- Requirements for heating industrial premises

- Calculation of autonomous heating of production premises

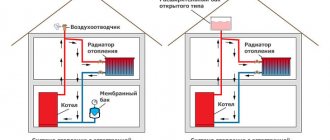

- Heating options for spacious non-residential buildings

- Air heating of industrial premises

- Central water heating

- Infrared heating

Send a quick request Heating is designed to maintain normal air temperature in production premises during the cold season.

In addition, it contributes to better preservation of buildings and equipment, since it simultaneously allows you to regulate air humidity. For this purpose, various heating systems are built. During the cold and transitional periods of the year, all buildings and structures in which people stay for more than 2 hours, as well as rooms in which temperature maintenance is necessary due to technological conditions, should be heated.

Heating of industrial premises

— a system of technical thermal measures that allows for heating the air space to the required temperature in the volume of the premises used for production.

INTECH-Climate is ready to implement professional solutions for climate control and other engineering equipment. We will carry out a full cycle of turnkey work: design, selection, delivery, installation and maintenance. Call now: +7 (495) 146-65-64

. Submit your application

Factors influencing the operating pressure

The amount of coolant pressure in high-rise buildings depends on many circumstances that directly or indirectly contribute to a deviation from the nominal value prescribed by the standards.

These include:

- degree of wear and tear of boiler room equipment;

- removal of a residential building from the boiler room;

- the location of the apartment, on what floor and how far from the riser it is located. In an apartment located even next to the riser, in the corner room the pressure will be lower, since the extreme point of the heating pipeline is most often located there;

- sizes of pipes installed by residents without permission. For example, when installing a pipe in an apartment with a diameter larger than that of the inlet pipe, the total pressure in the system will decrease, and when installing pipes of a smaller diameter, it will increase;

- degree of wear of heating batteries.

Which SNiPs regulate heating issues?

SantekhNIIproektSNiP 41−01−2003

The provisions of the building codes of this document have legal and technical regulation for heat supply, heating, air conditioning and ventilation systems in the premises of buildings and structures.

The contents of this document begin:

- from introduction;

- Areas of use;

- normative references;

- general links;

Requirements also considered:

- to indoor and outdoor air;

- heat supply and heating;

- to ventilation, air conditioning and air heating;

- smoke protection in case of fire;

- refrigeration;

- release of air into the atmosphere;

- energy efficiency of buildings;

- power supply and automation;

- space-planning requirements and design solutions;

- water supply and sewerage systems of heating, ventilation and air conditioning.

The appendices discuss all the necessary calculations, coefficients, and permissible deviations from standards for all systems and equipment for them.

Methods for measuring water pressure in a pipeline

Often, the pressure in the water supply in the apartment does not provide the necessary water pressure and it is difficult for a person to even wash the dishes. Household appliances also suffer from this. Standards have been developed to resolve the issue.

The apartment owner needs to follow the step-by-step algorithm:

- Study the legislation and know what the pressure should be for normal water flow.

- Protect household appliances from damage. For example, a washing machine will not be able to start working if the pressure is insufficient. Moreover, the device may break.

- Detect the time when the pressure is unstable, record the indicators on photo or video media.

- Try to identify the cause of the problem.

- Enter special measuring instruments and if the defect is poor supply, then file a complaint.

Before filing a complaint, you need to find out the reason, and there can be many of them:

- The pipeline is clogged and therefore the pipe does not allow water to flow under normal pressure.

- The pressure may jump due to a network outage or water supply level.

- The low flow is caused by a breakdown at the station.

- Stagnation in the riser.

- If one side of the pipeline is functioning and the other is not, there may be a leak or blockage somewhere.

Inspection in buildings is faster and does not require additional manipulations, because during the construction of houses, pressure gauges are initially installed. This is especially true for the private sector. To make accurate measurements, it is enough to record the indicators that the device produces throughout the day.

In old panel MKDs with a large number of floors, such devices are not provided, unless a person has made an insert for himself. If the situation has not changed during the day, then it is worth ruling out an emergency situation at the station and trying to take measurements.

Special instruments for measuring water pressure in an apartment

The stream must flow without interruption, and the pressure must comply with the approved standard. If the flow is unstable and the range of differences is regular, you should make sure that the problem is insufficient pressure.

Let's consider the main methods of this event using improvised and special instruments. There are several variations of pressure gauges: for household and industrial use. For self-measurement, the consumer can easily purchase a device that is used at home.

This device cuts into a pipe and the process is quite labor-intensive. Moreover, separate devices are installed for DHW and cold water. In modern buildings, such units are prescribed by GOST and should be in every home. A one-time measurement will not be enough. The procedure must be carried out several times every 24 hours and the readings recorded. Record data in the morning, lunchtime and evening.

Measuring water pressure without a pressure gauge

If the residential property was built a long time ago and the device was not installed during construction, there is a simpler method for performing calculations. To do this, take a jar (3 liters) and place it under running water.

Table for measuring water pressure using a 3-liter jar

While the liquid is filling the container and using a stopwatch, you need to note the time. If a three-liter jar is filled in exactly 10 seconds, then the pressure in the water supply is normal. When the indicator is less by 3-4 seconds, this indicates that the standard is exceeded, which is fraught with negative consequences.

Actions in case of non-compliance with heating standards

What to do if the apartment is too cold or too hot? If there is a clear deviation of temperatures from the optimal temperature regime, the tenant can independently or together with neighbors invite management workers to take measurements. The management company must respond to every request from residents, taking measurements upon request.

If contacting the management company did not produce the desired effect and did not lead to an improvement in the situation, the consumer should file complaints with the local housing inspection authorities and Rospotrebnadzor. The last step in the fight for comfortable living conditions is to file a lawsuit against the management company.

Importance

Water pressure is necessary for the normal functioning of the plumbing system. For the equipment to function properly, the following minimum values are required:

- Dishwasher and washing machine - from 1.5 to 2 atm. units

- Faucet with mixer, bathroom - 0.2 atm. units

- Shower, bath - 0.3 atm. units

Basically, water flow is supplied to city apartments under a pressure of 2-4 atmospheres. Insufficient pressure can create situations where the use of water by neighbors causes a pressure drop in other apartments. Low blood pressure can be affected by:

- Blockages in water supply pipes.

- Turning off pumps to save money.

- Weak power of central pumps.

- Incorrect installation of pipes, etc.

Normative references

- GOST 12.1.003−83 SSBT. Noise. General safety requirements.

- GOST 12.1.005−88 SSBT. General sanitary and hygienic requirements for the air in the working area

- GOST 24751–81. Air handling equipment. Nominal cross-sectional dimensions of connections

- GOST 30494–96. Residential and public buildings. Indoor microclimate parameters.

- SNiP 23−01−99*. Construction climatology

- SNiP 23−02−2003. Thermal protection of buildings

- SNiP 23−03−2003. Noise protection.

- SNiP 31−01−2003. Residential multi-apartment buildings. SNiP 31−03−2001 Industrial buildings

- SNiP 41−03−2003. Thermal insulation of equipment and pipelines

- SanPiN 2.2.4.548−96. Hygienic requirements for the microclimate of industrial premises

- SanPiN 2.1.2.1002−00. Sanitary and epidemiological requirements for residential buildings and premises

- NPB 105−03. Determination of categories of premises, buildings and outdoor installations according to explosion and fire hazards

- NPB 239−97. Air ducts. Fire resistance test method

- NPB 241−97. Fire dampers for ventilation systems. Fire resistance test methods

- NPB 250−97. Elevators for transporting fire departments in buildings and structures. General technical requirements

- NPB 253−98. Smoke protection equipment for buildings and structures. Fans. Fire resistance test methods

- PUE. Rules for electrical installations

Recommendations when choosing radiators

One of the main heating problems is leaking radiators. There are several components worth highlighting here:

- Steel radiators and convectors are most often not intended for installation in a working environment of more than 8-10 atm. Check with the seller or look in the passport for the parameters of the maximum permissible pressure and operating conditions in which the manufacturer recommends installing its heating devices. Even if your pressure gauge in the basement of your apartment building shows a pressure of 5 Atm. this does not mean that during the season the pressure will not rise to 12-13 Atm. Unfortunately, the wear of main pipelines can reach more than 100%, and the only way to check the integrity of the pipes and ensure trouble-free operation of the heating system is to carry out pressure tests. In these cases, the heating plant can supply a peak pressure of both 13 and 15 Atm. which will lead to the destruction of steel batteries. Measurements are taken every hour, and the pressure drop should not exceed 0.06 Atm. All this time, your radiators will be under dangerously high pressure.

- Long service life of batteries can lead to the formation of corrosion, and if in a private house, at a pressure of 1.5-3 Atm. the radiator can be quickly shut off, then in an apartment building, as a result of such an accident, you can flood your neighbors while you wait for the plumber or emergency crew to arrive. In this regard, in apartment buildings it is mandatory to install shut-off valves, shut-off valves or taps.

If you want to control pressure parameters, you can install special thermomanometers that allow you to evaluate operating heating parameters in real time.

In cases of a drop in temperature, pressure, leaks or damage to the heating system, you must immediately contact the operator servicing your heating network. Otherwise, you risk making the situation worse, which will lead to more serious consequences than a drop in battery temperature of a few degrees.

Apartment-by-apartment and general-house standards for utility consumption

Let's look at what the thermal energy consumption standard is and how it is calculated. The procedure for calculating and setting heating standards is regulated by Government Decree No. 306. General provisions and formulas for calculating heat supply, taking into account the presence or absence of metering devices, are established by Government Decree No. 354.

According to clause 10 of PP No. 306, standards are established in relation to individual consumption of utilities and maintenance of the common property of an apartment building. Owners who have not installed meters pay for heating according to standards that involve calculating the average rate of heat energy consumption.

The calculation formula takes into account the following features:

- the presence of a common house meter (read more about heat meters for heating here);

- number of installed individual metering devices;

- billing period: 12 calendar months or according to the heating season schedule.

The standards are established by regional regulations and, as of 2022, apply to apartment buildings that do not have individual or communal meters installed. If a house has a communal meter installed, but no individual meters are installed, then the calculation is made in accordance with its indicators. Owners with private ownership pay for heating according to individual requirements.

Who installs them?

Based on clause 9 of PP No. 306, average standards for thermal energy consumption per 1 sq. m has the right to establish:

- regional executive authorities;

- resource supply organizations;

- management companies;

- housing cooperatives;

- partnership.

The establishment of standards at the initiative of the management company or resource supplying organization is carried out on the basis of a collective application to the authorized body and is considered within 30 days.

Pressure and other characteristics of steel radiators

Wiring diagram for a steel radiator.

In new multi-storey buildings with two-pipe heating systems, the pressure in which is up to 10 atmospheres, steel radiators are most often installed. They look very attractive and are characterized by high heat transfer.

By their design, such batteries represent a system with horizontal and vertical water channels and an additional U-shaped surface. The elements of such batteries are made of stamped steel sheets and connected by welding. The fins of the steel radiators are connected to each other using perpendicular panels, so dust does not collect in the corners of such radiators. The standard depth of such batteries is 63, 100 and 155 mm, the height varies from 300 to 900 mm, and the width from 400 to 3000 mm.

Steel radiators come in tubular and panel types. Panel devices are devices that are used mainly in private homes or in rooms where there is low operating pressure. They are convenient because they are produced in different sizes and thermal power, which makes it possible to choose the battery needed specifically for a specific room and ready-made sizes of mounting niches. Steel radiators are produced throughout Europe and are of good quality in assembly and painting.

Steel tubular radiators are widely used heating devices with an elegant appearance that fits well into any interior. As a rule, tubular batteries are used in individual heating systems. Such devices are characterized by low thermal inertia, which makes it possible to easily regulate the temperature in a heated room. Tubular models have an elegant design, a wide variety of standard sizes and a wide color palette.

Steel batteries weigh less than cast iron ones, the metal in them is thinner, as a result of which they heat up faster. In addition, such batteries are characterized by a high degree of heat transfer due to their design features and large heating area.

Such heating batteries are designed for temperatures up to 150 degrees and pressure up to 10 bar. They can be installed in houses with a small number of floors (up to 3 floors), apartments and office premises.

Central heating

Route

- At the exit from the thermal power plant, the pressure on the supply line of the heating main reaches 7-8 kgf/cm2, on the return line - approximately 3 kgf/cm2. Due to hydraulic losses and a large number of consumers connected between the lines, when measuring at the end houses, the supply pressure will decrease to 5.5 - 6 kgf/cm2, and the return pressure will rise to 4 kgf/cm2;

- During the heating season, Heating Systems mechanics carry out periodic pressure measurements in heat wells. For this purpose, they are equipped with vents of diameters DN15 - DN25;

- Pressure gauges in thermal wells are not installed permanently, but are screwed in with each measurement. This prevents theft of instruments and the “sticking” of their needles when the readings remain unchanged for a long time;

- Once a year, after the end of the heating season, the route is tested for density. In this case, the pressure in both threads rises to 10 - 12 kgf/cm2. This way, all the weak points of the route that need replacement or repair are identified: a pipe that does not hold the appropriate pressure simply breaks. To avoid accidents and reduce costs, the track is filled with cold water during testing.

Elevator

- The pressure drop that ensures circulation in the heating system of an apartment building is only 0.1 - 0.2 kgf/cm, which corresponds to a pressure of 1 - 2 meters. A difference of 2 - 3 atmospheres at the inlet only ensures the operation of the water-jet elevator: the nozzle injects hot water with higher pressure into the water from the return, drawing part of its volume into a repeated circulation cycle.

This ensures a minimum temperature spread between the first and last radiators along the coolant flow

;

- By adjusting the diameter of the nozzle, you can change the pressure of the mixture (coolant entering the heating circuit) and, accordingly, the return temperature. Traditionally, adjustment is made by boring or reaming the nozzle; if necessary, it is pre-welded to reduce the working diameter.

In recent years, elevators with adjustable nozzles have begun to be used, making it possible to do without dismantling the elevator and stopping circulation. Alas, I have not seen them in action and cannot describe their capabilities first hand;

- You can reduce the return temperature if it deviates upward from the temperature curve with your own hands, using shut-off and control valves. To do this, it is enough to partially close the inlet valve on the return line while monitoring the difference using a pressure gauge

.

In this case, the valve is first completely closed and then opened until the desired differential value is obtained. If you simply close it, the cheeks may subsequently slide down the rod and completely stop the circulation. The price of such a mistake is guaranteed defrosting of the access heating;

- You can increase the temperature in the house by completely removing the nozzle and muffling the elevator suction with a steel pancake installed between the flanges. This is practiced in extreme cold when there are a large number of complaints about the cold in apartments;

- On the flanges of elevator units with DHW circulation taps (at least two taps for supply and return), retaining washers are placed between the taps to ensure circulation when DHW is supplied from one thread. The diameter of such a washer is usually 1 mm larger than the diameter of the nozzle. The puck creates a difference within half a meter (0.05 atmosphere).

In-apartment wiring

- The pressure in the risers, connections and radiators on the lower floor of the house is, for obvious reasons, equal to the pressure of the mixture or return and is 3 - 4 kgf/cm. With each floor it decreases by about 0.3 atmospheres (an excess pressure of 1 atmosphere raises the water column by 10 meters).

Water hammer

- Water hammer is a short-term increase in pressure at the water front when the flow suddenly stops. It is a practical consequence of the fact that water is almost incompressible and has a certain inertia. Water hammer can occur when a vented circuit fills quickly with a small amount of air in it, or when a shut-off valve is suddenly closed during circulation. The pressure during water hammer can reach values of 25 - 30 atmospheres. It is these values that are best to focus on when designing systems connected to central heating.

Norms and requirements

Modern apartment buildings can have several types of heating:

- have a central connection from utility companies;

- have your own boiler room and heat source, which further leads to its distribution to the consumer;

- The apartment can have its own independent heating source - gas or electric boiler.

If we are talking about the basic indicator of pressure in a house, such as a “Khrushchev”, then often the pressure level is within 6-9 Atm under ideal conditions. Practice shows that when the resource is exhausted, the efficiency of the heating system drops sharply. At the moment, despite the fact that interfering with the operation of the heating system is strictly prohibited, independent work, repair or replacement of radiators and pipelines, reduction of the nominal diameter of pipes due to rust and deposits - the pressure can drop down to 1-3 atm. Of course, this can be noticed by the temperature of the heating devices, which drops to 30-40 degrees.

Ventilation snip norms

During construction, technical supervision is responsible

on the part of the customer, production supervision on the part of the organization performing the work, and specialists who developed the project as designer’s supervision. For ease of understanding, all regulatory documents for ventilation systems of a multi-storey residential building can be divided into two groups:

A. Mandatory regulatory documents of the Gosstroy of Russia,

The Government of Moscow and the administrations of the constituent entities of the Russian Federation and regulatory documents of the State Fire Service of the Ministry of Emergency Situations of Russia. Basic list.

Rulebooks:

SP 60.13330.2012 “Heating, ventilation and air conditioning. Updated edition"

SNiP 41-01-2003" is fundamental for the development of building air systems. In addition to the basic general requirements, it contains calculation formulas for calculating air and requirements for the thickness of air ducts.

SP 7.13130.2013 “Heating, ventilation and air conditioning. Fire safety requirements” is a standard that reflects the conditions for ensuring fire safety.

SP 54.13330.2016 “Residential multi-apartment buildings. The updated version of SNiP 31-01-2003" does not apply to semi-detached residential buildings, which are subject to the design requirements of individual (private) single-apartment houses.

SP 73.13330.2016 “Internal sanitary systems of buildings. Updated version of SNiP 3.05.01-85.” This code of practice applies to construction work. The necessary stages, installation technology are described, and includes a list of final documentation based on the results of the work.

State standards:

GOST 30494-2011 “Residential and public buildings. Indoor microclimate parameters"

GOST 21.602-2016 “System of design documentation for construction. Rules for the execution of working documentation for heating, ventilation and air conditioning systems

Sanitary norms and rules:

SanPiN 2.1.2.2645-10 “Sanitary and epidemiological requirements for living conditions in residential buildings and premises”

B. Optional

– in them you can find system options, their features and calculations. These recommendations or guidelines are created by engineering communities. They are based on mandatory documents, but cover more broadly the issues of creating a comfortable air environment. Describe a calculation method for determining the required volumes of air based on released pollutants. They provide methods for achieving the most efficient and stable operation of systems.

R NP "AVOK" 5.2-2012 Technical recommendations for organizing air exchange in apartments of residential buildings. STO NP “ABOK” 2.1-2008 “Residential and public buildings. Air exchange standards"

For premises that do not belong to the main functionality of the facility, additional standards apply

, suitable for their purpose.

The above standards reflect all essential issues, including the safety of operation of ventilation systems. And with any intervention in systems after construction, be sure to check their compliance with current specialized standards.

Materials

- The pressure a polypropylene pipe can withstand is always indicated by the manufacturer in its labeling. Marking PN20 (typical for pipes without reinforcement) indicates a working pressure of 20 atmospheres, PN25 (standard for pipes reinforced with fiber and aluminum) - 25 kgf/cm2;

- The temperature of the coolant influences the pressure polypropylene pipes are designed for. Manufacturers always indicate operating pressure at a temperature of 20C. When heated to a maximum of 90 - 95C, the maximum operating pressure decreases to 7 - 9 atmospheres. The service life is also reduced: already at 80 degrees, polypropylene will last not 50, but not more than 25 years;

- All polypropylene fittings are without reinforcement and are designed for a working pressure of 25 atmospheres;

- What pressure can a metal-plastic pipe (with cross-linked polyethylene shells and an aluminum core) withstand? Manufacturers guarantee 10 - 16 atmospheres. The breaking pressure is usually not less than 25. From a practical point of view, metal-plastic can be installed in central heating systems only on the connections to the radiators after the shut-off valves, which make it possible to shut off the water in case of leaks;

- The pressure at which a polyethylene pipe can operate is determined by the ratio of its diameter to the wall thickness (this parameter is called SDR) and the type of polyethylene. Low-pressure polyethylene PE100 is noticeably stronger than high-pressure polyethylene PE32: for example, with the same diameter and wall thickness (SDR21), the first pipe can operate at a pressure of 8 kgf/cm2, and the second - only 2.5;

SDR is the ratio of outside diameter to wall thickness.

- The lower the SDR, the higher the tensile strength

; - There is an inverse relationship between pressure and pipe diameter with constant wall thickness. The larger the diameter, the larger the area of its internal surface, and if so, the greater the force with which the internal environment presses on them. Accordingly, at a constant operating pressure, the wall thickness, depending on the diameter of the pipe, decreases or increases;

- The most reliable and easy-to-install material for central heating systems is corrugated stainless pipe. Due to the corrugation, it absorbs water hammer and withstands the freezing of water in it without destruction. With a stated operating pressure of 10 - 15 atmospheres, the destruction pressure, according to the Lavita company, is 210 kgf/cm2;

Corrugated stainless steel is an ideal material for central heating systems.

- For steel pipes with welded joints, the strength calculation takes into account the strength coefficient of the weld. It is taken equal to 0.6 - 0.8. If a VGP pipe can withstand a pressure of 200 atmospheres without destruction, the design for the finished circuit includes a maximum of 120 - 160;

- All water and gas pipes are electric welded. Accordingly, during defrosting and the accompanying increase in pressure, they tear along the longitudinal seam. After welding a seam using electric arc welding, the strength of the pipe almost does not decrease;

- Central heating systems should be equipped with steel registers or bimetallic radiators. The strength of any system is equal to the strength of its weakest link: is there any point in using pipes that can withstand 150 atmospheres if the radiator collapses at 16?

- The champion in strength among bimetallic ones is Rifar Monolit of domestic production. A working pressure of 50 atmospheres and a destructive pressure of 100 are stated for it.

Changes in norms planned in Russia

According to TASS, from 2022 the calculation of the heat consumption standard will depend on the number of floors. The new system was planned to be implemented in 2016, however, at the request of members of the State Duma committee, the project was postponed to 2022. According to the new regulations, the Gcal norm is established depending on the following conditions:

- house material: brick, stone, concrete, wood;

- year of construction: before 1999, after 1999;

- number of floors

According to clarifications from the press service of the Russian Ministry of Construction, the application of new payment conditions will be the right of regional authorities, but not an obligation. As of 2022, the new procedure is not regulated by law, but is already applied in the constituent entities of the Russian Federation, for example, in Krasnoyarsk (Resolution of the Government of the Krasnoyarsk Territory No. 137-p).

Pressure standards for water supply in apartments

You need to understand that high pressure is dangerous for people living in a particular property, and low pressure interferes with the normal functioning of citizens. The minimum indicator directly depends on whether it is an apartment or multi-storey building or a plot of land.

In MKD

If for a low building the water supply column cannot be below 10 m, then the MKD defines an additional 4 m for each floor. Accordingly, on the 2nd floor. the pressure in the riser should raise the water to a height of 14 meters, and in the third - 18.

If consumption is kept to a minimum, then a value of 3 m is allowed. When it comes to individual devices, then in the pipe that is connected:

- to the washbasin with tap and mixer – 2 m;

- in the bathroom – 3 m;

- in a toilet flush barrel - more than 4 meters.

Hot water supply (DHW)

Optimal figures for water supply are important, since we are also talking about space heating. SNiP has established that for hot water pressure the parameter should be in the range of 0.3-4.5 atmospheres, but at night a decrease is allowed.

You can determine the pressure yourself, but if it is completely absent, then immediate contact with the management company is required, especially when the water flow is strong and the pressure begins to overwhelm the system.

In a private house

The norm for a house that stands on a plot of land is 2 atmospheres. Water supply to private areas must also be in accordance with the standards, including the number of floors that matters if the building consists of several levels. A pressure drop or poor pressure can cause negative consequences for the system as a whole and household appliances.

That is why management company employees must constantly check and measure data in the pipeline. The organization is forming a working department responsible for maintaining statistics on water pressure. Additionally, his responsibilities include responding to urgent calls.

Causes of deterioration in blood pressure

- Illegal spontaneous work on replacing pipelines - in apartment buildings the so-called “top heating supply” is often used, which means the supply of coolant through the main pipeline to the very top floor and its further distribution along vertical heating risers. If one of your neighbors below or above, as a result of inept and, in fact, criminal actions, narrowed the diameter of the pipeline, from 25 mm to 16 mm, then the entire entrance suffers from a sharp drop in the volume of coolant, which cannot circulate as it should it was before.

- An accident, malfunction or outdated equipment of heating networks - unfortunately, this remains one of the most widespread reasons for the poor quality of heat supply to apartments. Heat loss also depends on how high the pressure is in the heating system of an apartment building and how stable it is. Stable high pressure and good circulation allow the coolant temperature to be supplied almost the same as that obtained at the outlet of the heating manifold. If there is a broken valve, a destroyed pipe, or faulty fittings in the path of hot water, this will immediately lead to a deterioration in the heat supply in the apartments.

- Apartment buildings use a closed heating system. It is much more efficient than gravity and does not require large maintenance costs, but a drop in pressure in the system instantly stops the circulation of the coolant. This forces water to be pumped up in case of leaks, and to control the formation of air pockets, which are released using air vents or special valves at the top point of the heating system. If, as a result of an accident, improper operation of equipment, or due to interference with the heating system, a large amount of air is formed in the pipes, circulation decreases or stops altogether.

Which SNiPs regulate heating issues?

Federal State Enterprise SantekhNIIproekt

with the participation of the Center for Standardization and Standardization Methodology in Construction (FSUE TsNS), developed

SNiP 41−01−2003

“Heating, ventilation and air conditioning” to replace the existing SNiP 2.04.05−91. This document was proposed by the Department of Technical Standardization, Standardization and Certification in Construction and Housing and Communal Services of the Gosstroy of Russia. It was adopted on July 26, 2003 and came into force on January 1, 2004.

The provisions of the building codes of this document have legal and technical regulation for heat supply, heating, air conditioning and ventilation systems in the premises of buildings and structures.

- from introduction;

- Areas of use;

- normative references;

- general links;

Requirements also considered:

- to indoor and outdoor air

; - heat supply and heating;

- to ventilation, air conditioning and air heating;

- smoke protection

in case of fire; - refrigeration;

- release of air into the atmosphere;

- energy efficiency

of buildings; - power supply and automation;

- space-planning requirements and design solutions;

- water supply and sewerage systems of heating, ventilation and air conditioning.

In the appendices, all necessary calculations, coefficients, permissible deviations

from standards for all systems and equipment for them.

Battery Performance

The abundance of various heating radiators that have flooded the modern plumbing market literally provokes consumers to replace outdated cast-iron heating equipment.

The criteria for their selection, first of all, are:

- material,

- operating pressure,

- nameplate thermal power,

- appearance.

At the same time, the possible difficulties of operating the purchased heating device as part of the unpredictable domestic central heating system are not taken into account at all. Foreign manufacturers of beautiful radiators made of aluminum or steel do not at all protect against water hammer when the pressure in the heating radiators jumps to 20-30 atm. corrosion of internal cavities when water is released for six months, from gas formation in aluminum radiators during the flow of coolant with copper impurities and sudden temperature changes. They simply do not have these problems, which cannot be said about the heating systems of our high-rise buildings.

Characteristics of cast iron radiators

- inertness to poor quality coolant;

- working pressure - 9 atm. pressure testing - 15 atm.;

- withstands coolant temperature of 120 0 C;

- disadvantages - afraid of water hammer.

Characteristics of steel radiators

- working - up to 10 atm.;

- coolant temperature - up to 120 0 C;

- well regulated by thermal valve;

- Disadvantage: They are not resistant to corrosion.

Characteristics of aluminum radiators

- working - up to 6 atm. but for reinforced structures - up to 10 atm;

- well regulated by thermal valve;

- disadvantage is susceptibility to electrochemical corrosion and gas formation, which leads to the formation of air pockets.

Characteristics of bimetallic radiators

- working - up to 20 atm. for reinforced structures - up to 35 atm;

- good corrosion resistance;

- coolant temperature - over 120 0 C.

It is important! When planning to purchase new radiators, do not hesitate to contact your housing and communal services structure to find out exactly the operating and test pressure values in your home. Once a year it is submitted, higher than the working one, to identify weaknesses in the system

It may be higher than allowed for your new radiator.

- Tired of barrel water heaters? Buy a flat boiler!

- Brief overview of some models of water heated towel rails

- Manufacturers of tubular radiators

- A little about aluminum radiators

Calculation of autonomous heating of production premises

When calculating the autonomous heating of an industrial premises, we proceed from the general rule that a constant temperature must be maintained in the workshop, garage or warehouse, without strong changes. For this purpose, a central boiler room is built, and heating radiators for production premises are installed in the work area. However, at some enterprises there is a need to create separate zones with unequal air temperatures. For the first of these cases, a calculation is made for the use of a central heating system, and for the second, for the use of local heaters.

In practice, the calculation of the heating system of an industrial premises should be based on the following criteria:

- area and height of the heated building;

- heat loss through walls and roofs, windows and doors;

- heat loss in the ventilation system;

- heat consumption for technological needs;

- thermal power of heating units;

- rationality of using this or that type of fuel;

- conditions for laying pipelines and air ducts.

Based on this, the need for heat energy to maintain the optimal temperature is determined. A more accurate calculation of heating systems for industrial premises is facilitated by the use of special calculation tables. In the absence of data on the thermal properties of a building, heat consumption has to be determined approximately based on specific characteristics.

When making a choice among various types of industrial heating systems, one should take into account the specifics of production, thermal calculations, cost and availability of fuel, and build feasibility studies on this. Systems of infrared, water, air and electric types most fully correspond to the autonomous heating of modern industrial premises.

Pressure force on the bottom of the vessel

Let us take a cylindrical vessel with a horizontal bottom and vertical walls, filled with liquid to a height (Fig. 248).

Rice. 248. In a vessel with vertical walls, the pressure force on the bottom is equal to the weight of the entire poured liquid

Rice. 249. In all the vessels depicted, the pressure on the bottom is the same. In the first two vessels it is more than the weight of the liquid poured, in the other two it is less

The hydrostatic pressure at each point on the bottom of the vessel will be the same:

If the bottom of the vessel has an area, then the force of pressure of the liquid on the bottom of the vessel, i.e., is equal to the weight of the liquid poured into the vessel.

Let us now consider vessels that differ in shape, but with the same bottom area (Fig. 249). If the liquid in each of them is poured to the same height, then the pressure is on the bottom. it is the same in all vessels. Therefore, the pressure force on the bottom is equal to

,

is also the same in all vessels. It is equal to the weight of a column of liquid with a base equal to the area of the bottom of the vessel and a height equal to the height of the liquid poured. In Fig. 249 this pillar is shown near each vessel with dashed lines

Please note that the force of pressure on the bottom does not depend on the shape of the vessel and can be either greater or less than the weight of the poured liquid

Rice. 250. Pascal's device with a set of vessels. The cross sections are the same for all vessels

Rice. 251. Experiment with Pascal's barrel

This conclusion can be verified experimentally using the device proposed by Pascal (Fig. 250). The stand can hold vessels of various shapes that do not have a bottom. Instead of a bottom, a plate suspended from the balance beam is tightly pressed against the vessel from below. If there is liquid in the vessel, a pressure force acts on the plate, which tears the plate off when the pressure force begins to exceed the weight of the weight standing on the other pan of the scale.

In a vessel with vertical walls (cylindrical vessel), the bottom opens when the weight of the poured liquid reaches the weight of the weight. In vessels of other shapes, the bottom opens at the same height of the liquid column, although the weight of the poured water may be greater (a vessel expanding upward) or less (a vessel narrowing) than the weight of the weight.

This experience leads to the idea that with the proper shape of the vessel, it is possible to obtain enormous pressure forces on the bottom using a small amount of water. Pascal attached a long thin vertical tube to a tightly caulked barrel filled with water (Fig. 251). When the tube is filled with water, the force of hydrostatic pressure on the bottom becomes equal to the weight of a column of water, the base area of which is equal to the area of the bottom of the barrel, and the height is equal to the height of the tube. Accordingly, the pressure forces on the walls and upper bottom of the barrel increase. When Pascal filled the tube to a height of several meters, which required only a few cups of water, the resulting pressure forces ruptured the barrel.

How can we explain that the force of pressure on the bottom of a vessel can be, depending on the shape of the vessel, greater or less than the weight of the liquid contained in the vessel? After all, the force acting on the liquid from the vessel must balance the weight of the liquid. The fact is that the liquid in the vessel is affected not only by the bottom, but also by the walls of the vessel. In a container expanding upward, the forces with which the walls act on the liquid have components directed upward: thus, part of the weight of the liquid is balanced by the pressure forces of the walls and only part must be balanced by the pressure forces from the bottom. On the contrary, in a vessel that tapers upward, the bottom acts upward on the liquid, and the walls act downward; therefore, the force of pressure on the bottom is greater than the weight of the liquid. The sum of the forces acting on the liquid from the bottom of the vessel and its walls is always equal to the weight of the liquid. Rice. 252 clearly shows the distribution of forces acting from the walls on liquid in vessels of various shapes.

Rice. 252. Forces acting on liquid from the walls of vessels of various shapes

Rice. 253. When water is poured into the funnel, the cylinder rises up.

In a vessel that tapers upward, a force directed upward acts on the walls from the liquid side. If the walls of such a vessel are made movable, the liquid will lift them. Such an experiment can be carried out using the following device: the piston is fixedly fixed, and a cylinder is put on it, turning into a vertical tube (Fig. 253). When the space above the piston is filled with water, pressure forces on the areas and walls of the cylinder lift the cylinder upward.

Working pressure in the heating system of an apartment building

The page contains information about the working pressure in the heating system of an apartment building: how to control the difference in pipes and radiators, as well as the maximum norm in an autonomous heating system.

For efficient operation of the heating system of a high-rise building, several parameters must simultaneously meet the standard.

Water pressure in the heating system of an apartment building is the main criterion by which they are measured and on which all other components of this rather complex mechanism depend.

Types and their meanings

The working pressure in the heating system of an apartment building combines 3 types:

- Static pressure in the heating of apartment buildings shows how strongly or weakly the coolant presses from the inside onto pipes and radiators. It depends on the height at which the equipment is located.

- Dynamic is the pressure with which water moves through the system.

- The maximum pressure in the heating system of an apartment building (also called “permissible”) indicates what pressure is considered safe for the structure.

Since almost all multi-storey buildings use closed-type heating systems, there are not so many indicators.

The pressure norm in the heating system of an apartment building of any type (Soviet Khrushchev buildings, modern high-rise buildings) is equal to:

- for buildings up to 5 floors - 3-5 atmospheres;

- in nine-story buildings it is 5-7 atm;

- in high-rise buildings from 10 floors - 7-10 atm;

For the heating main, which stretches from the boiler room to the heat consumption systems, the normal pressure is 12 atm.

To equalize the pressure and ensure stable operation of the entire mechanism, a pressure regulator is used in the heating system of an apartment building. This balancing manual valve regulates the amount of coolant with simple turns of the handle, each of which corresponds to a specific water flow. These data are indicated in the instructions supplied with the regulator.

Working pressure in the heating system of an apartment building: how to control?

To know whether the pressure in the heating pipes in an apartment building is normal, there are special pressure gauges that can not only indicate deviations, even the most minor ones, but also block the operation of the system.

Since the pressure differs in different sections of the heating main, several such devices need to be installed.

Usually they are mounted:

- at the outlet and inlet of the heating boiler;

- on both sides of the circulation pump;

- on both sides of the filters;

- at points of the system located at different heights (maximum and minimum);

- close to collectors and system branches.

Pressure drops and its regulation

Jumps in coolant pressure in the system are most often indicated by an increase in:

- for severe overheating of water;

- the cross-section of the pipes does not correspond to the standard (smaller than required);

- clogging of pipes and deposits in heating devices;

- presence of air pockets;

- pump performance is higher than required;

- any nodes in the system are blocked.

When decreasing:

- about violation of the integrity of the system and leakage of coolant;

- breakdown or malfunction of the pump;

- may be caused by malfunctions of the safety unit or rupture of the membrane in the expansion tank;

- outflow of coolant from the heating system into the coolant circuit;

- clogging of filters and system pipes.

The norm in an autonomous heating system

In the case where autonomous heating is installed in the apartment, the coolant is heated using a boiler, usually of low power. Since the pipeline in a separate apartment is small, it does not require numerous measuring instruments, and 1.5-2 atmospheres is considered normal pressure.

During startup and testing of the autonomous system, it is filled with cold water, which, at minimum pressure, gradually warms up, expands and reaches normal. If suddenly in such a design the pressure in the batteries drops, then there is no need to panic, since the reason for this is most often their airiness. It is enough to empty the circuit of excess air, fill it with coolant, and the pressure will automatically reach normal.

To avoid emergency situations when the pressure in the heating radiators of an apartment building rises sharply by at least the permissible 3 atmospheres, you need to install either an expansion tank or a safety valve. If this is not done, the system may depressurize and then it will have to be changed.

- carry out diagnostics;

- clean its elements;

- check the performance of measuring instruments.

2 thousand 1.4 thousand 6 min.