A warm roof guarantees heat retention inside the house.

According to the laws of physics, warm air masses tend to rise. If the roof does not have a thermal insulation barrier, then the heat will quickly leave the house, and it will be replaced by cold.

To prevent this from happening, pitched roofs are insulated along the rafters.

Choice of insulation

Before you begin installing the roofing pie, you need to decide what materials you will use for insulation. The number of layers and thickness of thermal insulation directly depends on this. The most popular materials are:

- Polyurethane foam.

- Extruded polystyrene foam.

- Glass wool.

- Mineral wool.

- Foam glass or natural insulation in the form of wood chips, granulated paper, and so on are less commonly used.

Parameters that you should pay attention to when choosing insulation:

- Thermal conductivity (coefficient).

- Moisture resistance.

- Fire resistance.

- Eco safety.

The higher the moisture resistance of the material, the longer such insulation will last. The fire resistance indicator is the most important criterion for meeting fire safety requirements. The last two parameters determine how safe and environmentally friendly the insulation is for humans. These indicators in no way affect the effectiveness and durability of the material.

Installation of Penoplex slabs on top of rafters

As a rule, it is used in cases where it is not possible to use other insulation. This is possible if a residential building is built from scratch. Penoplex slabs can have a thickness from 60 to 120 mm.

Stages of work:

- After installing the rafters, a batten is attached to the bottom, the width of the insulation being thick. This will prevent the slabs from sliding down.

- Then the insulation is laid out in a checkerboard pattern.

- A vapor-permeable waterproofing film is laid on top.

- A sheathing of wooden blocks with a cross-section of 40×40 mm is installed to provide an air gap. The beams are fastened with self-tapping screws, but before fastening you should drill holes in the “penoplex”.

- Roofing material is mounted on top of the sheathing.

Penoplex does not require additional protection.

How to attach mineral wool insulation between wooden rafters

Mineral wool insulation between rafters can be secured in several ways. One of the most common is laying slabs or cut sheets between the rafters without fastening. In this case, the distance between the rafters should be 2-3 centimeters of the width of the insulation. The mineral wool is laid tightly, with slight tension.

Before laying, the mineral wool is unpacked and given time to lie down, take the desired shape, and then cut into slabs or sheets of the desired size. It is imperative to work with mineral wool in special clothing that fits tightly to the body so that microparticles do not get on unprotected areas of the skin, and of course, wear gloves on your hands and a respirator on your face.

The first described method of laying mineral wool is reliable if the thickness of the insulation boards is no more than 10 centimeters. Often the attic space is insulated with several layers of mineral wool and the slabs can fall out of the space between the rafters during work (and the force of attraction to the ground acts on the insulation). The insulation requires additional fixation.

You can secure the insulation with a large number of slats. And this is best done using nylon thread or polymer twine, or soft steel wire. To do this, hammer nails along the rafters and then pull the thread or twine in a zigzag pattern. Instead of nails, you can attach thread or twine directly to the rafters with staples. The distance between the fastenings is no more than 20 centimeters. The insulation, fixed in this way in the opening between the rafters, will be securely fixed.

Mineral wool is laid between the rafters without additional fastening.

In order to avoid problems with the installation of mineral wool, it is necessary to measure the distance between the rafters.

Mineral wool is cut so that its width is greater than the pitch between the rafters, two or even three cm more.

Before installing mineral wool, lathing is placed at the bottom of the rafters.

The laid mineral wool + lathing that holds it is the so-called “fastening” of the mineral wool.

Before installing the roofing material, a waterproofing film with a slight sag and overlap is attached on top of the mineral wool.

The film is attached to the rafters using staples and a stapler.

A vapor barrier is installed at the bottom of the sheathing, which will protect the mineral wool from fumes coming from the warm room.

Glassine can be a vapor barrier (the least expensive option.

The glassine is also secured with staples to the sheathing.

Next is the counter lathing and installation of the finishing material.

If you attach mineral wool from the inside of the roof (for example, you are insulating an attic), then in this case the mineral wool is placed tightly (by surprise) between the rafters,

But before installing it, we attach the waterproofing, and then the vapor barrier.

In some cases, string is used to hold the mineral wool between the rafters.

First, taking into account the thickness of the insulation, nails are driven into the side of the rafters.

Then the string is stretched (thin wire and fishing line will do).

Features of fastening insulating panels

Before you start insulating the attic yourself, you should read the instructions for carrying out this work.

Insulating the attic consists of the following steps

:

1. Preparing the space. 2. Direct installation of thermal insulation. 3. Final fixation of all material.

At the first stage of installation work, the pitch of the rafters is determined. If the material for insulation has already been selected in advance, then to make your work easier, the rafters must be lined up so that the insulation boards fit closely between them. This will not only simplify further work, but also minimize material waste.

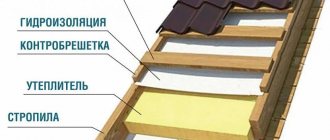

Between the sheathing and rafters, waterproofing is laid on top of the thermal insulation. Laying is carried out from the bottom edge, laying the material overlapping each other. Next, the counter-lattice is installed, in the form of wooden slats using nails or self-tapping screws. Mounted slats provide ventilation space between the roofing material and the insulation. Next, insulation is attached between the rafters.

It should be noted that you should not limit yourself to laying insulation only between the rafters, since the rafters themselves, due to their low thermal conductivity coefficient, serve as a bridge for the penetration of cold. Therefore, it is also recommended to use such a method of insulation as “solid layer insulation”; for this it is worth using a thin type of insulation. This method improves the quality of insulation. However, there is one drawback: with such insulation, the rafters are completely hidden, so it will be difficult to attach the following elements. But to prevent such an incident from happening, accurately mark the location of the rafters in advance.

After installing the insulation, it is necessary to lay a vapor barrier to remove excess moisture and allow the unhindered passage of steam through the roof. Next, a frame should be mounted from wood or metal profiles to fasten the ceiling, after which the final part of the whole work is performed - covering the ceiling on the inside of the attic.

Methods for attaching thermal insulation panels

There are two types of fastening of insulating panels: nails and staples.

Fastening panels with nails

. The panel is nailed with stainless steel nails or screwed directly to the rafters with self-tapping screws. But, if the rafters are located at such a distance from each other that it does not allow attaching the insulation panel, a beam should be secured between them, to which the insulation panel will be attached.

Fastening panels using special brackets

.

The staples must be pressed against the rafters, then a thermal insulation panel is placed on them and the staples are secured with self-tapping screws or nails. The next panel must be connected with a groove to the previous one and the bracket must also be secured to it.

Next, we will consider fastening insulating panels if the pitch of the rafters is uneven

, and mineral wool insulation is made in several layers.

The first layer is attached between the rafters, leaving a gap of 1-2 cm to ensure the necessary ventilation.

For the second layer, thin wooden slats are installed, similar to roofing counter-lattice, in order to level the plane of the rafters inside the attic.

After you have completed all of the above, you need to install and attach the insulating boards to each other. Do not forget to tape the seams between the panels on the inside of the room with adhesive tape. And then, you need to secure the drywall using U-shaped fasteners.

Installation of thin thermal insulation material

. The main advantage of thin material is that with its help you can save part of the room area.

So, let's begin the process of covering the wall. First, using scissors, you need to cut the material into sheets, the width of which will be 3 cm greater than the distance between the rafters. Next, you need to attach a wooden beam to the rafters, observing a step of 60 cm. The insulation strips must be attached by creating an overlap of 5 cm between them. It is also necessary to leave ventilation gaps.

Next, you need to cover everything with plasterboard using appropriate fastening materials, and the distance between fasteners should not exceed 2-25 cm.

If the entire sequence of insulation work is followed correctly, the attic can serve as a living space all year round, in which it will always be comfortable.

Combined insulation

Combined insulation increases the surface's resistance to heat loss. In this case, it is possible to use materials with different characteristics, comprehensively protecting the roof. In this case, the cost of work increases. But reducing the payback period brings the technology to the level of the most widely used.

Often, two layers of insulation are carried out in the distances between the rafters and on top of them. Light and soft mineral wool boards are used inside. They provide basic thermal protection by retaining heat indoors.

Rigid slab insulation is installed on top of the rafters. Basically, fibreboards are used for its construction. The joints of the slabs should be on the rafter leg. In this case, the products will be secured and the seams will not blow through.

This method is convenient when repairing the roof or covering it. The old insulation is left if it meets its functions. Also, an additional layer of insulation neutralizes the voids inside the main protection.

The combined thermal protection between the rafters and inside the room is quite effective. The following is used as internal insulation:

- cork sheet or slabs;

- penofol;

- drywall.

Rolled rafter insulation materials are attached to them using wooden slats. It is better to use foamed polyethylene substrates. They do not allow steam to pass through, thereby providing reliable protection for the next layer. The most commonly used are products with a reflective layer. The foil coating allows you to retain heat inside with a minimum thickness of insulation.

Plasterboard insulation requires the creation of a frame. In addition, the sheets have a certain width that needs to be calculated. But plasterboard will also provide noise protection

This is especially important when installing metal tiles

The most effective is three-layer insulation. In this case:

rafters are closed from internal and external influences; high-quality noise protection is provided; by covering the joints of materials with layers, complete thermal sealing of the room is ensured; Defects in the installation of one layer are compensated by the correct installation of the other two

This is important for additional insulation during roof repairs. This scheme is used in Germany for the construction of houses called Passivhaus

In such houses there is no need for heating or the costs for it are minimal. According to the standard, they amount to 10% of the energy consumption of a typical home

This scheme is used in Germany for the construction of houses called Passivhaus. In such houses there is no need for heating or the costs for it are minimal. According to the standard, they constitute 10% of the energy consumption of a typical home.

When installing thermal insulation, it is worth remembering that the work belongs to the hidden cycle. It will be impossible to control the correctness of execution after finishing. Therefore, it is worth selecting only high-quality materials for roof insulation between the rafters and complying with all installation requirements.

How to insulate rafters: options and rules for installing thermal insulation for attic roofs

When laying, you need to ensure that the joints of the material do not coincide with the joints of the previous layer.

- The final stage is the outer cladding, for which any finishing material can be used.

This roof insulation technology is considered the most effective, therefore, when deciding how to properly insulate a roof with mineral wool, you should give preference to this option.

Conclusion

Insulating the roof from the inside with mineral wool is a fairly effective means of protecting the roof from the cold. Knowledge of the theory and competent implementation of the chosen technology will allow you to create a reliable roof, under which it will be possible to arrange a living space in the future.

Insulation between rafters

The traditional way to insulate a sloping roof is to place the insulation between the rafters. In this case, you can arrange a flat ceiling in the attic space.

Before starting insulation, you need to install a waterproofing film over the rafters. It will protect the room from possible precipitation and allow work to be carried out in any weather. It is better to choose a diffusion membrane. When installing a micro-perforated or anti-condensation coating, a two-sided gap is created. Condensation often forms on the films. Its contact with the insulation:

- will increase the thermal conductivity coefficient;

- will lead to damage to the insulation;

- promotes the development of mold;

- will reduce the load-bearing capacity of roof elements.

The insulation is not laid to the full height of the rafter leg. A gap of 2-3 cm is enough to ensure air flow and natural drying.

With this technology, low-density insulation is often used. For proper operation, such insulation needs to be additionally fastened, which leads to excessive consumption of frame material.

Often soft insulation shrinks during operation. Deformations occur both in width and height. As a result, some areas become bare, becoming defenseless against the cold.

It is not recommended to use insulation in the form of dense materials: polystyrene foam, polyurethane foam. Due to the instability of dimensions, gaps form between the rafters and slabs. The use of polyurethane foam does not help the situation. Blows are formed.

Mineral wool thermal insulation Stone (basalt) wool Glass wool

Slab-type mineral wool is best suited for insulation inside rafters. When laying, the joints of the slabs are shifted by half the width of the product. In this case, the formation of cold bridges is prevented.

Seam bandaging is also important for multi-layer installations. The next product should overlap the seams of the previous flooring. For multi-layer installation, products of maximum thickness are used. For example, for insulation with a 150 mm layer, it is better to take 100 and 50 mm material than three 50 mm slabs.

When the slope angle is less than 30°, an additional frame is installed under the insulation. It will prevent the slabs from sliding and caking. The frame holds the slabs in the installation position during their entire service life.

The accepted width of the slabs should be 1-1.5 cm greater than the clear distance between the rafters. In this case, a tight connection will be ensured. With a smaller width, cracks will appear due to wood defects or builder oversights. Large thickness contributes to the deformation of the slab and its bending.

There should be no air gaps or cracks inside the insulation of pitched roofs along wooden rafters. The layers should be adjacent to each other tightly. This also applies to interlayer spaces and joints. Professionals lay the slabs by cutting them into two trapezoidal parts.

Polyurethane foam (PPU)

Another innovative method of insulation is polyurethane foam. The covering can be installed both after the installation of waterproofing and after the installation of the roof covering.

The application process is spraying. The work is carried out using special equipment. It is mandatory for the employee to have protection in the form of:

- suit;

- masks;

- respirator

Foam is applied both in the gap between the rafters and on the load-bearing elements of the roof. They must first be treated with antiseptics or an anti-corrosion solution. Foam:

- clogs the smallest air vents and cracks;

- hides bolt holes;

- covers all metal elements, protecting them from corrosion.

A continuous layer prevents the penetration of drafts and moisture. Low thermal conductivity allows you to reduce the cost of heating the under-roof space.

The second innovative continuous covering material is ecowool. The name itself speaks of environmental friendliness and safety of use.

Ecowool

The composition includes fire retardants and antiseptics. The former prevent the layer from igniting, the latter prevent the spread of fungi and mold inside. The bulk of the composition is waste paper and waste from cardboard production.

Laying is done dry and wet. When laying dry, the rafters are sewn up from the inside with facing material. The material is placed into the resulting boxes. With the wet method, wet cotton wool is applied to the surface under pressure. High adhesion of the material allows you to cover the surface with a dense, uniform layer.

Where to start insulating the attic

A few tips on the first thing you need to do before insulating the attic

:

1. Before starting work on the attic insulation, it is necessary to diagnose the building

.

The roof should not let moisture into the room, because if this is not noticed, all the work will be done in vain. 2. It is also important to check for cracks and crevices along the walls

.

For example, if, when diagnosing the inside of the attic roof, you find darkening, this means that warm air in the ceiling area condensed in winter. This means that the roof insulation in that area has been compromised. 3. It is very important that before installing the insulation, you need to check the condition of the walls

.

The walls must be smooth, without cracks, without chips, and also without excess plaster that has come loose. 4. It is necessary to check the entire attic structure and, if necessary, treat it

.

After all, after installing thermal insulation, you will no longer be able to do this. 5. If you have chosen mineral wool as the insulation of the attic roof, then you need to install a vapor barrier film from the inside of the attic, in other words, a vapor barrier, it will protect the insulation from moisture that will come from inside the room

.

It is worth noting that the vapor barrier is installed from the inside of the attic after all the insulation has been fixed, regardless of the number of layers of insulation. 6. It is very important that there is a ventilated gap of 2 to 4 cm between the insulation material and the under-roof waterproofing

.

But if the width of the rafter leg does not allow such a gap, a superdiffusion membrane should be installed instead of a standard water barrier, which will provide the necessary ventilation. 7. If you use mineral wool as insulation, you need to remember a few simple rules

.

Firstly, the more the cotton is compressed, the less it works. The mineral wool should be in a fluffy state, but it should evenly cover the entire plane of the roof, without cracks or gaps. Secondly, when insulating in several layers, the wool should be placed in a checkerboard pattern, this will eliminate the appearance of unnecessary gaps between the plates. 8. Don’t forget about the ventilation holes; they are provided by installing special roof aerators

. According to the standard, for every 100 sq.m. one aerator is installed on the roof.

Do-it-yourself installation of mineral wool on rafters

If the width of the thermal insulation material does not allow it to fit into the space between the rafters, its installation will have to be carried out in two stages. One layer of material will be laid according to the technology described above, and the second will be laid on top of the already installed layer. Such insulation of the roof with mineral wool is much more expensive, but the result is of better quality.

Insulation of the roof with mineral wool along the rafters is carried out according to the following algorithm:

- The first steps exactly repeat the installation algorithm between the rafters - the installation step of the rafter legs is measured, after which the insulation is cut so that it can be mounted by surprise. When using rolled material, you need to let it lie flat for a while.

- During installation, the edges of the slabs are folded inward, and after installing the insulation, they are straightened.

- A vapor barrier is attached to the rafters using a stapler. The rules are still the same: strips of material are laid with a slight overlap so that steam does not pass through the joints.

- Slats are nailed horizontally to the rafters, the thickness of which should exceed the thickness of the insulation by 1-2 cm. The distance between the slats should be sufficient for laying heat-insulating boards.

- Mineral wool is placed between the stuffed slats.

Installing insulation in the interior of the house

If the thermal insulation layer is placed in the lower part of the rafters, then the under-roof waterproofing is mounted in the upper part along the rafters. There is no need for solid wooden sheathing here, because in any case you will have to deal with a large gap (it is often located along the entire size of the rafters). However, when using a similar technique, the total volume of the attic is also reduced.

Algorithm for roof insulation, how to lay thermal insulation

Installation of a roof with insulation comes down to the following sequence of actions:

First, the installation step of the rafter legs is measured. The heat-insulating material slabs are cut in accordance with the obtained dimensions, but 1 cm is added to them - this will allow the insulation to stay in place on its own. You can simplify this stage of work when installing a new roof by calculating it so that the distance between the rafters corresponds to the width of the insulation boards. A waterproofing layer must be installed in the space between the rafters and the finishing coating. The membrane must be attached to the rafters so that it envelops them. For fixation, you can use a construction stapler, which attaches the waterproofing to the rafters and sheathing. Waterproofing material must be applied to the eaves so that the collected moisture escapes beyond the roof. The described method of fastening does not allow for proper ventilation, so only a special waterproofing membrane should be used as a material. If waterproofing is already installed under the upper part of the roof, then nails are driven into the rafters every 10 cm so that the distance between them and the membrane is at least 3-5 cm. The driven nails allow you to stretch a cord along the line of which the air gap will pass in the space between waterproofing and thermal insulation material. If the insulation itself is attached using a cord, then the nails will also need to be hammered along the outside of the rafters. When using insulation materials produced in the form of slabs, installation is reduced to inserting them into the space between the rafters (naturally, they will have to be compressed a little so that they fit into the gap). Before properly insulating the roof, more rigid materials must be carefully adjusted to fit the gaps in the rafter system. For maximum efficiency, it is worth installing two-layer insulation. When installing narrow fragments that require joining along one of the planes, you need to make sure that the joints of the first and second layers of thermal insulation do not coincide with each other. The thermal insulation layer should not extend beyond the rafters, and if this happens, then additional timber will have to be placed on the rafters. To attach the insulation, a cord stretched between nails or a lath made of slats can be used. These slats need to be nailed to the rafters at a distance of 30-40 cm from each other. In this case, the vapor barrier layer must be attached before the sheathing is installed - due to the thickness of the slats, an air gap is provided. When installing a vapor barrier, you need to make sure that the material is installed hermetically. To do this, the joints need to be covered with two layers of adhesive tape.

Particular attention should be paid to the points where the material connects to the wall and chimney. When all structural elements are installed, you can proceed to the final stage - installation of the sheathing.

Conclusion

Roof insulation is a very important part of the structure, which allows you to increase the thermal efficiency of the roof. Knowing how to properly install insulation on a roof and high-quality performance of all work will allow you to create a reliable and high-quality structure that will perform its functions throughout the entire period of operation.

Thickness calculation

An accurate calculation of the thickness of the thermal insulation material for roof insulation can only be made by someone who masters such a discipline as heating engineering. Therefore, in most cases, this parameter is determined according to the recommendations of professional roofers in a given region .

The calculation is based on the lowest winter temperature in recent decades in the location region. You can also use special tables from regulatory documents.

There are calculators on the Internet to calculate the thickness of a certain type of insulation. Data about the type of pitched roof, the region where the house is located, and the name of the thermal insulation material are entered into the meter interface windows. As a result, the desired value is obtained.

On a note. According to long-term practice in the middle climatic zone of Russia, the thickness of the insulation is 100 - 200 mm. Information about this indicator from the owners of neighboring multi-year houses also helps in this matter.

Works inside

After the roof has been installed, the laying of mineral wool between the rafters inside the attic begins. The mineral wool must be unpacked, allowed to rest for a while and straightened out, and then cut into pieces equal to the distance between the rafters with the addition of 3-4 cm.

The material should be pressed between the rafters with little effort to fill the entire space.

A vapor barrier film is placed on top of the mineral wool to the rafters, using the same technology as outside. Next, a gap is again made for ventilation, onto the sheathing of which the interior decor of the ceiling and walls of the attic is mounted.

This could be plasterboard for further finishing or lining for painting.

conclusions

In general, insulating the roof along the rafters is a rather labor-intensive process, but if done correctly, it will be possible to live in the attic even in winter. The main thing is not to forget about the obligation of steam and waterproofing.

Also interesting: professional turnkey roofing work https://ck-avtoritet.ru/krovlya/. Excellent quality and excellent prices for the entire range of work.

The need for roof insulation How to properly insulate a flat roof Insulation of a pitched roof Materials for insulation of a pitched roof Roof insulation algorithm - how to lay thermal insulation

In order for the roof to perform its functions efficiently and serve for a long time, it must be insulated. There are a lot of materials and methods for installing a heat-insulating layer, and the choice of the appropriate technology is always done individually. This article will discuss how to properly install insulation on the roof of a private house.

Vapor barrier

This is a necessary polymer shell that cuts off internal vapors from the insulation and prevents moisture from condensing on the surface of the insulation, which protects it from destruction. The vapor barrier covers the insulation materials, which helps create a comfortable microclimate inside the attic.

PVC film insulation is an accompanying material for roof thermal insulation. A film with a rough surface retains condensation until it evaporates completely. Installation of such a film occurs with the smooth side facing the insulation.

How to install insulation in the attic

The main thing is not to confuse its sides. On the outside it is covered with a moisture-proof layer. Laying is done from the cornice upwards, the canvases overlap by 10-15 cm and all joints will need to be taped with construction tape. To attach the film to the rafters, it is most convenient to use a construction stapler or you will have to work with a hammer. The main thing is that the nails are galvanized.

It is not recommended to stretch the waterproofing film over the rafters. As temperatures drop, it will begin to shrink a little and simply become damaged at the fastening points, and the canvas may also come apart with the formation of gaps.

Next, a lath is placed on top of the superdiffusion membrane. It will require wooden slats of 2.5-5 cm, depending on the planned space for ventilation and the type of roofing material. Galvanized self-tapping screws are quite suitable as fasteners. Finally, the roofing covering is installed on top of the sheathing.

If the insulation is carried out in an attic with an already laid roof and if the waterproofing was missed during its installation, then the roofing material will need to be removed and the film laid. Otherwise, the under-roof insulation will get wet and lose all its thermal insulation properties.

If membranes are laid from the inside and wrapped around rafters, they will simply begin to rot from excess moisture.

The technology considered involves the use of sheet roofing materials (slate, metal tiles, corrugated sheets). To insulate a soft roof along the rafters, you will need to nail moisture-resistant plywood over the sheathing, and then attach the finishing coating to it.

Preparing the roof for laying insulation

If you follow the technology, then the insulated roof consists of several layers, replacing each other.

When insulating the roof, it is necessary to observe consistency, because each component element performs its assigned function and must be located in a designated place.

In addition, during the process of roof insulation, it is important to ensure proper ventilation, vapor barrier and waterproofing.

Roof insulation by laying material between the rafters is the most popular, despite the difficulties in installing the heat-insulating layer.

In this case, a layer of insulation is laid along the height of the rafters and fastened between them.

In this regard, it is better if the size of the prepared insulation sheets is 20 - 30 mm larger than the distance between the rafters.

If this is not possible, then there will be a need to create additional fastenings that will keep the insulation from falling and sagging.

This can be a fishing line, stretched and fixed with nails driven into the lower edge of the rafter legs.

You should think about the waterproofing layer in advance. If the roofing material has not yet been laid, then a waterproofing superdiffuse film is spread on the rafters, designed in such a way that it does not allow moisture to pass through from the outside, and vapor in the opposite direction.

They begin to attach the film from the eaves overhang, moving upward. The canvases are laid with an overlap of 10 - 15 centimeters, while securing the joints with adhesive tape.

The membrane is attached to the surface of the rafters using construction staples or nails with a wide head to avoid damage.

It is very important not to stretch the waterproofing membrane: when the temperature drops, the material contracts, which can lead to its damage, and consequently to damage to the entire structure. The membrane should be laid with a slack.

As a rule, roof insulation is carried out before installing the roofing material.

However, there are situations when it becomes necessary to insulate the roof from the inside: lack of thermal insulation, insufficient amount of insulation installed previously, or when insulating an old house.

In this case, laying insulation is possible, but it will not be as reliable and durable.

The waterproofing film is laid indoors without dismantling the roofing material.

For this purpose, it is necessary to wrap the rafters with film and lay it in the space between them, and then follow the standard pattern.

However, this design does not protect the rafters from the elements, which can lead to premature wear.

Next, a ventilation gap should be formed to help remove vapors escaping from the heat insulator.

To do this, a wooden sheathing of slats is placed on top of the waterproofing layer, secured with self-tapping screws.

It is good if holes for fastening are prepared in the slats in advance, which will avoid damage to the waterproofing film.

Basic functions of thermal insulation

Properly performed insulation work ensures a good microclimate in the interior. In cold weather, heat will be retained, and in hot weather, the air will not overheat. Installation of high-quality thermal insulation is impossible without knowledge of the correct procedure for implementing a roofing pie and what materials/tools are best to use

The work process is no different from insulating conventional roofs. However, increased demands are placed on attic spaces. Because the walls of the living room are made of slopes and gables of the roof or are tightly adjacent to them. Accordingly, in the warm season the structure heats up greatly, and in cold weather it cools down quickly.

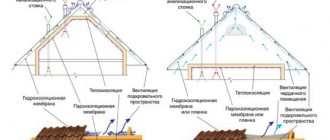

The attic roof pie consists of the following elements (the order goes from inside to outside):

- Vapor barrier layer.

- Insulation material.

- Gap for ventilation.

- Waterproofing layer.

- Roofing flooring.

Pay special attention to the thermal conductivity of the material. Using this parameter, you can easily determine the ability to transfer heat both into and out of the room.

The lower the number of this indicator, the slower the air temperature in the attic will fall.

If the room is heated, the greatest heat loss occurs through the roof. This is because the heated air is directed upward. If the roof is poorly insulated, it will be quite difficult to maintain the required temperature in the house.

Why do you need to insulate your roof?

A third of a home's heat loss occurs through the roof. Therefore, high-quality roof insulation primarily saves money on heating the house.

The infrared photo clearly shows that there is no heat loss through the insulated roof

Insufficient waterproofing and insulation of the under-roof space leads to the formation of dampness. It penetrates the load-bearing elements of the roof frame, as a result of which their service life is reduced.

Insulating a pitched roof allows you to turn the attic into a full-fledged living space.

Insulation of a pitched roof

Thermal insulation of a pitched roof is installed on the rafter system. Before laying insulation on the roof, it is necessary to design it in advance in order to avoid installation errors.

A pitched roof consists of the following elements:

- Roofing;

- Waterproofing layer;

- Thermal insulation;

- Vapor barrier material;

- Interior finishing (optional).

Mineral wool is most often used as a thermal insulation material, which has high performance characteristics and is relatively inexpensive. The main disadvantage of mineral insulation is its ability to absorb moisture, which is why its thermal insulation properties are lost over time. In addition, the presence of moisture under the roof leads to the gradual destruction of wooden parts.

To compensate for the described disadvantage, the structure must be supplemented with ventilation, hydro- and vapor barrier. The insulation itself on the roof of the house is laid on the underside of the roof during its arrangement or repair. If we are talking about repairs, then damaged wooden elements should be replaced, and new ones should be treated with protective compounds before installation.

In addition, for effective insulation and reliability, the roof must be well ventilated, so it is necessary to install ventilation ducts between:

- A layer of waterproofing and finishing coating;

- Thermal insulation and waterproofing layer;

- Vapor barrier material and internal lining.

The need for insulation of the roof structure

To minimize heat loss at home, you need to select high-quality insulation and install it according to technology. Special requirements are imposed on the thermal insulation of the roof structure of a residential attic. The roofs of used attics and summer attics are not subject to such strict requirements, which makes it possible to use thinner layers of thermal insulation. The roofs of unused attics may not be insulated, and to keep the house warm, insulation is laid on the ceiling.

Installation of insulation using technology

Insulation of an attic roof using technology comes down to the following steps:

- Preparing the site for laying the insulating layer.

- Installation of thermal insulation material.

- Fastening the insulation.

Even at the time of designing the rafter system, you should take into account the step in which the rafters will be installed

Please note that the design must be reliable. Do not exceed recommended values

If the insulation was selected at the stage of calculating the rafter system, then place the rafters so that the thermal insulation slabs are well located between them from the inside. Everything should be close. In this case, you will simplify installation and the amount of waste will be significantly less.

Waterproofing is installed on top of the insulation in the area between the sheathing and rafters. The material must be overlapped. It is recommended to start from the bottom edge of the slope.

Next, you need to mount wooden slats, the thickness of which will create the necessary gap for roof ventilation. They can be secured with nails or self-tapping screws. An insulating layer is laid and fixed on the prepared structure from the inside between the rafters.

Rafters made of wood/metal are a cold bridge, because the thermal conductivity of the material is significantly lower than that of insulation.

Accordingly, you additionally need to lay a continuous layer of thermal insulation on top of the already installed mats. The same type of material, only thinner, is perfect for these purposes.

This approach will allow you to achieve improved thermal insulation performance. The only drawback of this solution is the inaccessibility of the rafters for fastening other structural parts. To make this task easier, mark in advance the places where the rafters are located.

Place a vapor-permeable film on top of the thermal insulation. It will help remove excess moisture. The entire structure is secured with lathing. The final stage is the interior finishing of the ceiling.

To summarize, we note that properly insulated attic roofs will allow you to use the attic space all year round for various purposes (including living). Apply our recommendations in practice, and you will achieve your goal many times faster and with better quality.

Roof thermal insulation technology

Heat loss through the roof of a building can account for about 20% of the total heat loss occurring through the structural elements of the building.

The use of insulation is guaranteed to reduce the level of heat loss in the cold season and can reduce overheating of the attic or attic in the summer. In addition, the implementation of thermal insulation of the pitched roof will make the attic space insulated, which will allow achieving a significant increase (up to 40%) in the usable area of a private house without significant financial costs.

The following three schemes for laying the thermal insulation layer are considered the most effective:

- Between the rafters is the easiest way. To use it, it is necessary to correctly calculate the thickness of the heat insulation layer; it should not exceed the thickness of the rafters.

- Between and under the rafters - this method is popular for regions with high rainfall. Allows you to cover the roof as quickly as possible, in order to avoid damage to the building from possible vagaries of the weather.

- Between the rafters and above them - this technique will allow you to install thermal insulation even if its thickness exceeds the thickness of the rafters. In addition, space is saved on the attic floor.

Do-it-yourself installation of mineral wool from the inside

The easiest way would be to attach the thermal insulation between the rafters from the inside of the roof structure. This technique will be effective only if the thickness of the insulation layer is less than or equal to the width of the rafters. Otherwise, you will have to resort to a combined method of roof insulation.

In this case, the procedure for insulating the roof using mineral wool will be as follows:

- First, you will need to measure the lower tier of the rafters using a building level. This indicator should be uniform along the entire perimeter of the structure. If deviations are found, the support will need to be leveled, ensuring that the rafters are on the same line.

- To protect the insulation from the negative effects of moisture, a waterproofing membrane is laid on top of the rafters. If you refuse to use it, the thermal insulation layer will not be reliably protected, which may shorten its service life.

- Rolled insulation needs to be cut into pieces of the required size. The material is fixed between the rafters by surprise. Based on this, the pieces of thermal insulation should be three centimeters wider than the space between the rafters. When laying the material in two layers, it is necessary to ensure that the joints of the layers do not coincide with each other.

- The next step will be the process of adjusting the vapor barrier. The membrane is cut into strips, which are installed above the insulation layer. It allows you to protect it from dampness and air. The vapor barrier layer is installed horizontally from top to bottom, after which it must be fixed using a construction stapler.

- The final stage is the finishing of the thermal insulation. For this, edged boards, plywood or plasterboards are most often used. Upon completion of the work, this layer will become the basis for finishing the attic walls.

If the slope of the roof slopes is less than 25 degrees, this may cause the following problem: the slabs used for insulation may fall out because the pushing force is not enough. To avoid this situation, it is recommended to additionally strengthen the insulation using slats or strong fishing line, which will be stretched between the rafters. If the slope has a large slope, the likelihood of encountering such a problem is minimal.

Thermal insulation inside and out

Another method of laying insulation is a combined scheme, which involves two-layer insulation. In this case, the thermal insulation is divided into two parts: one of them is laid between, and the other under the rafters.

In this case, it is recommended to use glass wool or its mineral analogue with a standard density as a material. The top layer of insulation must be as strong as possible to prevent compression. Here it is better to use basalt slabs or wood fiber options. When you start installing the top slabs, you also need to cover the rafters to prevent cold bridges from forming.

First you need to install waterproofing, which is also attached using special nails or a stapler. You can then install insulation between and under the rafters. The inner layer is installed between the transverse elements of the beams so that the rafters are completely hidden. In this case, the dimensions of the thickness of the thermal insulation and timber must be equal.

Vapor barrier material is placed between the insulation. However, in this case there are small additions: to prevent condensation from appearing, the internal thermal insulation layer must exceed 20% of the main thermal resistance. Another option that is practiced by craftsmen is to install a vapor barrier on top of the internal insulation. However, there are some risks: the film may be damaged during interior decoration, installation of lighting fixtures, or installation of electrical wiring.

Pros and cons of the material

Table with the characteristics of mineral wool

Roof insulation with mineral wool has the following positive properties:

- high heat-protective characteristics;

- strength and durability;

- resistance to biological influences (mold, fungus, rodents);

- resistance to fire and high temperatures, which is especially important when ensuring the fire safety of a wooden house;

- when insulated from the inside, the slabs hold quite well without additional fastening (during operation, the bottom sheathing becomes an additional holding element);

- Do-it-yourself thermal protection with mineral wool ensures free movement of air through the material, this has a beneficial effect on the microclimate of the premises of the house.