Gas boilers are excellent for heating apartments, houses, cottages, industrial, administrative or commercial premises. When choosing a gas fuel boiler, it is important to decide on the type of combustion chamber.

Fuel is burned in the combustion chamber. It can be open or closed. This design element of the heating unit affects smoke removal, noise level and room requirements for the boiler.

Gas boilers with an open combustion chamber

The design of these boilers is quite simple. The heat exchanger is located directly above the atmospheric burner.

Due to the simplicity of the design, boilers with an open combustion chamber:

- easy to maintain;

- more reliable;

- have a lower cost (compared to analogues with a closed chamber);

- lower gas consumption when operating at partial power compared to a closed chamber;

- produce less noise during operation.

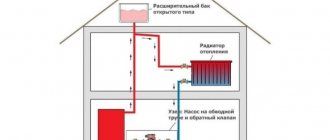

A conventional vertical chimney is used to remove combustion products.

Gas fuel boilers with an open chamber take the air necessary for gas combustion directly from the room in which they are located. Therefore, they are very demanding on the quality of ventilation and require an equipped boiler room.

The disadvantages of boilers with an open chamber include:

- difficulties in designing a chimney (if mistakes are made, there may be problems with draft and smoke removal, including the possibility of reverse draft when gusts of wind on the street can blow out the flame in the boiler);

- atmospheric burners are subject to accelerated clogging and require more frequent cleaning;

- boilers with an open combustion chamber are inferior in efficiency to their analogues with a closed chamber, they have lower efficiency, and worse environmental performance.

The best boilers with an open combustion chamber in 2022

- Gas floor-standing boiler Protherm Bear 30 KLOM Ver.17 (26 kW)

- Gas floor-standing boiler Protherm Bear 40 KLOM Ver.17 (35 kW)

- Gas wall-mounted boiler Protherm Panther 25 KOV

- Gas wall-mounted boiler BAXI ECO-4S 24

- Gas wall-mounted boiler BAXI LUNA-3 240 i

- Gas wall-mounted boiler BAXI NUVOLA-3 Comfort 280 i with built-in 60 l boiler

- Gas floor-standing boiler Vaillant atmoVIT VK INT 484/1-5

- Gas wall-mounted boiler BAXI LUNA-3 Comfort 1.240 i

- Gas wall-mounted boiler Vaillant atmoTEC plus VU INT 280/5-5

- Gas wall-mounted boiler Vaillant ecoTEC pro VUW INT IV 346/5-3 H

Heat exchangers

The main element of heating boilers are heat exchangers. It is the heat exchangers that are designed to transfer energy from the burned fuel to the coolant. Naturally, metal is used to perform this function:

- Steel – Steel heat exchangers are easy to manufacture and therefore inexpensive. However, steel rusts, so the service life of steel products is short and the weight is high. The efficiency is inferior to all other materials. Steel products are preferred by domestic boiler manufacturers;

- Copper is a very convenient material for a heat exchanger, it does not corrode, heats up and cools down quickly. Copper heat exchangers are most often used in imported boilers;

- Cast iron is also not susceptible to corrosion, but due to its fragility and insufficiently careful use, cracks appear on it. Cracks can also appear due to uneven heating during scale formation during long-term operation.

Optimal operation of a gas boiler Find out how to install autonomous gas heating in an apartment, how big the savings are when installing a gas boiler

IMPORTANT! Mandatory flushing of the coolant. If the carrier is water, then once a year. If antifreeze, then once every two years.

Gas boilers with a closed combustion chamber

Boilers with a closed chamber are more technologically advanced and complex, so their cost is often higher than that of boilers with an open chamber. Combustion of gas fuel occurs in an isolated closed chamber; air is pumped in and combustion products are removed using a fan (turbine). The gas combustion process is regulated automatically, which allows optimizing fuel consumption.

Air intake and smoke exhaust can be done either through a separate or through a coaxial chimney (side, through the wall). It is designed according to the “pipe-in-pipe” principle. This option is the safest to use. Air is not taken from the room, so boilers with a closed chamber can be installed in the kitchen or other suitable room.

Obvious advantages of boilers with a closed chamber:

- higher efficiency indicators (efficiency, environmental friendliness, safety) in comparison with atmospheric models;

- a coaxial chimney is easier to install than a classic one;

- stability of traction without the risk of being blown by the wind;

- there are no strict ventilation requirements;

- can be installed not only in the boiler room, but also in other suitable rooms.

The disadvantages include:

- higher cost (10-30% more expensive than atmospheric);

- energy dependence;

- higher gas consumption when operating at partial power compared to an open chamber;

- the risk of chimney icing, however, you can buy a special coaxial chimney with anti-icing protection;

- slightly increased noise level from the operation of the turbine (fan), but this is almost imperceptible.

The best boilers with a closed combustion chamber in 2022

- Vaillant turboFIT VUW 242/5-2, 24 kW

- Vaillant turboTEC pro VUW INT 242/5-3

- Vaillant ecoVIT VKK 286/4

- Protherm Cheetah 23 MTV

- Protherm Jaguar 24 JTV

- Protherm Lynx K 25 MKO

- BAXI ECO Nova 18 F

- BAXI ECO Nova 24 F

- BAXI LUNA-3 240 Fi

- BAXI SLIM 1.300 FiN 5E

Features of the device and principle of operation

The unit consists of a housing in which a closed combustion chamber is located.

The design also includes:

- forced-air burners;

- gas nozzle;

- heat exchanger;

- air channel.

A coaxial pipe emerges from the combustion chamber through the side wall of the boiler. The heat exchanger can be cast iron, copper or steel. The first option is optimal.

The chimney consists of 2 pipes, which are placed one inside the other. Through the gap between them, combustion products come out. Air enters the gas boiler through the internal pipe. It is pumped by an electrically driven fan.

The design also includes the following elements:

- condensation unit (increases the efficiency of the device through the use of heated gases and residual heat);

- circulation pump - to ensure uninterrupted movement of coolant;

- built-in expansion tank;

- electronic control unit (sensors control the ignition mode and power of the gas boiler).

The principle of operation of the device is simple: liquefied or natural gas is supplied to the combustion chamber, where it is burned and heats a heat exchanger with water circulating in it. The temperature of the liquid rises, after which it enters the heating system. The equipment does not require additional ventilation.

A special feature of a closed gas boiler is the possibility of installing it in an apartment. But devices of this type cannot be installed in rooms where there are power outages.

Which combustion chamber to choose: open or closed? Which is better?

If you are buying a boiler to replace an old one, you already have a ready-made boiler room with good ventilation and a well-installed chimney - you can consider atmospheric models with an open combustion chamber. This will save you some money. An atmospheric boiler also helps to save money if the heating unit most often does not operate at full capacity. However, this is not very economical in general (the efficiency drops); it is wiser to choose a less powerful model.

If you need a boiler for a new house, or even more so for an apartment, then you should consider more modern models with a closed chamber. This option is also suitable if there is no classic vertical chimney and no opportunity to equip it. If there is no boiler room or room for its arrangement, the best choice would also be a boiler with a closed combustion chamber; it is easier to choose a suitable place for it.

Double-circuit or single-circuit?

A single-circuit boiler only heats the house. The advantages of this type include: low cost, capable of operating without pressure from the water supply network, and if there is a boiler, there is no shortage of hot water.

In order to provide yourself with hot water, you need to purchase a water heating tank (boiler) - this is an additional expense, taking into account installation it is equal to the cost or is more expensive than double-circuit boilers. A double-circuit boiler not only heats the room, but also provides hot water. A wall-mounted double-circuit boiler occupies a smaller area than a single-circuit boiler with a boiler, no need to connect a boiler, easy installation, heats the required amount of water.

Disadvantages of this type:

- DHW water has an uneven temperature. It heats up smoothly.

- If the tap is located far from the boiler, then the water flows until the desired temperature is reached. The second circuit starts with a strong stream from the tap. It is configured so that when the flow is low, the equipment does not turn on. Consequently, low water savings.

It should be noted that the last drawback is absent in devices with a boiler or storage tank up to 60 liters, where water is heated layer by layer. Therefore, water is supplied at a certain temperature and does not depend on the pressure in the water supply network. Wall-mounted gas boilers are the best choice for heating private homes. Installation of a wall-mounted gas boiler (regardless of the number of circuits) is not difficult, as is their maintenance.

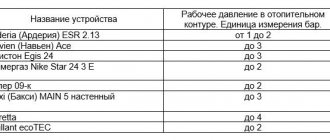

Comparison of popular boilers with open and closed combustion chambers

Let's look at the differences between two types of boilers from the same series using the example of popular wall-mounted double-circuit gas models with a power of 23 kW (for a heated area of up to 230 m2): Protherm Gepard 23 MTV and Protherm Gepard 23 MOV.

| Protherm Cheetah 23 MTV | Protherm Cheetah 23 MOV | |

| The combustion chamber | closed | open |

| Efficiency | 93,20% | 90,30% |

| Max. gas consumption in heating mode (G20) | 2.9 m3/hour | 2.7 m3/hour |

| Boiler weight | 34 kg | 31 kg |

| Dimensions (H x W x D) | 740x410x310 mm | 740x410x310 mm |

| Price | 61640 rubles | 58698 rubles |

Rules for safe use

Natural draft gas boilers are quite popular due to their low price and other advantages. But when operating gas boilers, we must not forget about the safety rules:

We will send the material by email

When choosing a gas boiler for your home, you need to take into account a number of nuances related to the technical characteristics of the building, the installed heating system, the actual need for heat and hot water supply.

Domestic and foreign manufacturers offer a wide range of products. So finding a suitable copy is not a problem. You just need to know what to look for in order to understand how to choose a gas boiler for heating and not make a mistake. It is also advisable to understand how the presented options differ from each other, and which boiler to choose for a private home.

There are very few external differences between boilers of various modifications

How to choose a boiler for heating a private house

When choosing a gas boiler, you need to consider not only what they come in. There are many more important parameters. Let's figure out what you should pay attention to.

How to choose a gas boiler for a private house by power

It should be noted that it is very important to calculate the appropriate power, that is, no less and no more. With the first, everything is clear: the building simply will not warm up sufficiently. But why is it undesirable for the boiler to be more powerful? In this case, the heating system begins to operate unevenly, which leads to excessive wear. The result is frequent repairs and premature replacement of the boiler. In addition, gas consumption increases.

Features of gas heating

Despite the presence of a large number of alternatives (electricity, diesel, diesel, fuel oil, firewood, coal), gas heating is still the leader in the world. And there are serious reasons for this:

Economical. Compared to other options, gas is relatively cheap and has high efficiency. In this case, not only the cost of the fuel itself is taken into account, but also additional expenses for its storage (for the consumer), maintenance of the entire system, etc. Thus, parts for rare types of boilers can be difficult to obtain, and sometimes you have to overpay. This is also taken into account.

Minimal human involvement. Heating a room using wood or coal requires mechanical addition of fuel. Here everything is automated, including gas supply and flame control.

Cleanliness, absence of soot, soot and other things. Boilers can be easily installed in the kitchen.

Possibility of heating large rooms. One powerful boiler can handle a building with several floors.

At the same time, gas heating also has its disadvantages. Or rather, specificity.

Installation should only be carried out by specialists

In particular, the installation of a boiler requires approval from Gaztekhnadzor. Installation can only be entrusted to an organization with a license giving the right to provide such services.

Do not forget that gas is explosive. Therefore, saving on automation is extremely undesirable: it monitors, among other things, its leakage (we are talking about modern technology).

In addition, you need to take care of ventilation. Combustion products can be removed from the building naturally. But if problems arise with draft, you need to change the installation location of the boiler (which is not always possible) or provide it forcibly.

Classification of boilers and the general principle of their operation

Heating boilers are classified according to several parameters:

- Type of fuel.

- Power.

- Number of circuits.

- Installation methods (floor or wall).

- Type of combustion chamber (open or closed).

If in an electric heating boiler the water is heated directly by heating elements, then in gas, solid fuel and diesel boilers an open flame is used to heat the coolant, which is created by burning fuel in a special chamber. Fuel combustion chambers can be open or closed, and the combustion process and temperature conditions are controlled by a reliable automation system.

The operating principle of any heating boiler is simple. The fuel burns, heats the coolant, which transfers heat to the room through radiators. Diesel boilers use open chambers, and various models of gas and solid fuel boilers can have both open and closed combustion chamber designs. Consider their distinctive characteristics, as well as their advantages and disadvantages.