Water heater and supply ventilation system

Many words like “mixing device”, “cooler device” and “connection of air heaters” confuse the inexperienced user. He has only heard about the structure of the freon circuit, and he understands quite roughly what the piping units are. To learn more about heat appliance systems, you can “learn” from disassembling such a unit as a water heater.

If we talk about the quantitative option, then a changing heat consumption is inevitable. This is not the best option, of course, which is why today the so-called good regulation principle is used. It ensures linearity of the process, no matter what position the control valve occupies. This principle also implies excellent resistance to possible freezing of the heating device.

A good control principle uses elements such as a centrifugal pump and a three-way rod valve. They allow you to increase the efficiency of the heater and piping. They also guarantee that there can be no leaks on the floor from the steam appliance.

Varieties

.

The standard version with a rigid liner is the most common and is used more often, as a rule, in water systems consisting of main steel pipes. This is due to ease of installation and lower costs.

When installing a standard piping unit, you must know in advance the exact location of the unit and operating features.

With a flexible version of the piping units, they resort to the use of corrugated hoses; metal pipes are not used. The flexible unit is designed for installation in systems of complex configuration, with insufficient space for installation, with difficult access to parts of the mechanism. This piping option is considered more functional, but its installation and maintenance are somewhat more expensive.

Please note: for full control over the device, additional thermomanometers are installed.

Design Features

Essential elements

- Air intake grille. It has both a decorative purpose and serves as a barrier to dust and other particles contained in wind masses.

- Valve. When ventilation is turned off, the valve blocks the passage for fresh air, creating an insurmountable barrier. In winter, it can block a lot of air flow. You can automate its operation using an electric drive.

- Filters clean wind masses. They need to be changed every six months.

- Water, electric heater, which performs the function of heating the air.

- For small buildings it is advisable to use an electric heater. In large rooms it is better to use a water heater.

Principle of operation

A fan, a heat exchanger and a convector - this is what a water heating device looks like in general terms.

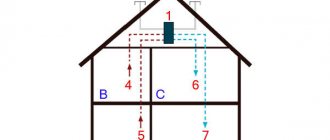

The operating principle of supply ventilation is as follows:

- The air flow enters special air intake grilles that prevent insects, small objects, birds, and animals from entering the ventilation channels.

- Filters clean the air from contaminants, harmful substances, and dust.

- The heater, using heat supplied from the water main, heats it to the desired temperature.

- The recuperator mixes the newly supplied air with the heated one.

- The fan supplies heated air masses into the room, and the diffuser distributes them evenly over the entire area.

- Sound absorbers reduce the sound power of a running installation.

- If the air supply is cut off, valves are activated to prevent cold air from entering the room.

An example of using a VOLCANO air heater in a tire repair shop (water temperature +90 ºС)

The heater, which does not have its own heater, consists of two main elements:

- A heat exchanger, the design of which is represented by a system of metal tubes - water coming from the general heating system reaches the required temperature here.

- Built-in fan that disperses heated air flow throughout the entire area.

Installation and connection features

Installation work, connection, starting the system, setting up work - all this must be carried out by a team of specialists. Installing a heater with your own hands is possible only in private homes, where there is no such high responsibility as in industrial premises. Basic operations include installation of the device and controls, connecting them in the required order, connecting to the coolant supply and removal system, pressure testing, and test run. If all components of the complex demonstrate high-quality operation, then the system is put into permanent operation.

Installation of the mixing block. Installation methods

The piping module is constructed using rigid wiring, i.e., all elements are connected using steel or plastic pipes. In this case, the location of the module is known in advance. All parts of this block are located in close proximity to each other. This simplifies the installation, maintenance or repair of the mixing unit.

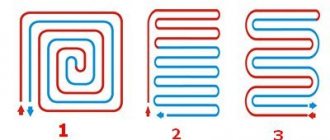

Two schemes for piping the thermostatic module have found practical application:

- High quality;

- Quantitative.

The first option, which ensures temperature control by the coolant while keeping its volume constant, is used today much more often than the other. The second scheme is based on a method of thermal regulation by changing the amount of coolant. Here, the volume of thermal energy and the heating temperature of the air are directly proportional.

Depending on the type of circuit provided, it includes either a two-way valve and a pump (quantitative method), or a three-way valve - with a qualitative heating method. In addition to these components, a typical steam heater piping unit includes:

- Ball valve for supply and removal of coolant;

- Coarse mesh filter;

- Bypass, which prevents the coolant from stopping as a result of sudden blocking of the solenoid valve;

- Thermometers, pressure gauges, piping.

In addition to rigid wiring, the method of threaded connection of circuit elements using corrugated hoses is also used. This option is used when rigid assembly is not possible.

What does the heater wiring diagram look like?

The operating principle can be outlined in general terms. Water, that is, a high-temperature coolant, enters the heater itself, first passing through a settling filter, and then an important three-way valve. To ensure that the water flows at the required pressure, a small circulation pump is used. The water, already cooled, enters the piping, goes to the boiler, and some of its volume also enters the valve.

As for the three-code valve, it necessarily comes with the heater piping and is considered an important control component. It maintains a constant temperature and volume of coolant entering the heating device. When the hot water temperature rises, this valve reduces the water supply while the chilled water supply increases. It turns out that the piping of the heat exchanger, without changing the water pressure in the system, changes its temperature.

Take note:

- The control valve is the main participant in the heater piping; it operates in auto mode and is controlled by an electric drive. The harness includes various sensors; they send signals to the electric drive, due to which the temperature is regulated and maintained at the desired level.

- Design of the piping - there may be standard wiring diagrams that, in principle, are connected to the heater, but they will still have to be adjusted to the device. However, the harness is usually designed for each specific device.

- Options for placing harnesses - this can be either vertical or horizontal. But not every harness can operate in every position. Therefore, the location of the piping is determined when designing the ventilation unit. Otherwise, incorrect operation of the heater piping is guaranteed, or it may even refuse to work at all.

The heater piping can be built according to several schemes. In practice, a standard circuit is more often used, the design of which is simple and the reliability is quite high.

Advantages and disadvantages

The main advantage of supply air exchange with a water heater is significant savings in energy costs. After all, the main element - the heat exchanger - is, in fact, a heating radiator built into the ventilation duct. There is no need to additionally heat the coolant or expend electricity to heat the air flow.

The second important positive point is high efficiency. A water heater is capable of quickly heating large volumes of air to the required temperature.

Equipment safety is also an important point. The water device does not create a load on the electrical network, and its breakdown will not lead to a fire.

But, like any equipment, a water device for heating air during circulation also has disadvantages.

Firstly, these are the dimensions of the installation, which do not allow installation in small spaces of residential apartments.

Secondly, this is a more complex installation, since it requires a connection to the heating, which entails a whole operation to remove the pipes.

Thirdly, to control the heating temperature of the air, it is necessary to manipulate the supply of coolant, or lower the temperature of the water in the heating boiler.

Strict control of the water temperature in the system is also necessary. It is not advisable to connect water heaters to central heating, where it is not possible to set a limit for heating the coolant. For such a heater in the supply ventilation, the temperature range is from +2 to +150 degrees.

Of course, you don’t have to bother and install such complex equipment. However, when arranging circulation in large rooms, supplying fresh cold air will significantly increase heating costs. You can also replace the water appliance with an electric one, however, this solution will also increase energy costs, which is not always cost-effective. Air exchange with this type of heating today remains one of the most economical and profitable with higher performance indicators.

Rules for operating the heater

For the correct and uninterrupted operation of heaters for supply ventilation systems, it is important to follow the following operating rules:

- It is necessary to maintain a certain air composition in the building. Requirements for air masses in premises for various purposes are listed in GOST No. 2.1.005-88.

- When installing, you must follow the manufacturer's recommendations and adhere to installation technology.

- You cannot supply coolant with a temperature above 190 degrees to the device. For some models this threshold is lower, as stated in the technical documentation.

- The pressure of the liquid medium in the heat exchanger must be within 1.2 MPa.

- If you need to heat the air in a cold room, then it is heated smoothly. The temperature rise within an hour should be 30 degrees.

- To prevent the liquid from freezing in the heat exchanger and breaking the tubes, the surrounding air masses around the device must not be allowed to cool below zero degrees.

- In rooms with high humidity levels, units with a degree of protection of IP66 and higher are installed.

Manufacturers of water heaters do not recommend repairing them yourself. It is better to entrust this work to the service center employees

It is equally important before purchasing to correctly calculate the power of the device so that it provides proper performance and does not run idle

Controller

- temperature sensors: air temperature in the duct

- return water temperature at the outlet of the heater

- fault on the internal overheating sensor in the air heater

Typical scenarios:

- In the “electric heater” operating mode: smooth regulation using a PWM signal with a period of 4 seconds.

- smooth start with warm-up

- smooth shutdown with blowing of the electric heater at low fan speed

- the settings for the return water temperature are adjusted: “temp. working" (+30 °C), "temp. duty" (+20 °C), "temp. threat of freezing" (+10 °C), "temp. warming up" (+45 °C)

- at system startup, if the return water temperature does not reach “temp. warming up", then the electric heater is connected

Interesting features of the Controller that I planned to use:

- the ability to adjust the temperature using an external room temperature sensor with a cascade coefficient, which shows by how many degrees the air temperature in the duct should be changed when the room temperature changes by 1 °C

- for air heaters from several sections (I have three sections of 1 kW each) step switching is provided: one step smoothly plus three steps discretely

Types of thermal energy consumption systems

There may be several such systems compatible with the heater. Let's look briefly at each.

Ventilation system

It is characterized by the fact that the maximum temperature of the coolant is directly influenced by the technical parameters of the existing equipment. The problem with regards to how to choose the right piping unit is the need to protect the heater from possible freezing. In winter, when the air is supplied at sub-zero temperatures, the temperature of the coolant cannot be reduced or the energy consumption lower than what the system requires.

Radiator heating

In this case, the coolant temperature is strictly limited. For single-pipe structures it is 105 degrees, for two-pipe structures it is 95 degrees. But the temperature of the carrier can decrease indefinitely, until the operation stops altogether, which distinguishes heating from a ventilation system. Here, all elements are in direct contact with the air in the building, and due to the fact that it also has heat-storing characteristics, the building cools quite slowly. In this case, the time period during which a decrease in temperature is possible is established for each individual case.

Underfloor heating

The heat consumption here is the same as in the previous version. The only difference can be considered that the temperature of the coolant (maximum) is limited. In most cases this is no more than 50 degrees.

Thermal curtain

The heater piping for thermal curtains differs significantly from all previous options, so we will consider it in more detail. First of all, this relates to the peculiarities of the operation of the thermal curtain itself: almost all the time the curtain “rests”, waits, but its working time often does not exceed two to three minutes. Moreover, the installation site is always located far from the heating source. In most cases, this is a place under the ceiling, and there, accordingly, hypothermia often occurs, as well as drafts. Below is a diagram with adjustment elements that are suitable for this case.

The system is equipped with special ball joints necessary to disconnect it from the described curtain or from the thermal route. There is also a coarsely cleanable filter that protects the device; an adjustment valve that prevents the entry of solid particles, which, in turn, can extremely negatively affect the performance of the system in general. There are two more valves:

- Regulating-shut-off.

- Regulating, equipped with a special drive.

Each of them is designed to provide maximum fluid flow in operating mode, and minimum flow when “inactive”. In order for the valve drives of such a piping intended for thermal curtains to be provided with proper power, a single-phase voltage of 220 volts should be connected.

Finally, all the elements that make up the heater piping in this case are necessary not only to regulate the temperature in the building, but to protect the device itself from temperature changes and pressure “jumps” that often occur in the heating supply network. If you install mixer blocks, the heating circuit will reach the operating mode that is necessary for the controlled parameters.

Note! Ventilation works more efficiently in this regard, since less energy is consumed

Kinds

Heaters for supply ventilation are classified according to the type of heat source and can be water, steam and electric.

Water models

They are used in all types of ventilation systems and can be of two- or three-row design. The devices are installed in ventilation systems of rooms whose area exceeds 150 square meters. This type of heater is absolutely fireproof and least energy-consuming, due to the possibility of using water from the heating system as a coolant.

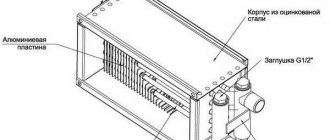

The principle of operation of water heaters is as follows: street air is taken in through air intake grilles and supplied through an air duct to coarse filters. There, the air masses are cleaned of dust, insects and small mechanical debris, and enter the heater. A copper heat exchanger is installed in the heater body, consisting of links arranged in a checkerboard pattern and equipped with aluminum plates. The plates significantly increase the heat transfer of the copper coil, which significantly increases the efficiency of the device. The coolant flowing through the coil can be water, antifreeze or a water-glycol solution.

Cold air flows passing through the heat exchanger take heat from metal surfaces and transfer it into the room. The use of water heaters makes it possible to heat air flows up to 100 degrees, which provides ample opportunities for their use in sports facilities, shopping centers, underground parking lots, warehouses and greenhouses.

Along with obvious advantages, water models have a number of disadvantages. The disadvantages of the devices include the risk of water freezing in pipes when temperatures drop sharply, and the inability to use heating in the summer when the heating system is not functioning.

Steam models

They are installed at industrial enterprises where it is possible to produce large amounts of steam for technical needs. Such air heaters are not used in domestic supply ventilation systems. Steam acts as a heat carrier for these installations, which explains the instant heating of passing flows and the high efficiency of steam heaters.

To prevent this from happening, all heat exchangers undergo a leak test during the production process. Tests are carried out using jets of cold air supplied under a pressure of 30 bar. The heat exchanger is placed in a tank with warm water.

Electric models

They are the simplest option for heaters and are installed in ventilation systems serving small spaces. Unlike water and steam heaters, an electric heater does not require the installation of additional communications. To connect them, it is enough to have a 220 V outlet nearby. The principle of operation of electric heaters is no different from the principle of operation of other heaters and consists in heating air masses passing through heating elements.

Even with a slight decrease in this indicator, the electric heating element overheats and breaks down. More expensive models are equipped with bimetallic thermal switches that turn off the element in case of obvious overheating.

The advantages of electric heaters are simple installation, no need for piping, and independence from the heating season. The disadvantages include high energy consumption and the inappropriateness of installation in powerful ventilation systems serving large spaces.

How is the heating of the heater regulated?

In order to control the heating procedure occurring in the device piping unit, you can use one of two possible methods:

- quantitative;

- quality.

If you choose quantitative control of the system’s operation, then you will face an inevitable and constantly “jumping” coolant consumption. Such a method can hardly be called rational, and this is one of the reasons that in recent years people have more often resorted to another principle of control - qualitative. Thanks to it, it became possible to regulate the operation of the heater, but the amount of coolant does not change at all.

In addition, if you regulate the system using the quality principle, then the control is guaranteed to remain linear, regardless of what position the control valve is in.

Important! Quality control has one more advantage - this way the heater will be maximally protected from possible freezing, since water will constantly flow into it. All this became possible only thanks to the fact that a water pump is installed in the heater circuit

There is a flow of water in the circuit, which will not depend on any external influences. In addition, quality control involves the use of a three-stroke rod valve and a specialized pump. All these parts built into the device’s piping have significant advantages that increase the efficiency of the heater and the entire system as a whole:

All this became possible only due to the fact that a water pump is installed in the heater circuit. There is a flow of water in the circuit, which will not depend on any external influences. In addition, quality control involves the use of a three-stroke rod valve and a specialized pump. All these parts built into the device’s piping have significant advantages that increase the efficiency of the heater and the entire system as a whole:

- The regulation valve is located in the place where the coolant enters the heater. If you compare this to a two-stroke device, it controls the entire mixing procedure. If the circuit is in a closed state, then internal circulation occurs; if it is open, then the coolant does not recirculate. If such a design is installed with a rod, this will not only increase the service life of the valve itself (which, as is known, very quickly becomes unusable in products that do not have rods), but will also increase heat transfer.

- The motor of a centrifugal circulation pump is “wet”; in other words, it operates while completely immersed in water. Consequently, the bearings of the device, as well as other elements, are constantly lubricated with water, so there is no need to use any kind of seals. If the heater piping is equipped with such a pump, then leakage is completely eliminated even in cases where the pump is broken or has completely exhausted its service life.

Basic diagrams of control units

Scheme No. 2

There are at least several basic heater piping schemes, which have fundamental differences in terms of the chosen control scheme and heat supply source. There is no clear answer as to which of the schemes described below is correct; it all depends on a large number of factors (heat supply source and its capabilities and coolant requirements, already installed network equipment, the value of the free pressure drop at the entrance to the building, etc.).

a two-way linear control valve is installed as a control element , which absorbs the excess difference at the connection point and performs the main function of limiting the flow of water through heater. But in order to ensure protection against freezing of the air heater, a circulation pump is installed on the internal circuit of the air heater, which ensures constant flow through the installation through an additional jumper. This is a classic method of quantitative zonal control at each air supply unit.

Scheme No. 3

No less common are heat supply schemes for heaters with installed three-way valves . These circuits can operate in different control modes depending on the position of the valve and the location of the jumper insertion.

Scheme No. 4

Three-way valves can operate in water flow separation mode or as a mixing element (diagram No. 4). If the valve is installed in such a way that, depending on the heating demand of the installation, port A (from the heating network side) opens or closes, and the coolant circulates through the clan bypass (ports B and AB), then the most common quantitative control scheme takes place. Its use, as a rule, is limited by the maximum pressure drop in the central heating system, therefore it is most often used in autonomous heating systems. But when designing such a scheme, it is necessary to take into account that the flow rate in the heat supply system or at the heat source is not constant, therefore the network pumping equipment must be equipped with frequency converters.

Scheme No. 5

If it is necessary to ensure a constant flow rate from the heat source, then a jumper with an installed check valve and balancing valve should be added to the previous diagram in front of the valve (diagram No. 5).

If the jumper and valve are swapped in the circuit, and water is circulated in the internal circuit through the jumper, then the pressure of the circulation pump in this case will be less by the amount of hydraulic resistance of the valve. The coolant flow from the heating network will remain constant, and the valve will operate on a free pressure drop (diagram No. 6).

Scheme No. 6

Coolant flow

To calculate the coolant flow rate, you first need to find the frontal cross-section of the device.

It is determined by the formula F = (L x P)/ V, in which:

- F – frontal section of the heat exchanger;

- L – air mass flow;

- P – table value of air density;

- V – air flow speed (3-5 kg/m²s).

After this, you can calculate the coolant flow using the formula G = (3.6 x Qt)/(Cin x (tin - tout)), in which:

- G – water requirement for the heater (kg/h);

- 3.6 – correction factor for converting the unit of measurement from Watt to kJ/h, so that the flow rate is in kg/h;

- Qt – heater power in W, which was found earlier;

- Cw – indicator of the specific thermal capacity of water;

- (tin - tout) is the difference in temperature of the coolant in the return and forward lines.

Power calculation

Obtaining air with the required temperature indicators requires making the correct calculations and choosing the right device for supply-type ventilation. Even though modern water appliances with a coolant in the form of hot water are especially popular, when choosing a device of any type, you initially need to determine its power based on the initial data presented:

- volume of heated supply air masses in m³/h or kg/h;

- temperature indicators of the initial air masses, equal to the calculated street air temperature in a particular region;

- preferred temperature conditions of air flows after heating;

- temperature graph of the thermal fluid used for heating.

A simplified determination of the power of a duct heater is carried out in accordance with a simple formula:

Q is the performance of the ventilation system in m 3 /hour;

T is the difference in temperature indicators at the inlet and outlet in the ventilation duct.

Table: power calculation for the main parameters of the ventilation system

| Capacity, m3 | Heating element power, kW |

| 80 | 1,2 |

| 160 | 2,4 |

| 240 | 3,6 |

| 330 | 4,8 |

| 510 | 7,5 |

| 730 | 10,8 |

| 1020 | 15,0 |

| 1520 | 22,5 |

| 2030 | 30,0 |

For example, the volume of air in a room with an area of 20 m2 with a ceiling height of 300 cm is 60 m3, so a single air exchange is 60 m2 / hour.

Table: power indicators of electric, steam and water duct heater

| Indicators | t air inlet oС | |||||||||

| -5 | -10 | -15 | -20 | -25 | -30 | -35 | -40 | -45 | ||

| Power, kWt | 0.06 | 0.08 | 0.09 | 0.11 | 0.13 | 0.14 | 0.16 | 0.18 | 0.19 | 0.21 |

The supply air supplied into the room from the street requires processing in order to obtain standard parameters. Air masses can be processed by filtration, heating, cooling and humidification. Heating of the supply air flows is carried out inside special heat exchange equipment, represented by heaters.

Liquid duct air heaters are the most popular today, widely used in most ventilation systems. The liquid coolant constantly moves in the direction opposite to the air flows, which provides efficient and inexpensive heating that significantly saves energy resources and maintains optimal microclimatic conditions in rooms of any type.

Brief overview of modern models

To get an impression of the brands and models of water heaters, let’s look at several devices from different manufacturers.

Heaters KSK-3, produced at the company T.S.T.

Specifications:

- coolant temperature at the inlet (outlet) - +150°C (+70°C);

- inlet air temperature – from -20°С;

- working pressure – 1.2 MPa;

- maximum temperature - +190°C;

- service life – 11 years;

- working resource – 13,200 hours.

External parts are made of carbon steel, heating elements are made of aluminum.

The Volcano mini water fan heater is a compact device from the Polish brand Volcano, characterized by practicality and ergonomic design. The air flow direction is adjusted using controlled blinds.

Specifications:

- power within 3-20 kW;

- maximum productivity 2000 m?/h;

- heat exchanger type – double row;

- protection class – IP 44;

- maximum coolant temperature 120°C;

- maximum working pressure 1.6 MPa;

- internal volume of the heat exchanger is 1.12 l;

- guide blinds.

Galletti AREO heater made in Italy. The models are equipped with a fan, a copper-aluminum heat exchanger and a drainage tray.

Specifications:

- power in heating mode – from 8 kW to 130 kW;

- power in cooling mode – from 3 kW to 40 kW;

- water temperature – + 7°C +95°C;

- air temperature – 10°C + 40°C;

- working pressure – 10 bar;

- number of fan speeds – 2/3;

- electrical safety class IP 55;

- motor protection.

In addition to the devices of the listed brands, on the market of heaters and water air heaters you can find models of the following brands: Teplomash, 2VV, Fraccaro, Yahtec, Tecnoclima, Kroll, Pakole, Innovent, Remko, Zilon.

Equipment selection

It is better to choose brass ball valves for piping the heater - they last longer

The elements that make up the system do not differ depending on the chosen scheme. To select the right components, you need to use the following recommendations:

- All fittings must comply with technical specifications. They are calculated based on the maximum temperature and pressure.

- The diameter of the elements must correspond to the size of the heating system pipelines.

Ball valves made of steel or brass should be selected as shut-off valves. For pipes with a diameter over 50 mm, flanged valves are required.

To simplify the work, buy taps with union nuts. To limit the flow, check valves are selected and placed on the return line or bypass of the units.

To control temperature and pressure, pressure gauges and thermometers are purchased. The temperature sensor is placed on the supply and return lines in front of the heater. The pressure gauge is installed in the pump group.

To create optimal coolant movement, install a circulation pump. It is mounted on an adjustable section, where it helps overcome hydraulic resistance. Additional parts include filters, valves, valves.

Methods for tying a heater

The connection of the supply air heater depends on the choice of installation location, technical characteristics of the unit and the air exchange scheme. Among the different installation options, the most often used is mixing recirculation air masses with supply flows. Less commonly used is a closed circuit with air recirculation within the room.

For proper installation of the device, it is important that the natural ventilation system is well established. Connecting the heater to the heating network is usually done at the intake point within the basement

If there is forced ventilation, the unit can be installed in any suitable location.

Also on sale are ready-made strapping units in several designs.

The kit includes the following items:

- ball valves with bypass;

- check valves;

- balancing valve;

- pump equipment;

- two or three way valves;

- filters;

- pressure gauges.

These parts within the assembly can be combined in different ways. Rigid connection of elements or installation using flexible metal hoses is used.

Areas of application

Piping units are necessary in engineering systems of air conditioning, ventilation and heat exchange:

- Supply unit piping unit - industrial and domestic supply and exhaust ventilation systems ensure air circulation between the interior of the building and the street. The external air temperature can fluctuate over a wide range, while the indoor temperature remains stable. Using the heater piping unit, stable heating of the gas working medium is ensured, its supply to the cooler, and maintenance of the set temperature values.

- Fan coil piping unit - creates a forced supply of refrigerant or coolant into the unit, regulates the flow rate for each individual fan coil of the system.

- The heat curtain piping unit differs from heater control structures. The thermal curtain is in standby mode most of the time. The purpose of the piping is to supply coolant constantly, but in minimal volumes. In this case, when the heat curtain enters operating mode, the control valve must open as quickly as possible.

The design solution of the piping unit for each engineering system can be individual or standard. The composition of structural elements is selected depending on the task and the specific design solution.

The basic package of control units includes:

- pipes - rolled metal or flexible hose are used;

- ball valve - needed to disconnect and connect the structure to the heating network;

- valves (two-way, three-way) - a direct valve ensures the movement of coolant along a small or large circuit, and a reverse valve prevents the flow of the working medium from the supply line to the return line;

- pumping unit - necessary for forced injection of coolant, stable circulation;

- filters – clean the coolant from debris and contaminants (it is necessary to periodically change the filters as the cleaning nozzles become clogged with debris);

- control and accounting devices - thermometer, pressure gauge, etc.

Non-standard tasks

To solve non-standard problems, when installing complex communications, it is necessary to provide in the project additional elements in case of emergency situations:

- backup pumping unit;

- bypass, bypass for pump and control valves;

- fittings, connecting and locking elements;

- instruments for monitoring and measuring system parameters - for example, pressure gauges for each section of the pipeline.

Installation diagrams for node blocks may differ depending on the type of equipment, the distance to the connection point to the heating system, and the configuration of the control structure.

For non-standard control structures, our company’s specialists will develop a project, calculate and select the necessary equipment, and draw up an installation diagram.

Adjusting the heating process

As for the regulation of the heating process, today two types are used: quantitative and qualitative. The first option is when the temperature of the heating elements is regulated by the amount of thermal energy supplied to them. That is, the more, for example, hot water passes through a water heater, the more it heats up. Accordingly, the temperature of the air passing through it becomes higher.

To do this, the heater piping unit of the air handling unit must include a pump, which creates pressure inside the hot water supply system. By increasing the supply, you can increase the temperature of the coolant inside the heating elements. Or, conversely, by reducing the supply, the temperature regime decreases. It should be noted that this method of heating the supply air is not the most rational. Therefore, today, ventilation systems increasingly use a high-quality heating method, that is, hot water is supplied with a constant volume.

A purely constructive distinctive feature of this piping scheme is the presence of a three-way valve, which is installed near the heater before supplying hot water to it. It is the valve that regulates the temperature, and the pump operates in constant mode. The valve got its name due to the fact that it can be placed in certain positions at which different processes occur. In the case of air heating, the valve performs three functional actions.

- It is completely open for the supply of hot water and closed for the coolant discharged from the heater.

- It is open so that part of the cooled coolant can mix with hot water, thereby reducing its temperature, and, accordingly, the heating elements.

- Completely closed, that is, no coolant enters the supply air heating system.

Basic rules and regulations

The design and installation of air heaters is regulated by regulatory documentation: SNiP 41-01-2003 “Heating, ventilation and air conditioning” and SP 41-101-95 “Design of heating points”.

Many customers require from designers a specific SNiP or GOST, describing the need to install a heater piping unit, as well as regulations for the circuits. Such information can be obtained from the accompanying documentation provided by the equipment manufacturer, or you can contact the network organization servicing this heating unit - they should have developed internal regulations.

The temperature of water, freon, external and internal surfaces of the heat exchanger pipes is determined based on standard values - these are the requirements of SNiP 41-01-2003. In any case, it should not be higher than +1500C.

When designing and installing air heaters and piping units, special attention is paid to the quality of the supply air. The efficiency and durability of the ventilation system depends on this parameter. The air is cleaned of large fraction pollutants: the calculated dust content is no more than 0.5 mg/m3, the outside air temperature is up to -200C.

Quality of work: air handling unit heater piping unit

There are 2 methods of installing the device, which are determined by the heat exchange diagram. If we talk about natural ventilation, the heater should be located in the basement near the water intake point. With a forced ventilation system, the device will begin to function correctly only with the correct installation of the heater module piping unit.

These devices allow you to regulate the temperature level of the heat exchanger:

- Bypass;

- Eyeliner;

- Cleaning filter;

- Pump;

- Ball Valves;

- Thermometers and pressure gauges;

- Electric valve.

If we are talking about installing a piping unit with a rigid liner, communications will be carried out using steel pipes. Sometimes flexible connections with corrugated hoses in the system are also used for installations. The location of the node is determined in advance. Tying a knot does not involve any serious expenses.

Operating principle of the mixing unit (thermal control unit) UTK

When fully open, the valve ensures circulation of the coolant along the “large” circuit (flow direction A-AB), thereby achieving the maximum thermal power of the unit.

In a completely closed state, the valve ensures circulation along a “small” circuit (flow direction B-AB), thereby achieving the minimum thermal power of the unit. In intermediate positions, the valve ensures circulation through a “small” circuit with a mixture of coolant from the network. The warranty period for thermal control units is 3 years.

For the manufacture of piping units, fittings from Genebre (Spain), pumps WILO, GRUNDFOS and UNIPAMP (Germany), and actuators with three-way valves from ESBE (Sweden) are used.

It is possible to manufacture any non-standard thermal control units according to customer designs.

The main function of the UTO water cooler piping units is, together with the control system, to monitor and regulate the temperature of the refrigerant in the water coolers of the air handling units. Thermal control units for water coolers are also called cooler piping units.

Supply ventilation with water-heated air

The air is heated to the required temperature by a water heater. It is presented in the form of a radiator with tubes containing coolant. The pipeline has fins that increase the area of contact with the circulated air.

The principle of operation of the system is as follows: the coolant heats the tubes to the desired temperature, they transfer heat to the fins, which in turn heats the air. Thus, heat exchange takes place.

Supply ventilation with water heated air is much more profitable than heating using electricity. On the other hand, there is water inside the water heater, so there is a risk of it freezing with minimal radiator operation.

The power of such a device is adjusted using electrical and plumbing components.

- Area with controller and temperature sensors. Servomotor that controls the valve.

- The mixer is responsible for heating the water in the heating equipment to the required temperature.

The electrical component will control the plumbing unit. It is enough to set the required air heating temperature, and the system will execute this program.

Elements

The main components of the harness:

- circulation pump;

- measuring equipment - sensors and pressure gauges;

- valves, two or three way;

- bypass;

- filter for cleaning.

This article answers the question “what is a bypass” and “what is it for” in detail: https://teplo.guru/elementy/truby/baipas.html

The circulation pump maintains a constant flow of coolant through the heat exchanger, ensures a constant temperature of the equipment, and prevents the device from freezing and failing.

The purpose of the valves is to mix water to maintain the desired temperature of the device. The control valve is complemented by an electric drive with an analogue or positional control signal. The valve's job is to supply enough coolant to heat the air in the heat exchanger.

What types of air heaters are there?

The device can be installed using one of two methods; in this case, it all depends on the characteristics of the air exchange of the system.

- Recirculated air can be mixed with supply air.

- The air in the system can be recirculated while being completely isolated.

If the ventilation in the room is natural, then the heater should be located in the basement, in the place where the air is taken in. And if the ventilation scheme is forced, then it does not matter where the device will be installed.

System installation

On the balcony side, the circuit changed, the input muffler was removed, and another G5 filter was installed in front of the fan instead. There is a valve on the main ventilation channel, bypassing the heaters; in winter mode it is closed - the air will flow through the heaters.

With the help of a janitor, a hole was made in the wall onto the balcony. It's good that walls are easy to break down. The inside is foam concrete, then 15 cm of polystyrene foam and facing the floor with bricks. The layout of the apartment made it possible to create a small storage room measuring 50x50 cm in the corner near the balcony.

The task was complicated by the fact that it was necessary to place the muffler (length 110 cm, diameter 30 cm) after the heater. Because of this, the installation turned out to be very tight.

Using a drill, some kind of thing and a round bend, I cut into the main ventilation duct, which runs under my ceiling. To the left of the new insert you can see the air conditioner's air intake for recirculation. Installed a silencer. It weighs about 5 kg, so it rests on supports.

I tried on the air heaters. Everything fits in smoothly, the margin is only a couple of centimeters. The distance between electric and water turned out to be too small - at least two diameters are needed. This was one of my serious mistakes.

Automated air heating in supply ventilation

Options for constructing round and rectangular ventilation shafts - the system is automated

- The operation of the equipment is controlled using a control panel (CP). The user presets the mode for regulating the supply air flow and temperature.

- Using a timer, the heated ventilation system automatically turns on and off.

- Equipment that provides heating can be connected to an exhaust fan.

- Heaters are equipped with a thermostat that prevents fire.

- A pressure gauge is installed in the ventilation system to monitor pressure differences.

- A shut-off valve is installed on the supply ventilation pipe; it is designed to block the entry of incoming wind masses.

(no votes yet)

Variants of typical solutions for piping steam equipment

Today, various equipment is used to install steam heaters. Depending on what it will be, completely different patterns and piping knots are used.

Special heater steam piping system for condensate removal:

Typical steam equipment piping.

- 3 shut-off valves, which are installed at the inlet, outlet and in the middle;

- thermodynamic diverter, which has a valve and a built-in filter to protect the system;

- sight glass for periodic inspection;

- check valve;

- special drain pipe for condensate;

- condensate drain;

- condensate line

The minimum length of the common condensate drainage unit for a steam heater is 1 m.

If it is necessary to connect several points, then the use of a steam manifold with drainage is required. The diagram includes the following nodes:

- 3 shut-off valves (at the beginning, end and middle for adjustment);

- pressure gauge for pressure control;

- viewing window for system monitoring;

- float drain for condensate, which has a built-in filter and valve to protect the system from contamination;

- check valve

Steam reduction unit with pilot control.

Such a unit is necessary for generating steam; it includes:

Steam reduction unit.

- shut-off valves;

- several pressure gauges to control pressure in different areas;

- filters that are designed to work for 3-9 hours;

- pressure reducing valves designed to control the system;

- check valve;

- viewing window for monitoring the system and its condition;

- blast safety valve;

- special drain pan for collecting condensate;

- conclusion;

- drain pipe.

The length for such a system unit cannot be less than 10 diameters of the steam line; in some cases, a built-in impulse tube is provided.

Types of air heaters used in supply-type ventilation systems

The choice of such devices for organizing supply ventilation is usually based on several main factors, which include productivity, total area of the room, equipment power, as well as the climatic features of a particular area. Taking into account all the listed characteristics, the following types are used:

- electric heaters for supply ventilation - the use of this type of heater is considered the most economically justified, based on the fact that the electric heater does not require complex communications (it is enough to connect the device to the power supply) and is equipped with special heating elements for the most efficient heat exchange, which convert electrical energy into heat.

- water heaters for supply ventilation - their main purpose is to heat air in ventilation systems with a round and rectangular cross-section, therefore they are successfully used for heating cottages, shops, large complexes, warehouses and premises, including livestock farms.

The use of electric heaters is effective when the area of the ventilated room is within 100-150 m2.

The main advantages of such heaters are the ease of installation and their general availability, but the disadvantage is the high level of energy consumption. Water heaters are quite practical, cost-effective and reliable devices for efficiently heating large volumes of air (more than 150 m2) and do not require constant or frequent maintenance. The quality of their work depends entirely on the presence of automatic control.

When installed at the top point with a downward direction, a water-type heater is able to quickly and easily equalize the temperature of the air mass of the room, thanks to the equipment of this type of heat exchanger with a special thermostat. For better heating, such devices can be combined into a single structure.

see also

- There is no ventilation system in the retail space, a requirement from firefighters

- Soundproofing of ventilation air ducts

- Automatic ventilation system

- Checking the ventilation in the apartment

- Built-in kitchen hoods with ventilation outlet

- Ventilation and air conditioning system cleaner

- Organized natural ventilation is carried out using

- Umbrellas for ventilation

- Kitchen hood without venting

- Ventilation requirements

- Rules for ventilation outlet device