Oil-filled electric heaters are popular units in everyday life, characterized by high durability, since their production is carried out in an industrial environment using modern technologies. However, these electrical appliances are not designed to withstand all emergency situations in everyday life and still fail.

The design of even the most modern unit allows, in some cases, to repair oil heaters yourself.

Household oil-filled heating electrical appliances: on the left - flat, on the right - ribbed.

Let's consider this popular household heater from the perspective of assessing the possibility of restoring it after failure, since an oil heater needs to be repaired with a guarantee of the safety of its further operation.

Common oil heater malfunctions, their symptoms and repair methods

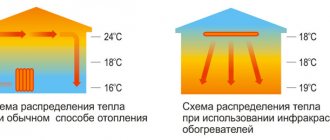

Troubleshooting an oil-filled electric heater, like repairing an infrared heater of any other type, requires certain skills and compliance with a number of rules.

Important! If any of the structural elements of the oil heater fail, operation of the heater must be stopped until the malfunction is eliminated.

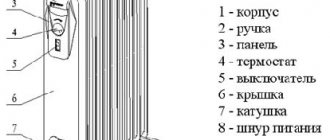

Actual image of one of the models of oil heaters with a list of external equipment

First of all, you should be aware that restoring the functionality of most of the components of this heating device at home is impossible or requires professional knowledge and skills. Experimenting with failed electrical components is fraught with unpredictable consequences (electrical injury, thermal injury, fire, explosion), so repairing an oil heater with your own hands, without professional training, in most cases should only be done by replacing the part that has become unusable.

In addition, when repairing an electric heater, the following rules must be followed:

- the device must be unplugged from the outlet;

- the heater must be cooled to room temperature;

- equipping the device with homemade components is prohibited;

- Avoid contact of transformer oil with the body, as well as with the wiring insulation;

- Replacing a standard power supply cable with a grounding conductor with a wire without grounding is prohibited.

Oil leak

A leak in the oil cooler usually occurs due to mechanical damage or as a result of corrosion caused by a defect in the protective paint coating.

When a long-used, familiar oil radiator leaks, a natural question arises: what to do, why not try to restore its tightness with your own hands?

However, repairing an infrared heater on your own in the event of a leak is only possible if the device is an old-style domestically produced unit with a flat steel radiator and a removable heating element.

Flat oil electric heaters of domestic production with steel radiators

*

To carry out repairs, the control unit, under which the heating element is located, is disconnected from the device body. Then, after disconnecting the contacts, the heater is unscrewed and the oil is drained through the mounting socket into a clean container. The remaining oil is allowed to drain, after which the radiator is filled with water to prevent the oil inside from igniting.

The wall thickness of such radiators is 1-1.2 mm, which allows the use of electric welding. The leakage area on the body is cleaned with a grinder with a grinding disc or manually with coarse sandpaper. Depending on the location and size of the damage, a patch of steel of appropriate thickness is cut out, applied to the hole and scalded using a Kemppi semi-automatic machine.

Kemppi machines of various models for semi-automatic electric welding in domestic conditions

The welding seam is cleaned and ground, after which, if necessary, it is welded again. After degreasing, the repair area is painted with heat-resistant paint, for example, Rustins High Heat Black Pain.

Important! If the heater is painted using powder technology, then when carrying out repair work you need to strive for minimal damage to the coating - it is impossible to restore it under domestic conditions.

Heat-resistant paint Rustins High Heat Black Pain in small volume packaging

After the paint has dried, the radiator is filled 80% with oil, and the heater is assembled in the reverse order.

If the oil heater clicked when heating before the repair, you should not expect that the clicks will disappear after the seal is restored - the mating parts of the housing are deformed when the temperature rises and at the same time crack.

Repairing radiators of finned oil heaters is not advisable, since they are made of thin sheet steel using laser welding. Restoring the tightness of such tanks is technically difficult, does not guarantee success in domestic conditions, or is comparable in cost to the cost of a new heater. In addition, if the heating element is non-removable, then the oil can be drained through damage, but it will no longer be possible to fill it back.

No heating

*

A technically sound oil-filled household heater makes a quiet noise when plugged in. This factor is not dangerous, as it is caused only by the expansion of the assembled body of the unit, which clicks when heated.

If, after turning on the unit and setting the required power and temperature values, the heater is silent, it means that the radiator is not heating, and the fault should be looked for in the electrical part.

First of all, visually inspect the integrity of the electrical cable. If there is no visible damage, you must first remove the racks with wheels from the bottom of the unit body.

Then you need to disconnect the control unit from the radiator, for which purpose, using a screwdriver, pry up and remove the standard plate on top of it with the inscription Do not cover, under which there are fastening screws.

Placement of fastening screws of the control unit to the housing

Having unscrewed the fasteners from above, the screws in the lower part of the control unit are also released or the fixing springs are unfastened (depending on the model), the shell is removed from the edge of the junction of the block with the radiator, and the dismantled unit is laid with the inside out.

Sequence of removing the control unit from the oil heater housing

Perform a visual inspection of the integrity of the wiring and insulation, as well as the quality of contacts at the junctions of the wires, paying attention to areas with kinks and oxidation. A wire with obvious internal damage is replaced with a new one, the oxidized contacts are disassembled, cleaned with sandpaper and reassembled.

Upon completion of the visual inspection, they begin to “test” the components using a tester - a multimeter, which begins with testing the cores of the wire section from the plug to the nearest connection. The operation is simplified by the different colors of the cores in the cable of the electrical appliance, which makes it easy to track the direction of the wiring.

The sound signal from the tester indicates the integrity of the area being called, while the absence of a signal indicates damage.

The initial stage of testing an oil heater using a multimeter is the section from the plug to the heating element

Replacing the Tubular Heater

*

The heating element, in addition to heating elements, is equipped externally with current and temperature fuses, the presence of which must be taken into account when dialing. It is possible that, with a working heating element, one of these fuses burned out, or even both failed.

Heating element fuses: on the left - by temperature, on the right - by current

If testing nevertheless reveals a failure of the tubular heater, then further actions depend on the method of installing the heating element in the radiator. The threaded fastening of the heater in the absence of rolling allows its replacement. In this case, the heating element is unscrewed from the radiator, and in its place, with the replacement of the sealing gasket, a heater with identical parameters in terms of power and shutdown temperature is installed.

Tubular electric heater with a threaded installation method in a heating unit

With a non-removable installation option, the heater is rolled into the radiator socket. In domestic conditions, it is very difficult to flare an old heating element and install a new heating element by sealing it, so you should think about buying a new oil heater.

Temperature controller malfunction

Testing this node is done as follows:

- ring the section of the chain from the plug to the thermostat;

- the regulator is set to the minimum temperature value and tested - the circuit must be open;

- when turning on each of the heaters individually, as well as two heating elements simultaneously, when setting the temperature regulator to a value other than zero, the circuit must be closed.

View from the inside of the thermostat of a Sinbo household oil heater with a power of 2 kW.

If a test of the thermostat shows its malfunction, that is, the oil heater does not respond to switching power modes or changing the temperature by turning the flywheel, the device must be replaced, since diagnostics of its technical characteristics with subsequent repairs based on the test results in industrial conditions are not advisable, and it is extremely difficult to do this in domestic conditions.

If there are no malfunctions, the regulator is cleaned of dust and the contacts are tightened.

Failure of the bimetallic strip

*

The question of whether an oil heater can explode is relevant, since the oil pressure in the radiator reaches high values, and the air “cushion” in the form of 20% of its volume still has limited potential. To prevent this from happening, the heater design contains a thermal relay, which should turn off the heater if it overheats.

Under normal conditions, this relay, which is a bimetallic strip, should complete an electrical circuit. If the multimeter detects an open circuit in this thermal fuse, then it should also be replaced with a new one with identical characteristics.

Continuity of the thermorelay of an oil-filled heater and appearance of the thermorelay

Oil heaters explode extremely rarely precisely because they have several degrees of protection that duplicate each other, and the likelihood of simultaneous failure of all safety devices is low.

No heater shutdown when tipping over

Opening the electrical circuit when the oil heater is tilted or tipped over is ensured by a device whose operating principle is based on the presence in its design of a suspended weight, which retains its position when the unit deviates from the vertical.

An option for equipping the oil heater with a circuit-breaking device when the device overturns is a plumb line with a metal weight

Testing of this device is carried out by manually deflecting the heater from the vertical. If the device does not turn off, the element must be cleaned of dust and removed, or better yet, replaced with a new one, the installation of which is not difficult.

It should be noted that if the protective switch fails, the oil heater does not explode - if heating elements that are not covered with oil overheat, the thermal protection of the tubular heater is triggered, or the thermal relay opens the electrical circuit.

Making a heater from improvised materials

How to make a homemade oil heater? Many video reviews on social networks are devoted to this topic. The principle of collection is identical everywhere, only the external indicators and the purpose of the heater differ.

The article presents an average option that is suitable for both a garage and a cottage or home. The appearance of the radiator and its functionality will depend on your capabilities, skill and availability of materials.

Preparation of material

A set of necessary materials will probably be found in the garage of every car enthusiast or skilled home craftsman. What you will need to create a heater:

- metal pipes or cast iron battery,

- heating element,

- new or used oil,

- wire with plug,

- welding machine if you plan to form the required dimensions of the structure.

Let us dwell in more detail on the principles of material selection.

The battery can be used, the main requirements are integrity, absence of external and internal contamination. For remodeling, time-tested cast iron samples are usually used.

Metal pipes can be used in different diameters, shapes and lengths; the thickness is also chosen at your discretion. The more area you need to heat, the larger your design should be. Radiators from cars and sealed metal containers are also actively used for the body.

Characteristics of the heating element for a homemade heater:

- 220V voltage is sufficient for connection,

- power 1.5–5 kW.

These parameters will be sufficient to heat a garage area and an average room.

You can use used car oil for the radiator or purchase new one. Before adding used oil, it is recommended to filter it and remove impurities and dirt.

Heater stand

Craftsmen offer two options for installing an oil heater: floor-mounted and wall-mounted. The most advantageous and convenient is wall-mounted; it takes up little space and is quickly hung in the chosen location on hooks deeply and firmly planted in the load-bearing wall.

Making a floor stand is not difficult. To do this you will need a metal corner or profile. Dimensions are selected based on the overall dimensions of the structure. We arm ourselves with a welding machine, a grinder and get to work.

- We draw a diagram of the structure of the legs and calculate the dimensions of the elements. It is recommended to provide for the possibility of disassembling and removing the stand in the future. It is possible that you will want to remove it during the warmer months.

- According to calculations, we cut all the parts of the future stand and sand the edges.

- We weld all the workpieces according to the diagram.

- We clean the welds and paint.

Working with pipes

Let's move on to more complex work - forming a body from metal pipes. First of all, we draw a drawing and determine the main parameters of the elements. Only after careful calculations can you start working with the grinder.

- We cut the pipes according to the diagram and carefully clean the ends.

- We weld the structural elements and install plugs; the tightness and operation of the entire radiator as a whole will depend on the quality of work.

- One of the lower ends must be left free. In the future, a heating element will be installed there. In the upper part it is required to provide a safety valve and a filler plug; it is made in the form of a welded squeegee with a coupling. The valve will allow you to control the pressure and secure the structure.

- We carry out piping using pipes of smaller diameter.

Installation of heating elements

The part of the homemade body responsible for working with electricity is easy to do and does not require special knowledge. You will need a heater radiator, a heating element, a gasket made of thermo-oil-resistant material and a wire with a plug.

The step-by-step steps for installing the heating element are as follows.

- We cut out the metal plate to which the heating element will be attached.

- A hole is drilled or cut out by electric welding in the plate to install the heater fasteners.

- We weld the plate to the end of the lower pipe. Previously, this place was specially left for installing a heating element.

- We process the seams after welding and install the heating element.

Now you can begin laying the gasket made of special heat-resistant rubber and attaching the electrical wire. At this point, you can complete the assembly and start filling in the coolant, namely oil.

Important: according to safety rules and technical standards, the amount of oil per total internal volume should be 80–85%.

Precautionary measures

An oil heater is a popular heating device that does not include complex technical solutions. When repairing the housing, it is necessary to carry out work in a well-ventilated utility room.

When repairing electrical wiring, disconnect the device from the power supply. Repairs must be carried out using insulating gloves.

Restoring failed radiator modules at home is dangerous; in this case, only installing new parts is allowed.

How to check the power cord

A faulty power cord is a simple failure, the repair of which is not difficult. If the oil device is in order, its internal parts do not require replacement, but it still does not turn on, you must:

- Inspect the cable of the de-energized device along its entire length for breaks, twists and frayed windings.

- Check the connection between the power cord and the control board for breaks or oxides.

- Clean the darkened contacts with fine-grained sandpaper or re-solder.

- Ring the treated area with a tester and make sure there is a chain.

If the power cord is damaged, you must replace it with a new one and after repair, make sure that the cable does not twist or fray.

The heater must be installed so that the power cord is not pinched by furnishings.

Prerequisites for breakdowns

A significant number of manufacturers supply cheap products of low quality to the markets. An early breakdown of a water heater in this group does not come as a surprise, since even the warranty obligations for the products are minimal. However, even high-quality products, distinguished by their quality and reliability, may end up being repaired soon after purchase due to a number of factors, which are not at all difficult to avoid.

The main causes of water heater malfunction

hiding in our everyday life. Hard water and unstable power supply have a detrimental effect on equipment. Our water contains various salts in large quantities. It is they that lead to the formation of scale inside devices and operating circuits. Installing flow filters at the inlet of the heaters will help to significantly reduce the salt content. In the supply networks of most regions, voltage and frequency can vary significantly in a short period of time. Connecting network filters or uninterruptible power supplies will solve the problem.

It is important to install and connect the device correctly. Many breakdowns occur precisely due to errors at this stage.

Even ignoring conventional grounding can not only lead to electrical shock, but will also contribute to the accelerated destruction of the magnesium anode and severe corrosion of all elements inside the tank. The optimal heating temperature is set to 60-70 C.

Selection of materials

As is clear from the above, to obtain a homemade heater you will need to get the following components somewhere:

- frame;

- oil;

- heating element;

- mobile stand;

- control and automation devices.

As a housing, you can borrow an old radiator from a central heating system, sheet or sectional. A car, or any similar product, the design of which will allow fluid to circulate inside naturally or artificially (using an electric motor), is also quite suitable. You can also make a closed loop from steel pipes with your own hands.

As for the oil, firstly, its quantity should be based on the calculation of ~85% of the body volume. The rest of the cavity is filled with air. This 15% area is maintained so that during operation the oil does not crush the housing due to thermal expansion.

Secondly, the quality characteristics of the liquid must satisfy at least two criteria: purity and heat resistance. Dirt and impurities will shorten the life of the heating element by causing scale to settle on it. A decent temperature of the heating element indicates that you should select technical oil of the appropriate brand. A suitable option would be, for example, a transformer.

The number and characteristics of heating elements are selected depending on the required power of the heater (and taking into account the overall dimensions of the housing). Conventionally, we can assume that to create a comfortable atmosphere in a room with normal ceiling heights, ~1 kW per 10 sq. m. is required. m. For rooms with high ceilings, poorly insulated, located in cold areas, etc., several times more powerful products are needed.

Of course, the capabilities of the power supply network in the place where you plan to use the hand-made device must also be taken into account.

In terms of durability, it is also important to consider possible combinations of metals of the heating element and the body. For example, it is not recommended to use heaters with a magnesium anode, or to combine aluminum and ordinary steel (not stainless) with copper

Is it possible to repair an oil radiator?

Damage to the heater is caused by electronic or mechanical failure. In the event of electrical equipment failure, pay attention to the heating element, control unit, fuses, relays and switch. In rare cases, the cause of the malfunction is the electrical wiring.

Mechanical damage includes breakage of the housing, rupture of sections from which oily liquid may leak. This malfunction is determined by inspecting the location of the oil heater. If there is an oily stain under the device, the housing is damaged.

Sometimes during diagnostics, specialists identify complex breakdowns with the replacement of expensive parts. In such cases, it is cheaper to purchase a new oil heater than to repair the old one.

How to check a bimetallic strip

Modern oil radiators are equipped with a bimetallic plate to protect against overheating. When the coolant pressure in the device reaches critical values, the part opens the circuit and forcibly stops the operation of the device.

The bimetallic strip may become deformed. Its serviceability is checked as follows:

- Open the radiator control panel and use a relay to set the temperature not too high to change the position of the plate.

- A powerful hairdryer is applied to the part until it reaches the specified degree of heating.

- They look at the reaction of the plate - a working element should bend and disconnect the contact. The deformed part will remain motionless after exceeding the set temperature.

The broken bimetallic plate is replaced with the same new one. After doing the repair yourself, you must first make sure that the part is working correctly and test it according to the above diagram, and then assemble the heater.

Advice! If the new plate also does not unbend at the required moments, it is adjusted by changing the pressure of the element to the contact corresponding to the minimum temperature.

If the bimetallic plate breaks, it is easier to replace the entire thermoregulation unit

What to do if the heater does not turn off when tipped over

Most modern oil heaters automatically turn off when changing position. The role of the sensor is performed by a special plumb line with a weight, which is sensitive to deviations from the vertical.

The element is simple and quite reliable, but in an old heater it can turn sour in one position. Do-it-yourself repairs are carried out as follows:

- Remove the cover of the device to gain access to the internal parts.

- Manually test the heater again, tilting it to the sides, and monitor the position of the plumb line.

- If there is no reaction, clean the mechanical sensor from accumulated dust, and then develop it with careful movements.

If the weight moves too tightly even after repair, it is better to change it.

The plumb line with the load should be located at the top of the device next to the thermostat

Repairing oil leaks

Loss of seal in the main part of the radiator and oil leakage are the most common problems with these heaters. Oil may leak out through an accidental hole or a wall that is rusted. If the second option occurs, then it is better to purchase another radiator, since corrosion can destroy a larger area than is visible. Therefore, after some time, oil will flow near the brewed or sealed area .

Holes or small holes, cracks can be:

The first option should be avoided. Soldering cannot provide a reliable connection, and with constant heating/cooling, the strong contact between the solder and the metal of the tank will begin to turn into a crack. Therefore, it is better to weld the hole.

Preparing the heater for soldering or welding is the same:

- Draining oil from the tank.

- Cleaning the problem area from dirt and rust. This can be done with sandpaper.

- Pouring water into the tank. This will avoid a possible fire (there was oil inside, and its remains were definitely preserved).

- Turning the radiator over to a position in which water will not flow out of the hole.

After eliminating the problem, the water is drained, the tank is dried and oil is added . Old oil is unlikely to be suitable, since some of it has leaked out. Therefore, its quantity is not enough to fill the container 90%. If you know the brand and characteristics of the oil, you can purchase the same one. Do not mix synthetic and mineral oils. If you plan to fill in new oil, then use only transformer oil. Work off cannot be used. Otherwise, scale will appear on the heating element.

The oil requires preparation. It consists of heating it to a temperature of 90 ° C and evaporating it. It is impossible to heat it any more, as oxidation and combustion of the liquid will begin. The amount of oil should be such that it does not exceed 90% of the tank capacity.