Just recently, it was difficult to imagine that something other than newspapers would be used as a preparatory layer for wallpaper. Probably, when carrying out repairs, you yourself used them more than once. Already today you can find innovative materials on sale that allow you not only to level the surface, but also to achieve an insulation effect.

“Polifom” for wallpaper, reviews of which you can read in the article, is a modern backing made of polyethylene foam. During the production process, the material is covered with thick paper on both sides. Its structure is quite voluminous and soft, so it can be used to hide surface defects and give them sound and heat insulating properties.

What is it used for?

The backing for Ecohit wallpaper, as well as its analogues made by other manufacturers, is usually made on the basis of a special material - polyethylene foam. Usually it is covered with paper on both sides. However, many companies also sell cork and non-woven insulation backing. In addition, foam backing may sometimes be found. Regardless of the base material used, they all have very positive reviews from both professional craftsmen and ordinary people whose activities are not related to repair and construction. This soundproofing surface also has certain insulation characteristics, thus combining several useful functions at once.

As for the types of wallpaper that can be glued over the backing, they can be different: paper, non-woven, vinyl, textile. Speaking about the main advantages of such coatings, first of all I would like to mention the following:

- Eliminates the likelihood of microorganisms, mold and mildew (read more about how to get rid of mold on wallpaper).

- Provides additional sound insulation due to sound-absorbing properties.

- It has strength and a high level of durability.

- Absolutely harmless to human health.

- Acts as additional insulation.

Cork is an interesting option that can even be used instead of wallpaper

All this points to multitasking, which indicates the wide versatility of this kind of substrate. Another interesting quality is the ability to re-glue the wallpaper several times without causing damage to the substrate itself.

Features of choice and types of glue for foam rubber

Choosing what to glue foam rubber with is not an easy process, because you need to take into account many factors. Only then will it be possible to obtain a strong and reliable seam that does not change its structure and properties. Therefore, you need to study the point in the instructions that describes the composition of the product; the presence of toluene and trichloroethane is unacceptable, they not only have a destructive effect on the material itself, but are also toxic substances, working in the house will be dangerous, special rules must be followed.

Choosing what to glue foam rubber with is not an easy process, because you need to take into account many factors.

General requirements for adhesive composition

In order not to make a mistake, you need to take into account a number of requirements for a high-quality solution, which will ultimately make it possible to obtain a reliable and durable fixation. These include:

The viscosity level should not be lower than 100c, this indicator provides the necessary elasticity; with hard and hard seams, the product will deteriorate too quickly and become unusable; Dry residue indicator

In this case, the larger it is, the better, because the clutch will occur much faster; In this case, the setting speed should not be less than two minutes, because it may be necessary to shift the parts in order to obtain their correct position; A one-component solution, it will be easier to work with; High degree of heat resistance; Non-flammability; Safety for human health; Reasonable cost; Ease of application, if you use glue in balloons, the process will be much faster and easier, which is important when you do the work yourself; The solution should not be too viscous, this will reduce the consumption of the product and it will not completely saturate the foam rubber; Select a product that is suitable in shade so that there is no unsightly contrast between the product and the seam. On sale you can find different colors from white, black to red

It is possible to paint the products later to obtain a single color.

The solution should not be too viscous, this will reduce the consumption of the product and it will not completely saturate the foam.

Some features

In addition to all of the above, we must not forget about the possibility of using it not only as a soundproofing and noise-insulating “lining” for wallpaper, but also for leveling walls. Of course, we are talking about leveling only minor mechanical damage, such as chips, scratches and cracks on the wall surface. If the wall is severely damaged, then in such cases you will have to take more serious measures.

By the way, its gluing is also associated with certain features that cannot be ignored. So, one of the most important conditions is that the wall surface should be pre-prepared. Preparation involves not only removing the old layer of wallpaper, but also getting rid of any remaining paint and glue. In addition, in cases where there is significant surface damage on the wall, it is advisable to level it using putty. After this, the wall must be covered with a layer of primer (the use of heavily diluted wallpaper glue is allowed).

Attention! It is better to use adhesive for gluing the backing that is intended for gluing so-called “heavy wallpaper”.

Why choose Polifom

If you have to make repairs in a cold and damp room, then its decorative finishing will imply the need to use insulation under the finishing material. If we are talking about “Polyfom”, then it will be able to reduce the coefficient of vapor permeability and heat transfer.

The material does not form condensation, which indicates that there will be no dampness in the room. Such a substrate is simply necessary for corner apartments in which the capabilities of the heating system are limited. The underlay is perfect for those rooms whose walls are in contact with the staircase. From the latter, cold and noise come inside.

Sticking

Be that as it may, let's take a closer look at how to properly glue this roll material. At the same time, you will be able to stick it on with your own hands, doing all the work yourself. In fact, in essence, the work is practically no different from gluing other roll wall coverings, with the only difference being that a lining is used instead of wallpaper. However, the general technology remains the same. In any case, both according to the reviews of craftsmen and the testimony of ordinary buyers, this approach (using glue or thick wallpaper) is completely justified, and the results are quite good.

So, first of all, you will need to cut the canvas into separate sections, the size of the height of the wall. Then they will need to be straightened. To do this, you can use small weights or any small objects at hand, but with sufficient weight to level the sheets.

Helpful advice! After gluing, it is advisable to additionally glue the seams with masking tape or ordinary tape. It is desirable, however, that they be transparent (this applies to adhesive tape, since masking tape cannot be transparent) or at least light-colored. Something darker may appear during subsequent wallpapering in white, beige, light green and pastel colors.

Another useful piece of advice from experts in their field is that, both during gluing and after completing all the work, you should make sure that there are no “bubbles” left under the backing. Otherwise, you risk getting unevenly pasted wallpaper and all the work will be in vain: you will have to redo everything again. Wallpaper backing by Polif:

As noted above, it will be enough for you to stick the backing only once, and after that re-glue the wallpaper many times. As for the preparation before gluing, you need to remember to fulfill the following conditions:

- Apply a layer of wallpaper paste or primer in advance.

- After applying the glue to the substrate, you should not stick it on immediately after that. First, wait 10-12 minutes, and only then glue.

- When air humidity is more than 70%, as well as at room temperature less than +10C, it is better to temporarily abandon gluing. So, it’s better for you to either reschedule the work or use a heater, which will raise the room temperature and lower the humidity.

- And finally, one more useful tip: Try to avoid drafts after applying the sticker.

Popular brands

Among the most common manufacturers on the Russian market, as well as other CIS countries, the following brands can be mentioned:

- Polyf (also known as Poliform).

- Ecoheat, from the manufacturer Isolon

- Penolon.

- Globex (Globex).

- Penohome.

Many buyers, considering popular brands, wonder which is better? In fact, it is difficult to draw clear conclusions and choose just one of them, since the products of all major manufacturers are of a high level of quality. As for the form of release, most of them (polyethylene foam, cork, and so on) are produced in rolls, thus reminiscent of more traditional and familiar wallpaper to all of us.

Ecohit is one of the market leaders

Main advantages

We have already briefly listed the main advantages of using such materials. Let's take a closer look at the advantages that using wallpaper underlay can provide. However, in addition to them, there are also points that can hardly be called exclusively a plus, since we are talking more about features or technical/operational characteristics. So here's what to take into account:

- The use of such materials can be extremely useful in the case of residential (and not only) buildings and premises that do not have high thermal insulation characteristics. Thus, the substrate is a kind of “supplement” for the insulation, if any. What buildings are we talking about? First of all, these are country houses, “panel” buildings built in the 1960s and 70s, and other similar “cold” buildings.

- It is better to avoid using it in places where there is a constant presence of moisture. We are talking about baths, bathrooms and other similar premises.

- On the other hand, it is quite acceptable to use it in such places of the apartment as the kitchen, living room (hall), hallway (corridor), bedroom and even a glazed loggia.

- In cases where fungus and mold have already formed on the surface of the wall, it is necessary, first of all, to get rid of them, and only after that glue the backing.

- You should also realize that putting cork on the wall instead of wallpaper is, of course, a possible option. However, in such cases it must be glued very carefully to avoid the appearance of joints between the individual panels.

- Despite providing some level of additional sound insulation, this material cannot completely rid you of excess noise that comes from the street or from overly loud neighbors. So, don’t expect complete silence to reign in your room.

- At the same time, circumstances such as complete safety for human health (including for children) can be mentioned as advantages, which allows it to be used in any room of the apartment, including the nursery.

- The ease of gluing, which can be done by almost anyone without relevant experience, is complemented by an affordable cost.

Thermal insulation material “Polifom”

Polyph

– chemically cross-linked polyethylene foam, produced in combination with such materials as: paper, lavsan, aluminum, bio-oriented metallized film, metallized polyethylene film and others.

Cross-linked polyethylene foam “Polifom” has the following properties:

- excellent thermal insulation - thermal conductivity coefficient 0.038 (V/(mK)) at 0 0 C with a density of 30 kg/m 3. On average, 1cm of Polyfoma can replace: 12cm of brickwork

- 4.5cm wood

Cross-linked polyethylene foam “Polifom” has the following properties:

| Possible areas of application | Recommended thickness, mm | PPE density |

| Under equipment, for noise absorption purposes | 5-10 | 90 |

| Under linoleum and carpet for heat and sound insulation | 5 | 45 |

| Under parquet, laminate, for heat and sound insulation | 2-4 | 30 |

| Under the wallpaper | 2 | 30 |

| Under wooden flooring | 15-20 | 30 |

| For insulation of bases, foundations, ceilings above basements and interfloor ceilings | 25-60 | 30 |

| To reduce the tapping sound | 5-20 | 30 |

| Under heated floors (with a reflective layer) | 10-20 | 30 |

General installation recommendations:

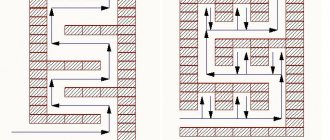

- Sheets of foamed polyethylene must be laid in layers tightly to each other, and the top layer - crosswise relative to the line of connection of the sheets of the bottom layer

- When building along the length of walls and fittings, it is necessary to ensure insulation by using self-adhesive dilatation tape

- The construction of the “floating” layer must be carried out so that the polyethylene foam layer is not damaged and the solid “floating” layer does not come into contact with the wall, as this leads to the formation of a sound bridge

- In places where moisture may be present both below and above, sheets of polyethylene foam must be tightly connected to each other with special tape

Scope of application: insulating layer under wallpaper

The insulating backing for the wallpaper is made of a layer of foamed polyethylene (density -30kg/m3 and thickness -5mm) with a closed cell structure, both sides of which are covered with paper. This coating allows gluing in the traditional way for heavy wallpaper.

Thickness -5mm Width -500mm Roll length -14mm Roll diameter -350mm

Installation recommendations

The insulating substrate is used to cover internal walls, primarily in residential premises, as well as cold (northern) walls of country houses and concrete walls that have rapid heat absorption properties.

- The rolls are cut into pieces of the required length.

- Old wallpaper and peeling plaster are removed. Potholes and cracks are filled and primed.

- Glue is applied to the wall surface and the substrate, the material is glued to the wall (the room temperature should not be lower than +10 0 C, the humidity level should not be more than 70%).

- For reliability, seal the seams with thin paper tape or paper tape. After complete drying (at least 72 hours), the wallpaper is glued according to the instructions for it. Before sticking regular wallpaper, you need to make sure that the glue is completely dry and the backing is tightly attached to the wall.

Installation instructions

It is quite simple to stick “Polif” on the walls; even a beginner can cope with this work. The main requirement is to follow the instructions. First you need to prepare the base surface. To do this, dirt, old wallpaper and peeling plaster are removed from the walls. If there are bumps and depressions on the wall, then they need to be leveled and covered with putty. Before making repairs in a room, the surface must be primed with a deep penetration compound, this will increase the adhesive properties of the surface.

Next, you should prepare the Polyfoma canvases by first taking measurements and cutting the material into separate pieces. “Polyfom”, the gluing instructions for which are described in the article, must be laid on PVA glue. However, you can use any other composition that is intended for vinyl and non-woven wallpaper.

If the room is operated under conditions of high humidity, then liquid nails or baguette glue should be prepared. The composition is applied to the canvas and left in this state for up to 10 minutes. Next, “Polif” should be applied and pressed against the wall, smoothing its surface with a special spatula, moving the tool in different directions.

Polypom insulation - technical characteristics

Internal wall insulation is considered a mandatory element in construction. A variety of insulation materials help conserve heat in a room and ensure an optimal microclimate. In terms of demand and popularity, polypom is the leader.

Inexpensive and easy to use, the material satisfies quality and functionality. Polyfom has unique heat-retaining properties. With its help, they protect against extraneous sounds and achieve ideal smoothness of the walls. The triple benefit and the resulting effect are appreciated not only by construction professionals, but also by ordinary people. This material deserves consumer preferences and a detailed study of its characteristics.

Customer Reviews

In general, buyers are satisfied with foam and polyfoam. It is noted that, although these materials do not completely muffle noise, they perfectly retain heat in the house. Insulation materials such as penofol and penoplex are also distinguished.

According to customers, cork insulation helps create and maintain optimal temperature conditions in the room. In winter, the material creates a temperature in the house with conventional heating that is a couple of degrees higher than in a room without insulation. In the summer, the cork prevents heat from moving from the heated walls to the air, allowing you to keep the house cool.

About the advantages of polyphony. Overview of the main benefits

A high-quality polypom is ahead of its competitors in many respects.

There are many advantages, but the main advantage is reliable thermal insulation. The participation of this material in insulation ensures a comfortable temperature in the room all year round. Regardless of weather conditions, the walls remain warm. Another competitive advantage is excellent sound absorption. Soundproofing properties prevent the penetration of extraneous sounds from the street and protect from noisy neighbors.

An indispensable polyp in repair work. For many, this insulation is positioned as a backing for wallpaper. The soft volumetric structure allows you to hide wall defects. Thanks to the elasticity of the material, it is easy to eliminate unevenness and cracks. There is no need to plaster the walls; polyfoam does an excellent job of eliminating defects and making surfaces smooth. You don't have to worry about condensation appearing on the wallpaper. Moisture-resistant polyfoam is not exposed to dampness and reliably protects walls from condensed vapors. In addition to its main advantages, the material is valued for:

- Environmental safety;

- Resistance to deformation, fungi and insects;

- Microbiological resistance;

- Ease of use;

- Long service life (up to 50 years);

- Affordable price.

Summarizing the advantages, we can safely say that it is optimal to use polyfoam as insulation. It’s not for nothing that experts consider the participation of an energy-efficient layer mandatory. This is excellent protection from the cold and the most cost-effective insulation option compared to other known technologies. Excellent results can be achieved quickly, for little money and with minimal labor costs.

What is polypom made of? Composition and features of insulation

Polyfom is produced in Hungary. All rights to use the trademark belong to Polifoam Ltd Co. Russian analogues of these products are also known. Regardless of where the material was produced, its base and composition remain unchanged. Polyethylene and air are involved in the creation of a polyphome. The two environments interact perfectly.

The manufacturing technology is based on the foaming method. Under the influence of chemical components, foam turns into bubbles. They do not contact each other, and the result is a closed cellular structure.

The material is laminated on both sides. The surface is smooth and the thickness is the same. It is these external characteristics that distinguish a real high-quality polyfoam from the numerous fakes that appear on the market.

This polypom meets all technological standards. There should be no streaks, roughness or unevenness on the white double-sided surface. Its structure is distinguished by density, elasticity and resilience. Foamed polyethylene is odorless and does not harm health, since butane and freon are not used in production.

Recommendations for choosing "Polyfoma"

"Polifom", the price of which is 1500 rubles. per roll, covered on both sides with thick paper. Before purchasing, it is recommended to inspect the material; the protective layer should have an even white color, there should be no roughness, drips or stains on it. It is recommended to try to peel the corner of the paper from the base. If this was achieved without difficulty, then the material cannot be called high quality. In some cases this may happen if storage conditions are not followed.

"Polifom", the price of which is quite reasonable, should not have a smell. If you have high-quality thermal insulation in front of you, then it should be elastic, resilient and dense. You can try to tear it, if this happens, then the material is of low quality.

How to stick polyfoam?

Working with insulation is convenient and easy; the gluing technology is quite simple, but requires compliance with installation rules. If they are violated, the problematic consequences will have to be eliminated, which means additional costs and loss of time.

Before gluing, the walls must be prepared and removed from cracks, holes, chips, etc. Having eliminated flaws and cleaned the base surfaces from dust and dirt, the walls are primed.

Polyfom cuts well and is perfectly fixed with ordinary PFC glue. Before cutting the sheets, take measurements. The roll form simplifies installation, and the convenient texture allows cutting of any complexity and texture.

The sheets are glued end-to-end; for maximum reliability, the joints are sealed with masking tape. This creates additional protection and improves thermal insulation. After applying the polyp, you can level it with a regular spatula. If you want to change the wallpaper, you don’t need to change the insulation. It does not deteriorate and retains its best properties.

Areas of application of polyfoam

Insulation is most often used as a backing for wallpaper, but the scope of the material is not limited to this. Proven practical benefits and thermal efficiency have significantly influenced the growth of consumer demand. Today polyfoam is used in the following industries:

- construction;

- tunnel construction;

- automotive industry;

- light industry;

- shoe production.

Polyfom is used in the manufacture of heated floors and split air conditioning systems. It is used in the production of sports equipment and packaging materials. The key heat-saving ability of the material is in demand when insulating dachas, apartments, hospitals, childcare centers and office buildings. Polyfoam can be used as an independent material or act as an element of a thermal insulation structure. In any capacity, this insulation copes with its functions and is rightly considered a guarantor of heat preservation in rooms.

Using Polyf wallpaper underlay to insulate walls

When wallpapering their home, modern people expect not only an updated aesthetic interior, but also a longer service life of the wallpaper, improved sound insulation and thermal insulation of the room. To achieve the desired effect, experts recommend using a substrate.

Wallpaper backing for walls is sold in all construction stores; among the most popular brands are: Ecoheat, Penolon, Polifoam, Penohome. These wall insulation materials have similar characteristics, and today we want to talk about one of them.

How to calculate insulation thickness

Insulating walls in an apartment is quite a responsible, but also difficult task.

Therefore, every preparatory step should be taken seriously.

First, it is necessary to measure the wall thickness (D) and determine the conductivity coefficient of the material used.

It is necessary to determine the true heat transfer resistance.

The calculation can be done using the following formula:

R=D/L

Therefore, the difference must be compensated by thermal insulation material.

To calculate the thickness of the insulation layer, the inverse formula is required: D = L * R

Which insulation material should I choose for the walls inside the home are all personally based on the recommendations in this article.

Video for reference:

It is important to follow all practical advice and use high quality materials.

The main thing is that insulation brings back into the house the warmth and comfort that is expected to be felt during construction work.

Substrate and its use

The use of this material enhances the adhesion between the main wall and the wallpaper. Even 50 years ago, old newspapers were glued to improve adhesion and level the surface. But such a layer also had negative sides: only paper wallpaper was available, through which the printed material was often visible.

With the advent of wall paintings made from more durable and dense components, the need for a layer disappeared. But with the popularization of energy-efficient technologies, experts remembered it again. Only modern materials that act as a backing for wallpaper are very different from ancient newspapers. The use of advanced technologies has made it possible to launch the production of insulation materials specially adapted for these purposes.

Promotional banner of famous insulation material

According to experts, the use of an insulating layer between the surface of the walls and the wallpaper is not mandatory. Simply using a substrate has several positive aspects:

- You can refuse additional treatment of the wall surface.

- There is no need for intensive finishing work.

- The substrate protects the decorative coating from the appearance of harmful bacteria on it.

- Longer service life (almost doubled) of decorative coatings due to high adhesion to the wall surface.

- Uniform absorption of glue, thereby preventing the appearance of bubbles and smudges.

- Makes wallpapering easier, especially at joints and corners.

- It has heat and sound insulation characteristics.

- Serves as an additional surface leveling layer.

- Easy to use, that is, you can glue the wallpaper backing yourself without involving professionals.

- It is allowed to change the decorative coating multiple times without affecting the layer.

Consumers have the right to decide whether they need an additional insulation layer on the wall or not. However, you can make a simple comparison of financial costs and time for finishing and processing, estimate the service life of the wallpaper, and understand that the experts are right.

What it is?

The underlay is a special intermediate layer that serves to level the wall and also enhances the adhesion between the wallpaper and the plaster. There are ordinary, standard substrates and materials with specific properties, such as vibration damping and noise suppression.

Substrates are made from synthetic materials and natural raw materials. Synthetics are often represented by a layer of polyethylene and paper fused with it.

Natural products are most often made from cork oak bark and other materials that have a pronounced property of absorbing and dampening vibration.

Famous brand

The backing for wallpaper is presented quite widely in modern industry. Professionals recommend using Polyfom at home. This material is presented in the segment as insulation from the ECO group. This substrate is incredibly popular for good reason, because it:

- has a thickness of 4-8 mm;

- made from foamed polyethylene;

- is environmentally friendly, because butane and freon were not used in production;

- resistant to various chemicals and fuels;

- has technical characteristics that allow use in the temperature range from -60° to +90°;

- has white paper lining on both sides;

- Available in rolls.

It is immediately clear that the additional layer will not affect the footage in any way, since the thickness is less than a centimeter. The presence of a white surface without a pattern will prevent stains from appearing on the wallpaper, and the roll form is convenient to use. The wide temperature range of application makes it possible to use Polyfom for wallpaper in residential buildings, production facilities, and in open areas almost anywhere on our planet.

The technical properties of absorbing noise, retaining heat and the absence of harmful components have led to the fact that this material is actively used in children's preschool and school institutions, medical institutions and office buildings.

Polyfom is easy to use not only due to its roll form. The material can be easily cut, glued, and can be given any desired shape. This insulation does not rot, does not condense moisture, and is not susceptible to mold, harmful insects and rodents.

A combination of aesthetics and practicality

Cork backing - can be used as a decorative covering

All traditional wallpaper, with the exception of liquid and stretch modifications, perform a purely decorative function. That is, they are designed to make the room beautiful and, as a result, cozy. Currently, along with traditional materials, wallpaper is used that can reduce the thermal conductivity of the walls in your home.

The ability to retain heat is achieved through a special substrate, directly on which the main canvas with a particular image or ornament is attached. Installation of these coverings is not much different from gluing conventional wallpaper. However, special requirements are placed on the surface of the base and the composition of the adhesive on which installation will be carried out.

Substrate characteristics

Paper side of thermal insulation backing

Thermal insulation under wallpaper will help you make your walls less thermally conductive and save on space heating costs. The backing is a thin layer of cork, polyethylene foam or polystyrene. For greater adhesion, the material is made with single-sided or double-sided paper lamination.

On the market, thermal insulation underlay for wallpaper is mainly represented by the following brands: PenoHome NomaTherm and Polif. The price of 1 meter is from 100 to 150 meters. The coating is sold in rolls of 5–7 m.

The use of a synthetic thermal insulating substrate allows you to:

- reduce the thermal conductivity of walls (the effect is comparable to the effect of using mineral wool or polystyrene foam 2 cm thick);

- level out small bumps on the walls;

- prevent mold formation by containing antiseptic additives;

- reduce the level of noise entering the room from the outside.

Features of installation work

In the photo - rollers for rolling wallpaper in hard-to-reach places

Gluing thermal insulating wallpaper with your own hands is not as difficult as it might seem.

To carry out finishing work we will need the following materials and tools:

- thermal insulation substrate (you can read about how to correctly measure the coating for gluing walls in the corresponding article on our portal);

- glue for heavy wallpaper (on smooth walls it is advisable to use compounds such as PVA, Liquid Nails or Baguette Glue;

- shallow penetration soil for walls;

- leveling compounds in accordance with the type of wall surface;

- spatulas wide and narrow;

- trowel (trowel);

- roller for pressing the insulating sheet;

- wide flat brush;

- wide masking tape;

- tape measure, square and pencil.

Surface preparation

Leveling the surface with a layer of finishing putty

At the first stage, we prepare the surface of the walls. The main requirement for the base is strength and smoothness. Therefore, if the backing is glued directly after removing the old wallpaper, it is necessary to remove the remaining glue, sand the surface and prime it.

If installation is carried out on untreated cement plaster or on an uneven surface, you will first have to apply a layer of primer, and after it has completely dried, apply putty.

Wall putty is applied with a wide spatula and smoothed with a trowel. After the putty layer has completely dried, it must be sanded, dusted and covered with one or two layers of primer. You can begin installation after the soil has completely dried (on average 2-3 days).

Material preparation and gluing

In the photo - gluing a strip of thermal insulation to the base

At this stage, we measure the height of the walls and cut the substrate into strips of the required size. We lay the strips on the floor for several hours so that they straighten under their own weight. We apply glue to the inside of the strip, leave it for the time specified in the manufacturer's instructions and glue it to the wall.

Unlike traditional wallpaper, the backing is thicker, and therefore air pockets can only be dispersed using a rubber roller. After we have rolled the entire surface with a roller, we glue the joints along the cut line with masking tape.

At the floor and ceiling, we cut the canvas with a knife to fit a wide spatula. We do not bend the backing at the corners, but cut it so that the cutting line runs along the line of the corner.

Method of application

However, when using it, you should still follow some rules:

Installation of roll insulation on walls

- Before gluing, it is recommended to divide it into strips of the required length. The standard rolled Polyfoam for wallpaper is 14 meters long and 0.5 meters wide.

- The surface of the walls should be cleaned of crumbling plaster, old wallpaper, glue, and dirt.

- Existing cracks should be filled with putty.

- If the surface of the walls is with fresh plaster, it is recommended to smooth it and treat it with a primer.

- Under Polyf, glue is applied not to the surface, but to the material itself.

- You should purchase special glue for gluing backing or wallpaper made of non-woven fabric or vinyl.

- The tapes need to be glued end-to-end, and it is recommended to glue the joining seam with paper tape or special tape.

- Wallpaper can only be pasted onto the substrate after 72 hours.

- The recommended room humidity should not exceed 70%.

- When working and when drying the material, drafts should be prevented.

Despite the recommendations of experts and the popularity of Polif’s material, consumer opinions are divided.

Main problems with the material

The main disadvantage that most people point out is the effect of a thermos in rooms. To avoid such discomfort, you have to ventilate the room repeatedly, or increase ventilation through additional hoods. Also, consumers do not like the softness of the walls. There are dents from furniture and other objects, and, as a result, deformation of the wallpaper in these places. Although manufacturers indicate that the material is not subject to mechanical stress.

In addition to these disadvantages, consumers are not satisfied with the insulating effect. In a separate room, even without furniture, there is no echo, the acoustics improve, but the noise of neighbors can be heard at the same level. Sounds from the street are also poorly absorbed.

They also indicate problems after the wallpaper dries. In some places, the underlay is visible at the joints, since the decorative coating on the insulation diverges more than on bare walls. The percentage of shrinkage of heavy wallpaper is much higher. The coating did not peel off only where the surface of the layer was additionally primed.

Label for insulation layer under wallpaper of a popular brand

In response to all of the above shortcomings, experts suggest not to rush into accusations. Since when purchasing this material, one should take into account the ventilation capacity of the room, the constant level of humidity, the material used in the construction of the building and climatic conditions. When purchasing a substrate in a store, it is recommended to familiarize yourself with the manufacturer and check for a certificate for the product. After all, you can get on sale “left-handed”, uncertified insulating material. Hence the other technical characteristics and all the above problems.

And despite the ease of use, it will still be better if professionals work with the Polif material. Only they can determine whether a sufficient amount of glue has been applied, whether the surface has been prepared correctly, and whether the walls should have been treated with a primer. Do not forget about the level of humidity in the room - only a specialist will determine how it can be increased or decreased.

In the modern market, Polyfom still occupies a leading position. We can only hope that manufacturers take into account all consumer opinions and will soon present an improved product in which it will be difficult to find flaws. And when using this material, you will not hear your neighbors, the walls will be without dents, the thermal effect will disappear, and all the positive aspects will remain at the same level.