The most optimal and economical source of heating for a country house is still a gas boiler.

There are a huge number of manufacturers of these products on our market - Bosch, Buderus, Viessmann, Vaillant, Baxi, Navien, etc.

In addition, there are single-circuit and double-circuit models, traditional and condensation, wall-mounted and floor-mounted, with an open and closed chamber. Which one should you choose and what technical issues should you pay attention to in addition to the brand?

Let us help you understand this matter in order to avoid irreparable mistakes when purchasing.

Power calculation

At present, no one questions the project for power supply to the building. This is taken for granted.

Mistake #1

At the same time, not everyone orders the same heating project.

This leads to problems, first with the correct selection of the power of a gas boiler, and then with its operation.

Mistake #2

You cannot select power based on some average parameters.

The most popular way of them is to divide the total area of the house into 10 m2. As a result, the calculated value is supposedly obtained.

In this case, the thickness and material of the walls, dimensions, number and type of windows, doors, the presence of an attic, etc. are not taken into account.

If you want to find out the average power without a project, at least use online calculators. You should choose those that require you to enter the maximum number of parameters.

For example, this one is TYTS.

But still, for a comfortable and quiet life, initially include in your expenses a separate amount for the heating supply project. It should also include a diagram of the entire heating system and calculate the heat loss of the house.

CONTENT

Introduction 1. Why a solid fuel boiler 2. How to choose the power of the boiler 3. Is the boiler only for heating or for heating and hot water (DHW)? 4. Dependence of power on the type of fuel 5. Steel or cast iron 6. Hot water or hot air

7. Features of choosing a boiler for industrial and non-residential premises

8. Features of choosing a boiler for greenhouses 9. Selection of boiler power for drying chambers 10. What parameters to pay attention to: 10.1. Power 10.2. Efficiency 10.3. In EU, dimensions 10.4. Fuel (including size of firewood) 10.5. Warranty period and service life 10.6. Price 10.7. Equipment

Electrical and thermal power

When people first see a boiler plate with a power of 24 kW or more, it makes them dumbfounded.

Mistake #3

Wow, how much electricity will such a boiler “reel” in?

Do not confuse the electrical and thermal power of heating devices. In the worst case, a gas boiler consumes no more than 150-200 W per hour from the outlet.

Therefore, to power it during a blackout, conventional batteries with an inverter or so-called UPS are sufficient.

We are not talking about any kilowatts here.

SELECTION OF BOILER POWER FOR DRYING CHAMBERS

When selecting boiler power for drying chambers, they are based either on the volume of the drying chamber, or on the volume of raw materials that are to be dried. To select power, you can focus on the following ratios: 1) “Raw materials usually occupy about 20% of the total volume of the drying chamber” 2) “For drying 1 cubic meter. raw materials, about 5 kW of thermal energy is required.” Thus, for a drying chamber, for example, with a volume of 50 cubic meters. meters we need a boiler with a capacity of W=50 cubic meters*20%*5 kW/cub.m = 50 kW. This formula is simplified, although it allows you to quite accurately select the required boiler power. At the same time, if there are strict requirements for the production process, it is necessary to confirm the calculations with the help of a specialized organization.

Boiler with power reserve

Mistake #4

The greater the power reserve of the boiler, the greater the gas consumption will be.

Therefore, it is not economically profitable to take a gas boiler with a reserve. This is not always true.

First of all, this problem concerns “dumb” floor-standing and obsolete wall-mounted boilers.

This is what the operating schedule for a 20 kW and 30 kW device looks like.

Vertically we have gas consumption, horizontally we have operating time. Two modes, the so-called clocking, are drawn at the top. Bottom – comfortable operation mode with constant power in cold weather.

Types of heating boilers for a private home

The operating principle of all boilers is similar: fuel is burned in the combustion chamber, this heats the heat exchanger, which contains the coolant (usually water), then the water circulates through the system and releases heat through heating radiators. First of all, the classification of hot water heating boilers is made according to the type of fuel used.

Gas

In the photo - wall-mounted dual-circuit gas Buderus Logamax U072-24.

If gas is connected to the house or a gas main is laid near it, you should buy a gas boiler without hesitation. In 2022, this is still the most optimal and most economical solution in Russian conditions. The equipment is relatively inexpensive, the market and its choice are large, natural gas itself is extremely cheap compared to other types of fuel. At the same time, there is no need to worry about the delivery and storage of fuel, and gas boilers can operate for days and weeks without human intervention, stably and accurately maintaining the set temperature.

This option is especially suitable for permanent residence in a house; double-circuit boiler models can provide not only heating, but also the preparation of sanitary hot water for 1-3 points of consumption at a cost that is only 10-15% higher than single-circuit ones.

There are also nuances in the case of gas boilers. The equipment requires registration of technical conditions (permits), compliance with the requirements for the premises, ventilation and chimney. It is necessary to call specialists for scheduled maintenance once every few years (and it is recommended - annually), the cost of the issue is about 500-1,000 rubles. The design, connection and commissioning of a gas boiler will take from 1 to 3 months, but in terms of cheapness and ease of use it is worth it.

Service life: 10-40 years (depending on device and materials).

Cost: from 13,000 rub. for the most budget floor models; the average good boiler is 33,000-38,000 rubles.

Gas heating boilers: the most detailed selection instructions. Checklist by criteria, best models, prices and owner reviews

Electrical

In the photo - a heating element electric boiler Proterm Skat.

Maximum operating comfort, but high energy costs - this is how electric boilers can be described in one sentence. Despite the lower initial cost, the absence of the need for a chimney and ventilation (even permission to install an electric boiler is not required), the cost of heating a house using electricity is the highest. Heating an uninsulated or poorly insulated house with an area of 100 m2 can cost about 15 thousand rubles on average per heating season.

If the budget is limited, an electric boiler is an excellent option only for temporary residence in the house or as a backup boiler unit. As a last resort, the option is suitable for very small private houses with an area of up to 60-70 m2. In such cases, the initially low cost of equipment and its connection will pay off high operating costs for a long time.

To connect a boiler with a power of more than 6 kW, a three-phase (380 V) electrical network is required, since a standard two-phase (220-230 V) simply cannot provide operation at maximum power. Installation of an electric boiler with a power of more than 10 kW requires approval from the Energy Supervision authorities. Otherwise, the electric boiler is a mini-boiler room; it is enough to connect the supply and return lines to it. The safety group, expansion tank, circulation pump and other elements of the heating system are usually already installed. There is no need to service the electric boiler annually; it is enough to clean it from scale once every 3-7 years and change the heating element, the cost of the issue is about 1,000-5,000 rubles.

Service life: 3-7 years without replacing the heating element; 15-30 years with regular replacement of heating elements.

Cost: from 4,000 rub. for the most budget models; the average good boiler is 28,000-41,000 rubles.

How to choose an electric boiler for heating a private home Types of electric boilers, selection criteria, the best models and their cost

Solid fuel

The photo shows a long-burning solid fuel boiler KSP Duo with an automatic feed hopper.

Solid fuel boilers burn coal, wood, pellets, peat, logs and other types of solid fuel to produce heat. The most common reason for choosing a solid fuel boiler is the absence of a gas main near the house, less often - the low cost or availability of solid fuel, for example, in coal-mining regions. Also, solid fuel boilers are still in demand due to their low cost, reliability and energy independence. At the same time, modern models are far from the old-style models in terms of efficiency and operating comfort, even to the point of complete automation of fuel loading.

But this is if we talk about expensive boiler units; budget models have also become more advanced, but still require the work of a fireman: regular refilling of fuel for 3-5 hours, daily cleaning of soot. You also need to organize a place to store fuel, preferably it should be a room. The choice of solid fuel boilers is also huge; long-burning boilers with a burning duration of one fill from 10-15 hours to 2-3 or even 7 days have been especially popular lately. A permit to install a TT boiler is not required.

Service life: 15-40 years (depending on the heat exchanger material).

Cost: from 14,000 rub. for the most budget models; the average good boiler is 25,000-35,000 rubles.

Solid fuel boilers: the most detailed instructions How to choose, review of the best models, their characteristics and prices

Liquid fuel

Diesel Kiturami Turbo and plastic fuel storage tank.

Diesel is supplied using a fuel pump. Liquid fuel means diesel fuel (diesel fuel), waste oil and fuel oil, and kerosene. Liquid fuel boilers are something between solid fuel and gas: they still require space for storing fuel and tanks for it, and are still not completely autonomous due to the need for regular maintenance. At the same time, liquid fuel boilers do not require a large number of documents, on average they have a higher efficiency than their gas counterparts, they are reliable and autonomous.

However, they choose boilers that run on liquid fuel, mainly due to the availability of a stable source for the purchase of this fuel at a lower price (service stations, vehicle fleets, agricultural equipment service centers, etc.). The initial cost of the equipment, with the exception of rare models, is extremely high, which is also the reason for the unpopularity of liquid fuel boilers. In addition, the burners in such boilers are very noisy, and during operation they produce a specific smell; high-quality ventilation is necessary.

Service life: 20-40 years.

Cost: from 35,000 rub. for the most budget models (there are only a few of them on the market); the average good boiler is 75,000-100,000 rubles.

Features of operation and types of liquid fuel boilers Selection criteria, best models, prices and owner reviews

Combined

Combined model with an installed gas burner.

Diagram based on the example of the Teplodar Kupper OK 15 model. These are universal boilers that operate on several of the types of fuel listed above - an excellent option if you haven’t been able to decide on fuel or if a temporary solution is needed, for example, before laying a gas main near your house. There are 5 main types of universal heating boilers:

- gas-wood;

- on wood and electricity;

- on gas and electricity;

- on gas and liquid fuel;

- multi-fuel, operating on 3 or more types of fuel.

The transition from one type of fuel to another in combination boilers is carried out by simply switching or simply replacing a quick-release burner. For example, using a model with wood and electricity, you can burn logs during the day, and at night switch the boiler to a heating element built into the heat exchanger, which will maintain a satisfactory temperature in the house until the morning. Particular savings can be achieved if a multi-tariff electricity meter is installed.

The disadvantage of such designs is the lower efficiency when burning any type of fuel, a higher price compared to two single-fuel boilers, and a small selection on the Russian market.

Service life: 10-25 years.

Cost: from 20,000 rub. for the most budget models; the average good boiler is 50,000-75,000 rubles.

Combination boilers for heating a private home Types, selection criteria, best models and prices

Timing and solution methods

Typically, clocking is observed during the off-season, when there are no severe frosts and there is no need to warm up the system for a long time.

In this situation, the boiler starts at maximum, quickly heats the water and turns off. Next, the pump removes the coolant throughout the system, the temperature drops, and the burners start up again.

In this mode, both 20kW and 30kW boilers operate. What's the difference?

And the difference is that the first one will consume gas during the launch intervals, conditionally 2m3, and the second 3m3. When the boiler cycles, it does not have time to evaluate anything and reach optimal power.

It starts at maximum and stops at maximum. But all this applies to old, “dumb” models.

In modern wall-mounted appliances with modulating burners (1:10) and smart electronics, the boiler’s operation is designed in such a way that if the automation initially detects overheating of the coolant, the next switching on will occur at a lower power, or you can reduce it yourself.

The only problem is when the minimum power of the boiler is not so minimal.

Therefore, check the instructions and ask the seller whether the gas boiler has a modulation function or not. And the more frequent the adjustment step, the better.

Mistake #5

But there is no need to overdo it with the so-called “brains”.

90% of consumers never use weather-dependent automation or GSM modules in their lives. It's not worth overpaying for them.

It’s better to install a couple of smart and inexpensive room thermostats.

More details

Most people solve the age-old problem with clocking in this way.

FEATURES OF CHOOSING A BOILER FOR GREENHOUSES

To calculate the boiler power for heating a greenhouse, you need to know the heat loss of your greenhouse.

The heat loss itself can be calculated using the following formula: Heat loss = Surface area * K * Temperature difference (°C)

, where:

Surface area (sq.m) - the entire external surface of the greenhouse (roof, walls).

IMPORTANT! For greenhouses, unlike other objects, they take not the area of land that is located under the greenhouse, but the area of all EXTERNAL SURFACES. Temperature difference (degrees) – the maximum temperature difference between the temperature outside and inside the greenhouse. You know the temperature needed to grow certain plants, and the minimum outside temperature can be easily found on the Internet (you need the temperature of the coldest five-day period for your region) K (Watt/sq.m*deg) - the thermal conductivity coefficient of the material. For materials used in the construction of greenhouses, the thermal conductivity coefficient has the following values: Single-chamber cellular polycarbonate 4mm - 3.9 / 6mm - 3.6 / 8mm - 3.3 / 10mm - 3.0 Double-chamber cellular polycarbonate 16mm - 2.3 Glass 3mm - 6.0 Single-chamber double-glazed window 4mm - 1.9 Polyethylene film 1 80 -200 mkm — 7.5 Two-layer inflated polyethylene film 180-200 mkm — 3.5

Separately, I would like to write a little about such a material as polycarbonate. The structure of polycarbonate sheets provides significant advantages where thermal insulation is important. The hollow form provides higher thermal insulation properties with lower heat losses than solid glazing materials. Heat loss is characterized by the thermal conductivity coefficient - this is the amount of heat passing through 1 m2 of glazed area material in 1 hour when the temperature changes by 1°C. The insulating properties of polycarbonate sheets will also help reduce the penetration of cold into the building. The lower the thermal conductivity coefficient, the higher the temperature is maintained on the inner surface of the sheet in winter. Below is an example of the temperature process through a 6 mm thick polycarbonate sheet, at an outside temperature of -10°C and an indoor air temperature of +20°C. If compared with single glass, the inner surface of the glass under the same conditions will have a temperature much below zero, which will affect the overall temperature in the room and will create discomfort near the windows.

Water volume and gas consumption

Mistake #6

The greater the volume of water in the heating system, the greater the power of the gas boiler should be.

This is not true at all. The final power is affected solely by the heat loss of the building.

The volume of water affects only the speed of INITIAL warming up.

When the temperature reaches the set values, the amount of heat released from the boiler will be the same. It doesn’t matter how much water there will be in the system - 10 liters or 100 liters.

Types of existing boilers

There are various types of boilers on the market for heating a private home. They are classified according to the type of fuel consumed:

- solid fuel;

- gas;

- electric boilers;

- liquid fuel.

To this day, the best heating boiler in terms of price for heating in a private home remains a solid fuel boiler. A gas boiler is universal. It is a little more expensive, but does not require constant intervention in the work. An economical option can also be arranged with an electric boiler, having affordable electricity prices or an affordable night tariff. Let's discuss each option in detail. After all, we are interested not only in this factor.

Manufacturer country

Which wall-mounted gas boiler is better - Korean or European? It is between them that the struggle most often occurs in this segment.

Mistake #7

Korean boilers are more economical than European ones.

Mistake #8

European boilers are more economical than Korean ones.

All wall-mounted turbocharged boilers work approximately the same. Yes, their filling is different, but this does not affect the SAVINGS.

The efficiency of both Korean and European models is the same. Here you need to look at another parameter, namely, the availability in your city of a service for maintenance and repair of a specific brand.

Because sooner or later your boiler, no matter how reliable it is, WILL BREAK.

Based on this factor, it is worth making a choice in one direction or another. Remember a simple rule - the further you live from the service, the simpler the units you choose.

Types of electric boilers

When selecting the power of a heating boiler according to the area of the house, it is worth understanding the main types of such devices:

- heating elements . This is the traditional and most common version of electric boilers. Multi-stage units are considered more economical, since they are capable of operating in several modes. Among the disadvantages is low efficiency due to heat loss for heating heating elements. But the advantages include low prices for consumables (heating elements) and easy repairs.

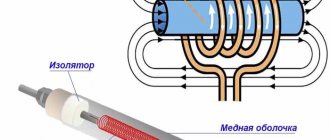

- Induction . In such equipment, the coolant is heated at the moment water passes through the inductive coil. It is believed that induction boilers are more economical compared to heating elements, they have no heat loss and virtually no inertia. In addition, such boilers are very compact - they look like a piece of pipe from 35 cm to 1 m long. Among the disadvantages is the need for constant circulation of the coolant, otherwise the boilers overheat and burn out quickly.

- Electrode . Many buyers, when they want to choose a boiler according to its parameters, choose this type of equipment the least often. Although they are considered the most economical, in most cases consumers are stopped by the need to circulate electrolyte through the pipes as a coolant, that is, water with certain additives. This requirement is due to the fact that heating of the coolant occurs due to the passage of current between the electrodes. When operating boilers of this type, it is necessary to monitor the condition of the electrodes and electrolyte. In addition, the entire installation operates under voltage - this also somewhat frightens consumers.

Thus, if you don’t know how to choose a boiler based on the area of your house and which option to choose, then pay attention to induction and heating elements products.

How to check the manufacturer?

Mistake #9

Often, instead of a gas boiler with European components, you can easily buy a Chinese boiler.

In fact, there is nothing wrong with this, it’s just that sellers should be honest with you from the beginning, and not push purely European quality.

How can you avoid falling for this and check everything yourself? Elementary.

Type the full name of the model into Google and add two words – “CERTIFICATE OF CONFORMITY”. Download it and study it carefully.

Mistake #10

If you cannot find such a certificate at all, then it is better to immediately avoid this model.

Each product that is imported into the territory of the CIS countries must have a certificate. The “Manufacturer” column indicates exactly where the boiler was actually manufactured. Here are two certificates for a visual comparison.

See the “Products” column for the specific brand.

This applies not only to assembly, but also to components. Already, few manufacturers save only on labor at the expense of the Chinese.

Therefore, you should not believe the sellers that the boiler was only assembled with a screwdriver in China, and all its internals are European. Although, again, we repeat, in the modern world, Chinese components are not always bad.

Here, first of all, we are talking about the honesty of the seller.

Comparison of fuel costs and operating costs

According to surveys and practice, the top three most important selection criteria for most buyers include gas consumption. For gas, some liquid fuel and solid fuel boilers, the maximum flow rate is indicated in the characteristics. But besides the fact that this is just the maximum possible indicator, it is difficult to deduce from it the degree of boiler efficiency, because fuel consumption also depends on the parameters of the house, correctly selected power, operating conditions of the boiler, etc.

In general, it is impossible to calculate the actual consumption of any type of fuel in a generalized form. However, approximately - quite realistic. The difference between heating costs is noticeable, which makes the picture clearer.

Natural gas . The normal calorific value of natural gas is 9.3-10 kW per m3 (the minimum allowable by GOST 5542-2014 is 8.84 kW/m3), this means that for 1 kW of thermal power of a gas boiler you need 0.1-0.108 m3 of natural gas gas For the 1st half of 2022, 1 m3 of main gas in the Moscow region is 5.92 rubles/m3 or 0.59-0.64 rubles. for each kW of boiler thermal power.

The generally accepted norm for an average uninsulated or weakly insulated house with a ceiling height of 2.7 m is: 1 kW for every 10 m2 of heated area.

The technical characteristics of any gas boiler indicate the maximum gas consumption, from here you can calculate the maximum possible heating bill. Using the example of BAXI SLIM 1.150 i (power 14.9 kW), the maximum natural gas consumption is 1.74 m3/hour:

- Per day – 24 (hours) * 1.74 (m3/hour) = 41.76 m3. In value terms – 41.76 (m3) * 5.92 (tariff for Moscow region, rub.) = 247.2 rubles/day.

- Per month – 30 (days) * 41.76 (daily consumption, m3) = 1,252.8 m3. In value terms – 1,252.8 (cubic meters) * 5.92 (tariff, rub.) = 7,416.6 rub./month.

- For the heating season (suppose from October 15 to March 31) - 136 (days) * 41.76 (m3) = 5,679.4 cubic meters. In value terms – 5,679.4 * 5.92 = 33,621.8 rubles/season.

It is important to understand that in practice the boiler does not operate 24/7 at full capacity: in this case, the wear of its elements accelerates many times over. A gas boiler correctly selected in terms of power (taking into account the area, heat loss of the house and a small power reserve of 10-20%) consumes only 50-70% of the values calculated above for the maximum possible operating mode of the boiler. Consider how many kW is needed specifically for your home.

How to calculate how much gas a gas boiler consumes All calculation methods and online calculator

Electricity . With electricity, calculations are much simpler: the efficiency of all modern electric boilers is 99%, that is, at maximum heating output, a 15 kW boiler unit will consume 15.15 kW of electricity. For the 1st half of 2022, 1 kW of electricity for a private house in the Moscow region costs 4.01 rubles. or 4.05 rub. for each kW of boiler thermal power.

The maximum possible heating bill using the example of any modern 15 kW electric boiler:

- Per day – 24 (hours) * 15.15 (kW) = 363.6 kW. In value terms – 363.6 (kW) * 4.01 (rubles per 1 kWh) = 1,458 rubles/day.

- 30 (days) * 363.6 (kW) = 10,908 kW per month In value terms – 43,741 rubles/month.

- For the heating season (suppose from October 15 to March 31) - 136 (days) * 363.6 (kW) = 49,449.6 kW. In value terms – 198,292.9 rubles/season.

Let us remind you that this is the maximum possible, and not the actual consumption.

How to calculate how much electricity an electric boiler consumes Calculation based on house parameters, examples of electricity bills

Firewood . The calorific value of ordinary freshly cut or recently cut firewood, the humidity of which is w ≈ 60–50%, is on average 1,800–2,000 kW/m3. This means that to obtain 1 kW of thermal energy, 0.0005-0.00056 m3 of firewood is needed. The cost of 1 cubic meter of freshly cut birch, alder or oak firewood is 1,600-1,800 rubles. or 0.8-1.01 rub. for each kW of boiler thermal power.

Coal . The calorific value of the most common coal is (w ≈ 7–15%), on average 7.5-8 kW/kg. This means that to obtain 1 kW of thermal energy, 0.133-0.125 kg of coal is needed. The cost of 1 ton of coal is 6,000 rubles. or 0.75-0.8 rub. for each kW of boiler thermal power.

Of course, it would be correct to make an adjustment for the efficiency of solid fuel boilers, which is on average 80%. For a more realistic picture, it is advisable to multiply the obtained cost indicators for 1 kW by 1.2 (80% efficiency).

Diesel fuel and fuel oil. Without going into details, liquid fuel boilers, when burning 1 liter of diesel fuel, waste oil or fuel oil, produce 10 kW of thermal energy. That is, 1 kW of thermal power accounts for 0.1 liters of fuel. The cost of Euro 4 diesel fuel is 35-40 rubles/l or 3.5-4 rubles. for each kW of thermal power. The cost of used oil in Moscow Region is on average 8-15 rubles/l or 0.8-1.5 rubles for each kW of thermal power.

Maximum consumption of a diesel boiler (l) – Boiler power, kW / 10, hence, having a 15 kW boiler:

- Per day – 24 (hours) * 1 (l) = 24 l. In value terms – 24 (l) * 35 (rubles per 1 l) = 840 rubles/day.

- Per month – 30 (days) * 24 (l) = 720 l. In value terms – 25,200 rubles/month.

- For the heating season (suppose from October 15 to March 31) - 136 (days) * 24 (l) = 3,264 l. In value terms – 114,240 rubles/season.

It is important to understand that these figures are given for continuous operation at full power, which is quite rare. Typically, boilers operate no more than 1/3 of the time of day, so these calculations can be safely reduced by 2-3 times. Also, liquid fuel boilers are usually purchased if there is a source for purchasing fuel at lower than average market prices.

| Type of fuel | Calorific value, kW.h/m3 (kg, t, l) | Cost of fuel unit, rub. | Cost of 1 kW of thermal energy, rub. |

| Natural gas | 9,3-10 | 5,92 | 0,59-0,64 |

| Electricity | 1 | 4,01 | 4,05 |

| Firewood | 1 800-2 000 | 1 600 | 0,8-1,01 |

| Coal | 7,5-8 | 6 000 | 0,75-0,8 |

| Diesel fuel | 11-11,3 | 35 | 3,5-4,0 |

| Working off | 11-11,3 | 8 | 0,8-1,5 |

Double-circuit or single-circuit?

Mistake #11

If in addition to radiators at home there is also a heated floor, then you must definitely buy a double-circuit boiler.

Double-circuit boilers are needed only for hot water supply (DHW) - heating + separate hot water. The single-circuit device copes well with both heated floors and radiators.

All it does is simply heat the water. What kind of heating system you have doesn’t really bother him.

The main thing is to design and calculate everything correctly. In general, for normal hot water supply it is not recommended to buy a boiler with a power of less than 24 kW.

There are many copies on the Internet about double-circuit and hot water supply.

To briefly formulate the essence, it is as follows:

- one bathroom or two hot water points + all this is not far from the boiler room - your choice is a double-circuit boiler

- three or more water points - single-circuit and indirect heating boiler

We select a boiler according to different parameters

Now it’s time to talk about how to select a heating boiler according to its parameters. These parameters include the area of heated premises and the power of heating equipment.

Let's look at how to make the right selection of a heating boiler based on area. There are several points to consider:

- If your house is insulated according to the standards, its ceilings are 3 m, then the power will be determined at the rate of 1 kW per 10 sq.m.

- If the house is not insulated in the best way, or verandas and uninsulated attics are heated, then the power will be greater.

- If the boiler will be used not only to heat the house, but also to supply hot water, then the power will be increased by 20-50%.

Of course, if you do not have certain special knowledge, then you will only make an approximate choice of heating boiler power. After all, if you apply a more complex formula, then some more indicators are included.

Boiler power depending on the area of the house

Let's consider the formula for calculating the power of a heating boiler. Boiler power is the most important operating parameter. This does not depend on what type of fuel will be used in the future. If the power is not enough, you will freeze; if, on the contrary, you buy a device that is too powerful, then you will overpay.

To select the power of a heating boiler, consider the formula. So, this includes the following parameters:

- Room area S.

- Specific boiler power per 10 sq.m of premises Wud. – taking into account climatic conditions: Moscow and the region – 1.5 kW, North – 1.5 – 2 kW, South – 0.7 – 0.9 kW.

The formula will look like this: Boiler power = SWud./10.

When choosing a boiler, first of all it is necessary to calculate the energy demand of the heating object. The parameters of the heating system are calculated according to the heat loss of the room, which depends on the size of the room, the thermal conductivity of external walls, internal partitions and ceilings, the difference between external and internal air temperatures, therefore the final determination of the boiler power should be trusted only to professional heating engineers. But it is possible to pre-determine the power of the boiler, and accordingly, the cost of the equipment and its other parameters independently. Approximately, you can use the following ratio - 1.2 kW of boiler power is required to heat approximately 10 m2 of a well-insulated room with a ceiling height of up to 3 m.

The defining parameters that should be relied upon when calculating power are:

- area of the heated room (S);

- specific boiler power per 10m? premises, which is set taking into account amendments to the climatic conditions of the region (W spec.).

There are generally accepted specific power values for climatic zones:

- for the Moscow region - W beat. = 1.2 - 1.5 kW;

- for the Northern regions - W beat. = 1.5 - 2.0 kW;

- for the Southern regions - W beat. = 0.7 - 0.9 kW.

Calculation of boiler power (W cat) is carried out according to the formula:

W cat. = SW beat / 10

Often, for the convenience of calculations, the average value of W beat is used. equal to one. Based on this, it is customary to choose the boiler power at the rate of 10 kW per 100 m 2 of heated space.

Example:

1. Area of the heated room S = 100 m²;

2. Specific power (Wsp.) for the Moscow region = 1.2 kW;

W cat. = 100 1.2 / 10 = 12 kW;

The table shows the approximate power of boilers depending on the area of the house served (for the Moscow region).

Condensing or traditional boiler?

Boilers are like people, some are traditional and some are not.