To solve air exchange issues in private homes and industrial buildings, along with fans, devices are used that heat or cool the air that comes from the street. This helps improve the characteristics of the indoor microclimate and increase the level of comfort.

One of the economical and affordable devices is a water heater for fresh air ventilation, more familiar to residents of the northern regions. From our material you will learn about the operating principles and design features of equipment of this type. We will also talk in detail about several popular models of air heaters for ventilation.

What is it and what is it for?

A heater is a special device designed to provide heat exchange by heating the air flow by contacting it with a certain number of heating elements.

Such a unit is installed in ventilation systems both in combination with monoblock structures and in the form of separate modules.

How does the device work?

Depending on the heat source used, heaters are divided into water, electric and steam.

In the vast majority of cases, the heat transfer elements of air heaters are steel pipes with a finned surface. It is the fins that help increase the area and, accordingly, the efficiency of heat transfer. A heating or cooling coolant passes inside such pipes, and air flows pass outside, cooled or heated upon contact with the pipes.

The rib structure of the device consists of metal plates mounted on tubes, or a tape or thin wire wound on them.

The operating principle of air heaters is based on the fact that the coolant has a higher heat transfer coefficient in relation to air flows.

The energy efficiency of a heater depends on the heat transfer coefficient of the device at certain energy costs. In other words, the more heat the unit is capable of delivering at constant energy costs, the higher its efficiency.

The device is capable of significantly heating the air flows passing through it - raising their temperature by 70-110 degrees, so you can use the heater even at minimum temperatures (up to -25 degrees).

The heater can be installed according to two air exchange schemes - according to the principle of mixing recirculation and supply air, as well as in a closed air recirculation system. For forced or artificial ventilation systems, this condition is not relevant, since air is driven through the heater using duct fans.

Heater: this is a device for heating air in different systems

Before you start choosing a device, you need to understand the very concept of what a heater is, as well as what types there are and what are the typical and functional features of each of them.

Air heaters are capable of heating both small and fairly spacious rooms.

Air heaters are used to heat air in various systems:

- heating;

- air conditioning;

- ventilation.

Heating in thermal equipment is carried out due to the reaction between chemically aggressive substances in the middle. That is why the classification of air heaters is based on the type of heat exchanger. The device can be water, steam, freon and electric. A water heater for heating is used as a heat exchanger with an intermediate coolant. A steam heater is used to heat air in heating systems.

If we classify air heaters according to thermal and aerodynamic characteristics, then the types of air heaters are divided into three-row and four-row. Based on the number of connecting sizes, heaters of individual models are divided into 7 numbers.

Steel pipes, which have a ribbed surface on the outside, serve as a coolant transporter in the middle of the heater. Due to this design, the area increases and, as a result, such piping of the heater increases the efficiency of heat transfer. In the middle of the tubes with fins, a heating or cooling element in the form of water, steam or freon is transported. Air currents flow outside, which heat or cool during contact with the pipes.

Volcano air heater structure: 1 - movable adjustable blades, 2 - built-in diffuser with fan, 3 - heating elements, 4 - warm air supply.

The general scheme is based on the following operating principle: the coolant has a high heat transfer coefficient when interacting with air flows. The rib trim on the device is metal plates that are simply mounted on tubes or wound like ribbons or wire.

Kinds

Heaters for supply ventilation are classified according to the type of heat source and can be water, steam and electric.

Water models

They are used in all types of ventilation systems and can be of two- or three-row design. The devices are installed in ventilation systems of rooms whose area exceeds 150 square meters. This type of heater is absolutely fireproof and least energy-consuming, due to the possibility of using water from the heating system as a coolant.

The models are equipped with an automatic control and monitoring system. This allows you to set the desired temperature of the exhaust air and, thanks to the presence of a thermostat, adjust it as necessary.

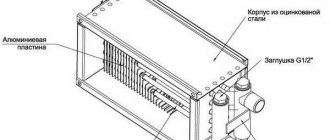

The principle of operation of water heaters is as follows: street air is taken in through air intake grilles and supplied through an air duct to coarse filters. There, the air masses are cleaned of dust, insects and small mechanical debris, and enter the heater. A copper heat exchanger is installed in the heater body, consisting of links arranged in a checkerboard pattern and equipped with aluminum plates. The plates significantly increase the heat transfer of the copper coil, which significantly increases the efficiency of the device. The coolant flowing through the coil can be water, antifreeze or a water-glycol solution.

Cold air flows passing through the heat exchanger take heat from metal surfaces and transfer it into the room. The use of water heaters makes it possible to heat air flows up to 100 degrees, which provides ample opportunities for their use in sports facilities, shopping centers, underground parking lots, warehouses and greenhouses.

Along with obvious advantages, water models have a number of disadvantages. The disadvantages of the devices include the risk of water freezing in pipes when temperatures drop sharply, and the inability to use heating in the summer when the heating system is not functioning.

Steam models

They are installed at industrial enterprises where it is possible to produce large amounts of steam for technical needs. Such air heaters are not used in domestic supply ventilation systems. Steam acts as a heat carrier for these installations, which explains the instant heating of passing flows and the high efficiency of steam heaters.

A prerequisite for the operation of such models is to guarantee complete tightness of the heat exchanger pipes. Otherwise, the steam will begin to escape, escape with the air into the room, and ultimately rupture the heat exchanger.

To prevent this from happening, all heat exchangers undergo a leak test during the production process. Tests are carried out using jets of cold air supplied under a pressure of 30 bar. The heat exchanger is placed in a tank with warm water.

Electric models

They are the simplest option for heaters and are installed in ventilation systems serving small spaces. Unlike water and steam heaters, an electric heater does not require the installation of additional communications. To connect them, it is enough to have a 220 V outlet nearby. The principle of operation of electric heaters is no different from the principle of operation of other heaters and consists in heating air masses passing through heating elements.

One of the mandatory operating conditions for electric heaters is compliance with the minimum air flow passing through the device.

Even with a slight decrease in this indicator, the electric heating element overheats and breaks down. More expensive models are equipped with bimetallic thermal switches that turn off the element in case of obvious overheating.

The advantages of electric heaters are simple installation, no need for piping, and independence from the heating season. The disadvantages include high energy consumption and the inappropriateness of installation in powerful ventilation systems serving large spaces.

Conclusion

Air heaters for fresh air ventilation are an effective, high-performance and fairly economical way to heat large industrial, production and commercial premises. The units significantly save heating costs and replace heating devices where their use is undesirable. The reliability and high fault tolerance of the equipment allows you to maintain optimal temperature parameters and a comfortable microclimate in the room. Now you know what a heater is, what types there are and how to install it.

Water heater: operating principle and purpose

Water heaters are used to heat air in various rooms where there is no central heating. They are also intended for ventilation or air conditioning systems. This type of air heaters is climate control equipment that serves as a heat exchanger filled with an intermediate coolant. The coolant in this equipment is heated or hot water.

Important! If the heater is used in a climate with an ambient air temperature below 0°C, the device must be equipped with special frost protection. Otherwise, frozen water in the pipes may simply rupture them.

A steam heater differs from a water heater in that dry saturated steam serves as the coolant in the device. These are more advanced models of heaters, so the price of a heater of this class is much higher.

Operating principle of a heating coil: blue arrows - cold air, red arrows - warm air

Water air heater: features of the design and operation of the device

The water heater has a very high level of performance. This is possible thanks to the wide temperature range, ranging from 70 to 110°C. The temperature difference is created by the heater itself. The design of the device is a tubular metal body covered with rib plates.

The most common type of air heater is a water heater with perpendicular flow. It is used in various ventilation devices. In this case, the water moves opposite to the air flow, in a rectangular direction. As a result, water rises through the channels from bottom to top, air bubbles enter the top of the device, and are removed from there through special air vents.

In any water heater, a piping unit must be installed, which is a special component of the device responsible for supplying hot water to the heat exchanger.

The design of a water heater includes the following required parts:

- coolant circulation pump;

- three-way valve;

- structural reinforcement;

- Control block;

- a piping unit that controls the performance of the heater and prevents it from freezing.

Diagram of the structure of an electric heater

Water heater for supply ventilation: operating principle and scope of use

An electric heater for fresh air ventilation is used to heat or, conversely, to cool air that comes from the street. Such devices are installed in the middle of the ventilation duct. The unit creates a beneficial microclimate, regardless of the time of year. Duct heaters are used in rooms of different sizes. The operation of a heater for supply ventilation will be especially effective in spacious workshops, greenhouses, and warehouses that are equipped with an appropriate ventilation system.

An air supply unit with a water heater is considered the most effective way of heating or cooling in large areas. Their operation is most relevant in winter, when the air that enters through the ventilation supply system requires heating.

Helpful advice! Duct-type water air heaters should be selected depending on the type of ventilation system. It is determined based on the supply ventilation scheme, which has a square, round or rectangular cross-section.

The units are installed in the middle of the ventilation duct, which has a round or rectangular cross-section. Air coming from the street is passed through the filtration system and enters the air heater for supply ventilation, where it is heated due to the heat given off by the water heating system supplied to the heat exchanger through the air heater duct.

Installation diagram of air heaters in supply ventilation

Air supply units with an electric heater also ensure that fresh, clean, cool air enters the room. At the same time, waste materials exit through the ventilation system. Both in industry and in everyday life, air supply units with an electric heater operating from the network are more in demand.

Installation Tips

Heaters with sensors in the greenhouse maintain the desired temperature.

The water heater is installed in rooms connected to the central heating main. When installing yourself, you should follow the recommendations of specialists:

- The diagonal of the heater depends on the bending characteristics of the channels, the type of damper and structural elements.

- To protect the heater from freezing, installation is carried out in rooms with a temperature not lower than 0 degrees.

- Before installation, it is necessary to inspect the plates and tubes for integrity.

- Weld-on flanges are easiest to connect end-to-end.

- Direct-flow air vent valves are located at the top of the outlet and supply manifolds.

- The joints between the device and the ventilation system are sealed.

- Wall-mounted models are installed by fastening the console with two self-tapping screws.

If you have no experience connecting and tying the system, it is better to entrust the work to specialists.

Water heaters with a fan: characteristics and manufacturers

A water heater with a fan is one of the most economical and efficient devices used for heating air in hangars, warehouses, gyms, shopping, exhibition and concert halls, car service centers, and workshops. It is also used to heat greenhouses, farms and other spacious objects with a large area.

Such units also come in different designs depending on the intended placement. That is, there can be wall or ceiling heaters that can be easily installed in any room.

The main advantages of water heating coils are their energy efficiency and performance, which is manifested in the ability to both increase and cool the temperature in the room. At the same time, fan heaters are generally low-cost, since they consume little electricity and allow you to save on heating.

Electric fan heater with Flowair control panel

Both foreign and domestic brands specialize in the production of such air heaters, including Teplomash, Greers, Flowair and Volcano. A water heating coil with a fan is an excellent solution in most cases for heating large objects.

KSK air heaters are considered popular in the domestic market. Devices of this brand are compact and economical. The units are widely used in industry, as they do an excellent job of quickly heating air in large areas, while using a minimum of electricity. The devices are also used as a heat exchanger. They are a component in various units, heating, air conditioning and ventilation systems. The coolant in the KSK heater is hot water with a temperature of over 190°C.

Heating coils with fans: design and operation features

Heating coils with fans are available in six standard sizes. These are very popular heating products, therefore they have a wide range of models from many manufacturers. There are two-row and three-row models. Heater power from 10 to 60 kW allows you to select equipment for rooms of different sizes.

Interesting to know! Modern fan heaters are characterized by a low noise level, which at a five-meter distance from the unit when operating at full power does not exceed 55 dB. When the fan speed is reduced, the noise level is reduced to 30 dB.

The power of heaters varies between 10-60 kW

Such heaters are also called fan heaters or duct heaters; they are compact and lightweight. They are mounted on the ceiling or wall using special brackets.

For wear resistance, the unit body is made of polypropylene or galvanized steel, and the top is coated with enamel. Polypropylene is characterized by a high degree of resistance to mechanical damage and resistance to various gases and vapors. Therefore, the housing can withstand high temperatures and is resistant to corrosion and damage of various types.

Copper tubes are used to produce the heat exchanger, and aluminum plates are used for fins. They are mounted on the rear panel of the device, which greatly simplifies the installation of the device and improves its design.

The device is equipped with a silent axial fan with blades made of a special profile and bearings of the highest class that do not require lubrication. This device provides high performance with low power consumption. In addition, the air flow is adjustable within the operating range. Water from the central heating system serves as the coolant.

The units are produced in ceiling and wall versions. Due to the lightness of the mounting console, the unit can be rotated 180 degrees during operation.

Ceiling heating fan heater

Efficiency of using air heaters instead of heating radiators

The coolant circulating through water heating radiators transfers thermal energy to the surrounding air through thermal radiation, as well as through the upward movement of convection flows of heated air and the entry of cooled air from below.

The heater, in addition to these two passive methods of transferring thermal energy, drives air through a system of heated elements with a much larger area and intensively transfers heat to them. Assessing the efficiency of heaters and fans allows for a simple calculation of the cost of installed equipment for the same tasks.

An example of heating a vehicle maintenance service room with air heaters.

For example, it is necessary to compare the cost of radiators and heaters for heating the showroom of a car dealership, taking into account compliance with SNIP standards.

The heating main is the same, the coolant is the same temperature, piping and installation can be ignored in a simplified calculation of the costs of the main equipment. For a simple calculation, we take the known norm of 1 kW per 10 m2 of heated area. A hall with an area of 50x20 = 1000 m2 requires a minimum of 1000/10 = 100 kW. Taking into account a margin of 15%, the calculated minimum required heating capacity of heating equipment is 115 kW.

When using radiators . We take one of the most common bimetallic radiators Rifar Base 500 x10 (10 sections), one such panel produces 2.04 kW. The minimum required number of radiators will be 115/2.04 = 57 pcs. It’s immediately worth considering that placing 57 radiators in such a room is unreasonable and practically impossible. If the price of a device for 10 sections is 7,000 rubles, the cost of purchasing radiators will be 57 * 7000 = 399,000 rubles .

When heating with air heaters . To heat a rectangular area in order to distribute heat evenly, we select from 5 Ballu BHP-W3-20-S water heaters with a capacity of 3200 m3/hour each with a similar total power: 25 * 5 = 125 kW. Equipment costs will be 22900*5 = 114,500 rubles .

The initial cost of heaters is almost 4 times less than the purchase of efficient bimetallic radiators.

When comparing the installed capacities of radiators and heaters by price, it is necessary to take into account in the calculation that one of the main indicators of standard heaters is the productivity of warm air. With a ceiling height of 6 meters in our example, the volume of the exhibition hall will be 1000 * 6 = 6,000 m3. Five air heaters with a capacity of 3200 m3/hour will refresh the air in the hall almost three times per hour, which will ensure its normal quality for workers and visitors not only in temperature, but also in composition.

The main area of application of air heaters is the organization of heating of rooms with large spaces for air movement:

- production workshops, hangars, warehouses;

- gyms, exhibition pavilions, shopping centers;

- agricultural farms, greenhouses.

Compact devices that allow you to quickly heat air from 70°C to 100°C, easily integrated into the overall automatic heating control system, are advisable to use in buildings with reliable access to coolant (water, steam, electricity).

The advantages of water heaters are:

- High profitability of use (low cost of equipment, high heat transfer, ease and low cost of installation, minimal operating costs).

- Fast air heating, ease of change and localization of heat flow (thermal curtains and oases).

- Reliable design, ease of automation and modern design.

- Safe to use even in high-risk buildings.

- Extremely compact dimensions with high heating output.

The disadvantages of these devices are related to the properties of the coolant:

- At temperatures below zero, the heater is easy to freeze. If water is not drained from the pipes in time, they can break if disconnected from the main line.

- When using water with a large amount of impurities, the device can also be damaged, so using it at home without filters and connecting it to a central system is impractical.

- It is worth noting that air heaters dry out the air greatly. When used, for example, in a showroom, humidifying climate control technology is required.

Electric heater: operating features

Electric heaters are now successfully used to heat various premises, both residential and commercial and industrial. Considering that the source of energy is electricity, there are certain safety measures when using them. First of all, the presence of vapors from explosive objects, as well as conductive dust, should be excluded.

Electric heaters are mainly installed in spacious warehouses, workshops, halls, garages and drying chambers. They are available for vertical and horizontal installation. An important condition for safe operation is access to the system reboot panel in manual mode. Air heaters are especially popular and are successfully used on construction sites.

Electric heaters significantly speed up the drying process of various building materials, in particular plaster and paint. They are often used to form a thermal curtain at gates or door structures.

The wide temperature operating range allows its use in the temperature range from -30 to 50°C. To avoid overheating of the unit, care should be taken to ensure sufficient air flow, so it is necessary to first carry out the appropriate calculation. If used correctly and carefully, the heater can last quite a long time.

The heater can be used in the temperature range from -30 to 50°C

Helpful advice! When choosing an electric industrial heater, you must be extremely careful and take into account the size of the serviced area. It is also necessary to take into account that wall-mounted units are most often used, therefore, for safety reasons, care must be taken to securely fix them using special brackets.

Which heater to choose?

To choose the best option, you need to calculate the power of heaters taking into account the following parameters:

- System performance is the amount of air distilled per hour.

- Initial or outside temperature.

- Final air temperature.

- Density and heat capacity of air at a certain temperature.

It is often difficult to make such calculations on your own. In this case, you can resort to the help of a contractor. When choosing a particular heat exchanger, you should proceed from considerations of feasibility and operational characteristics of the house. An electric heater is ideal for small areas, and a water or steam heater for large industrial and commercial facilities.

Selection of industrial air heaters

Having decided on the primary heating source, we select the type of air heater. The first question is under what conditions and within what temperature conditions it will work. The second is the degree of contamination of the coolant and air. If the operation of heat exchangers occurs under poor conditions with air temperatures from -20°C and below, it makes sense to opt for TVV, KP and KFB air heaters. These are bimetallic heaters, in which a metal pipe with aluminum fins is used as a heat exchange element (similar to KSk and KPSk). Their fundamental difference is as follows:

1. Increased area for coolant passage. A particularly important factor for operation in conditions of low outdoor temperatures. The possibility of contamination with dirt, and in the case of steam air heaters, with scale, is reduced. Which, firstly, extends their overall service life; secondly, when the coolant is contaminated, it prevents complete blocking of the internal section and, accordingly, freezing of the heat exchanger; thirdly, the thermal characteristics are stable over a longer period of time. 2. The thickness of the aluminum fin of these air heaters is greater than that of KSk and KPSk, which contributes to less mechanical deformation of the heating element during transportation and operation. And the increased pitch of the aluminum fins contributes to less clogging of the interfin space with dirt and dust, and, accordingly, a decrease in aerodynamic drag. This has a positive effect when operating heaters in buildings with increased dust and air pollution, and, which is again important, when operating in conditions of low temperatures, where the recommended mass velocity in the frontal section when selecting heaters is up to 3.5 kg/m2*s. 3. Less hydraulic resistance.

All of the above factors contribute to the fact that for many years, mining enterprises have chosen to create process heat - water heaters TVV and steam KP, and for the layout of air heating installations heaters KFB 10 A4, which have significant advantages under poor operating conditions in regions with low temperatures modes.

Delivery of purchased industrial air heaters to customers is carried out both on a self-pickup basis and by our company’s vehicles. It is widely practiced to send equipment by freight forwarding companies, and air heaters are delivered to local terminals of transport companies free of charge.

Mass air speed

3. Find the actual mass velocity for the selected one or more heaters. v (kg/m²•s) = G / f G - mass air flow, kg/hour; f is the area of the actual frontal section taken into account, m².

An example of selection and calculation of a KSk air heater. Step-3

Select a suitable KSk heater for heating 16,000 m³/hour from a temperature of -25°C to +23°C. The coolant is hot water with a schedule of 95°C at the inlet to the air heater, 60°C at the outlet. 3. The task is to find the actual mass velocity of the heat exchangers that we have selected. We accept KSk air heaters number 11 as the most suitable frontal cross-section for air passage (1,660 m²). Let's calculate all three models: two-row heater KSk 2-11, three-row KSk 3-11 and four-row KSk 4-11. v (kg/m²•s) = (20800/3600) / 1.660 = 3.48 kg/m²•s 20800 - mass air flow, kg/hour; 1.660 is the frontal cross-sectional area of KSk heaters taken into account, m². Since all three models have the same overall dimensions, the mass velocity in the frontal section of each air heater, regardless of the row, will have the same value.

Models and principles of operation of industrial air heaters

LLC T.S.T. produces six models of industrial heaters: water KSk and TVV (hot water coolant); steam KPSk and KP (coolant dry saturated steam); electrical SFO; The production of KFB industrial air heaters is carried out in two versions (with water and steam coolant). Below is brief information about all types of bimetallic spiral air heaters. More detailed information (technical characteristics, overall dimensions, operating parameters, drawings, photographs and tables) for each type of heat exchanger can be viewed by clicking on the link.

- Water heaters KSk

- Steam heaters KPSk

- TVV water heaters

- Steam heaters KP

Industrial heaters KSk (KPSk) manufactured by T.S.T. LLC designed for heating air in ventilation, air heating and air conditioning systems. The heat-dissipating elements are made of electric-welded steel or seamlessly drawn pipe 16×1.5 mm and aluminum rolled fins with a diameter of 39 mm. Finned heat exchangers KSk and KPSk are divided into twelve standard sizes and can have two, three or four rows of heating tubes along the direction of coolant movement.

Finned water heat exchanger KSk is a heating device in which the heating source is hot or superheated water. It is manufactured in a multi-pass design, which is achieved through partitions in the manifold covers. At the same time, the speed of water in the air heater increases, which leads to an increase in the intensity of heat transfer. The operating principle of the KSk industrial heater is that hot water coming from the central heating or hot water boiler circulates inside the heat exchanger tubes. The cold air flow, forced by the fan, passes through the interfin space of the heat-transfer elements, is heated and supplied to the room being served.

KPSK finned steam heat exchanger is a heating device in which the coolant is dry saturated or superheated steam. The air heater is made in a single-pass design. The coolant passes through all the tubes simultaneously, which implies very fast and uniform heating of the air flow throughout the entire cross-section of the heater. It is advisable to use heat exchangers of the KPSK series for industries that are connected to process steam pipelines. A steam boiler can also serve as a source of primary coolant.

Industrial heaters TVV (KP) manufactured by T.S.T. LLC designed for heating air in air conditioning and ventilation systems, air heating, and technological drying units. The heat-dissipating elements are made of straight-seam or seamless steel pipe 22×1.5 mm and aluminum rolled fins with a nominal diameter of 41 mm. TVV and KP finned heat exchangers are divided into seven standard sizes and are manufactured with three and four rows of heating tubes in the direction of coolant movement.

Increased cross-sectional area for coolant passage, expressed in the use of support tubes with a diameter of 22 mm, in contrast to other air heaters of the KSk (KPSk), KVS (KPS), KVB (KPB), VNV (VNP) types, which use heating elements with a diameter of 12 and 16 mm, provides a number of advantages. These include: lower hydraulic resistance of the heater, longer service life, preservation of stable thermal characteristics, the ability to operate at low temperatures of external supply air.

TVV air heater - the source of heat exchange is hot water flowing in the tubes. From the outside, these finned tubes are washed with air less heated than water. Air movement is created by a fan. As a result of heat exchange, the water in the heat exchanger tubes is gradually cooled, and the air is sequentially heated as it passes through the rows of finned tubes.

The gearbox air heater is a source of heat exchange - water vapor. Due to the existing temperature difference between the steam-condensate mixture and the air, heat transfer occurs, as a result of which the air heats up and the steam condenses.

Industrial heaters TVV (KP) are indispensable in poor operating conditions. This is the best choice for creating process heat in workplaces of industrial workshops, ventilating mine workings at mining and metallurgical enterprises in Siberia and the northern regions of the country.

Industrial heaters KFB-A manufactured by T.S.T. LLC - medium-sized air heaters that use steam and hot water to produce heat. KFB steam heaters differ from water heaters in that they are made in a single-pass design, installed with a vertical arrangement of heat exchange elements, steam passes through the tubes in parallel once. The coolant is supplied to the heating unit from above, and the water condensed from the exhaust steam is removed from below. The operating principle of multi-pass air heater models involves multiple sequential movements of water flow. KFB water heaters are installed with a horizontal arrangement of heat exchange elements; the coolant is supplied and removed from the side.

The technical qualities of this heat exchanger model with an increased cross-section for the passage of coolant are developed at a high level. In terms of overall dimensions and built-in design, the assembly and installation of several KFB thermal modules is the best option for assembling air heating units in areas with an estimated outside temperature for the cold period of the year below minus 30 degrees. Heat exchangers are divided into thirteen standard sizes. Air flow design of three A3 and four in-line A4. Air productivity range from 2000 to 18000 m3/hour, thermal power from 40 to 500 kW. KFB air heaters are widely used at various mining enterprises.

Brief overview of modern models

To get an impression of the brands and models of water heaters, let’s look at several devices from different manufacturers.

No. 1 - KSK air heaters

Heaters KSK-3, produced at the company T.S.T.

The model range of domestically produced KSK water heaters includes 2/3/4-row devices that differ in performance and size

Specifications:

- coolant temperature at the inlet (outlet) - +150 °C (+70 °C);

- inlet air temperature - from -20 °C;

- working pressure - 1.2 MPa;

- maximum temperature - +190 °C;

- service life - 11 years;

- working resource - 13,200 hours.

External parts are made of carbon steel, heating elements are made of aluminum.

No. 2 - Volcano fan heaters

The Volcano mini water fan heater is a compact device from the Polish brand Volcano, characterized by practicality and ergonomic design. The air flow direction is adjusted using controlled blinds.

One Volcano mini fan heater is capable of generating as much heat as a dozen conventional bimetallic radiators made up of ten sections

Specifications:

- power within the limits - 3-20 kW;

- maximum productivity - 2000 m³/h;

- heat exchanger type - double row;

- protection class - IP 44;

- maximum coolant temperature - 120 °C;

- maximum working pressure - 1.6 MPa;

- internal volume of the heat exchanger - 1.12 l;

- guide blinds.

Volcano water fan heaters are designed to heat the air in domestic and industrial premises using water coolant.

No. 3 - Galletti AREO air heaters

Galletti AREO heater made in Italy.

Galletti AREO water heaters are capable of both heating the premises being treated and cooling the space in hot weather

The models are equipped with a fan, a copper-aluminum heat exchanger and a drainage tray.

Specifications:

- power in heating mode - from 8 kW to 130 kW;

- power in cooling mode - from 3 kW to 40 kW;

- water temperature - + 7°C +95 °C;

- air temperature - from 10°C to + 40°C;

- working pressure - 10 bar;

- number of fan speeds - 2/3;

- electrical safety class - IP 55;

- motor protection.

In addition to the devices of the listed brands, on the market of heaters and water air heaters you can find models of the following brands: Teplomash, 2VV, Fraccaro, Yahtec, Tecnoclima, Kroll, Pakole, Innovent, Remko, Zilon.

Differences in air heaters by tube type

Heating heaters may differ in the type of tubes used to transfer heat. The following models of such devices are distinguished:

- Smooth tube - products consist of a large number of thin hollow pipes.

- Plate devices have fins, which significantly increases their heat transfer.

- Bimetallic - such products use tubes made of copper and aluminum. Copper ones transfer heat, and collectors are made of aluminum.

Attention ! Caloriferous smooth-tube heating is the least efficient, but the cost of such products is noticeably lower.

Cost of air heaters for supply ventilation

The price of the equipment will depend on a number of factors: the type of unit, its power. The higher the device's performance, the higher its market value. The price will be affected by the heat source in the device and the manufacturer's brand. As a rule, imported heater models are an order of magnitude more expensive than air heaters from a domestic manufacturer. Naturally, the price will depend on what kind of device is purchased - for use in domestic conditions or for use in an industrial ventilation network.

You can find out the exact price of the unit at a ventilation equipment store, but first you need to choose a model that will be optimal for use in specific conditions.

Connecting an electric heater

In electrical types, the main parameter is the power in kW; accordingly, it requires caution and compliance with safety precautions when connecting it. This option uses a control unit that is capable of controlling the temperature in the room. When the indoor temperature is below the set temperature, the heater automatically turns on. Using a thermostat, you can maintain the set temperature and be protected from heating the device over 140 degrees.

The way it works is that when the “Start” button is pressed, the engine and heater ventilation start. A thermal relay at a certain current is connected to the motor. In case of problems with ventilation, the thermal relay is triggered, after which the power circuit is opened.

When the heater fan is on, you can turn on the heating elements by closing the blocking contacts. The heating elements are turned on using the “Start” button. At this time, the intermediate starter is turned on, which activates a powerful starter, which turns on the heating elements through its contacts. For the fastest possible heating, all heaters turn on immediately.

- For fire protection, the circuit includes the following elements:

- Thermal relay that protects the engine when stopped;

- Protection against switching on without a fan;

- Thermal relay, which protects the heater housing from overheating. While the thermostat is activated, the fan will continue to operate and cool it down.

The circuit can be supplemented with a starter power-on indicator and an emergency indicator. In addition, it is advisable to install an automatic switch on the circuit that powers the heating elements, as well as a more powerful circuit breaker at the input of the device. Circuit breakers should not be installed on fans.

To control the heater, a control cabinet is installed, which should be located near the heater. The shorter the distance, the smaller the wire cross-section can be used.

Connection diagram and control

Electric heaters must be connected in compliance with all safety requirements. The connection diagram for the electric heater is as follows: when you press the “Start” button, the engine starts and the heater ventilation is turned on. At the same time, the engine is equipped with a thermal relay, which, if there is a problem with the fan, instantly opens the circuit and turns off the electric heater. It is possible to turn on the heating elements separately from the fan by closing the blocking contacts. To ensure rapid heating, all heating elements are turned on simultaneously.

To increase the safety of the electric heater, the connection diagram includes an emergency indicator and a device that prevents the heating elements from turning on when the fan is turned off. In addition, experts recommend including automatic fuses in the circuit, which should be placed in the circuit together with the heating elements. But installing automatic machines on fans, on the contrary, is not recommended. The heater is controlled from a special cabinet located near the device. Moreover, the closer it is located, the smaller the cross-section of the wire connecting them can be.

When choosing a water heater connection diagram, you need to focus on the placement of mixing units and units with automation. So, if these units are located to the left of the air valve, then a left-hand design is implied, and vice versa. For each version, the location of the connecting pipes corresponds to the air intake side with the installed valve.

There are a number of differences between left and right placement. So, with the right-hand version, the water supply tube is located at the bottom, and the “return” tube is located at the top. In left-sided circuits, the supply pipe enters from the top, and the outflow pipe is located at the bottom.

When installing a heater, it is necessary to install a piping unit necessary to monitor the performance of the device and protect it from freezing. Piping nodes are the reinforcement frames that regulate the flow of hot water into the heat exchanger. Piping of water heaters is done using two- or three-way valves, the choice of which depends on the type of heating system. Thus, in circuits heated by a gas boiler, it is recommended to install a three-pass model, while for systems with central heating, a two-pass model is sufficient.

Controlling a water heater involves regulating the thermal power of heating devices. This is made possible by the process of mixing hot and cold water, which is carried out using a three-way valve. When the temperature rises above a set value, the valve releases a small portion of cooled liquid into the heat exchanger, which is taken at the outlet.

To increase the efficiency of the system, it is recommended to include a circulation pump in the connection diagram. The device is installed at the outlet of the heat exchanger, which allows it to work with already cooled glycol solution or water.

In addition, the installation diagram of water heaters does not provide for the vertical arrangement of inlet and outlet pipes, as well as the location of the air intake at the top. Such requirements are due to the risk of snow getting into the air duct and melt water flowing into the automation. An important element of the connection diagram is the temperature sensor. To obtain correct readings, the sensor must be placed inside the air duct in the blowing section, and the length of the flat section must be at least 50 cm.

Benefits of professional installation

According to the rules, the installation and maintenance of ventilation systems, as well as control units, must be carried out by specialists with an engineering education. They bear full responsibility for incorrect selection, installation, connection of devices, as well as for maintaining technical devices in improper or unsafe condition.

To correctly determine the contents of a panel or cabinet, installers do a full monitoring of the ventilation network.

Then you need to do the following:

- analyze the load;

- choose the optimal scheme;

- determine the operating modes of devices in order to increase efficiency;

- select equipment.

The assembly itself takes a little time: all the devices are mounted one by one in several rows, the wires are carefully connected to the terminal blocks and laid along the lines in organized bundles, then taken out.

One of the connection options, where NK1 and NK2 are duct-type heating devices; M1 – 3-phase fan; A, B, C – network connection, N – neutral, PE – ground; Q – protective thermostat against overheating; Y – ignition protection thermostat

Professional installers have experience installing and operating control panels, so they are unlikely to make a mistake with the choice of model and the nuances of connecting devices. In addition, they are well versed in the diagrams of ventilation systems for apartments and country houses and can quickly determine if there is an error in the drawing.

If you don’t figure it out in time and connect the devices according to an illiterate diagram - and this also happens - you can create an emergency situation.

The sale and distribution of panels and cabinets is carried out by many companies that produce or sell ventilation, refrigeration and heating equipment. For example, in Moscow this can be done in, “Roven”, “AV-automatics”, “Galvent”, etc.

Control of water duct heater

To monitor and control the temperature in the duct and room when using water heaters, a mixing unit is used. It is selected for each system individually.

Necessary automation for frost protection:

- Capillary sensor (factory setting +5 °C);

- Temperature sensor (return water temperature);

- Duct temperature sensor;

- Controller.

A water heater, as a rule, is more complex than an electric one, however, in economic terms it is preferable because electricity is more expensive.