms up, the pressure will increase.

Having a pump in a closed system makes it more efficient and economical. Depending on the power of the pump, the heating can be equipped with the required number of batteries and a pipeline of the required length. Radiators are connected in series or parallel (less load on the boiler).

In the off-season, a closed system with a pump allows you to regulate the degree of heating by setting minimum values.

Possible faults and corrective actions

Significant pressure drops in the heating system when the boiler operating temperature changes can be caused by incorrect calculation of the volume of the expansion tank and the pressure in its air chamber.

Leaks are usually found at threaded connections and are due to insufficient sealant. It will be easier for a beginner to achieve the tightness of such a connection using the Tang it Unilock sealing thread. In case of some “overdose”, unlike tow, it does not cause destruction of the screwed-on part.

In polypropylene pipelines, leaks often occur due to improper welding technology.

For example, some users weld pipes without a coupling - just butt welding.

Such a connection is very short-lived and breaks down very quickly under pressure.

Incorrectly made or defective connections must be cut off and replaced with high-quality ones.

If the water used as a coolant has not been desalted, the heat exchanger will have to be descaled over time. To do this, the boiler is disconnected from the heating circuit and washed with special reagents, for example, Antiscale. The entire heating system can be subjected to such flushing, but due to its complexity, this task should be entrusted to professionals.

Spring safety valves can stick, so they must be opened periodically using a special lever.

In the USSR, the issue of reducing the cost of construction, including the organization of the heating system, was especially relevant. It was at that time that the Leningradka heating system for private and apartment buildings was invented. Let's consider whether it is relevant today.

In what cases is a hydraulic arrow needed for heating and how it functions, read this article.

Types of heating systems

Based on the type of coolant circulation, heating systems are divided into open and closed. In the first case, the flow of water is due to natural causes. The hot coolant located in the tank is forced out into the main line when cold liquid enters the same container - this occurs due to the difference in density. In addition, there are some nuances that facilitate the flow of water. For example, the lines leading to heating radiators are located at a slight slope, which makes it possible to also use gravitational force in the movement of the coolant.

A closed heating system ensures the movement of water through pipes using special equipment - a circulation pump. This approach has both advantages and disadvantages. For example, the disadvantage is that such a system requires an uninterrupted supply of electricity to operate. but the issue of a possible power outage is easily resolved with the help of a backup power generator.

An advantage of a closed system is a higher dynamic pressure and, accordingly, a higher coolant flow rate. Thus, it manages to pass along the entire circuit without cooling down. Therefore, all radiators in the room heat up evenly.

But an open system cannot boast of this - the slower coolant flow leads to the fact that the radiators furthest from the boiler warm up much worse than the closest ones. Therefore, the number of batteries that can be placed on one circuit with natural circulation is quite limited.

Step-by-step instructions for connection

There are usually no difficulties during installation, so it’s quite possible to do all the work yourself . So that the pressure gauge can be changed at any time without shutting down the system, a tap is installed in front of it.

The location does not play a special role, but usually a place is chosen close to the boiler. The main thing is convenience. The pressure gauge must have direct access so that pressure readings can always be viewed.

If there is no tap, the device should be installed only on a disconnected system. To do this you will need:

- choose a place;

- take the wrench;

- if there is no gasket on the pressure gauge, you need to rewind the thread;

- tighten the device using the key.

It is worth noting that you cannot tighten the pressure gauge while holding the housing. This way it can be damaged. It is better to use a special nut on the fitting.

The pressure gauge is part of the heating safety group. This also includes an automatic air bleeder and a safety valve. If the group has not yet been installed, you can buy it assembled . You just have to connect it to the highest point of the pipe, since the air bleeder should be located there.

Heating pressure adjustment

In apartment buildings, the main problem associated with the functioning of the water supply system is low water pressure

This is especially important for tenants on upper floors and private homeowners. When the water supply is weak, household appliances do not work well - washing machines, dishwashers, bathtubs with built-in automation, sprinklers

Increase the voltage drop in the heating:

- installation and installation of pumping equipment that increases the intensity of the incoming water flow;

- equipment of a special pumping station, installation of a storage tank.

The choice of a method for increasing water tension is carried out taking into account the needs for a certain daily volume of supplied water by its consumer and the persons living with him.

Pumping equipment to increase the pressure of water supply to the apartment is inserted into the cold water supply system, after which it is adjusted.

To increase the water voltage in individual nodes of the autonomous water supply system, additional pumps can be installed at the disassembly points.

Features of using autonomous water supply systems

The specific features of the functioning of an autonomous water intake system include the need to collect and supply water from depths from a well or well, as well as ensuring normal water supply to all points and nodes of the water supply system, even in remote places.

When choosing a pump for autonomous water intake, it is necessary to take into account its performance, as well as the performance of the well itself. If the well productivity is low, the water pressure will naturally be insufficient to satisfy the domestic and economic needs of a private homeowner, and if it is large, it will lead to damage to equipment and household appliances, as well as the occurrence of leaks.

The installation of an autonomous pumping station requires the presence of a storage tank, which, together with a hydraulic accumulator, ensures the normal need for water at low system pressure or when it is completely absent from the water supply system.

In heating, pressure adjustment to the optimal level is carried out by turning special screws - regulators located under the pressure switch cover so that a voltage drop does not occur.

It should be remembered that the pumping station requires appropriate maintenance; it is necessary to regularly check the operation of the pump and other hydraulic elements and components, and clean the storage tank. When installing such equipment, it is necessary to take care in advance of sufficient space for its placement, ease of maintenance and repair. The large hydraulic accumulator itself can be buried in the ground, having previously made the necessary waterproofing, and installed in the basement or attic of a country house.

Top 3 models

There are a lot of pressure gauge models, but there are 3 most popular ones:

The Watts F+R250 is a good meter with a ½ inch fitting. Measuring range - from 0 to 6 bar. The body is made of coated ferrous metal. But the diameter is 100 mm, so it is not suitable for everyone. Price - about 900 rubles.- Itap 483/1/4 - the body of this pressure gauge is made of ABS plastic, but this does not mean that it is worse. The connection size is ¼ inch, so in some cases an adapter may be required. It can measure pressure up to 10 bar and its diameter is 63 mm. Price - approximately 400 rubles.

- Tim Y50T-10bar - from the name it is already clear that the pressure gauge is intended for systems in which the pressure does not exceed 10 bar. The plastic case with a diameter of only 50 mm allows it to be installed even in the most difficult to reach places. The diameter of the fitting is ¼ inch. Price - from 110 to 150 rubles.

If you choose these models, you don’t have to worry about breakdowns and service life. This also includes the accuracy of measurements.

Causes of pressure drop

If you find that there is low pressure in your gas boiler, there may be two reasons:

- The heat exchanger has failed.

- There are leaks in the heating circuit.

Any problems with the heating boiler must be identified and corrected as quickly as possible. A drop in pressure can be caused by a manufacturing defect, defects in the expansion tank, clogged heat exchanger, cracks or excessive wear. In any case, all problems should be corrected.

No less often, the pressure in the system drops due to leaks. In particular, they can occur in places of poor-quality soldering of plastic or steel pipes, at joints with radiators, in sections with great wear of the pipe, as well as in the presence of cracks in the rubber gasket in the expansion tank, which leads to coolant entering the air chamber.

You can establish a leak in the rubber membrane by pressing on the spool through which air enters the chamber. If water drips from it, the cause of the pressure drop has been found.

It is somewhat more difficult to detect leaks in pipelines if they run through a wall or under the floor. First of all, they diagnose visible sections of the contour and inspect the condition of the floor to detect stains from dried water. Salt deposits and signs of rust at the joints may also indicate depressurization of the system.

Some systems have the ability to turn off individual sections of the circuit one by one to make it easier to identify leaks.

If visual diagnostics of the condition of a closed pipeline does not produce results, perform pressure testing. This is done by professionals with experience and equipment. First, the coolant must be drained from the circuit, after which the batteries and the boiler are isolated. Then air is pumped into the circuit, bringing the pressure in the system to a value 20% higher than the working one. After a few hours, the pressure level is rechecked. If it falls, they begin to search for a leak. At the same time, on visible sections of the pipeline, the joints are lubricated with a soap solution. Where the soap begins to bubble and hiss, the seal of the circuit is broken.

Next, the defective seam is either sealed or the pipe section is replaced.

When the pressure increases

The reasons for the increase in operating pressure in a gas boiler are:

- malfunction of the automatic control unit - poor quality of filling the line with coolant;

- a decrease in the circulation rate of the coolant contributes to overheating of the resource in the pipes and an increase in pressure;

- formation of air jams in the system;

- the cleaning filter is full or any part of the heating structure is clogged with dirt;

- the valve may be closed;

- installation was performed incorrectly.

Why the pressure in a gas boiler increases cannot be simply determined. First of all, it is necessary to identify the emerging factors, analyze them and draw conclusions.

It is possible to solve the problem of an increase in water pressure above the norm by releasing excess heat resources, forcibly turning off the pumping device, and, if necessary, pumping up the liquid until the value returns to normal.

If during the repeated process the range of jumps becomes smaller, that is, the pressure in the working boiler gradually approaches the optimal value, it means that there were air plugs in the system.

The proposed method of troubleshooting may result in nothing: this means that where the line is clogged with dirt deposits, which prevents the boiler from functioning fully. To solve the problem, it is necessary to clean the filter, and, if necessary, the heat exchanger. The cleaning procedure can be either mechanical or hydraulic. The main thing is not to cause damage to the internal surfaces and pipes connecting the boiler to the pipeline.

Defining the concepts

First of all, let's look at the basic concepts that owners of private houses or apartments with autonomous heating should know:

- Working pressure is measured in bars, atmospheres or megapascals.

- The static pressure in the circuit is a constant value, that is, it does not change when the heating boiler is turned off. Static pressure in the heating system is created by the coolant circulating through the pipeline.

- The forces driving the coolant create dynamic pressure, which affects all components of the heating system from the inside.

- The permissible pressure level is the value at which the heating system can operate without breakdowns or accidents. Knowing what pressure should be in the heating boiler, you can maintain it at a given level. But exceeding this level threatens with unpleasant consequences.

- In the event of uncontrolled pressure surges in an autonomous heating system, the boiler radiator is the first to fail. As a rule, it can withstand no more than 3 atmospheres. As for batteries and pipes, depending on the material they are made of, they can cope with heavy loads. Therefore, the choice of battery must be made based on the type of system.

It is impossible to say unambiguously what the operating pressure is in a heating boiler, since this indicator is influenced by several other factors. In particular, this is the length of the heating circuit, the number of floors in the building, power and the number of batteries connected to a single system. The exact value of the working pressure is calculated during the creation of the project, taking into account the equipment and materials used.

Thus, the normal pressure in a heating boiler for houses on two or three floors is approximately 1.5-2 atmospheres. In higher residential buildings, it is allowed to increase the operating pressure to 2-4 atmospheres. For control, it is advisable to install pressure gauges.

Methods for checking water pressure in the pipes of a private house

In a plastic pipeline, the testing technology looks different:

- The system is filled with water, the temperature of which corresponds to the ambient temperature;

- For half an hour, the system maintains a pressure 1.5 times higher than the nominal pressure;

- The pressure is reduced by half compared to the working one and is maintained for an hour and a half;

- If the system is sealed, then the indicators will increase.

Sometimes the test is performed using air. It is launched into the system from which all water has been pumped out. This method is great for small buildings. If the static pressure in the autonomous heating is at the proper level during testing, then you need to start troubleshooting the heating equipment.

Exercising control

In order to be able to constantly monitor the pressure level, special sensors - pressure gauges - are installed when installing the heating system. Based on their readings, you can notice any deviations in time and take timely measures. With the help of this equipment, quite dangerous situations can sometimes be prevented.

For example, very often heating lines are hidden in the walls of the house. This is done so that the aesthetic appearance of the room is not compromised. but this approach risks the fact that in the event of a coolant leak from any section of the pipeline, you risk not noticing it in time.

The consequence of such a situation can be flooding of the house, a strong breakthrough, and the formation of mold and mildew inside the wall - all this is quite difficult to eliminate. But if you focus on the indicators of the pressure gauge, you can determine the onset of a leak in time, since the pressure in the system decreases. Timely measures taken to correct the problem reduce the risk of negative consequences to a minimum.

Of course, for full control, one pressure gauge is not enough - you need several devices installed in different places. For example, they are mounted on the input and output circuits of a heating boiler (if the equipment belongs to the double-circuit category), at the highest and lowest points of the system, on both sides of the circulation pump. It is also advisable to install one device at each fork in the pipeline.

But before focusing on pressure gauges, it would be nice to know what pressure can depend on, which can affect its performance. And the first thing worth talking about is the type of coolant circulation.

Types of devices

Since the scope of application and operating conditions are different, the pressure gauges are also different. For heating there are 5 types:

- Spring. The most popular models that are used in domestic and industrial environments. There is a spring inside. Under pressure, it transmits force to the dial hand.

Membrane. These pressure gauges are also in good demand. The principle of operation is similar to spring ones, only an elastic plate or membrane box is used as a sensing element.- Liquid. There is a tube running inside them that operates on the basis of communicating vessels.

When a load is applied to one vessel, the liquid in the other rises to a certain height. Such devices are very accurate, but are more suitable for laboratory research. - Electric contacts are used not only for measuring pressure. They can be connected, for example, to a circulation pump to control it. When the arrow reaches the desired value, the circuit will close or open. This is especially useful in industrial settings.

- Differential. They consist of several chambers that are separated from each other by a sensitive element. Usually these are portable devices with the help of which the pressure difference is calculated.

If we talk about working conditions, pressure gauges are also divided into:

- general technical;

- exemplary;

- self-writing;

- railway;

- ship's

Only general technical ones are suitable for heating. The rest are either too accurate or contain additional functions that are not needed in everyday life.

Pressure in the heating system, its parameters and regulation standards

Pressure in the heating system is one of the main factors affecting not only the efficiency of heating equipment, but also its performance itself. If it drops below the permissible value, cavitation may occur. The coolant reaches boiling point, the pump breaks down, and air enters the system. If the maximum permissible level is exceeded, the heating system is destroyed.

It ensures that the coolant gets into the pipes and radiators located in each apartment of the high-rise building. Maintaining constant pressure allows you to minimize heat loss by delivering water at the same temperature with which it “left” the boiler room.

Useful: about choosing a coolant for a heating system.

To talk more specifically, let's look at a few basic terms:

- The static pressure in the heating system depends on the height of the liquid column. Static pressure in a closed heating system is the pressure of the water column + in the expansion tank.

- The working pressure in the heating system consists of static and dynamic. The latter is due to the operation of pumps and the convective movement of water in the pipes.

Drop

The system is being pressure tested

The pressure drop in the heating system is adjusted using special regulators. They are installed in circuits with dynamically changing hydraulic conditions to minimize its influence. Also, if the water pressure is too high, the regulators prevent the formation of noise.

To determine the exact flow rate of the coolant in order to prevent it from exceeding it, connect impulse pipes before and after the control valve. The regulator operates (opens) when the differential increases and transfers water into the suction pipe, thanks to which the coolant flow remains constant.

The regulator is placed in a jumper between the supply pipe and the “return”, tying the non-condenser boiler.

How to exercise control?

To control “excess” pressure, pressure gauges are connected:

- At the inlet and outlet (boiler, circulation pumps, differential regulators, filters and mud traps).

- At the entrance to the building.

- At the exit from the boiler room.

Pressure gauges must be installed through 3-way valves. They provide the ability to purge, reset to zero and even replace without turning off the heating circuit.

Helpful installation tips

The design and installation of an autonomous heating system should be approached responsibly and rationally: even minor errors can significantly reduce its efficiency. For those who doubt their abilities, it is better to use the services of professional installers. If the master is confident that he can handle the job, several recommendations from experienced installers will help him:

- Tension fittings must not be installed in floors or walls. If this cannot be avoided, free areas are left for their placement.

- The width of the radiators should be within 70% of the length of the window opening. To meet this condition, the thickness of the heating device is changed, selecting its heating capacity.

- The chimney of a gas boiler should not pass through rooms where people can stay for a long time. In addition, a chimney laid outside the building should be placed no closer than 80 cm to the windows.

- If non-freezing liquid is used as a coolant, the use of sectional radiators is not recommended. Low antifreeze viscosity will lead to leaks.

- To save energy resources, you can install a programmable room thermostat. The device allows you to reduce up to 40% of the energy spent on heating.

To measure pressure, pressure gauges are installed on the supply and return lines. This configuration will allow you to effectively configure the system and protect it from damage. In addition, by the pressure drop it will be possible to judge the degree of clogging of the water filter and the entire heating circuit as a whole.

Instrument verification

Verification is a series of operations that are performed to confirm the correct operation of measuring instruments.

Usually its validity period is 2 years , although it all depends on the manufacturer. If the pressure gauge is working properly, leave it.

Obvious damage includes a broken case and an arrow that does not change position. Special equipment for testing at home is almost never used, since it is easier to simply replace the pressure gauge.

Jumps in a working heating system and how to deal with them

If, even a few weeks after the start of the regular heating season, the pressure in the system “dances”, it is worth rechecking all problem areas and making sure that each of the elements of the heat exchanger safe operation unit is working:

- pressure gauge,

- an air vent through which air leaves the coolant,

- a safety valve that releases part of the water in the event of a pressure surge or boiling (by the way, it is better to connect the valve to the sewer, otherwise hot water will end up on the floor),

- For large houses, expensive but very “smart” automatic machines are relevant, capable of monitoring the situation around the clock.

In any case, it is worth remembering that problems with the heating system are not only a loss of a comfortable microclimate in the home and material costs, but also a threat to the safety of both the entire building and its inhabitants. This means that inattention is unacceptable here.