Stone wool in sheets (mats).

Previously, we described the ecowool insulation method and reviews after use. Today we will look at the most popular type of thermal insulation, which is called basalt insulation. Reviews from literally everyone who has at least once come across him closely are only positive. This is probably the cleanest and safest material today. He is not afraid of fire, water and copper pipes, too.

But it still has a weak point - rodents that can live in it. Although the realities are such that there is not a single modern insulation in which mice could not establish their quiet life. Therefore, one should not focus on this drawback, since there is still no alternative.

What is basalt insulation, characteristics

Stone wool, also known as basalt insulation, is, according to reviews, the most environmentally friendly and practical thermal insulation material. It is used for insulation of all types of structures:

- floors;

- shelves;

- interwall spaces;

- pitched roofs;

- facades.

As you can see, there are no types of work where basalt insulation cannot be used. The characteristics of the material make it a leader among all possible insulation materials. It is not afraid of moisture, it is quite rigid, and at the same time it has the ability to pass steam without condensation settling in it. This material is made from volcanic rock, basalt.

Stone wool was first discovered in the Philippines. Yes, it was discovered. After the next volcanic eruption and the cooling of the rock, local residents at the foot found a porous cotton wool-like material with a strong structure.

Later they were able to produce it under artificial conditions. Production process:

- the rock heats up to 1.5 thousand degrees;

- the hot mass is blown by air under pressure into small particles (fibers);

- the fibers are impregnated with a fixative and oil;

- the fibers form a carpet from which thick sheets are formed;

- the sheets are given the required shape, then they are compressed;

- then the material is heated so that the fixative firmly connects the fibers to each other;

- the last stage is slicing.

You can purchase basalt insulation, as well as other building materials at low prices and with delivery, from the Samstroy company. At the end of the production process, basalt insulation has the following characteristics:

- heat conductivity coefficient – 0.032-0.045;

- water absorption – no more than 5%;

- steam conductivity – 0.3 mg/mchPa;

- flammability - class NG.

Manufacturers of basalt insulation produce products with different densities. It ranges from 40 to 200 kg/m. cube According to the manufacturers, mice do not live in this type of thermal insulation, which, unfortunately, is not the case. In fact, there is no such insulation where mice would not swarm. Colonies of rodents even settle in Soviet-era glass wool, which is very scratchy, not to mention modern materials.

If you plan to use stove heating in a wooden house, take care of the foundation for the stone stove before building the walls.

About what convection ovens are for heating a home and how they work is written here

Varieties

Dense basalt material with a fibrous structure has unsurpassed thermal insulation characteristics. Modern basalt insulation varies by type. Although the main difference between the material comes down to the type of fiber: continuous and staple fiber. The main parameter of staple fiber remains the diameter.

It is taken into account when dividing materials into groups such as:

- microfine fibers – 0.6 microns;

- ultra-thin fibers – 1.0 microns;

- superfine fibers – 1.3 microns;

- thin fibers – 9–15 microns;

- thickened fibers – 15–25 microns;

- coarse fibers – 50–500 microns.

When choosing an insulating basalt material, you should pay attention to the thickness and length of the fiber, because many quality indicators of the product depend on this. Basalt fiber insulation is also divided into soft, semi-rigid and more rigid options

On sale there is always basalt slab, wool, slab or bulk insulation, rolled wall insulation, heat insulation in bags or mats. Specific differences relate to the surface - is it a foil or non-foil product, which is easy or difficult to cut with a construction knife. In general, the insulation under consideration is usually divided into several types

Basalt fiber insulation is also divided into soft, semi-rigid and more rigid options. On sale there is always basalt slab, wool, slab or bulk insulation, rolled wall insulation, heat insulation in bags or mats. Specific differences relate to the surface - is it a foil or non-foil product, which is easy or difficult to cut with a construction knife. In general, the insulation under consideration is usually divided into several types.

Foil

Foil tile insulation can significantly reduce heat loss. Today, more and more often, houses are covered with foil mineral wool or basalt wool, which is suitable for most types of premises. This insulation also allows you to save on additional shelter during the heating season. The building material significantly reduces heat loss. This is an excellent heat insulator, consisting of a double protective layer that reflects heat into the room.

The material with a foil surface, in addition to its thermal insulation properties, is distinguished by its ability to absorb sound, therefore providing an additional level of environmentally friendly sound insulation. The service life of the insulation is up to 40 years or more. Basalt (foil) mineral wool is applicable for both interior and exterior decoration. It is used to avoid the possibility of rotting, mold formation, and as a hydro- and vapor barrier. It is applicable in both non-residential and residential premises. The material is suitable for insulating floors, walls and ceilings, as well as for covering ventilation systems and various tanks.

Mineral wool

The general name mineral wool often implies the use of high quality mineral wool - this is the so-called stone wool, glass wool and slag wool. Increased strength is associated with the dense fiber structure of the material. Two types of rocks are used to produce basalt mineral wool. It contains no synthetic impurities. Natural origin adds positive qualities to the insulation. The finished building material made from basalt mineral wool is characterized by its low thickness and minimal mutual friction of the fibers (prevents sound vibrations).

Inorganic product is resistant to high temperatures. Basalt wool is fire resistant and is used for fire insulation. Non-combustible slabs do not shrink. They do not change their original properties even over time. Basalt wool slabs can be used to prevent moisture condensation on the load-bearing walls of a building.

Stone wool

The use of stone wool from basalt rocks is also widespread today. Basalt-fiber insulation is a special type of mineral wool. Gabbro-basalt rock is used as the raw material for production. Due to its natural origin, the building material is called stone or mineral. Although we are talking about one product. Basalt is a volcanic rock that is processed at the highest temperatures. After which, when separated, the product acquires its recognizable fibrous quality.

Types of basalt insulation

Stone wool in rolls.

In addition to the difference in the density of the material, manufacturers of basalt insulation produce it in three versions, each of which has its own strengths and weaknesses. Basalt insulation, types:

- rolls;

- mats;

- scattering

The density of basalt insulation in mats is the highest, sometimes so much so that it cannot be deformed in order to be inserted between the guides. Therefore, some manufacturers make one edge less dense for ease of installation. In addition, the material in the mats can be made of two layers of different densities. Such boards are used for thermal insulation of facades under plaster. There are also mats with reflective insulation (foil). They are widely used for baths, although a layer of foil will be appropriate in almost any work. Also read: “Insulation of a bathhouse built from timber.”

There is not a single person who, before purchasing, would not ask the question which basalt insulation is better to choose? This topic has been discussed more than once on forums and, having studied them, we can conclude that Rockwool remains the best. Everyone speaks only positively about him, he has proven himself well and continues to hold his position as a leader.

Why is a stove for heating a home still relevant and in demand today?

Read here how a stove for heating a two-story house can heat such a large area.

Bulk basalt

Bulk basalt insulation is a “blown”, “stuffed” material. It is very convenient and economical. The material is supplied in bags and in bulk. This is an excellent addition to existing thermal insulation made from slag, sawdust, expanded clay and other things. The density of the material is about 35-50 kilos per cubic meter. The material is in high demand in Europe, and the volume of purchases of this material there is growing every year. Reviews about bulk basalt insulation are quite positive. The main disadvantage is the impossibility of using the material as the main insulation, but only as a supplement.

Methods for installing basalt insulation

As we have already said, stone wool is used for all types of work. The thickness of basalt insulation for walls is calculated for each climate zone separately. Each region has its own coefficient, below which the thermal resistance of the walls should not fall. The thermal resistance of the enclosing structure is calculated by dividing its thickness in meters by the thermal conductivity coefficient of the material. For each material it is calculated separately, and the results are summarized. For example, first we calculate the thermal resistance of the wall. Then we adjust the thickness of the insulation based on basalt fiber so that the overall thermal conductivity coefficient is no less than the coefficient for your region.

For Moscow, the normalized value of heat transfer resistance is 3.14. Let's say there is a wall of two bricks 50 cm thick. The thermal conductivity of white brick is 0.7. This means that the entire structure will have a heat transfer resistance of 0.714 (0.5/0.7), and the standard required is 3.14 (difference 2.426). To compensate for heat loss, a layer of stone wool 8.5 cm (2.426 * 0.035) is needed.

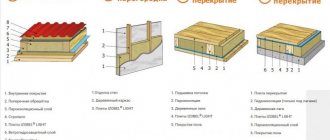

Wall insulation

If the wool is laid in two layers, the seams should not match.

Although the composition of basalt insulation does not allow the material to absorb moisture (due to the oil impregnation of the fibers), it is better to lay a vapor barrier on the side of the room close to the insulation. It will retain all moisture coming from the room. It is important that there is a ventilated gap between the vapor barrier and the interior finishing. It is needed so that the moisture that the vapor barrier will retain is not absorbed into the finish.

Layers of materials, starting from the inside:

- interior decoration;

- ventilation gap;

- vapor barrier;

- stone wool;

- outer wall.

It is desirable that the exterior finish be made of breathable materials so that moisture from the insulation is removed outside. For work, material with a density of 50 kg/m is used. cube

Facade insulation

Diagram of layers when insulating a facade with stone wool.

is 70 years, so it can be safely used for long-term insulation of facades. The work is carried out both under a ventilated facade and under plaster. The second method is simpler - the sheets are glued to the wall and additionally secured with plastic dowels (fungi). The top is plastered using reinforcing mesh. A ventilated façade is somewhat more difficult to implement:

- guides are attached to the wall with an indentation 2 cm less than the width of the wool;

- cotton wool is placed between the guides. If it consists of two layers with different densities, then the soft layer lies against the wall;

- a wind barrier is placed closely on the cotton wool;

- guides for finishing are filled, at the same time a ventilation gap is created;

- the finishing is stuffed.

For facades, material with a density of at least 80 kg/m is used. cube

Insulation of floor and ceiling

A vapor barrier is laid under the stone wool.

Whether it’s a floor or a ceiling, you need to lay a vapor barrier, and then you can lay stone wool on it. The properties of basalt insulation not to absorb moisture do not mean that you can forget about the vapor barrier. But an even more serious mistake is to cover the thermal insulation on top with a vapor-proof membrane. A certain amount of moisture will still get into the material, since it will not be possible to completely insulate it. If you lay a vapor barrier on top of it, then all the moisture will remain in the stone wool, which will lead to the formation of fungus.

How to understand all these insulating films. Let's explain in simple terms:

- vapor barrier - does not allow moisture or steam to pass through, that is, it completely insulates the material. It is placed on the inside of the room, as well as under the insulation, if we are talking about thermal insulation of the floor;

- waterproofing - does not allow moisture to pass through, but steam does pass through (there are options for complete insulation). These are the so-called membranes. They are spread over the insulation so that water does not get into it and steam can escape;

- wind protection - prevents air from entering the upper layers of insulation and deteriorating its properties. At the same time, both water and steam pass through. Used only for ventilated facades.

You should always leave a ventilation gap between films and finishing materials. Although it will not interfere between the foam and the insulation. For work, stone wool with a density of up to 35 kg/m is used. cube

Roof insulation

A vapor barrier is laid between the insulation and the room so that moisture from the room does not enter the thermal insulation layer. A waterproofing membrane is placed behind the stone wool, which releases the steam. Do not forget about ventilation gaps, otherwise condensation and mold will appear. Also remember that insulating films are sensitive to ultraviolet radiation, so they should not be exposed to direct sunlight. To insulate a sloping roof, a material with a density of 40 kg/m is used. cube

Features of insulation

The scope of application of this material is horizontal surfaces, as well as cavities, including vertical ones, formed inside walls specifically for insulation.

Insulation with basalt chips involves one of three installation options:

- bulk;

- blown;

- printed.

Bulk installation method

Everything is simple here: you just need to sprinkle the crumbs in an even layer over the insulated surface. Please note that this method is only suitable for horizontal surfaces. It is not labor intensive, does not require compaction, simple leveling is sufficient.

Insulation with basalt chips. Teplostroy Photos

This way you can insulate a cold attic. A polyethylene film is spread under , placed on top of it . That's right. You shouldn't leave it unprotected.

Blown installation method

Blowing basalt chips is no different from blowing the same ecowool and requires the same professional equipment for implementation. Therefore, you can only produce it yourself by renting a compressor and everything else.

Blowing is designed to fill voids and cavities. It is not used in open spaces.

An important advantage of blowing is the ability to fill hard-to-reach places.

Pressed mounting method

If there is no equipment for blowing, but you need to fill a vertical cavity, then you can use the stuffing method. To do this, the insulation is first poured and then compacted.

It is logical that it will be possible to compact it only if full access to the space being filled is possible. But sometimes this also happens.

By the way, you shouldn’t compact it too much - this insulation performs its function only under the condition of a certain looseness.

Advantages and disadvantages

Stone wool does not absorb moisture, unlike mineral wool.

The advantages of basalt insulation are manifested in almost everything, with the exception of price. Therefore, the question of whether basalt insulation is harmful can be answered with confidence - no. Even despite the fact that such dangerous components as phenol and formaldehyde are used for production. Hearing this, some may jump to conclusions that are not supported by facts. These two substances are bound in the structure of the material and cannot leave it in any way; this is absolutely impossible. If price is important, then there is the option of insulating the house with the most economical material - sawdust.

What is good about stone wool in terms of ecology:

- it is made of stone, that is, a natural material;

- this is not dusty insulation;

- withstands heating up to 1100 degrees without releasing harmful substances;

- complete chemical inertness;

- does not cause irritation to the epidermis upon direct contact.

From all sides the material is extremely positive, therefore it is useless to look for shortcomings in basalt insulation. Of course, if you wish, you can pull them by the ears, but this is no longer constructive.

Vermiculite

It is also a floor insulation material of natural origin. The material is very hard and non-flammable. Water absorption of vermiculite is more than 500%! The insulating properties of vermiculite are simply amazing. With a vermiculite layer thickness of only five centimeters, heat losses are reduced by almost 80%. The material is protected from mold and mildew. Vermiculite is also sold in bags or in bulk. Under certain conditions, such material can last almost forever.

How to choose basalt insulation

So, let's summarize our story today. Let's start with how to choose basalt insulation. Decide whether you need the material in rolls or in mats; you may want to buy loose stone wool. It’s easier to work with mats; they also come covered with foil, which is great for thermal insulation of baths. Then calculate how much insulation layer is needed to know the amount of material needed.

In addition, you need to select the density:

- for floors, ceilings – up to 35 kg/m. cube;

- for pitched roofs – 40 kg/m. cube;

- for walls – from 50 kg/m. cube;

- for facades – from 80 kg/m. cube

As for the health safety of basalt insulation, it is environmentally friendly, the material does not enter into any chemical reactions. Safety for housing is also beyond any praise; it can withstand heating up to 1100 degrees. Why is basalt insulation dangerous? Essentially - nothing, if you don’t organize a witch hunt.

Perlite

This is a natural material of volcanic origin. The material absorbs moisture; studies show that perlite weighing one hundred kilos can absorb up to four hundred kilos of moisture. For this reason, experts recommend perlite for floor insulation in rooms with high humidity. The material is non-flammable. The material is supplied for sale in the form of perlite sand, sold in bulk or in bags.

A remarkable fact: perlite is used not only for insulating floors, but also for filtering vegetable oil, juices and even beer. The service life of the material is extremely long, almost unlimited!

Ecowool (cellulose)

The components of this insulation are ecowool (about 10%), shredded paper (about 80%), antiseptics (about 5%) and fire retardants (about 5%). The material is non-flammable and does not rot over time due to the presence of special impregnations. Ecowool has been used in the world for almost a century! Insulation appeared in Russia and the CIS about ten years ago, but the buyer really liked it and is rapidly gaining popularity. It must be admitted that in Europe they know a lot about construction and the materials that are used for this construction.

Boric acid is used as an antiseptic in ecowool, and borax plays the role of a fire retardant. These substances are 100% environmentally friendly. This insulation material is quite practical in every sense. Ecowool fibers perfectly fill small voids, so the material can be used even for the most complex structures.

Tips for choosing

You need to choose the material based on your goals and objectives. The characteristics of thermal insulators should be taken into account, because some are not suitable for hot rooms, while others tolerate moisture and elevated temperatures well. In addition, some bulk insulation materials are very hard and are suitable as a substrate or base for a floor.

In any case, one general piece of advice can be given; it concerns the fact that it is worth purchasing these thermal insulators in trusted places with good reviews, so as not to run into fake or low-quality products.

In general, it must be objectively admitted that bulk insulation materials are very attractive in terms of prices. We also must not forget about their durability; classic mineral wool will last no more than ten years or twenty at best. And for bulk insulation materials, the service life is much longer, many times!

You also need to understand that not all bulk thermal insulators are the same. They differ in their properties. Certain tasks require certain materials. If you are in doubt about your choice, then contact a specialist with this question; he will be able to advise you on the right materials.

For example, expanded clay is not suitable as the main insulation in regions with extremely harsh winters (frosts of 40 degrees). This needs to be taken into account. In addition, there are many other nuances, which is why consultation with specialists is extremely important for each individual case.