SHARE ON SOCIAL NETWORKS

FacebookTwitterOkGoogle+PinterestVk

A pellet burner is installed on a solid fuel boiler and is used to organize space heating. It can be purchased ready-made, but it is quite expensive. If necessary, such a device can be made independently. A DIY pellet burner can be made from different materials and have both a simplified and a more complex design.

The pellet burner is installed on a solid fuel boiler and can be made by hand

Why do you need a pellet burner: features of the device

Pellets are a fuel that is of high quality and can compete with conventional firewood. To produce such raw materials, wood and agricultural waste, as well as peat, are used. Pellets are small granules.

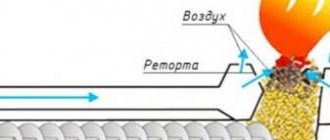

The operating principle of a pellet burner installed in a boiler

What is the advantage of such pellets over standard types of fuel? First of all, it is necessary to note the high efficiency of raw materials. Ordinary firewood, after burning, releases from 40 to 80% of its energy. The remaining material is recycled, so the economic feasibility of such heating is questionable.

A boiler with a pellet burner allows you to increase material recycling up to 90%. This is one of the highest combustion rates among all types of fuel. It is worth noting that granulated raw materials are not recommended for use for some types of boilers. For example, such fuel can harm equipment whose operating principle is based on pyrolysis.

Helpful information! When choosing a burner, you need to pay attention to its power. Today you can purchase models that automatically adjust this indicator. An example is the Zota pellet burner.

During fuel processing, the temperature inside the burner can reach 1000 °C. It follows that extreme caution must be exercised when using such a device. This is especially true for do-it-yourself designs. Errors in assembly or improper use may result in a fire.

During operation of a pellet burner, the temperature inside it can reach 1000º

What are gas-wood combination boilers?

Mixed-type boilers operating on solid fuel and gas are always a floor-standing design, the dimensions corresponding to conventional solid fuel models. Without the use of a gas burner, these are ordinary solid fuel boilers that burn not only wood, but also coal, pellets, peat, and anthracite. Piping, installation and connection of universal boilers is carried out similarly to single-fuel boilers.

Why are they needed and how are they used?

As we have already said, without special conditions, the purchase of a gas-solid fuel boiler is not justified either economically or practically.

Firstly , the total cost of separately purchased gas and solid fuel boilers is 90% lower than the combined model. The cost of gas-wood boilers is 19,000-35,000 rubles and the gas burner is not included in this amount: it must be purchased separately. Only in rare cases are ready-made assemblies found with a gas burner included. The cost of the burner is on average another 6-12 thousand rubles.

The most economical of the budget simple boilers for heating a private home.

Secondly , the efficiency and functionality of individual single-fuel models is almost always higher than combined ones. The usual design of a solid fuel boiler does not show the highest efficiency (at best, up to 85%) when burning natural or liquefied (cylinder) gas, when even budget gas boilers have an efficiency of 88-92%. And this, accordingly, is lower consumption with the same heat transfer. Also, combined gas-wood boilers are devoid of any functional automation, which is found even on budget gas models.

Thirdly , a small bonus of two single-fuel boilers is that if one breaks down, the second can be used as a backup.

However, there are cases when buying a universal boiler that runs on gas and wood may be more profitable. For example:

- if you have access to any type of solid fuel for a symbolic price. When solid fuel reserves are exhausted, stable combustion without human intervention is required, or a previously missing gas line is installed near the house, you can always switch to a gas burner;

- if the area of the house is quite small and allocate at least 8 square meters. m. area for separate single-fuel boilers is impossible.

Pellets: what is it? Detailed fuel characteristics

This raw material is characterized by high energy intensity. It is thanks to this that it has become widespread. When processed, one kilogram of granulated pellets releases approximately 5 kW/h of heat. It follows from this that to organize the heating of a standard private house with average dimensions, you will need about 2 kg of material per hour.

Pellets for the burner are loaded into the device approximately 1-2 times a day. When loading a new portion of raw materials, it is recommended to clean the ash pan from combustion products. Store-bought burners require weekly cleaning, and homemade devices get dirty even faster. It is recommended to clean a home-made device approximately once every 3 days. Otherwise, it will fail quite quickly.

Some burner models do not require loading for 5 days. An example is the APG-42 pellet burner. This model is compatible with Teplodar-Cooper boilers.

The disadvantage of pellet burners is reverse combustion, which is accompanied by the penetration of the pyrolysis zone into the bunker intended for storing and supplying fuel. This entails smoke in the room in which the heating equipment is located, and there is also the possibility of a fire.

Pellets are small granules that are made from wood and used as fuel.

Pellets made from sawdust or any other processed waste can be blown away if there is excess air in the structure, which will lead to the generation of a large amount of waste (ash). The air supply must be clearly regulated, otherwise not only its excess, but also its deficiency can lead to ineffective operation and rapid clogging of the device.

The need for granular fuel in air is determined primarily by the combustion mode. Selecting the right regimen is a primary and very important task. The burner enters operating mode in 5 stages. Before starting to operate the device, you must become familiar with each phase in more detail.

The first step is to ignite. The burner for a pellet boiler is ignited using a special ceramic lighter rod, which, when turned on, heats up to a very high temperature (900-1100 °C). Devices made by yourself can be ignited with an ordinary torch.

Note! Under no circumstances should flammable liquids be used to ignite the burner. In this case, the combustion process will immediately go into the bunker, resulting in a fire.

When burning, 1 kg of pellets releases approximately 5 kW/h of heat

The second stage of preparing equipment for operation is startup. It is very important to adjust the correct air supply to adjust the burner flame. Next, the device is overclocked. At this stage the burner enters normal operating mode.

After acceleration, it is necessary to adjust the air so that the correct temperature of the coolant in the return is set inside the device. Then you need to stop the supply of granular fuel and set the required air intensity.

Advantages and disadvantages

The equipment has a number of advantages:

- Pellets are a safe fuel compared to gas and electricity;

- Allows you to significantly reduce space heating costs compared to using electric boilers. At the same time, pellet installations are more expensive than gas equipment, but do not forget that it is not always possible to supply gas and purchase gas cylinders;

- Homemade installations guarantee high efficiency - 95%. Some store installations are over 97%;

- They are used not only for heating the room, but also for producing hot water;

- There are no rules for transporting and storing fuel. When near a person, pellets do not cause allergic reactions, and there are no toxic fumes when burning;

- Fuel is available for purchase. Equipment owners complained about the lack of fuel and the need to prepare a supply of pellets from the winter when the devices appeared; now there is no need to store a large volume of pellets at home; if necessary, they can be bought everywhere;

- The price of pellets is on average at the same level, unlike gas and electricity, the tariffs for which periodically experience seasonal fluctuations;

- Installation of the device does not require special skills, and there is no need to coordinate the installation with authorized bodies;

- After combustion of pellets, natural mineral ash is formed, which does not require special rules for disposal.

Along with the advantages of such equipment, there are also a number of disadvantages:

- High cost of ready-made store equipment. Despite the popularization of devices in recent years and some reduction in prices, pellet boilers are still more expensive than gas or electric equipment of similar power;

- The equipment requires constant maintenance (especially outdated models). The user will have to clean the ash pan and heat exchanger from accumulated ash once a week. In modern models, cleaning is provided at an automatic level;

- In the absence of automatic fuel supply, the user has to load pellets into the bunker manually;

- It is necessary to ensure minimum humidity conditions in the rooms in which pellets will be stored awaiting use;

- Imported equipment is practically not designed for the conditions of the harsh domestic winter, as a result of which breakdowns and malfunctions often occur;

- In remote areas, fuel for the winter still has to be stored due to the instability of supplies.

Design features of pellet burners

The main task of any burner is to ensure uniform heating of the boiler. This goal is achieved through the processing of granular fuel. From a structural point of view, the burner is a combustion chamber, which most often resembles a pipe in shape. Combustion inside such a device occurs due to the continuous supply of air.

Fuel delivery is carried out by a special device - an auger. To pump air into the structure, a fan is provided, the operation of which does not allow the flame to go out. The burner can have a variety of shapes, which does not significantly affect the efficiency of the device. Chambers that have a round cross-section are the most common. This is due to the fact that they are the easiest to make. However, rectangular options are also quite common.

The device of a pellet burner, where 1 – LCD display, 2 – control knob, 3 – backup battery, 4 – connecting connector, 5 – fuel level sensor, 6 – safety thermal relay, 7 – photosensor, 8 – internal auger motor, 9 – igniter , 10 – internal auger, firebox, 11 – combustion grate, 13 – fan

Round burners used for pellet processing have a flat base. It is used to accommodate fuel and is mounted externally to the front surface. It is worth noting that some burners have the ability to connect a GSM module. An example is the Terminator 15 pellet burner. Its cost is approximately 75 thousand rubles.

The operating principle of these devices is quite simple. First, the sawdust is loaded into the hopper, after which it is delivered through the channel to the burner. A fan blows air to maintain the required flame level inside the device. Combustion products accumulate in the ash pan. It is recommended to clean this compartment at least once a week.

Prices: summary table

| Manufacturer and model | Heat exchanger material | Number of circuits | Efficiency, % | price, rub. |

| Teplodar Kupper OK 15 | steel | single-circuit | 78 | 19 900-21 200 |

| Viadrus Hercules U22 D-4 | cast iron | single-circuit | 80 | 63 000-67 500 |

| Roda Brenner Classic BCR-04 | cast iron | single-circuit | 80 | 53 000-55 000 |

| HEPHAESTUS VPR KSTGV-20 | steel | double-circuit | 80 | 23 500-26 400 |

| Karakan 20 TEGV | steel | double-circuit | 75 | 22 500-25 000 |

DIY pellet burner: varieties

Devices that are used for processing granular raw materials are divided into two types depending on the principle of operation - with forced intake and gravitational. The choice of one type of equipment or another depends primarily on individual operating conditions.

Note! The most common burner option requires the presence of electricity. In this case, electricity is necessary to operate the mechanism that ensures an uninterrupted supply of granular fuel. Automatic pellet burners (with forced intake) are considered the optimal solution for organizing heating of a building.

At the moment, pneumatic pellet burners from Obshchemmash are popular

Devices of this type include several mechanisms through which granules are delivered. The first of them operates using a pneumatic system. The second mechanism is equipped with a special tool - a screw. Safety in the system is ensured by the design of the channel, installed from the bottom up, through which the granules are supplied.

Automatic devices have one serious advantage - fire safety. Such devices are used in equipment from different manufacturers. For example, they are integrated into Teplodar boilers. Pellet burners, reviews of which are mostly positive, are quite expensive. The price of some models exceeds 150 thousand rubles. More budget options can be purchased for 60-80 thousand rubles.

The pneumatic type design is characterized by maximum safety. This is because the pellet delivery system delivers fuel in small portions. Thus, it is not delayed in the communication channel. For such a burner, it is possible to install a large hopper that does not require frequent loading. If desired, a device of this type can be purchased. Currently, pneumatic pellet burners from Obshchemmash are very popular.

Screw-type feed mechanisms include two main units. Using the first auger, granulated fuel is taken from the bunker. The operation of this device allows you to transport pellets to another receiver. After this, the second screw sends the raw material directly to the burner.

Automatic pellet burners are characterized by high fire safety

The disadvantage of devices in which fuel supply is forced is their dependence on energy. In the event of a power outage, the burner stops operating.

Gravity pellet burner: design features

Devices of this type, operating on pellet fuel, have a different operating principle for supplying pellets. It should be said right away that such units are more convenient to use. The main advantage of the gravitational mechanism is that it does not require a connection to the electrical network.

In this case, the pellets are located in a bunker and can enter the connected channel under the influence of their own weight. There are several popular domestic companies producing such units (Pelletron, Behemoth). A pellet burner of this type is started very simply - by changing the position of the damper. It is important to remember that the chimney has a draft regulator, which can also be adjusted.

Note! The main disadvantage of all gravity structures is that they do not provide as much safety during operation as their counterparts. During operation, there is a possibility of ignition of granulated fuel in the bunker. An increased risk of ignition exists due to the design of the hopper, which is directly connected to the opening through which the fuel is supplied.

Gravity pellet burners can be used without an electrical connection

The efficiency of gravitational devices is slightly lower than that of analogues that operate through the forced supply of granular fuel. Installing this type of pellet burner is not a difficult task. Its complete connection can be completed in just a few hours.

In order to increase the fire safety performance of this device, many manufacturers install special dampers on it. They are equipped with thermal sensors, which, if a flame enters the channel connecting to the bunker, are activated and block the passage.

Other differences

Let's consider the division of atmospheric burners according to the type of ignition. A simplified version is with a burning pilot wick (wick). When the automation is triggered, the wick ignites the gas and the boiler begins to warm the coolant. There are two disadvantages here - very high gas consumption and low safety (the ignition wick may go out). Primary ignition is performed with matches or using a piezoelectric element that produces a spark.

Mains gas from the mains provides even combustion without creating excess soot on the walls of the chimney pipe.

Electronic ignition of the burner takes into account the presence of a high-voltage converter in the gas boiler. Energy is taken from batteries or an electrically powered network. The first option is used in non-volatile boilers that do not have electronic automation. Another option is important for complex units with electronics on board. Simultaneously with such ignition, modules for ionization control of the presence of flame are often installed.

There is also a division according to the type of fuel used. The network gas supplied from the mains is cleaner, it is supplied at good pressure (we do not consider situations of pressure drops back and forth). The flame in the boiler comes out clean, without soot. The equipment is connected to the network without modifications. There are burners that can operate on propane - this requires setting up the system and installing a jet. The flame from propane combustion gives off a yellow color, and there is a very high soot deposit on the chimney.

How to draw a drawing of a pellet burner?

Before starting to independently design a burner intended for processing pellet fuel, it is recommended to complete its individual drawing. The diagram must necessarily contain information about all components and parts. The drawing requires you to indicate the main elements:

- camera;

- fuel bunker;

- screw;

- fan.

The diagram must contain all the necessary dimensions of these products. When making a drawing of a pellet burner with your own hands, you should remember that the detail of its execution determines how reliable the device for processing fuel pellets will be.

Manufacturing drawing of a pellet fuel burner

Before starting to draw up the diagram, it is recommended to calculate in advance the required dimensions of the bunker. When performing calculations, you should take into account how much area the structure will heat. It is also worth noting that the parameters of the bunker have a direct impact on the frequency of its cleaning.

The fan operation is controlled by an electronic unit. When drawing up a diagram, you need to remember that the performance of the main components of the device depends on the availability of electricity.

Related article:

How to make a long-burning solid fuel boiler with your own hands: drawings

Device and principle of operation. How to do it yourself. Drawings and diagrams for self-production. Recommendations.

Thus, making a drawing of a pellet burner with dimensions with your own hands is not so difficult. If necessary, you can use a ready-made scheme, of which there are many on the Internet. But in such a situation, it is necessary to select a drawing that will meet specific conditions.

Principle of operation

All pellet installations that can be purchased in the store are equipped with additional components:

- Auger – supplies fuel from the bunker to the combustion chamber;

- Controllers for automating the work process;

- Bunker – the place where the fuel is located before being supplied to the combustion chamber;

- A lambda probe is a special sensor that monitors the oxygen content in smoke chambers and independently controls the fuel combustion process depending on conditions.

The pellet burner must be protected with a plastic corrugated pipe. It acts as a fuse when reverse draft occurs. If the fire begins to move towards the bunker, the pipe burns out, preventing the flame from spreading.

Additionally, a fan is used, which enhances the combustion of pellets by pumping air, as well as a thermoelectric heater, which allows the fuel to be ignited without human intervention.

In automated devices, pellets are fed into the combustion chamber automatically; a person is only required to monitor the amount of fuel in the bunker. The need to supply fuel to the combustion chamber is determined using temperature sensors (they can monitor the air temperature in the room, the water temperature, or any other environmental indicators depending on the operating mode of the equipment).

The required temperature of the coolant is set by the user, all further increases and decreases are controlled using automated equipment. As soon as the temperature reaches the set level, the burner begins to operate in standby mode (the pellets do not go out, they begin to smolder). If the temperature, on the contrary, drops, the controller activates the built-in fan. Under the influence of air, the pellets flare up and the burner goes into operating mode. If during downtime the pellets go out for any reason, the heating element is activated, which re-ignites.

DIY pellet burner: preparatory stage

Before you begin assembling a burner that processes granular fuel, you need to do some preparatory work. First of all, you need to calculate the area that will be heated using this device. Knowing this indicator, it will not be difficult to calculate the required power of the heating device. When calculating the power indicator of a pellet unit, the following factors are taken into account:

- average annual temperature in a particular region;

- building area;

- ceiling height in the building;

- number of door and window openings;

- building materials from which walls, floors and ceilings are made.

Before making a burner with your own hands, you need to calculate the area of the room that will be heated

Then you should prepare all the tools that will be used when assembling the pellet burner with your own hands. Video and photographic materials help to get an idea of this process, so it is recommended to study them in detail.

It is necessary to determine the thermal transfer resistance of the materials used. This coefficient will be required in the future to calculate heat loss. The power of heating equipment must be at least 10% higher than heat loss.

Helpful information! There are special online calculators that allow you to determine the power of the boiler. They can be easily found on the Internet using the search bar of your browser.

Experts recommend purchasing ready-made pellet burners. The price of these devices varies from 50 to 200 thousand rubles. Making such a device is quite difficult, since many operational nuances need to be taken into account. Purchased models are also equipped with the necessary thermal sensors, which makes their operation convenient and safe.

Manufacturing a pellet burner is a complex and time-consuming process.

How to make a homemade pellet burner: basic recommendations

The most important structural element that is part of a pellet burner is the basket. When making such an element yourself, you should remember that there is one common problem - granules getting stuck in the back wall, which is located at an angle and has slots. To solve the problem, you need to make the cracks differently. The standard version takes into account continuous slots, but it is recommended to make a more cellular structure.

The ideal size of the rear wall slots should be 2 mm smaller than the size of the secondary fuel pellets. The gap between the back wall and the bottom of the basket must be at least 6 mm. The front wall also has slots, but in this case they must be solid.

Before work, it is recommended to study videos demonstrating the assembly of a pellet burner. Reviews of various home-made devices will also help you choose the right device option.

There is a channel located under the bottom of the basket that is part of the burner. It is necessary for secondary air. The height of the channel should be approximately 29 mm. A deviation of 1 mm is allowed here. The back wall itself is not perpendicular, but at an angle. The tilt angle is 45°.

It is recommended to make the size of the slots in the rear wall of the basket 2 mm smaller than the size of the pellet fuel granules

The price of a pellet burner purchased ready-made is several times higher than the cost of a prefabricated version. Thus, self-manufacturing of this device allows you to significantly save money.

The size of the basket with tray is selected taking into account individual needs. In this case, it is necessary to focus on the indicator that determines how much fuel will be processed per 1 hour of burner operation. The best option is considered to be a device with dimensions of 13x13 cm. The depth of such a basket should be approximately 10-12 cm. Such a device allows you to burn about 2-3 kg of granular fuel in 1 hour.

Making a hopper for a pellet burner with your own hands

The second necessary element of any burner installed on heating equipment is a hopper. The most common problem that arises during the operation of homemade devices is related to the penetration of flame into this structure. In order to assemble a reliable bunker, it is recommended to use ready-made drawings of popular bunkers from Teplodar or Pelletron. A pellet burner can be made of any power, but it is best to take standard 15 kW devices as an example.

Hopper drawings for 34 kg and 17 kg pellet burners

The volume of the bunker is also selected individually. You can make a box that will hold 17 or 34 kg of granular fuel. For the manufacture of the combustion chamber, a material such as stainless steel is traditionally used. Moreover, its thickness should be at least 2 mm.

Note! Steel walls are joined using welding equipment.

The dimensions of the bunker are borrowed from any suitable model (for example, Pelletron 15). The pellet burner includes a secondary air channel, which is best made in the shape of the letter “L”. This will significantly increase the efficiency of the operating device.

In addition, the burner should be provided with air supply. This will make it possible to simplify its launch, since the reaction to draft in the chimney structure will be reduced. For a device with a power of 15 kW, 20 W fans are suitable. Experts recommend purchasing a fan, which is called a snail. This is due to the fact that the operation of such a device is easiest to regulate.

The fan is an important part of the pellet fuel burner, as it simplifies its operation

Further arrangement of a pellet boiler with your own hands

Assembly of the device body is carried out in several stages. You can handle this task yourself, but you need to clearly understand the nuances of the work. The body is best constructed in a horizontal plane. This is because this arrangement allows for maximum equipment efficiency.

It is recommended to use brick (fireclay) as a material for the manufacture of the body. The process looks pretty simple. It is necessary to assemble the box and place the heat exchanger inside it. It is worth noting that the brick body is made without a top cover. The heat exchanger must have outlets for connecting heat supply pipes.

Do not forget that the burner should be equipped with a special controller. Pellet burners can be completely mechanical, but in this case it is much more difficult to set them up. Regulation is made taking into account the individual characteristics of the device and the area of the heated room.

The use of brick for the installation of the housing is recommended because it has good insulating qualities and is able to accumulate heat to a greater extent than other common materials such as steel and cast iron. Photos of burners and other heating equipment can be easily found on the Internet.

To make a heat exchanger, you need to cut pipes with a rectangular cross-section and connect them together

First of all, the heat exchanger is manufactured. To do this, you need to prepare pipes with a rectangular cross-section. Then they need to be cut (in accordance with the drawing) into pieces of the required length. After this, the individual segments are connected to each other using welding. It is necessary to provide pipe supply to the heat exchanger. Then a chimney with an ash pan is installed.

Work technology

Knowing the structure of a pellet burner, you can make it yourself. There are different types of homemade burner devices - it is recommended to study them and select the optimal design option.

Pellet burner drawing

Preparatory work

At the preliminary stage, detailed drawings of the device are prepared indicating the dimensions of all elements, and the necessary materials are selected.

To make a burner you need

:

- a pipe (square or round) made of heat-resistant steel, with a wall thickness of 5 mm or more - otherwise the combustion chamber will quickly burn out or deform under the influence of high temperatures;

- heat-resistant steel sheet for making a burner tray from a round pipe;

- sheet metal for making the outer casing of the device;

- sheet steel for the manufacture of a flange plate (metal thickness - from 3 mm);

- steel pipe, auger, gearbox, bearings, electric motor operating at low speeds - for the conveyor that supplies fuel to the combustion chamber;

- electric fan;

- a flexible hose for supplying fuel from a large hopper remote from the burner (connects the screw conveyor and the combustion chamber pipe);

- tools for working on metal and installing fasteners.

Installed pellet burner

Installation and configuration features

The assembly of the structure is carried out according to the drawings. The burner tube is secured in a flange plate, which is attached to the boiler casing. The open part of the burner chamber, from which the flame of fire escapes, is located inside the combustion chamber of the boiler and heats the water jacket.

Inside the burner pipe, under the nozzle, an auger is installed that supplies fuel in portions to the combustion zone. The speed of its operation must be adjusted in accordance with the intensity of the air supply. The stability of the device and the efficiency of fuel use depend on the accuracy of the settings.

Installing a manual regulator makes it possible to adjust the number of revolutions of the auger motor and blower fan. This is the simplest and cheapest solution, but you will have to constantly monitor the operation of the boiler and change the operating mode of electrical devices depending on weather conditions and the level of heating of the coolant.

One of the possible installation options

Date: September 25, 2022

How to automate the process and configure a pellet burner yourself?

Homemade pellet boilers have one feature - the absence in the design of a device that provides an influx of natural draft. Without draft, as you know, it is impossible to maintain a flame inside the device, so you will need to install a fan. To ensure uninterrupted operation of the boiler, an auger is also used, which is responsible for delivering fuel from the bunker to the combustion chamber.

In order to fully automate the workflow and, if necessary, achieve its adjustment, you need to integrate a controller into the design. Its role is played by the pellet burner control unit.

Note! Mechanical control is carried out using a simple regulator.

Using the control unit, you can fully automate the operation of the pellet burner

The main task to ensure the normal operation of heating equipment is to achieve a balance between two main indicators. The first of them is the volume of granular fuel, and the second is the air intake rate. If you can correctly adjust these indicators, then the flame will evenly heat the heat exchanger.

All necessary indicators can be set using the burner control module. What it is? The control unit provides complete control over the operation of the heating unit. Of course, the best option is to purchase a new device.

Purchased models have the ability to quickly connect to the main working elements of a pellet boiler. As a result, the controller will regulate the supply rate of granular fuel, as well as the fan speed. The display located on the control unit allows you to configure the pellet burner.

It is worth noting that the auger must have a sensor that monitors the need to supply granular fuel. It works as follows: it detects when the auger is full and sends a signal to the equipment. After this, the supply of pellets is suspended.

Using the controller, the speed and volume of pellet fuel supply is adjusted

Automation methods

The ratio of fuel and air supply to the combustion chamber must be adjusted, otherwise the operation of the heating equipment will be unstable or constantly occur at high power.

The easiest way to change the speed of the fan and screw motor is to install a simple regulator. But in this case, there will be an added need for regular supervision and adjustment of the equipment, taking into account the ambient temperature and coolant. Setting up a heating system with your own hands consists of selecting, in different operating modes, such a ratio of air and fuel supply, during which the flame will be stable and even. This can only be achieved by automating the operation of the boiler.

First you need to purchase an electronic control unit. If the boiler is already equipped with this device, then you need to carefully study the possibilities of its use. Typically, controllers from leading manufacturers have free control contacts where electric auger and fan motors can be connected. In this case, taking into account the sensor readings, the controller will begin to increase or decrease the fuel supply and regulate the fan speed.

In terms of ignition and flame control, the burner can also be automated. It is necessary to purchase a photosensor, as well as an electronic filament element. The latter turns on at the very beginning, igniting the pellets, and the photosensor, when a persistent flame appears, will notify the controller, which will turn off the incandescent element.

A filling sensor is installed on the pipe; its main task is to send a signal to the electronic control panel if the auger is filled with pellets in order to complete the fuel supply. All these automation methods make it possible to burn fuel efficiently and create comfort during heating boiler maintenance. But there are also certain disadvantages:

- The cost of manufacturing the burner increases significantly.

- The electronic unit of the heating boiler included in the kit is usually not suitable for simultaneous operation with devices for controlling and igniting the burner; in this case, it is necessary to purchase a new one.

- The burner cannot be connected to any controller.

Pellet burner Zota Fox 25: reliable and efficient model with wide functionality

This type of pellet burner is used in Zota Fox series boilers. It is used in heating units, the design of which does not include a plate made of cast iron material. To date, such a burner has proven itself only from the best side. It is characterized by efficiency and reliability, as well as a long service life.

The Zota Fox pellet burner processes granular fuel. The size of each pellet used in this case ranges from 6 to 8 mm. The power of this unit is regulated by an automatic system. This indicator may vary (from 5 to 25 kW).

Installing a Zota pellet burner on a solid fuel heating boiler allows you to automate its working process. Equipment equipped with a granule processing unit has certain advantages:

- reduction of heating costs for residential buildings;

- increase in operating time when loading one portion of granulated fuel;

- maintaining the required temperature in the room.

Helpful information! The power of the burner used for processing pellets is determined depending on the area of the heated room. It is worth noting that a 1 kW device can provide heat to a room of 10 m².

The Zota Fox 25 pellet burner is an efficient and reliable unit

The burner power is adjusted automatically. For this purpose, the design provides a special control module. Zota Fox pellet burners (5-25 kW) have many additional functions that are easy to activate and configure on the control panel. These include automatic ignition of granular fuel, quick start and stop, automatic cleaning of the burner and other modes.

Safety in such a device is realized by a sensor that regulates the combustion temperature of the fuel. This device can also be connected to a GSM module or thermostat installed in a heated room. The cost of such a burner is approximately 75 thousand rubles.

Brief overview of imported products

A foreign alternative to domestic products is the Kiturami pellet burner , the list of its characteristics is as follows:

- power range – from 8 to 33 kW;

- Product efficiency is up to 95%, the overall efficiency value depends on the design of the boiler;

- remote controller;

- sensors for temperature, water level, overheating, overflow of auger with granules;

- self-cleaning grate.

The disadvantages of this device are its high cost and dependence on the reliability of the power supply. Otherwise, the product is quite reliable and does not cause any complaints; it is equipped with DRAGON KRP solid fuel installations.

Ferroli pellet burner

The Ferroli Sun P7 and Sun P12 pellet burner, which is installed on solid fuel units BUDERUS and SFL, is no less highly reliable. Maximum power is 34 and 55 kW, respectively, the set of options is the same as that of the previous manufacturer. The fan is a centrifugal type that provides a sufficient amount of air.

The imported Pelltech pellet burner has a wide range of available capacities, from 20 kW (Pelltech PV-20) to 1 MW (Pelltech PV-1000). It works well in conjunction with VIESSMANN boilers; the latter’s delivery package includes, as an option, a gas cleaning unit with a smoke exhauster; it is needed for installations with a power of over 200 kW.