Due to the constant rise in prices of common energy sources (gas, oil, electricity) and the difficulty of connecting them, private homeowners prefer to find another solution to the problem of heating and hot water in their home. Returning to wood heating is one reasonable solution. Moreover, modern wood-burning boilers are quite relevant and effective as the basis of a heating system, allow different levels of automation and are economically beneficial, being the second most common after gas boilers.

What are solid fuel wood boilers?

The market for wood-burning boilers offers a huge number of different external models, but what they have in common with the brick wood-burning stove of the past is the presence of devices with a similar purpose: a firebox (fuel combustion chamber), a ash pit, a brick mass (heat exchanger) and a chimney. These components are present in any boiler, but modern technology and engineering have brought the efficiency of the components to a level unattainable in a furnace.

The application of the principles of wood combustion control with an efficiency increase of up to 92% and a loading period of several days make such boilers quite capable of competing with both gas and liquid fuel ones. Firewood in modern high-tech devices burns with almost no ash or emissions into the atmosphere.

Design and principle of operation

Construction of a modern budget wood-burning boiler using the example of Teplodar Kupper Pro.

At its core, the operating principle of a wood-burning boiler remains unchanged:

- Loading firewood into the firebox (combustion chamber).

- Ignition of fuel.

- Installation of oxygen supply to burning fuel.

- Heating the coolant in the heat exchanger.

- Discharge of combustion products through the chimney into the atmosphere.

- Discharge of heated coolant into the heating system.

- Removing ash from a furnace or boiler.

The goal of extracting all the energy it can provide from burning wood encourages boiler designers and manufacturers to improve the design of each component to accomplish these points with maximum efficiency.

The method of supplying oxygen to the combustion zone and removing combustion products divides boilers into:

- non-volatile, autonomous . The ash door is controlled mechanically, and combustion products are released into the atmosphere due to the pressure difference created by the chimney pipe and the firebox;

- volatile . Oxygen is supplied by a pressurization fan, and smoke with the remains of unburned fuel is pulled out of the firebox by a fan-exhaust fan, so for the boiler to operate, it must be connected to the electrical network through a standard socket.

The method of controlling the combustion and loading process divides wood boilers into several types:

- direct (direct) combustion - a direct analogue of a brick stove, in which the fuel, burning, heats water in a steel or cast iron container for heating the house;

- long burning - sometimes these are simply models with a larger firebox and a more complex heat exchanger, but the most successful are mine boilers, in which long burning is ensured by the “top-down” combustion principle - slow smoldering of only the top layer of fuel;

- gas generator (pyrolysis) boiler unit - it separates the smoldering phases of the fuel (the release of pyrolysis gases and their afterburning in another combustion chamber with the release of a large amount of thermal energy), this makes it possible to achieve greater efficiency and combustion duration of one load, less ash.

Boilers with a burning duration of one load of fuel up to 7 days

Long burning boilers

One not very pleasant necessity when operating a wood-burning heating unit is the regular loading of firewood into the firebox. In most boilers of older designs, it is necessary to load a portion of fuel every 3-4 hours. To overcome this problem, long-term combustion models have been developed in which fuel is added every 1-3 days. In addition to the fact that the furnace capacity of such boilers has increased overall dimensions, they use the principle of top combustion.

After the system reaches the nominal mode (the coolant reaches the set temperature), the control switches the fuel combustion to smoldering mode, reducing the supply of oxygen to the top layer of the fill.

Visual process of long-term combustion.

The fuel smolders layer by layer, falling down a stack of properly stacked firewood, maintaining the set temperature in the rooms. In experienced hands, such a long-burning, wood-burning solid fuel boiler can operate for more than three days, but on average, raw materials need to be loaded once every two days. The duration of work on one bookmark depends on the quality of the firewood, adjustments of the combustion mode and the correct placement of firewood in the firebox.

Pyrolysis boilers

Operating principle of pyrolysis boilers.

Modern gas generator boilers are used for greater efficiency and savings (due to afterburning of pyrolysis gases). After reaching the desired operating mode of the boiler, at a certain temperature, smoldering firewood begins to intensively emit wood (pyrolysis) gas. This high-energy product is discharged into the second combustion chamber, is saturated with oxygen and burns, releasing a large amount of heat. The burning air-pyrolysis mixture is driven by a smoke exhauster through a complex heat exchanger, transferring maximum energy to the coolant.

High efficiency of complete fuel combustion (efficiency up to 95%) in such boilers is achieved by the presence of different levels of automatic systems, fans, and sensors. Under computer control, such heating systems are rarely energy independent. In addition, such boilers are very critical to fuel moisture.

Useful tips

When selecting equipment for creating a steam heating system, during its installation it is advisable to take into account the following recommendations:

- You cannot use used heating radiators. They are highly likely to have hidden damage, which will subsequently cause the system to depressurize.

- It is not advisable to use cast iron batteries. Under the influence of large temperature changes, they begin to collapse.

- Installation of the circuit must be carried out by workers with certain knowledge and skills. Otherwise, the created design may be ineffective.

- If you install a steam generator in a conventional wood-burning stove, you can significantly save usable space. In addition, home heating costs will be minimal.

- When using natural circulation, it is recommended to install the stove in the basement of the house. This will ensure that condensation quickly drains to the lowest point.

- For safety reasons and to prevent emergency situations, you cannot refuse to install valves.

The installation of steam boilers in a central heating system is prohibited by law. In private homes, this type of autonomous heating can function for decades without requiring replacement of the main structural elements.

The chimney of a stove with a built-in heat exchanger gets dirty faster than a conventional stove, so it needs to be cleaned more often Source roof-tops.ru

Reviews of domestic wood heating boilers: advantages and disadvantages

| Advantages | Flaws |

| The cheapness and availability of wood, omnivorousness to other types of solid fuels make obtaining heat, hot water and cooking inexpensive | Capital investments in good equipment are high and increase significantly with the increasing level of automation (as well as the manufacturer’s brand) |

| You do not need permission to install equipment, as when connecting power to electrical networks and gas mains. No need to pay a subscription fee for service | Organizing a seasonal fuel warehouse will require space, investment and effort |

| Ease of use – for most boilers, control and maintenance are clear and not burdensome | Installing a boiler in a residential building is not advisable, there will always be minimal odor, a bulky boiler unit and two or three portions of fuel must be taken out into the annex |

| Fire danger and carbon monoxide poisoning are excluded in modern boilers if the instructions are followed. | Despite the boiler manufacturer’s promises to free the owner from many responsibilities due to automation and computer control, regular monitoring is necessary |

| Prices for the most budget wood-burning models start from 13-14 thousand rubles | |

| Availability of both single-circuit and double-circuit models |

How does steam heating differ from water heating?

In a water heating system, the coolant is often water. It moves inside the pipeline and gradually cools there. In the case of steam heating, the liquid being poured evaporates and hot steam moves through the pipes. After cooling, it condenses and then flows through the return pipeline back to the heating unit.

When the coolant is steam, the thermal output of heating devices is significantly higher, rooms heat up three times faster. Such a system starts up quickly even after a long break in use.

Additionally, it is worth noting the lower cost of materials for steam heating devices. This is explained by the use of compact and ergonomic equipment during installation (for example, pipes of relatively small diameter).

Unlike water heating, steam heating gives greater heat transfer and warms up the room three times faster Source pechiexpert.ru

How to choose a wood boiler

Before you start choosing a wood-burning boiler model, you need to decide on its future purpose: heating a country house, a summer cottage. Then decide on a budget and, in order not to be disappointed with the result, study the parameters of the available equipment. The need for a homeowner to be confident in their requests before communicating with the seller is a prerequisite for getting something that will not disappoint after purchase and will last for many years.

Direct, long burning or pyrolysis

Traditional direct combustion boilers are an analogue of a furnace; they are extremely easy to operate, do not require connection to the electrical network, are unpretentious in terms of fuel quality and are cheap. However, they allow power and temperature adjustment only within small limits and have low efficiency. If the future owner of the unit is ready, as a boiler room operator, to monitor the temperature of the water in the system, load logs every 3 hours, close the vent and damper in time so as not to get burned, not overheat the water and not let the fire go out in winter - this is a good, profitable and very budget-friendly option. choice. Moreover, even inexpensive modern options are much more practical to maintain than old-style models.

When choosing a wood-burning boiler with long burning for a summer house or a house with year-round living, you can get a completely autonomous system with mechanical control or a volatile one with a low level of automation. The efficiency of such units is significantly higher than that of the previous ones; a well-regulated smoldering process can work effectively for up to 10-12 hours on one load; in some models of well-known brands (STROPUVA, LIEPSNELE), additional loading is possible once every 2 days. The cost of such equipment occupies the average niche of the market.

Currently, the most effective are gas-generating boilers with various levels of automation. They are mostly energy dependent and very demanding on the quality of firewood. But they have high performance characteristics: efficiency up to 95%, long periods between loads (up to 5 days), smooth power adjustments, computer control with control via a mobile phone, etc. Naturally, this level of comfort is expensive and very expensive.

Heat exchanger material

To burn wood, it is better to use a cast iron boiler; it cools down longer and lasts for centuries. But the choice here is:

- steel heat exchanger - lighter in weight, easier to transport and install, it is repairable (can be welded), cheaper, efficiency is the same as cast iron, but durability depends on thickness and operating conditions, since steel is susceptible to corrosion (service life 12-18 years) ;

- cast iron heat exchanger - it is heavier in every sense, fragile, damaged sections can only be replaced, but if treated with care and avoiding a large temperature difference between the supply and return, it will last a long time (at least 30 years).

Important differences between cast iron solid fuel boilers for heating a private home and cottage

Single-circuit or double-circuit

The first option, single-circuit (usually more powerful), is used only for heating. Some models already from the factory allow operation with an indirect heating boiler to produce hot water, but in general, such a scheme can be organized in conjunction with any wood-burning boiler.

Double-circuit ones are structurally designed and created for heating and hot water supply. When choosing, it is necessary to evaluate the heated area, as well as the temperature and amount of hot water produced by the water circuit per hour during normal operation.

Despite the fact that a double-circuit boiler is the cheapest way to organize hot water supply in a house, in the case of a solid fuel boiler it is better to take a single-circuit model and connect an indirect heating boiler, this is much more practical.

What are modern double-circuit solid fuel boilers?

Efficiency

The higher the efficiency of the boiler, the lower the fuel consumption and the more complete accumulation of thermal energy it can provide. However, the nominal value of this parameter requires scrupulous compliance with the manufacturer’s instructions. This primarily concerns the fuel: type of wood, humidity, correct installation. Then: careful adjustment of combustion control at all stages and timely routine maintenance work. Under all conditions set by a reliable manufacturer, the declared efficiency is quite achievable.

Having decided on the previous, more important, parameters, it is worth starting from efficiency values of 80-85% (for direct combustion boilers). Lower figures today indicate significant technical imperfection.

Minimum required power

For solid fuel boilers, rough calculations of the minimum required power are usually sufficient. Therefore, in practice, the rule is that to heat a room with normal ceilings up to 3 m high, standard insulation requires about 1 kW of power per 10 m2 of area. We also recommend setting aside + 20% reserve for inaccuracies and possible expansion of consumption. If you plan to use hot water supply, you need to factor in another +20%.

For example: for the above-described house with an area of 200 m2, the minimum boiler power is (200/10) * 1.2 = 24 kW for heating, and if there is also DHW - 24 * 1.2 = 28.8 kW.

Scheme

The heating system operates thanks to natural circulation. Therefore, the heat exchanger must be installed below the level of the radiators. The circulation pump ensures constant operation of the thermal circuit.

There are open and closed steam heating circuits: in the first case, the system is connected to the atmosphere (open), in the second, it is completely isolated from the effects of atmospheric pressure Source s-proms.ru

Steam heating in a house involves the installation of a one- or two-pipe heating system. The optimal choice of the latter depends on the area of the building that is planned to be heated.

Single-pipe

With single-line wiring, radiators are connected in series. The resulting steam passes through a pipeline from one battery to the next. As a result, the first radiator is always the hottest, the last one is almost cold. The single-pipe system is suitable only for small-sized rooms (no more than 80 m²).

Two-pipe

If the house has a huge area, a two-line heating option should be used. A constant supply of hot steam is carried out through the upper pipe. The cooled condensate returns to the heating unit through the lower pipeline. Regardless of the distance from the boiler, all heating batteries heat up evenly.

A single-pipe heating system is more suitable for heating a summer house or a small house; for a spacious cottage or two-story building, it is recommended to use a two-pipe system Source gubernia.media

The best known manufacturers and models: characteristics and prices

The presence of German-made units from well-known brands is noticeable on the domestic market. Typically, it is characterized by a high level of automation, careful execution and increased requirements for compliance with environmental regulations. Equipment and additional options provide owners with any level of comfort, but they are very scrupulous about the quality of local fuel and, without serious preparation, may not provide the promised power and efficiency.

Czech and Slovak production supplies us with fairly high-quality equipment for heating private houses. They are quite comparable in level of automation, reliability and safety with German ones, but at lower prices. Russian production is also gradually becoming noticeable in this market. First of all, this is a large number of simple, but quite modern low-budget boilers.

Teplodar Cooper Praktik 14

One of the best and most common wood-burning boilers for heating a private home or cottage. A simple, single-circuit, mechanically controlled classic direct combustion boiler with a power of 14 kW. Despite the fact that it is positioned as non-volatile, it has a pre-installed block of heating elements with a power of 6 kW, which can help maintain the temperature in the system by connecting it to an outlet. According to reviews from the owners, the power of the heating elements is enough to keep the house warm until the morning after the last filling burns out in the evening (with an area of up to 150 m2).

The efficiency is not so great - 80%, but for the most budget price segment it is more than sufficient. When fully loaded, the burning time of one portion of firewood is 8 hours. There are also disadvantages inherent in most budget models: a steel heat exchanger, a small combustion chamber, limiting the length of the logs.

Protherm “Beaver” 20 DLO

A Slovak cast iron boiler is one of the best options if the budget is not limited to 20-30 thousand rubles. Among single-circuit direct combustion boilers with mechanical control, this one stands out for its high efficiency of 91% and low heat losses (thanks to the complex design of the heat exchanger and good alloy). Almost all owners note the excellent build quality, the acceptable size of the firebox window, through which firewood up to 30-32 cm can easily fit, and the practical design of the boiler. The ash drawer is large, very easy to remove, and quite easy to clean.

Over the course of installation practice and more than 7 years of operation, the model has proven itself to be absolutely problem-free, which is not surprising, since there is nothing to break in such a simple, cast-iron design. The only drawbacks are the heavy weight, typical of cast iron boilers, as well as the firebox is not deep enough; when adding wood, ash can fly out of it.

Viadrus Hercules U22 D4

Another Czech-made boiler. Single-circuit, direct combustion, with a cast iron heat exchanger, but its efficiency is lower - 80%. For this reason, the fuel requirements are much simpler: you can use not the driest firewood with a humidity of more than 25% and a length of up to 34-35 cm. This is an excellent alternative to Protherm “Beaver” when you plan to use firewood of any quality. The assembly is still of the same high quality, the design is practical, and there are no serious reliability problems known.

The disadvantages are the heavy weight of the unit - 247 kg (with a power of 24 kW), and also not the most affordable price.

Kentatsu ELEGANT-03 17

Single-circuit direct combustion mechanical boiler, Turkish production and assembly, but designed and developed in Japan. This is one of the cheapest cast iron models on the market. At the same time, it has a very good design and efficiency: efficiency – 80%; compact dimensions; the presence of a layer of thermal insulation that reduces heat loss through the body; protected from overheating by water-cooled grates.

Due to the low price, there are more disadvantages: mediocre build quality, small firebox and combustion time for one load of up to 4 hours. It is also important to understand that the service structure in Russia is not so developed and is completely absent in a large number of regions.

Cost: 32,000-36,900 rubles.

Buderus Logano S171-22W

High-tech German pyrolysis boiler with a lower gas afterburning chamber. It is distinguished by high efficiency up to 89%, and a large number of modern automation systems: adjustable speed of the blower fan and smoke exhauster; control of heating system circulation pumps; accounting of external temperature sensors; control from mobile phone and PC.

Separately, it is worth noting the size of the firebox and the practicality of the design, since for burning you can easily use logs up to 58 cm long. The burning duration is on average 3-4 hours, the wood consumption is on average 6.2 kg/hour. The heat exchanger here is not cast iron, but made of thick 5 mm furnace steel. Of course, you need to be connected to an electrical outlet to operate. Apart from the high price, it is difficult to find any shortcomings.

Cost: 179,000-198,000 rubles.

STROPUVA S20

The most famous Lithuanian model of long-term combustion of the shaft type (with top combustion). The main type of fuel is wood, but the boiler can also burn other types of fuel such as coal, peat, pellets. Efficiency is 85%, the 20 kW model has a firebox volume of 262 liters, and can operate for up to 40 hours on one load of wood (and up to 7 days with coal). In this case, you can use logs up to 45 cm long. The boiler is completely energy-independent, the heat exchanger is cast iron, in a steel casing.

The only disadvantages are the relatively high fuel requirements, abundant formation of tar on the walls and the large weight of the boiler - 231 kg.

Cost : 89,000-110,000 rubles.

Heat exchanger shape

Furnaces with a self-made water circuit are equipped with several types of heat exchangers. When choosing and constructing a boiler for a stove, the complexity of manufacturing (cost and labor), as well as placement possibilities, are taken into account.

In addition, the choice of design is determined by the purpose. For example, in a bathhouse it is desirable to quickly heat a volume sufficient for washing, which involves intense heat transfer. And for the heating system of a residential building, gradual heat transfer from fire to water is preferable.

Heat exchangers differ not only in shape, but also in the material of manufacture. By correctly combining shape, material and placement, the efficiency of the system can be significantly increased.

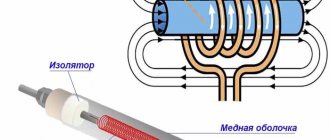

Tubular steel heat exchanger Source 1-teplodom.ru

The following types of heat exchangers are possible in the designs of brick kilns:

- Coil. This is the name given to a pipe that is bent at different angles. The advantage of the coil is that it heats up quickly, the disadvantage is that its volume is usually small and is not suitable for large areas. It is mounted behind the firebox or inside it; if the coil has the shape of a spiral, then it goes to the chimney.

- Register. The heat exchanger resembles a pipe radiator and can consist of pipes of different diameters. It is valued for its versatility and energy efficiency; The installation location is selected according to the general scheme.

- Water jacket. A type of tubular device, mounted inside the firebox or placed on the chimney. The design is prone to leaks, but is efficient; There is no need to disassemble the oven for installation.

- Flat type heat exchanger. Installed in houses and baths, a practical option in terms of manufacturing, installation and maintenance. It looks like a flat container and is installed next to the firebox. For correct operation, it is necessary to comply with the technical parameters: inclination and location of the forward and return pipes. Optimal for heating circuits, as it heats water as quickly as possible.

Homemade combined heat exchanger Source etokirpichi.ru

Prices: summary table

| Model | power, kWt | Efficiency, % | price, rub. |

| Teplodar Cooper Praktik 14 | 14 | 80 | 20 000-27 000 |

| Protherm “Beaver” 20 DLO | 19 | 91 | 79 000-83 000 |

| Viadrus Hercules U22 D4 | 24 | 80 | 59 000-90 000 |

| Kentatsu ELEGANT-03 17 | 17 | 85 | 32 000-36 900 |

| Buderus Logano S171-22W | 22 | 89 | 179 000-198 000 |

| STROPUVA S20 | 20 | 85 | 89 000-110 000 |

The summary table reflects the approach of our manufacturers to the production of wood-burning boilers for heating. The price and declared characteristics in the first position may well suit a villager and not tempt him to experiment with homemade boilers. In our open spaces, such a low-budget boiler is preferable at long distances from service centers.

How to burn properly and what kind of wood is best

The operating instructions for a wood-burning boiler determine the basic requirements for the fuel at which it produces the declared parameters. Typically, the passport indicates the length of the logs and, for some models, their diameter, depending on the size of the firebox. The optimal humidity of raw materials is also indicated in the documents and does not exceed 20%. Of the tree species, it is better to use denser wood species: ash, birch, alder. Their calorific value is on average 25% higher than that of coniferous species: spruce, pine.

Before putting the boiler into operation, it is advisable to warm up the firebox and chimney with a small, no more than 50% load of firewood. Paper, splinters, wood chips and light logs are placed on the grates. Then the whole thing is set on fire and filled with firewood up to half of the firebox so that air circulation is possible between the logs. You need to let this batch burn out with the ash pan closed and the chimney damper open. Then the ash pit and firebox are cleaned and the main batch of firewood is stacked denser than before, and the boiler is put into operation. To obtain the desired parameters, you should initially strictly follow the recommendations of the equipment manufacturer; with experience, you will understand how best to achieve the desired result.

Wood boilersBoilersSolid fuel boilers

Briefly about the main thing

If a brick stove is supplemented with a water heating circuit, then such a system can significantly (up to 100 square meters) increase the heated area of a house of any configuration. The design has high efficiency and good heat transfer, evenly distributing energy throughout all rooms.

To select or make a high-quality heat exchanger, you need to take into account its shape, location and material of manufacture. The design should follow the shape and dimensions of the firebox (or chimney) as accurately as possible; only in this case the efficiency of the system will be maximum.