A cellar can be found in almost every courtyard of a private house or summer cottage. It is there that people store their supplies of collected/purchased fruits and vegetables, including canned ones.

In this room it is necessary to organize proper air exchange, otherwise the products stored in it can quickly deteriorate. This is especially true in winter, when temperature and humidity levels change the most.

Because of such conditions, people often wonder whether it is necessary to close the ventilation in the cellar for the winter, or leave everything as is. To answer this question, you need to understand in more detail the operation of the ventilation system of this room.

The need for ventilation in the cellar

The safety of the crop is the result of good ventilation.

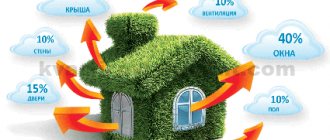

The movement of air that enters and exits the cellar through vents, as mentioned above, is very important for storing food. Ventilation in the cellar performs the following functions:

- maintaining the required level of oxygen in the room;

- changes in temperature inside the cellar, as well as humidity levels. A properly organized ventilation system helps normalize the indoor microclimate;

- protection against the appearance and development of microorganisms harmful to products;

- increasing the shelf life of fresh vegetables and fruits.

Even if nothing is stored in the cellar for most of the year (or all products are not perishable), it is still worth taking care of minimal air exchange.

If the temperature and humidity inside are not controlled at all, excess moisture will constantly accumulate on all surfaces.

And in winter it will also freeze, and an ice crust will appear on the walls. The owners of the cellar will obviously not like all this.

Be careful of gases!

It is known that gases accumulate in closed cavities near the surface of the earth, from which people suffer. If you climb into a deep, unventilated cellar or well without protective equipment, you can suffocate. This will not happen in residential premises, but harmful gases, for example, radon, methane and others, can leak into the rooms through micropores.

Another unpleasant feature of radon is radioactivity. Although the concentration of radionuclides is low, they accumulate and can cause dangerous diseases.

Features of air exchange in the cellar in winter

Typically, air exchange in the cellar is carried out through several pipes. For a small room, just one is often enough.

The pipes must be equipped with special valves - thanks to them, it is possible to control the operation of the system.

Ventilation in the cellar in winter requires special care. Before the onset of cold weather, it is highly advisable to insulate the air duct (mineral wool or expanded polystyrene are ideal as insulation), and also provide at least minimal waterproofing so that water does not penetrate into the cellar. All this will allow the system to work and perform its function without failures.

It is worth keeping in mind that at low temperatures the air circulates at a higher speed. This means that the temperature in the cellar will drop faster.

Therefore, it is advisable to regulate the level of air intake in advance if the weather forecast indicates the onset of frost.

Even if the entire system was very well insulated, this does not give a 100% guarantee that there will be no frost or frozen water on it. This can significantly impair air circulation.

Therefore, in winter it is important to inspect and clean your air ducts at regular intervals. To make the process easier, you can make the most problematic areas removable.

Making air vents at the foundation construction stage

Ventilation holes are made at the stage of arranging the formwork structure. Pieces of sewer pipes of appropriate length can be used as vents.

To make an vent in the base in the form of a concrete strip, you can use the following technology:

- The formwork is assembled and the foundation is reinforced (read our article on the construction of an armored belt).

- The locations of the vents are marked on the walls of the formwork in accordance with preliminary calculations.

- Make through holes of the appropriate size on both sides of the formwork.

- The prepared pipe sections are wrapped in a layer of roofing felt and placed in the holes made. The workpiece must pierce the formwork through.

- The spaces in the formwork walls around the pipe are filled with sealant.

- To prevent deformation or destruction of the pipe under the influence of the concrete mass, you can create an additional frame around each ventilation element.

- After pouring the foundation, you need to wait about a week for the concrete mass to acquire a certain hardness. After this, the pipe can be dismantled from the formwork structure and the blanks for the ventilation holes can be pulled out.

Types of ventilation in the cellar

Forced ventilation system

Typically, only two types of ventilation systems are used for cellars:

- natural;

- forced.

The natural ventilation system is very simple and inexpensive. It is used for those cellars whose area does not exceed twenty square meters. It consists of an exhaust and supply pipe.

Accordingly, air leaves the room through the exhaust air, and fresh air enters its place through the supply air. The pipes must be installed in opposite parts of the room so that air circulates throughout the entire area.

Otherwise, air stagnation and freezing of places remote from the pipes cannot be avoided.

Forced ventilation will force air to circulate constantly, regardless of weather conditions. To create it, low power fans are placed in the exhaust pipes - up to 100 watts.

How to close the vents in the foundation from mice

When the first autumn frosts arrive, field rodents begin to look for places to live with more comfortable conditions. Mice-voles find such shelters in suburban buildings. There they are not afraid of the piercing wind, which at sub-zero temperatures makes the fields unsuitable for existence.

Their small size and innate dexterity allow mice to penetrate through the smallest openings in buildings. They are most attracted to underground rooms, where the accumulated heat lasts longer.

Vents (holes for ventilation of the underground space) are the easiest way for rodents to enter the home. From underground they will find opportunities to spread throughout the house.

The best ventilation system in winter

The best ventilation option, especially when it comes to large cellars, is ventilation with two pipes.

This system works based on simple physical laws - the greater the temperature difference, the faster the air flows move, and when heated, warm air moves upward.

When such ventilation is operating, the vents must be closed. Otherwise, additional volumes of air will pass through them, which will affect air exchange.

Air masses will flow through the exhaust ducts at a lower speed, and over time, stagnation of air in the room will occur.

For arranging ventilation with two pipes, there are the following recommendations:

- air ducts can be either round or square;

- It is necessary to install the supply and exhaust pipes at opposite ends of the room.

- the diameter of the outlet openings is calculated by the formula: area (room) × 26/13;

- The air ducts should be routed to the roof of the structure. Only the supply pipe can be placed on the wall;

- Fresh air masses should flow through the supply pipe into the lower part of the room. But the pipe should not be located close to the floor. The exhaust pipe is installed as close to the ceiling as possible;

- For the winter, dampers must be installed in the ventilation system and well insulated.

Installation diagram

- A visor is installed at the end of the exhaust duct.

- To ensure proper ventilation, it is necessary to place the upper end of the exhaust duct higher above ground level.

- The radius of the air ducts must be the same.

- When calculating the diameter of the pipe, you need to use the formula: for every 1 m3 of the cellar located below ground level, there should be 20 cm2 of the diameter of the ventilation pipe.

This approach is used for both natural and forced ventilation. To properly install ventilation, you must first make a calculation, namely, establish the cellar area and air flow rates. This ensures proper air exchange and will allow in the future to completely renew the air in the cellar every 30 minutes. This level of circulation can be ensured by laying 25 cm of channel for every 1 m2 of space.

Important! After installing any type of ventilation, there should be no extra holes in the pipes through which air will penetrate into the room. The gaps significantly reduce ventilation, so damp air can enter the garage. Therefore, condensation can settle on car parts, which is very undesirable.

In principle, installing ventilation in the cellar is a job that can be done independently by the homeowner with great desire and ordinary non-professional tools. Start with design - basic drawings, calculations of materials, determination of the operating features of the ventilation system under different temperature conditions.

A cellar can be found in almost every courtyard of a private house or summer cottage. It is there that people store their supplies of collected/purchased fruits and vegetables, including canned ones.

In this room it is necessary to organize proper air exchange, otherwise the products stored in it can quickly deteriorate. This is especially true in winter, when temperature and humidity levels change the most.

Because of such conditions, people often wonder whether it is necessary to close the ventilation in the cellar for the winter, or leave everything as is. To answer this question, you need to understand in more detail the operation of the ventilation system of this room.

Rules for maintaining an optimal microclimate in the cellar in winter

The most acceptable microclimate in the cellar is one in which the stored products will retain their taste and appearance for as long as possible.

The optimal temperature in the cellar, at which vegetables and fruits can be stored even until spring, is from two to four degrees Celsius. In this case, deviations are allowed, but not more than one degree.

Freezing of the cellar during the winter season can lead to food spoilage. Basements that were dug in clay soil are especially susceptible to hypothermia and freezing.

This is due to the high thermal conductivity of clay - although it heats up quickly, it just as easily transfers heat to the environment.

Ideally, it is best to take care of this issue during construction and, if possible, arrange the cellar in sandy or sandy loam soil, which will store heat much better.

If it is impossible to choose the area and type of soil (and this happens in the vast majority of cases), then all necessary measures must be taken to insulate the cellar.

The high thermal conductivity of soils can be reduced using polystyrene foam, sheets of which must be attached to the walls of the room using polyurethane foam or special glue.

Particular attention should be paid to areas that are located at the level of soil freezing. If the basement is located very deep, then it is enough to insulate only the upper part of its walls.

Of course, it is impossible to predict exactly what the temperature will be in the basement during the winter. Therefore, it is advisable to monitor the air temperature in the cellar, especially if there is doubt about the reliability of the insulation.

If after frost the temperature still drops to zero or even below, additional measures need to be taken.

If a large amount of snow has fallen, you can fill the basement hatch with it. This method is suitable if the hatch is located on the street.

Snow has good thermal insulation - it's all about the air, which lingers between snowflakes and does not conduct heat well.

And the fluffier the snow is, the better it will cope with this task. Of course, while everything is covered with a thick layer of snow, and until the temperature in the cellar returns to normal, it will no longer be possible to use the room and get supplies out of it.

You will have to wait a while, perhaps several days.

Also, in extreme cases, you can warm up the storage using heating devices. To do this, it is advisable to conduct electricity into the basement.

It should be borne in mind that for effective and safe heating in the room, the ventilation system must work well, since with sudden heating, the humidity in the room will sharply decrease.

A forced ventilation system is best suited for this.

And for effective heating, the best options would be thermosiphons and special split systems. But it is worth keeping in mind that their cost can be extremely high. And they will pay for themselves only in large cellars.

Do-it-yourself vents

I will say right away that it is quite difficult to make vents in the foundation with your own hands, since the thickness of the tape ranges from 40-60 cm. And drilling reinforced concrete of such thickness is long and expensive.

There are several ways to make holes in the foundation:

- The superstructure of the basement part is made of bricks and with pre-drilled openings. This method is the most correct and quite simple, but applicable in all cases. So, for example, if the walls have already been erected, then, of course, it will not be possible to build a basement.

- Making holes with a hammer drill is the most popular and affordable method among private developers. Depending on the brand of concrete and the degree of its reinforcement, it will take from several hours to one full working day to complete one blow. In this case, you will have to spend several concrete drills. Holes are drilled around the perimeter of the ventilation hole; the hammer drill should not be used at full power and the drill should be periodically moistened with water to avoid overheating.

- Use core bits and drill out the concrete step by step, piece by piece, and then use a hammer drill with a pick to knock out the concrete. This is also a difficult and slow method.

Using a round pipe

The easiest way is to use a plastic or asbestos-cement pipe with a round cross-section with a diameter of 10-14 cm. Before installation, they are filled with sand for strength.

When to close vents

The issue of closing and opening vents in winter must be approached individually. It all depends on many factors - on the temperatures inside and outside, on the difference between these temperatures, on the level of humidity, etc.

If it’s quite easy to monitor the temperature - you just need to buy an inexpensive thermometer and hang it on the wall, but to determine the humidity you will have to buy a more expensive hygrometer.

If this is not possible, you can navigate by the level of condensation formation.

Vents should be closed when there is a strong increase in humidity and/or a sharp drop in temperature. If drops of liquid begin to condense on the ceiling, this is a signal that the vents should be closed.

The temperature factor for each cellar is individual - it all depends on the level of thermal insulation. And here it is up to the owner of the storage facility to decide when to close the vents and when to keep them open.

The main thing is to focus on optimal microclimate indicators.

Moisture is a home's worst enemy

The worst thing for a residential building, especially a wooden one, is mold. It thrives in warm and damp spaces, which is the subfloor. If there is constantly high humidity under the house, microscopic fungi settle not only on wood, but also on concrete, brick, and metal structures.

Mold and mildew eat wood floors and floorboards, thereby compromising the strength of the structure. They release poisonous spores that lead to various diseases. In addition, the unpleasant smell of rot and dampness worsens the quality of life of residents and damages clothes and furniture.

Rare shot: Viktoria Isakova showed her grown-up daughter from Yuri Moroz (new photo)

If there is little snow, there will be no harvest: December 16 is Ivan the Silent Day

A Brazilian travels 36 km by bike every day to take his loved one home.

If there are no vents or they are not made correctly, condensation accumulates under the floor at different times of the year. It seeps through the ground and ceilings, especially in winter and wet weather. Accumulating in the walls of the house and in the soil, moisture serves as an ideal breeding ground for a variety of fungi, bacteria, and insects.

What diameter pipes can be used?

Many people wonder what cross-section the sewer pipes should have for proper ventilation? Experts say that for high-quality ventilation of one square meter of the basement, the cross-section of the pipeline should be 26 square centimeters.

If the diameter of the pipeline is 1 cm, then its cross-section is 13 square centimeters. Taking this into account, anyone can calculate the required pipeline diameter using the formula: (Cellar area h 26) h 13. For example, if the basement area is 8 square meters, a pipe with a diameter of 16 centimeters will be required for ventilation.

To organize proper supply and exhaust ventilation, you need two pipes of the same diameter. In order to speed up the air exhausted outside, it is allowed to install a pipe whose diameter is slightly larger than the cross-section of the supply pipeline.