Fibrous thermal insulation materials such as stone wool and glass wool are considered not only effective, but also safe for health. But this statement can be considered true only if the insulation is correctly laid and covered with a special film that does not allow fine dust from the fibers to pass through. However, during installation, the cotton wool has to be cut, cutting out pieces of the required sizes, and this process is certainly accompanied by the formation of microparticles that irritate the skin and mucous membranes and enter the lungs. Therefore, it is so important to know how to cut insulation in order to minimize the formation of harmful dust, and the cut is accurate and even.

Microparticles of insulation fibers become visible only when they settle on the surface Source chistyjdom.ru

Means of protection

Working with sharp tools always carries a risk of injury. But in the case of mineral wool insulation, it is minimal, since the sufficiently soft and pliable material does not require serious efforts, due to which the knife may slip in the wrong direction.

Much more dangerous is the inhalation of fine prickly dust, its contact with the eyes and skin, causing irritation. It is especially important to use protective equipment when working with glass wool and slag wool. The latter is not used in residential construction due to the toxic substances it contains, but it is sometimes used to insulate garages and other outbuildings.

Therefore, before cutting mineral wool, you need to prepare:

- clothes with long sleeves and trousers - to protect the skin;

- closed glasses that fit tightly to the face - to protect the eyes;

- respirator or multi-layer fabric mask - to protect the respiratory system.

When working with mineral wool, closed-type glasses are used Source prigor.ru

You will also need gloves that protect the skin of your hands not only from dust, but also from accidental cuts. It is best to take special polyamide ones with silicone or polyurethane coating.

How to cut mineral wool

Mineral wool has a fiber structure, and accordingly, when it is cut, small particles of these fibers enter the air. To prevent them from getting into the respiratory tract and onto the skin, it is important to create safe working conditions:

- ensure good ventilation in the work area;

- use special clothing and protective equipment - overalls, gloves, mask or respirator, goggles;

- Immediately after finishing work, thoroughly wash your hands and then your face with cold water.

To minimize the amount of harmful dust in the air, cutting mineral wool should be done with tools with a well-sharpened, sharp working edge. It is better to cut across the grain .

To obtain strips of the same width , mineral insulation produced in rolls is recommended to be first cut directly in the roll, without unfolding, and the mineral wool slabs are cut one at a time.

To ensure smooth and precise cuts, you must first mark the material or cut directly along a ruler.

Cutting tool

How to cut mineral wool depends on the thickness and density of the insulation. The scope of work should also be taken into account. If it is small or the thermal insulation work is carried out once, you can get by with a regular cutting tool. If you have to insulate several objects, it is better not to waste money on a professional one.

See also: Catalog of companies that specialize in home insulation

Regular tool

Before cutting the mineral wool insulation, determine the thickness of the slab or mat. If it is less than or equal to 5 cm, for cutting you can use:

- construction knife;

- stationery or wallpaper knife.

Construction knife with a retractable segment blade Source ozone.ru

The main thing is that the length of the blade exceeds the thickness of the material being cut, otherwise it will wrinkle and the cut will turn out torn.

It is better to cut thicker insulation with other tools that you will probably find on the farm.

- A long kitchen knife, better for cutting bread with a serrated edge.

- Metal hacksaw with fine teeth.

- A hand saw or hacksaw with straight, fine teeth.

You can cut the insulation with a fine-toothed wood saw Source stroyday.ru

Are there any nuances in transportation and storage?

*

Manufacturers recommend storing mineral wool in intact packaging, and it is better if the pack is placed on a flat surface. Each stack of packages should not be higher than 2 meters. Optimal storage conditions are closed rooms that are resistant to moisture. It is not recommended to store insulation outside, but if this happens, then you need to cover it with a tarpaulin or film.

Cotton wool should only be stored horizontally

When transporting, you should follow the same rules: transport the cotton wool horizontally and in a dry truck bed. It is also necessary to provide the material with protection from mechanical influences and precipitation. When loading and unloading material, do not compress it too much.

Unpacking mineral insulation also requires certain nuances. The material should be removed from the packaging only before starting work, which will minimize various risks associated with damage to the insulation. When laying out the material for cutting, use its packaging as a bedding. Thus, the product will not get dirty. Also, the packaging can be used to collect other waste at a construction site.

Tips for cutting insulation

To prevent the material from tearing when cutting, creating a large amount of dust and waste, the tool must be sharp. Due to the nature of the insulation, consisting of stone or glass fibers, it quickly becomes dull and requires frequent sharpening. Or, in the case of a utility knife, replacing the blade.

Before cutting mineral wool in slabs, markings are applied to them, an even strip is pressed against it and the cut is made by pressing the tool blade against the guide and holding it vertically.

To cut rolled insulation, markings are made directly on the packaging, gluing masking tape around its circumference.

It is important! In order for the insulation to fit tightly to the side edges of the frame or rafters, its width should be 5-20 mm greater than the distance between them. Take this into account when marking.

The best way to cut basalt insulation

Today, manufacturers offer a sufficient number of insulation materials. Each of these materials is used in certain conditions and has its own price. However, the most popular are insulation materials that provide optimal heat retention and have a long service life. The second no less important point is the cost, which should be acceptable. A material such as mineral wool meets these requirements. Its use does not involve the use of special tools or devices. You can solve the problems of how to select and secure the material and how to cut basalt insulation yourself.

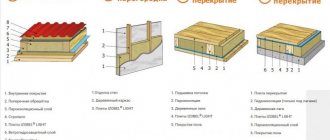

Scheme of insulation of the roofing pie system.

Operational features of basalt wool

Basalt and other rocks of its group are used for production. Thin fibers are taken, into the melt of which limestone (10-15%) or charge is added. Additives increase the resistance of the material to excessively high temperatures and aggressive environments. The result is an insulation material with fairly high performance characteristics:

Choosing a material for insulating the attic roof

Today there is a huge choice of insulation: slab, roll, bulk and sprayed. Theoretically, you can use any of them, but practice shows something completely different. Let's see why.

Slag mineral wool

This material is made from blast furnace slag and is available in rolls and slabs. The latter is quite suitable as insulation for an attic roof. The slabs are quite solid and do not settle or sag. Slag wool is very hygroscopic, which, on the one hand, is good - the room will “breathe”. On the other hand, if there is the slightest leak in the roof, the material will get wet and lose its heat-retaining properties. Slag wool is relatively fireproof: it begins to smolder at 300C°.

Insulation for attic roof: slag wool

Roof insulation with stone wool

It is made from volcanic rocks, hence the name - stone wool. One of the varieties of stone wool is basalt. This insulation is an order of magnitude better than slag wool. It has higher indicators for sound and heat insulation, fire safety. The thermal conductivity coefficient of stone wool is 0.12, while that of the same slag wool is 0.48.

Another characteristic that speaks in favor of basalt wool is the absence of formaldehyde binders in the composition, which cannot be said about other stone wool. Mineral wools are produced with different densities; the numbers in the marking indicate the weight of a cubic meter of material: from 75 to 200 kg per m 3. To insulate the pitched roof of an attic house, wool with the lowest density is suitable - they have the lowest thermal conductivity of all.

The best way to insulate an attic roof: basalt wool slabs

Spraying polyurethane foam

The main advantage of the material is ease of installation. The polyurethane foam is simply sprayed onto the surface. The material has low thermal conductivity and does not absorb water. Insulation of a sloping attic roof using this material is the easiest to do: it does not require the installation of special structures.

The material also has disadvantages. Thus, the vapor permeability of polyurethane foam is very low, therefore, the room must have a good ventilation system, ideally it should be forced. And, of course, the price: It is quite high for PPU.

How to insulate an attic roof: spraying polyurethane foam

Insulation of the attic with ecowool

Ecowool is an environmentally friendly material that does not emit any harmful substances during operation. In essence, it is recycled cellulose. Boric acid contained in the material provides it with resistance to fungal infections. In addition, ecowool is fireproof, rodents do not live in it, and the heat and sound insulation rates are quite high.

The main disadvantage of ecowool is that its application requires special equipment, which means that doing attic insulation with your own hands will be problematic, if not impossible.

Attic roof insulation technology: wet and dry methods

Attic insulation: video about how ecowool insulation occurs.

Polystyrene foam perfectly retains heat and protects the room from noise. The material absorbs water, but very little. And, by the way, polystyrene foam “breathes”, contrary to popular belief. The fairly low price also speaks in favor of the material. If we talk about the disadvantages, polystyrene foam emits toxic gases when burned, and its combustion temperature is quite low. The only drawback in installation is fragility.

Insulating the attic roof with foam plastic

Scraps and remnants of insulation after cutting

During insulation, while working with mineral wool and other materials, scraps often remain, which are advisable to use for insulating sheds and garages. This is a fairly inexpensive method of thermal insulation. The waste is also recycled so that it can be used again. In this case, the remaining insulation materials must be crushed using special equipment. They can be used to insulate ceilings and walls or sold at a low cost to those looking for an inexpensive insulation option.

Knife for cutting insulation: how to choose, types and characteristics

Hi all! I think there is no point in reminding us once again about why insulation materials are needed. This is not a whim, but an urgent need to make your home warmer and more comfortable. Plus it saves on heating, which is important considering utility prices. And in order to lay this insulation, it needs to be processed and cut. A knife for cutting insulation may come in handy here.

There are different thermal insulators. But they are all quite soft. This allows cutting to be done with the appropriate tools. Although in some cases it is impossible to do without specialized and powerful machines.

Therefore, today on the agenda is a knife for insulation. Let's talk about what they are, how to choose the right one, and what you need to know about the features of choosing a tool.

Varieties

When thinking about how to cut mineral wool or other insulation, there are quite a few potential options.

In general, a knife for cutting insulation is a general concept that includes several types of tools.

Having considered each of them, you can decide for yourself how to cut mineral wool into slabs, or process other types of insulating materials for subsequent use. After all, it is not always possible to lay the insulator in whole slabs or rolls. Somewhere you have to cut, trim, and also make material of complex geometric shape.

Now let's see what a knife can be like for cutting mineral wool, as well as other heat-insulating materials.

Construction knives

This is a universal tool that can also act as a knife for cutting insulation.

In general, such a tool is used to work with the following materials and products:

- paper;

- cardboard;

- rubber;

- plastic;

- leather;

- Styrofoam;

- mineral wool;

- wires, etc.

An important feature is that you can install a special blade here, getting a full-fledged knife for cutting mineral wool, or some other specific material.

But there is a drawback. This is a short blade. Therefore, when using the device to install insulation, chips, tears, cracks, and other defects may remain on it. This is more of a trimming and straightening option. But he is unlikely to be able to cut a thick sheet of polystyrene foam perfectly evenly and accurately.

Hacksaws

Another option for how to cut stone wool or how to cut fiberglass with all other types of thermal insulators. This is a hacksaw that can be used for metal and also for wood.

Decent option for pruning. It is especially convenient to cut wide layers of mineral wool. Good hacksaws have high-quality sharpening, as well as small, unset teeth. This allows you to efficiently complete the job without causing damage or defects.

But this is not exactly a knife for cutting thermal insulation. This is a hacksaw for insulation, since cutting large pieces is not a problem. But a hacksaw will not be able to cope with small elements, soft cotton wool, or curly cutouts. This requires a thinner tool.

Kitchen knives

If there is no specialized knife for cutting thermal insulation materials, this is not a problem. A regular mineral wool knife will also work. It can be found in the kitchen.

To cut the insulator layer, use ordinary kitchen knives, which are used to cut meat, vegetables and fruits. For denser insulators such as foam, a bread knife will work better.

Proper transportation of material

Since the material is porous, brittle and hygroscopic, it must be handled accordingly.

When transporting and storing mineral wool, it is recommended to observe the following rules:

- During the loading and unloading process, do not throw the packages, but carefully place them, avoiding their falling and strong compression.

- Transport bales in covered trucks, placing them horizontally on a level bottom. Fix the insulation

so that it does not hit the body walls. - Store products in dry, closed areas. If this is not possible and it is stored outside, cover it with film or tarpaulin to protect it from precipitation.

- Remove slabs from the stack immediately before laying them. This will prevent moisture absorption and reduce the risk of accidental damage to the material.

External wall insulation technology

To cut basalt insulation, it is best to use a mounting knife.

- a vapor barrier film is attached to the wall; it must release moisture under the mineral wool slabs and prevent cold air from entering the house;

- Then wooden blocks or a metal profile are attached to the wall in a vertical position. Their width should correspond to the thickness of the insulation. The interval between the posts should be such that the mineral wool is inserted with little effort;

- The insulation is fastened with glue and special dowels if the wall is stone, or with nails (screws) with large washers if the surface is wooden. For 1 sq. m you need 5-6 pieces;

- It is recommended to lay a windproof membrane on the fixed basalt wool, the joints of which are taped with adhesive tape;

- To ensure ventilation under the subsequent decorative coating, it is advisable to make a counter-lattice over the slabs from wooden blocks or a metal profile 10-15 mm high.

Insulation scheme using basalt wool.

This technology is suitable when facade insulation under siding is required. However, in some cases, for example, in multi-story buildings, it is necessary to secure the insulation more firmly. In this case, it is additionally fixed to the surface with glue, and reinforcement is carried out at the same time. This operation strengthens the structure and dampens the thermal expansion of the material, which can contribute to the formation of cracks and increase thermal conductivity.

Reinforcement is made on the already installed insulation using special glue and mesh that is resistant to alkali. First, glue is applied on which the mesh is laid, then it is covered with another layer of adhesive. The final decorative finishing can be done using facade paint and decorative plaster.

To start insulating the roof with mineral wool, you need to cut it (if necessary) so that it fits in size to the distance between the rafters.

The first is to insulate the floor, and the second is to strengthen the roof slopes. The first case does not require any special preparation or special costs.

There is no need to go around the rafters, as in the second case. Strengthening the roof slopes of non-residential premises is thus costly. A large amount of wool will be required, which must be strengthened by going around the rafters.

To insulate the roof with mineral wool, it is necessary to install steam-hydro- and thermal insulation. The pitched part of such a roof is a multi-layered pie. It can be installed both inside and outside the roof.

To create high-quality thermal insulation of the roof, you must perform the following steps:

- install a vapor barrier layer. It will protect thermal insulation from air saturated with moisture;

- use mineral wool as a thermal insulation material;

- to protect the rafter system and insulation from precipitation, a layer of waterproofing should be installed;

- it is necessary to provide a ventilation gap. It is created by installing a counter-lattice;

- At the last stage, the roofing material is laid.

Laying a waterproofing membrane

- When insulating the roof of a building with mineral wool, you must ensure that it does not block the ventilation hole.

- If a superdiffusion membrane is used during installation work, the heat insulator should be placed tightly on it. This is necessary so as not to block the ventilation gap.

- If a regular roofing film is used, then it is necessary to make two gaps: at the top and at the bottom.

- When laying mineral wool slabs in rows, care must be taken to ensure that the joints do not coincide with each other.

- In order for the insulation to fit tightly to the surfaces of the rafter legs, it is necessary to choose mineral wool of such a size that its width is slightly larger than the distance between the rafters.

- Mineral wool slabs must fit very tightly to each other.

- When insulating a roof with mineral wool, it is necessary to install a layer of waterproofing. In this case, it is necessary to monitor the quality of the connection of the waterproofing film.

Material strength

Basalt fibers inside the material are arranged randomly, and some of them run in the vertical direction. Thanks to this, even not very dense stone wool

capable of withstanding considerable loads.

Thus, at 10% deformation, basalt wool has compressive strength limits from 5 to 80 kilopascals. The specific value of this indicator depends on the density inherent in a given grade of material.

Such strength characteristics of basalt wool guarantee that the heat insulator will serve for a long time without changing its shape and size over the entire period of use.

Basalt wool fibers.

Stone wool is chemically passive - this is its undoubted advantage. If you lay it close to a metal surface, then you can be one hundred percent sure that rust will not appear on the metal. And basalt insulation treats aggressive biological environments completely calmly.

It is not characterized by either rotting or damage by mold and other harmful microorganisms. It withstands the invasion of rats and mice into the house - after all, these rodents cannot handle stone wool.

READ How to Hammer a Wall with a Hammer

Stone wool is made from natural raw materials – the mineral basalt. Its fibers are bonded using formaldehyde resin. It gives the material the necessary strength characteristics and also makes it more dense. Although they say that phenol is dangerous, but not in this case.

After all, it cannot be released from basalt wool, since it is completely neutralized during the production of the material. However, even at the manufacturing stage of this mineral insulation, phenolic fumes are extremely small - much less than the permissible limit of 0.05 milligrams per m2/hour.

Unlike glass wool fibers, basalt fibers do not irritate the skin, do not prick and do not cause allergies.

Today on the construction market there are a large number of brands of stone wool of various densities, the technical characteristics of which are slightly different from each other.

But all types of basalt insulation are distinguished by strength and long service life.

This insulation can be used in almost all building structures. They can be used to insulate roofs of any shape, as well as walls, partitions, and ceilings.

Many people do not know how to cut mineral wool correctly without disturbing its structure; in this material we will look at all the ways to properly cut mineral wool, and also recommend the tools that are best suited for this.

Mineral wool is usually classified according to the material from which it is made. This leads to the conclusion that mineral wool, made from different starting materials, differs in structure - fibers, and, accordingly, in the type of cutting. So there are the following types of mineral wool:

- Glass mineral wool. Consists of glass melts.

- Stone mineral wool. It is most often made from various rock melts.

- Slag mineral wool. The starting material is blast furnace slag.

In fact, you should pay attention to the fact that sometimes mineral wool

can be harmful. This is due to the fact that it contains dust and phenol-formaldehyde resins. Therefore, it is necessary to treat this material selectively, although mineral wool cannot be classified as a human carcinogen.

Cutting mineral wool can be done either independently at home or using various equipment. Equipment for cutting mineral wool boards can be different. The question is one of scale. The mineral wool cutting machine is suitable for serious and large scale applications - for enterprises, manufacturers, etc. But a knife for cutting mineral wool will become an indispensable assistant in cutting insulating materials at home.

It is important that cutting mineral wool does not damage the fibres, so equipment must be selected carefully. The cut should be smooth.

It is important that the work is done properly. Circular cutting of mineral wool can be convenient. A mineral wool cutting machine can easily cope with such a task.

So, for cutting mineral wool, a good, sharp stationery knife or a hacksaw is best suited; carefully cut the mineral wool in the right directions; for greater accuracy, you can draw a line with a pencil or cut directly along a ruler. The process of cutting mineral wool is somewhat similar to cutting paralon, only you need to apply a little more effort, pressing a little harder on the tool for cutting mineral wool.

Popular knife manufacturers

The Vira brand of tools is inexpensive, but lasts a long time.

To avoid problems during work, you should purchase a knife for mineral wool and other materials only from trusted manufacturers. Their list includes the MORA brand, which produces tools for glass and stone mineral wool. Their blades are made of cold-rolled stainless steel and are well-sharpened.

No less popular are the options from the ISOVER brand, including the Specialist and Professional models, suitable for cutting heat and sound insulating materials. They are lightweight and equipped with specially adapted handles. The extended blades of these models up to 297-350 mm help to cut even large-sized materials of any type.

It is possible to insulate premises efficiently only with the help of professional tools. A cutter for any polystyrene foam or a knife for mineral wool must be made from the most durable and comfortable materials and meet quality standards.

Characteristics and properties of the material

Before starting construction or renovation work, the owner of the premises thinks about what criteria should be used to select materials. Currently, the sales range is replete with a variety of canvases that differ from each other in raw materials, price, scope of application, and operating characteristics.

The term “mineral wool” implies three types of materials, namely:

- basalt (stone);

- slag;

- glass wool

Glass wool (made from fiberglass) is characterized by low density and high hygroscopicity. The material does not have moisture resistance properties, and heat resistance should not be expected from it: when a high heating temperature is reached (about 300 degrees), the wool fibers melt, and the material no longer serves as an insulator. Glass wool is sold in rolls.

Glass wool is produced using the blow molding method: an industrial centrifuge creates air flows that go directly into the raw material. Due to the flow of air, fibers appear from the threads, and they can have different lengths, directions and thicknesses.

Mineral wool has low thermal conductivity, allows steam to pass through due to the cells in its structure, and almost does not absorb water. In addition to the base, there are few binding elements in the composition, which allows it to withstand high temperatures. The material is widely used as sound insulation and insulation for various substrates and surfaces. It is produced in sheets that vary in strength.

Slag wool

for insulation of premises

Slag wool

is the cheapest option for insulation. The material consists of fibers that are waste from blast furnaces; it is not dense and does not have good heat resistance. If you overheat slag wool, it will sinter. Therefore, the material is not suitable for insulating rooms adjacent to heat sources, and is also not recommended for building houses.

The structure of the horizontal layer of any type of mineral wool is created in the direction of the fiber. The formation of vertical sections occurs due to elements that are located chaotically. Each type of material has its own characteristics and external differences.

Terms of use

Before starting work, it is imperative to read the instructions for using the knife and ensure the safety of the installation in order to prevent both gross and minor mistakes and harm to your health. There are several basic rules.

The insulation should be cut at low ambient temperatures - in order to safely start cutting mineral wool, you will have to dress in a special durable suit that will prevent skin contact with toxic material and irritation.

To protect your hands from getting cuts and abrasions when cutting carelessly, you need to cover them with rubber or silicone-coated gloves.

The respiratory organs must be covered with a durable respirator, and the eyes must be protected with special professional glasses , since glass particles of foam or mineral wool can enter the respiratory tract or the mucous membrane of the eyes.

During installation work, it is necessary to take short breaks and open windows to ventilate the room. If possible, it is better to immediately work in a room with good ventilation.

To ensure that the heat-insulating material does not break and fewer particles fly off from it, the cutting tool must be technically sound and well sharpened. To reduce the amount of dust in the air, the insulation should be cut along the fibers.

During the cutting process, you need to count on the remainder of a small layer about 2 cm long in order to ensure a tight overlap of the insulated space.

Mineral wool lends itself better to cutting before unrolling.

Mineral wool panels should be removed from the packaging box and cut one at a time, so as not to accidentally damage its shape when transferring the material from one place to another and when placing them on top of each other.

Already cut pieces of insulation cannot simply be thrown onto the floor or onto another piece, since a huge amount of foam fibers will immediately begin to rise into the air. The material should be handled with extreme care.

In addition, when carrying out installation work yourself, the best option would be to consult with specialists, since you may have to cut pieces of complex shapes. Recommendations from a professional will help you avoid unnecessary waste of material. Manufacturers also advise starting to cut the wool before unrolling the roll, and to ensure smooth and accurate cuts, you need to mark the material on a ruler in advance.

The remaining thermal insulation material does not have to be thrown away. They will remain suitable for insulating pantries, garages, sheds or other utility rooms. In addition, they can be recycled and sold at a low price for later use.

Upon completion of work, it is recommended to thoroughly wash your face and hands with soap and cool water.

For more information about knives for cutting insulation, see the video below.