DIY pellet burner: quick assembly and process automation

A pellet burner is installed on a solid fuel boiler and is used to organize space heating. It can be purchased ready-made, but it is quite expensive. If necessary, such a device can be made independently. A DIY pellet burner can be made from different materials and have both a simplified and a more complex design. Burner for testing: varieties, device, how to make it yourself (read more)

The pellet burner is installed on a solid fuel boiler and can be made by hand.

Malfunctions and their elimination

A self-made or purchased industrial pellet burner may have malfunctions caused by:

- content of foreign inclusions in pellets. Diagnosed by the presence of dirty greenish slag in a stopped burner. Eliminated by cleaning the hopper or increasing power and air flow;

- using pellets of different diameters or sizes exceeding those required by the design. Leads to failure of mechanical fuel supply elements, which can only be restored by completely replacing parts;

- transition to a new pellet size. A possible shutdown of the boiler in this case can be prevented by increasing the feed rate of wood pellets;

- using peat pellets, which causes contamination of the optical sensor and leads to an error indication. The solution to the problem is replacement with wood fuel, or constant visual monitoring;

Equipping boiler rooms with economical and automated solid fuel burners greatly simplifies the life of home occupants. However, any technical device requires timely diagnosis and preventive care. Clean up waste and take time to periodically inspect the technical condition of all elements of the boiler room. These simple steps will ensure maximum safety and comfort.

Why do you need a pellet burner: features of the device

Pellets are a fuel that is of high quality and can compete with conventional firewood. To produce such raw materials, wood and agricultural waste, as well as peat, are used. Pellets are small granules.

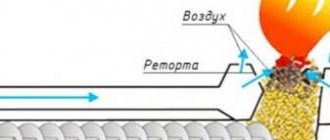

The operating principle of a pellet burner installed in a boiler.

What is the advantage of such pellets over standard types of fuel? First of all, it is necessary to note the high efficiency of raw materials. Ordinary firewood, after burning, releases from 40 to 80% of its energy. The remaining material is recycled, so the economic feasibility of such heating is questionable.

A boiler with a pellet burner allows you to increase material recycling up to 90%. This is one of the highest combustion rates among all types of fuel. It is worth noting that granulated raw materials are not recommended for use for some types of boilers. For example, such fuel can harm equipment whose operating principle is based on pyrolysis.

On a note! When choosing a burner, you need to pay attention to its power. Today you can purchase models that automatically adjust this indicator. An example is the Zota pellet burner.

During fuel processing, the temperature inside the burner can reach 1000 °C. It follows that extreme caution must be exercised when using such a device. This is especially true for do-it-yourself designs. Errors in assembly or improper use may result in a fire.

During operation of a pellet burner, the temperature inside it can reach 1000º.

Reverse heat flow to the bunker (fire)

A rare but familiar accident to manufacturers is the reverse flow of heat to the bunker. In 9 cases out of 10, the situation arises due to the negligence of the boiler user himself. Also, a reverse flow of heat occurs when the safety pin breaks, after which the auger stops rotating.

If the bunker is tightly closed, the fan is running, and nothing prevents the movement of flue gases from the boiler into the chimney, even if the auger does not rotate, there is nothing to fear.

Reverse heat flow (fire) is a rare phenomenon in boilers with automatic fuel supply. However, boiler manufacturers equip supply systems with two safety stages to eliminate such a possibility in principle.

The first stage is a temperature sensor, installed on the fuel supply pipe: if the temperature exceeds the set one, the sensor signals the boiler controller to solve the problem. The controller begins to continuously circulate fuel through the pipe until the sensor temperature returns to normal. The continuous supply interval in Galmet boilers is 10 minutes.

If the problem remains, the thermostatic valve is activated - water is supplied from the emergency tank into the pipe and eliminates the fire in the feeder pipe.

One of the causes of fuel fire in the tank is backdraft, which occurs if the bunker is left open or closed incorrectly. To prevent this from happening, some manufacturers equip the fuel tank lid with a limit switch. When the hopper lid is not closed tightly, the sensor is triggered and gives a warning signal. If measures are not taken, the controller will stop the boiler.

Pellets: what is it? Detailed fuel characteristics

This raw material is characterized by high energy intensity. It is thanks to this that it has become widespread. When processed, one kilogram of granulated pellets releases approximately 5 kW/h of heat. It follows from this that to organize the heating of a standard private house with average dimensions, you will need about 2 kg of material per hour.

Pellets for the burner are loaded into the device approximately 1-2 times a day. When loading a new portion of raw materials, it is recommended to clean the ash pan from combustion products. Store-bought burners require weekly cleaning, and homemade devices get dirty even faster. It is recommended to clean a home-made device approximately once every 3 days. Otherwise, it will fail quite quickly.

Some burner models do not require loading for 5 days. An example is the APG-42 pellet burner. This model is compatible with Teplodar-Cooper boilers.

The disadvantage of pellet burners is reverse combustion, which is accompanied by the penetration of the pyrolysis zone into the bunker intended for storing and supplying fuel. This entails smoke in the room in which the heating equipment is located, and there is also the possibility of a fire.

Pellets are small granules that are made from wood and used as fuel.

Pellets made from sawdust or any other processed waste can be blown away if there is excess air in the structure, which will lead to the generation of a large amount of waste (ash). The air supply must be clearly regulated, otherwise not only its excess, but also its deficiency can lead to ineffective operation and rapid clogging of the device.

The need for granular fuel in air is determined primarily by the combustion mode. Selecting the right regimen is a primary and very important task. The burner enters operating mode in 5 stages. Before starting to operate the device, you must become familiar with each phase in more detail.

The first step is to ignite. The burner for a pellet boiler is ignited using a special ceramic lighter rod, which, when turned on, heats up to a very high temperature (900-1100 °C). Devices made by yourself can be ignited with an ordinary torch.

On a note! Under no circumstances should flammable liquids be used to ignite the burner. In this case, the combustion process will immediately go into the bunker, resulting in a fire.

When burned, 1 kg of pellets releases approximately 5 kW/h of heat.

The second stage of preparing equipment for operation is startup. It is very important to adjust the correct air supply to adjust the burner flame. Next, the device is overclocked. At this stage the burner enters normal operating mode.

After acceleration, it is necessary to adjust the air so that the correct temperature of the coolant in the return is set inside the device. Then you need to stop the supply of granular fuel and set the required air intensity.

Automation methods

The ratio of fuel and air supply to the combustion chamber must be adjusted, otherwise the operation of the heating equipment will be unstable or constantly occur at high power.

The easiest way to change the speed of the fan and screw motor is to install a simple regulator. But in this case, there will be an added need for regular supervision and adjustment of the equipment, taking into account the ambient temperature and coolant. Setting up a heating system with your own hands consists of selecting, in different operating modes, such a ratio of air and fuel supply, during which the flame will be stable and even. This can only be achieved by automating the operation of the boiler.

First you need to purchase an electronic control unit. If the boiler is already equipped with this device, then you need to carefully study the possibilities of its use. Typically, controllers from leading manufacturers have free control contacts where electric auger and fan motors can be connected. In this case, taking into account the sensor readings, the controller will begin to increase or decrease the fuel supply and regulate the fan speed.

In terms of ignition and flame control, the burner can also be automated. It is necessary to purchase a photosensor, as well as an electronic filament element. The latter turns on at the very beginning, igniting the pellets, and the photosensor, when a persistent flame appears, will notify the controller, which will turn off the incandescent element.

A filling sensor is installed on the pipe; its main task is to send a signal to the electronic control panel if the auger is filled with pellets in order to complete the fuel supply. All these automation methods make it possible to burn fuel efficiently and create comfort during heating boiler maintenance. But there are also certain disadvantages:

- The cost of manufacturing the burner increases significantly.

- The electronic unit of the heating boiler included in the kit is usually not suitable for simultaneous operation with devices for controlling and igniting the burner; in this case, it is necessary to purchase a new one.

- The burner cannot be connected to any controller.

Design features of pellet burners

The main task of any burner is to ensure uniform heating of the boiler. This goal is achieved through the processing of granular fuel. From a structural point of view, the burner is a combustion chamber, which most often resembles a pipe in shape. Combustion inside such a device occurs due to the continuous supply of air.

Fuel delivery is carried out by a special device - an auger. To pump air into the structure, a fan is provided, the operation of which does not allow the flame to go out. The burner can have a variety of shapes, which does not significantly affect the efficiency of the device. Chambers that have a round cross-section are the most common. This is due to the fact that they are the easiest to make. However, rectangular options are also quite common.

The device of a pellet burner, where 1 – LCD display, 2 – control knob, 3 – backup battery, 4 – connecting connector, 5 – fuel level sensor, 6 – safety thermal relay, 7 – photosensor, 8 – internal auger motor, 9 – igniter , 10 – internal auger, firebox, 11 – combustion grate, 13 – fan.

Round burners used for pellet processing have a flat base. It is used to accommodate fuel and is mounted externally to the front surface. It is worth noting that some burners have the ability to connect a GSM module. An example is the Terminator 15 pellet burner. Its cost is approximately 75 thousand rubles.

The operating principle of these devices is quite simple. First, the sawdust is loaded into the hopper, after which it is delivered through the channel to the burner. A fan blows air to maintain the required flame level inside the device. Combustion products accumulate in the ash pan. It is recommended to clean this compartment at least once a week.

Smoke from the fuel tank.

There is a simple “at-home” way to check the quality of smoke removal from the boiler: open the boiler door - if adjusted correctly, smoke does not come out, even if all doors are open.

If exhaust gases (smoke) come out of the fuel tank, this is a sign of insufficient chimney draft. This happens when the boiler chimney or the incoming combustion air mixer is clogged. The second reason is incorrect boiler control settings or a simply unsuccessful boiler design.

Another note: when adding fuel to the firebox, make sure that the burner is at rest (the fan is turned off and does not create excess pressure in the boiler).

DIY pellet burner: varieties

Devices that are used for processing granular raw materials are divided into two types depending on the principle of operation - with forced intake and gravitational. The choice of one type of equipment or another depends primarily on individual operating conditions.

On a note! The most common burner option requires the presence of electricity. In this case, electricity is necessary to operate the mechanism that ensures an uninterrupted supply of granular fuel. Automatic pellet burners (with forced intake) are considered the optimal solution for organizing heating of a building.

At the moment, pneumatic pellet burners from Obshchemmash are popular.

Devices of this type include several mechanisms through which granules are delivered. The first of them operates using a pneumatic system. The second mechanism is equipped with a special tool - a screw. Safety in the system is ensured by the design of the channel, installed from the bottom up, through which the granules are supplied.

Automatic devices have one serious advantage - fire safety. Such devices are used in equipment from different manufacturers. For example, they are integrated into Teplodar boilers. Pellet burners, reviews of which are mostly positive, are quite expensive. The price of some models exceeds 150 thousand rubles. More budget options can be purchased for 60-80 thousand rubles.

The pneumatic type design is characterized by maximum safety. This is because the pellet delivery system delivers fuel in small portions. Thus, it is not delayed in the communication channel. For such a burner, it is possible to install a large hopper that does not require frequent loading. If desired, a device of this type can be purchased. Currently, pneumatic pellet burners from Obshchemmash are very popular.

Screw-type feed mechanisms include two main units. Using the first auger, granulated fuel is taken from the bunker. The operation of this device allows you to transport pellets to another receiver. After this, the second screw sends the raw material directly to the burner.

Automatic pellet burners are characterized by high fire safety.

The disadvantage of devices in which fuel supply is forced is their dependence on energy. In the event of a power outage, the burner stops operating.

Possible options for fluid movement

There are many schemes. But all methods can be divided into two main groups depending on the principle of movement of the coolant through the pipes. Therefore, a specific scheme is selected depending on whether natural or forced pumping is used in the system.

Features of natural circulation

The simplest and most inexpensive solution is piping the boiler, where the coolant will move through the pipes using the laws of physics. Even a beginner can implement such a scheme, and it will take a minimum of time.

The peculiarity of a heating system with natural circulation is the absence of a pump. In this case, the movement of liquid in the pipeline occurs due to the ability of a colder medium to push out a hotter and less dense one.

When organizing a heating system without a pump, the radiators should be located higher than the boiler. At the same time, the number of bends and turns of pipes must be minimized (+)

The advantages of this solution include:

- low installation cost;

- low cost of service;

- ease of installation;

- the ability to quickly restore system operation if a breakdown is detected.

But the scheme with natural fluid movement also has its drawbacks. First of all, it can only be used with a single-circuit system. In addition, such a solution will be effective only in small houses.

Forced circulation option

The greatest demand is for heating systems that use a circulation pump. And this is not at all surprising, because such a scheme is convenient, versatile and practical. It can be used in houses and buildings of absolutely any size.

But even despite the unique advantages, schemes with forced coolant circulation have some significant disadvantages:

- high cost of installation - the average cost of a pump is about 150-160 dollars;

- complexity of implementation - the circuit consists of a large number of elements, which significantly complicates its implementation;

- the need for balancing - all components of the home heating system must be precisely aligned with each other;

- dependence on the availability of electricity - the heating pump will only work if current is supplied to it.

When organizing a heating system for a building with two or more circuits, it is recommended to use the option with forced movement of the coolant.

The heating system with forced liquid pumping operates thanks to a circulation pump. Therefore, it is better to give preference to reliable devices from trusted manufacturers

However, in this case, the fundamental performance factor is the power of the heating boiler. Please note that if it is not enough, the equipment will not be able to heat a sufficient amount of coolant.

Gravity pellet burner: design features

Devices of this type, operating on pellet fuel, have a different operating principle for supplying pellets. It should be said right away that such units are more convenient to use. The main advantage of the gravitational mechanism is that it does not require a connection to the electrical network.

In this case, the pellets are located in a bunker and can enter the connected channel under the influence of their own weight. There are several popular domestic companies producing such units (Pelletron, Behemoth). A pellet burner of this type is started very simply - by changing the position of the damper. It is important to remember that the chimney has a draft regulator, which can also be adjusted.

On a note! The main disadvantage of all gravity structures is that they do not provide as much safety during operation as their counterparts. During operation, there is a possibility of ignition of granulated fuel in the bunker. An increased risk of ignition exists due to the design of the hopper, which is directly connected to the opening through which the fuel is supplied.

Gravity pellet burners can be used without an electrical connection.

The efficiency of gravitational devices is slightly lower than that of analogues that operate through the forced supply of granular fuel. Installing this type of pellet burner is not a difficult task. Its complete connection can be completed in just a few hours.

In order to increase the fire safety performance of this device, many manufacturers install special dampers on it. They are equipped with thermal sensors, which, if a flame enters the channel connecting to the bunker, are activated and block the passage.

Installation

Pellet boilers must be installed in compliance with certain requirements for the installation site.

Choosing a place

It is better to install the unit in a separate room due to its impressive dimensions. The best option is a room with a temperature of at least +10 °C.

Installation outside the building is not recommended. However, when placing equipment outdoors or in a garage, pipes should be located underground below the freezing level to reduce heat loss.

Preparing the floor and walls

It is necessary to level the floor in the place where the equipment will be installed. The platform must be strong enough to support the weight of the device itself and the pellet hopper. Non-flammable plates should be fixed to the walls and floor. There must be a place for pellets near the device.

Ventilation and chimney

We install ventilation and a chimney made of non-combustible material. The latter, as a rule, is displayed on the roof, protruding above its surface by at least half a meter. It should be protected from precipitation and insulated.

The cross-section of the chimney pipes must be larger than the diameter of the hole intended for removing exhaust gases from the equipment.

Installing equipment

Having prepared the site, we install the device itself. We install and connect the burner, hopper, auger and automatic control panel. Communications are connected to the equipment through ball valves.

This will make the system easier to maintain. It is advisable to install filters. After connecting all the elements, a test run of the heating system is performed.

How to draw a drawing of a pellet burner?

Before starting to independently design a burner intended for processing pellet fuel, it is recommended to complete its individual drawing. The diagram must necessarily contain information about all components and parts. The drawing requires you to indicate the main elements:

- camera;

- fuel bunker;

- screw;

- fan.

The diagram must contain all the necessary dimensions of these products. When making a drawing of a pellet burner with your own hands, you should remember that the detail of its execution determines how reliable the device for processing fuel pellets will be.

Manufacturing drawing of a pellet fuel burner.

Before starting to draw up the diagram, it is recommended to calculate in advance the required dimensions of the bunker. When performing calculations, you should take into account how much area the structure will heat. It is also worth noting that the parameters of the bunker have a direct impact on the frequency of its cleaning.

The fan operation is controlled by an electronic unit. When drawing up a diagram, you need to remember that the performance of the main components of the device depends on the availability of electricity.

Thus, making a drawing of a pellet burner with dimensions with your own hands is not so difficult. If necessary, you can use a ready-made scheme, of which there are many on the Internet. But in such a situation, it is necessary to select a drawing that will meet specific conditions.

Product structure

Let's look at what main parts a homemade pellet burner consists of. Its task is to ensure uniform combustion of fuel and stability of the flame, due to which the water jacket of the boiler unit is heated

Particular attention is paid to the possibility of adjusting the combustion intensity

The pellet burner consists of the following elements

:

- combustion chamber (in the form of a round or rectangular pipe);

- loading hopper for fuel;

- screw conveyor for supplying bulk fuel;

- fan for forcing air into the combustion chamber.

The volume of the loading hopper determines how often the boiler operating in automatic mode will have to be serviced. The operation of the blower fan is regulated by an electronic control unit - the intensity of the air supply affects the rate of fuel combustion.

Electricity is required to operate the electronic unit, fan and screw conveyor, so this burner device is energy dependent.

Principle of operation

The pellet stove is equipped with a burner that works according to the following principle

:

- The first portion of fuel entering the combustion chamber is ignited with minimal air supply.

- During the combustion of the first portion of fuel, the air supply increases, the flame intensifies and warms up the combustion chamber.

- The fuel supply begins in small portions, the air pressure stabilizes, and the flame becomes even.

- Operation of the burner in a stable mode allows for economical fuel consumption and efficient heating of the water jacket of the boiler unit.

Design Features

The combustion chamber, made of a round or square pipe, has a tray inside for burning fuel, and on top there is a pipe with a screw conveyor for dosed supply of sawdust, granules or other fine-grained energy carriers. The chamber is attached to a flange plate, which is adjacent from the outside to the front plane of the boiler unit.

The natural flow of air does not make it possible to burn fuel in a suitable mode, so a fan is installed, turning the combustion chamber into a wind tunnel.

Dry bulk fuel with optimal air supply burns with virtually no residue. The flow of forced air carries a small amount of ash into the ash pan - that is, the combustion chamber cleans itself during operation. It is necessary to remove ashes from the ash pit once every 7-10 days - the frequency depends on the intensity of the accumulation of unburned residues. If the fuel moisture content is high, the ash pan must be cleaned more often.

Organizing the supply of bulk fuel to a homemade pellet burner is carried out in two ways

:

- A large hopper is installed in the room, into which fuel is loaded for 7-10 days of continuous operation of the boiler (it is with this frequency that the burner ash pan needs to be cleaned). To supply fuel to the burner nozzle, it is necessary to install a screw conveyor, the length of which depends on the distance between the hopper and the boiler.

- The hopper is mounted directly on the pellet burner so that bulk fuel enters the burner auger under its own weight. A gravity pellet burner is simpler and cheaper to manufacture, but it will have to be serviced more often - usually a hopper is used, the volume of which is enough for 1-3 days of boiler operation.

Positive Features

A do-it-yourself sawdust burner is a device that helps expand the functionality of a conventional solid fuel boiler. Its installation allows you to save firewood and coal if inexpensive or free waste from wood processing or crop production is available. This approach will significantly reduce the overall heating costs of a private house, cottage or garage.

Pellet burners have a number of advantages, including

:

- economical fuel consumption;

- minimum amount of ash and harmful emissions into the atmosphere due to optimization of the combustion mode - fuel and combustible gases burn almost completely;

- little need for maintenance - fuel is added no more than once a day, the ash pan is cleaned no more than once a week, the operation of the unit is automated.

Pellet burner device

DIY pellet burner: preparatory stage

Before you begin assembling a burner that processes granular fuel, you need to do some preparatory work. First of all, you need to calculate the area that will be heated using this device. Knowing this indicator, it will not be difficult to calculate the required power of the heating device. When calculating the power indicator of a pellet unit, the following factors are taken into account:

- average annual temperature in a particular region;

- building area;

- ceiling height in the building;

- number of door and window openings;

- building materials from which walls, floors and ceilings are made.

Before making a burner with your own hands, you need to calculate the area of the room that will be heated.

Then you should prepare all the tools that will be used when assembling the pellet burner with your own hands. Video and photographic materials help to get an idea of this process, so it is recommended to study them in detail.

It is necessary to determine the thermal transfer resistance of the materials used. This coefficient will be required in the future to calculate heat loss. The power of heating equipment must be at least 10% higher than heat loss.

On a note! There are special online calculators that allow you to determine the power of the boiler. They can be easily found on the Internet using the search bar of your browser.

Experts recommend purchasing ready-made pellet burners. The price of these devices varies from 50 to 200 thousand rubles. Making such a device is quite difficult, since many operational nuances need to be taken into account. Purchased models are also equipped with the necessary thermal sensors, which makes their operation convenient and safe.

Making a pellet burner is a complex and labor-intensive process.

Starting and maintaining the boiler

Comparison of heating costs

The equipment can be started only after installing the pellet boiler and connecting the corresponding heating system pipes to it. Once the mentioned tasks are completed, turn on the cold water supply to the heating system.

Observe the operation of the boiler. If any unusual symptoms occur, turn off the equipment and do not use it until the problem is resolved.

Observe the boiler operation

Homemade pellet boilers, like any other heating units, require appropriate care.

Every 2-3 weeks, empty the ash pan of waste. Clean the smoke exhaust duct every 2-4 weeks. This will not take you much time, but ignoring such simple maintenance will lead to a significant decrease in the efficiency of the boiler and make the equipment potentially unsafe.

If desired, additional automation equipment can be connected to the pellet boiler. This will make the operation of the equipment more convenient - you can simply forget about the need to reload fuel and other related activities for some time.

Modern automation tools even allow you to set up remote control of the heating unit, which is also very convenient.

And these are not the only possible additions. How do you like, for example, self-cleaning systems for boilers? Be sure to study the available modifications and, if desired, purchase such additions for your boiler.

Boiler with pellet hopper

You can assemble a simple pellet boiler with your own hands, following the instructions you received earlier.

Video - Operating principle of a pellet boiler

The unique smell of natural wood, a clean and decorated room in a modern style - this is exactly what a boiler room in a house can look like if you choose the right equipment. Innovative heat-generating equipment that will create the described conditions indoors is a pellet boiler or an automatic pellet burner, running on special fuel pellets, which are created from waste from agro-industrial or woodworking production.

If just a few years ago pellet installations were used in only 20% of homes in Europe, now the figure has increased to 70%. The use of pellet boilers and burners is the most beneficial option for heating a living space from an environmental and economic point of view. Today we will talk about the operating principles of the equipment, its advantages and disadvantages, and also consider a diagram for making a pellet burner with your own hands.

How to make a homemade pellet burner: basic recommendations

The most important structural element that is part of a pellet burner is the basket. When making such an element yourself, you should remember that there is one common problem - granules getting stuck in the back wall, which is located at an angle and has slots. To solve the problem, you need to make the cracks differently. The standard version takes into account continuous slots, but it is recommended to make a more cellular structure.

The ideal size of the rear wall slots should be 2 mm smaller than the size of the secondary fuel pellets. The gap between the back wall and the bottom of the basket must be at least 6 mm. The front wall also has slots, but in this case they must be solid.

Before work, it is recommended to study videos demonstrating the assembly of a pellet burner. Reviews of various home-made devices will also help you choose the right device option.

There is a channel located under the bottom of the basket that is part of the burner. It is necessary for secondary air. The height of the channel should be approximately 29 mm. A deviation of 1 mm is allowed here. The back wall itself is not perpendicular, but at an angle. The tilt angle is 45°.

It is recommended to make the size of the slots in the rear wall of the basket 2 mm smaller than the size of the pellet fuel granules.

The price of a pellet burner purchased ready-made is several times higher than the cost of a prefabricated version. Thus, self-manufacturing of this device allows you to significantly save money.

The size of the basket with tray is selected taking into account individual needs. In this case, it is necessary to focus on the indicator that determines how much fuel will be processed per 1 hour of burner operation. The best option is considered to be a device with dimensions of 13x13 cm. The depth of such a basket should be approximately 10-12 cm. Such a device allows you to burn about 2-3 kg of granular fuel in 1 hour.

Making a hopper for a pellet burner with your own hands

The second necessary element of any burner installed on heating equipment is a hopper. The most common problem that arises during the operation of homemade devices is related to the penetration of flame into this structure. In order to assemble a reliable bunker, it is recommended to use ready-made drawings of popular bunkers from Teplodar or Pelletron. A pellet burner can be made of any power, but it is best to take standard 15 kW devices as an example.

Drawings of a hopper for a 34 kg and 17 kg pellet burner.

The volume of the bunker is also selected individually. You can make a box that will hold 17 or 34 kg of granular fuel. For the manufacture of the combustion chamber, a material such as stainless steel is traditionally used. Moreover, its thickness should be at least 2 mm.

On a note! Steel walls are joined using welding equipment.

The dimensions of the bunker are borrowed from any suitable model (for example, Pelletron 15). The pellet burner includes a secondary air channel, which is best made in the shape of the letter “L”. This will significantly increase the efficiency of the operating device.

In addition, the burner should be provided with air supply. This will make it possible to simplify its launch, since the reaction to draft in the chimney structure will be reduced. For a device with a power of 15 kW, 20 W fans are suitable. Experts recommend purchasing a fan, which is called a snail. This is due to the fact that the operation of such a device is easiest to regulate.

The fan is an important part of the pellet fuel burner, as it simplifies its operation.

Further arrangement of a pellet boiler with your own hands

Assembly of the device body is carried out in several stages. You can handle this task yourself, but you need to clearly understand the nuances of the work. The body is best constructed in a horizontal plane. This is because this arrangement allows for maximum equipment efficiency.

It is recommended to use brick (fireclay) as a material for the manufacture of the body. The process looks pretty simple. It is necessary to assemble the box and place the heat exchanger inside it. It is worth noting that the brick body is made without a top cover. The heat exchanger must have outlets for connecting heat supply pipes.

Do not forget that the burner should be equipped with a special controller. Pellet burners can be completely mechanical, but in this case it is much more difficult to set them up. Regulation is made taking into account the individual characteristics of the device and the area of the heated room.

The use of brick for the installation of the housing is recommended because it has good insulating qualities and is able to accumulate heat to a greater extent than other common materials such as steel and cast iron. Photos of burners and other heating equipment can be easily found on the Internet.

To make a heat exchanger, you need to cut pipes with a rectangular cross-section and connect them together.

First of all, the heat exchanger is manufactured. To do this, you need to prepare pipes with a rectangular cross-section. Then they need to be cut (in accordance with the drawing) into pieces of the required length. After this, the individual segments are connected to each other using welding. It is necessary to provide pipe supply to the heat exchanger. Then a chimney with an ash pan is installed.

Kinds

flare

Such burners for solid fuel boilers are typical mainly for Russian products. The fire rushes to the side plane. The pellets are supplied via a horizontal auger or using a vacuum tube. Draft into the boiler must be provided by force. The air pressure created by the fan is fully consistent with the needs of heating equipment; depending on the vortices that form, combustion occurs more or less stably.

Flare burners provide excellent process efficiency. You can put almost any fuel inside. In addition to pellets of various types, it is possible to use even ordinary dry wood chips that are suitable in size. The device uses the supercharging effect. Smooth adjustment is ensured by a direct connection between the fan and the automatic control system.

How to automate the process and configure a pellet burner yourself?

Homemade pellet boilers have one feature - the absence in the design of a device that provides an influx of natural draft. Without draft, as you know, it is impossible to maintain a flame inside the device, so you will need to install a fan. To ensure uninterrupted operation of the boiler, an auger is also used, which is responsible for delivering fuel from the bunker to the combustion chamber.

In order to fully automate the workflow and, if necessary, achieve its adjustment, you need to integrate a controller into the design. Its role is played by the pellet burner control unit.

On a note! Mechanical control is carried out using a simple regulator.

Using the control unit, you can fully automate the operation of the pellet burner.

The main task to ensure the normal operation of heating equipment is to achieve a balance between two main indicators. The first of them is the volume of granular fuel, and the second is the air intake rate. If you can correctly adjust these indicators, then the flame will evenly heat the heat exchanger.

All necessary indicators can be set using the burner control module. What it is? The control unit provides complete control over the operation of the heating unit. Of course, the best option is to purchase a new device.

Purchased models have the ability to quickly connect to the main working elements of a pellet boiler. As a result, the controller will regulate the supply rate of granular fuel, as well as the fan speed. The display located on the control unit allows you to configure the pellet burner.

It is worth noting that the auger must have a sensor that monitors the need to supply granular fuel. It works as follows: it detects when the auger is full and sends a signal to the equipment. After this, the supply of pellets is suspended.

Using the controller, the speed and volume of pellet fuel supply is adjusted.

general description

As a rule, a standard pellet burner is sold by manufacturers already equipped with various accessories. Most often, the following items are included in the package:

- controller for automation of work;

- auger for feeding pellets;

- lambda probe, which measures the residual air volume and automatically regulates combustion;

- bunker fuel tank.

In some cases, a plastic corrugation is installed in the area from the auger to the burner, which prevents the spread of flame when reverse draft occurs. The main components of the burner are also:

- electric heating element, which is involved in automatic ignition;

- fan for air supply, located at the bottom of the device or at the back of the boiler, controlled using a controller.

In this video we will learn how to make a pellet burner with your own hands:

Automated supply of fuel from the bunker to the furnace occurs without human intervention. The pellets are fed using an electrically driven screw device, and the process is additionally checked by a controller with thermal sensors and an indication system that displays the operation of the burner itself.

The control circuit for the coolant temperature mode is simple. When the set temperature is reached, the burner, using the controller, goes into standby mode with prolonged smoldering of the fuel. Then, when the coolant cools down to a certain temperature, the sensor transmits a signal to start the fan, this causes the fuel to ignite and transfer the device to normal operation. A heating element is often used for ignition.

The efficiency of the burner will depend on the speed at which fuel is poured into the firebox and the volume of the fuel itself, therefore only the correct setting of all indicators contributes to the optimal effect of the operation of this equipment.

Pellet burner Zota Fox 25: reliable and efficient model with wide functionality

This type of pellet burner is used in Zota Fox series boilers. It is used in heating units, the design of which does not include a plate made of cast iron material. To date, such a burner has proven itself only from the best side. It is characterized by efficiency and reliability, as well as a long service life.

The Zota Fox pellet burner processes granular fuel. The size of each pellet used in this case ranges from 6 to 8 mm. The power of this unit is regulated by an automatic system. This indicator may vary (from 5 to 25 kW).

Installing a Zota pellet burner on a solid fuel heating boiler allows you to automate its working process. Equipment equipped with a granule processing unit has certain advantages:

- reduction of heating costs for residential buildings;

- increase in operating time when loading one portion of granulated fuel;

- maintaining the required temperature in the room.

On a note! The power of the burner used for processing pellets is determined depending on the area of the heated room. It is worth noting that a 1 kW device can provide heat to a room of 10 m².

The Zota Fox 25 pellet burner is an efficient and reliable unit.

The burner power is adjusted automatically. For this purpose, the design provides a special control module. Zota Fox pellet burners (5-25 kW) have many additional functions that are easy to activate and configure on the control panel. These include automatic ignition of granular fuel, quick start and stop, automatic cleaning of the burner and other modes.

Safety in such a device is realized by a sensor that regulates the combustion temperature of the fuel. This device can also be connected to a GSM module or thermostat installed in a heated room. The cost of such a burner is approximately 75 thousand rubles.

Kinds

flare

Such burners for solid fuel boilers are typical mainly for Russian products. The fire rushes to the side plane. The pellets are supplied via a horizontal auger or using a vacuum tube. Draft into the boiler must be provided by force. The air pressure created by the fan is fully consistent with the needs of heating equipment; depending on the vortices that form, combustion occurs more or less stably.

Flare burners provide excellent process efficiency. You can put almost any fuel inside. In addition to pellets of various types, it is possible to use even ordinary dry wood chips that are suitable in size. The device uses the supercharging effect. Smooth adjustment is ensured by a direct connection between the fan and the automatic control system.

Automatic pellet burner Teplodar APG-25

This device is automatic. It has many advantages. The products of this company are of high quality and have a long service life. A burner of this type is sold together with a hopper, which is delivered disassembled. In addition to the bunker, the kit includes an auger that delivers pellets, as well as a control panel.

This model has many advantages. One of them is ease of installation. If you wish and have certain skills, connecting such a model can be done in just 30 minutes. Teplodar pellet burners require preliminary settings, which are made according to needs. The hopper should not be filled too often (twice a week is sufficient).

Pellet burners Teplodar APG-25 are a high-quality product with a long service life.

In this case, cleaning the ash pan from combustion products is done no more than 2 times a week. As a rule, only once is enough. It is worth noting that, in addition to the APG-25, there are also more powerful modifications produced by this manufacturer. For example, the APG-42 model has become widespread.

These devices are installed on Cooper brand heating equipment. Pellet burners of this type are equipped with an improved auger, thereby increasing the overall reliability of the design and its service life. The control panel has a convenient and clear display, which indicates all the necessary operating parameters of the heating equipment.

Thus, in order to make a burner that processes pellet granules, you must first calculate the power and prepare a drawing. During work, you must be careful, since any mistakes made during assembly of the structure can lead to a fire of the pellets in the bunker.