Today, the underfloor heating system is extremely popular. This is due to a large number of positive qualities, as well as the possibility of installing any type of flooring. In addition, you can choose absolutely any option for the heating system, depending on the need and the room itself. But it is worth noting that when installing all components of a heated floor, special attention should be paid to the thermal insulation layer so that heat is not wasted just like that. An excellent option here would be underfloor heating. The main thing is to know which one to choose.

Advantages of heated floors

Perhaps the most important requirements that a person who wants to acquire a heated floor poses are:

Environmental friendliness- Durability

- The optimum ratio of price and quality

- Easy to install

- Simplicity of design and maintenance

Water heated floors meet all these requirements. It does not emit any kind of radiation, except perhaps thermal radiation, it is economically justified and has a long service life.

Warm floors are unpretentious to use, and taking into account the durability of modern materials, they will serve the owners for a long time and effectively, creating a truly cozy, “warm” atmosphere in the house.

Laying technology

Laying the substrate is an important step when installing infrared heated floors. Therefore, when installing it, you must follow a number of rules:

- when using fiberboard sheets or magnesite boards, the screed should first be covered with aluminum foil;

- in cases of polymer metallized film, its reflective side should be positioned upward;

- the insulating material must cover the entire surface of the heated room.

As when installing the underlay into the “pie” of any heated floor, the underlay for infrared film is mounted on a clean base equipped with a vapor barrier layer (polyethylene).

The insulation is spread over the entire area of the room, reflective side up, with a distance of 100 mm from the walls. These openings are closed with a tape damper. The joints are taped with special metallized tape. To prevent the material from moving when the floor is in use, it is attached to the base with double-sided tape.

After this, the infrared film is mounted; there should be no air gaps between it and the substrate. Then the finishing coat is applied.

The efficiency of the floor, and therefore the comfort in the house, depends on the correct and high-quality installation of the underlay.

Choosing a substrate for a warm water floor

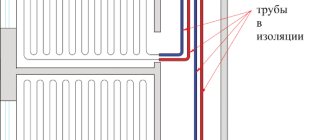

If the choice is a water heated floor, then the substrate must be suitable for it and comply with the recommendations of experienced builders, manufacturers of underfloor heating components and specialists in the field of water heating.

Almost all experts in this field agree that thermal insulation between load-bearing foundations (walls and floors) and the water heating system requires special attention. Properly selected thermal insulation (subject to other recommendations) will allow you to use a heated floor as the main, or even the only, source of heat in a heated room, and will also save energy that would be spent on heating the street or neighbors without thermal insulation.

In addition to these quite obvious things, a good substrate promotes uniform heat distribution in the room and has a beneficial effect on the microclimate.

Almost all specialized substrates for warm water floors have thermal insulation properties, so in the article we will consider them.

Polypropylene boards

One of the optimal options for thermal insulation of water heating, it is not afraid of elevated temperatures and humidity, and is the cheapest material in terms of cost. It is not afraid of aggressive chemical compounds and does not emit harmful substances during heating. It has low flammability and does not support open combustion. The reproduction of various microorganisms, including mold, is inhibited on the surface. It is approved for use by sanitary control organizations without restrictions. The slabs may have ready-made grooves for laying pipelines.

Polypropylene boards

Sheet polypropylene

Mats for warm water floors

There is a whole range of mats for warm water floors, they all have different characteristics and are in different price categories. Let's look at their main types:

Foil mats On the price tag in the store, in addition to this name, you can see “Foil underlay for heated floors” or “penofol with a reflective coating.”

From the name it’s easy to guess that their main working element is a reflective surface.

Although this type of mat is cheap, it is far from the best option; it is not suitable for basement floors, but it will be a good solution when it is important to save 3–4 centimeters of living space.

Foil mats for warm water floors are laid on the base with the reflective surface facing up. The installation of pipes takes place directly on top of such a substrate. After installation, you can immediately screed.

- Film mats

Film mats for heated floors are a more advanced solution than foil mats; their thermal insulation properties are an order of magnitude higher due to the use of more modern polymers than penofol. The design features allow them to be used as a substrate for heated floors under laminate. In addition, the installation of underfloor heating pipes will be simplified by the presence of special markings and a system of fastenings (lamellas) for the pipes. The screed can also be laid on top of film mats for warm water floors without the use of intermediate layers. - Flat polystyrene foam mats

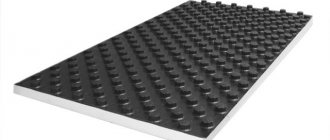

They are also foam mats, they have a high class of sound insulation, but have a number of disadvantages, which include low resistance to damage and chemical sensitivity to the composition of the screed. Due to the low chemical resistance of polystyrene foam underfloor heating, it is necessary to lay a second layer of high-density polyethylene film before laying pipes. - Special mats with bosses.

The price of underfloor heating with bosses is higher than that of polystyrene foam mats, but it justifies itself at later stages of installation.

A substrate with bosses for a heated floor is one of the best solutions and has a number of advantages: rows of shaped protrusions simplify the installation of pipes - no additional pipe fixation required

- does not require additional layers before laying the screed

- accompanies the uniform distribution of heat-conducting structural elements

- has high noise, heat and waterproofing properties

Other types of substrates

cork mats and slabs made of chipboard and OSB

are widely used , however, it is worth noting that although such materials have high thermal insulation and sound insulation characteristics, their use as a substrate for a warm water floor is not economically profitable, since they require additional measures for vapor barrier, which entails additional costs.

In addition, when it comes to heated floors, it is better to work with such materials by specialists who have extensive experience.

Combined underlay for water heated floors

It is permissible to use 2 types of insulation at once, laid in layers, for example, the simultaneous use of foil and flat mats will give a double effect in thermal insulation, where the foil coating will have reflective properties, and polystyrene foam will have thermal insulating properties.

This type of combination is not the only one; combinations of mats with bosses, metal profiles and gypsum fiber sheets are increasingly being used.

Perhaps the only disadvantages of such a “layer cake” system will be the high cost and a significant reduction in the height of the room (not suitable for rooms with low ceilings).

Requirements for bedding material

The characteristics of the substrate are selected depending on the type of roughing base, finishing coating and operational features of the water floor. However, there is a basic list of properties that any type of bedding material must meet.

Strength and elasticity. As a rule, the heating circuit is embedded in a cement-sand screed. The pipes of the water system themselves, especially those made of metal, also place a considerable load on the substrate.

The lining material should not be irrevocably deformed, sag or change its thickness. It is important that the substrate has the ability to restore its original shape after removing the load

Low thermal conductivity. It is optimal if the heat capacity of the material is combined with its insignificant thickness. The water floor system reduces the height of the room; depending on the type of substrate, the size of the “pie” can be 5-15 cm.

A positive effect is provided by the ability of the substrate to reflect heat, which ensures the presence of a foil film with reflective properties.

High waterproofing properties. An important characteristic is the percentage of maximum water absorption. The material should not absorb or transmit moisture.

The permissible water absorption coefficient is no more than 2-4%. The use of such a substrate is permissible if the material is able to dry completely without dismantling the floor - solely due to natural ventilation

Resistance to temperature changes. The declared properties of the substrate must be maintained at different temperature conditions. When choosing, it is important to evaluate such an indicator as permissible operating temperatures. The limit value is not less than +70°С.

In addition to the stated requirements, the substrate should not emit toxic or harmful substances. A definite plus is the low price and ease of installation.

Puzzle backings are practical to use. The mats are assembled into a single fabric, similar to a construction set - this makes it possible to easily adjust the heating circuit to the configuration of the room

Installation

- Measurements Installation of the underlay for a heated water floor should begin with measurements of the room in which heated floors need to be installed. When taking measurements, it is important to take into account that film and foil mats are sold in rolls, while all others are mainly sold in slabs. At the measurement stage, your task will be to minimize the length of the joints and, based on this task, you need to select the width of the rolls or the width and length of the mats for the underfloor heating.

Preparing the load-bearing surface At the next stage, the floors need to be cleaned of debris and uneven surfaces. This will allow the substrate material to be distributed more evenly in the next step.- Laying the material The substrate material must lie freely and without tension.

To prevent roll materials from creasing, it is better to use a long, but not heavy load, such as a block.

- Gluing The joints of the substrate should be glued before laying pipes and screeds; aluminum tape, or its cheaper analogue - metallized tape, is best suited for this purpose.

Stability of characteristics

Groups of porous materials, such as polyethylene foam and expanded polystyrene, have an unpleasant feature. Over time, under the influence of static stress (burden from lying pipes and the load when walking on the floor) they are compressed. The thickness of the substrate decreases, the process may proceed unevenly, differing in different areas of the room. This can cause unpleasant consequences.

You need to select a substrate material based on the service life and physical characteristics declared by the manufacturer. Temporary changes in geometry are taken into account, as well as production technology. For example, expanded polystyrene foam has an open structure and sticks together over time. At the same time, extruded has completely closed cells, is elastic, retains its geometry and properties for decades.

conclusions

- Installation of warm water floors must begin with an assessment of the situation and measurements. It is necessary to decide whether the heated floor will be the main or additional type of heating of the room.

- The choice of the best underfloor heating must be approached responsibly and based on the characteristics of the room, taking into account not only the area of the room and the expected temperature, but also the humidity and height of the ceilings.

- It is much safer to use those materials that are specifically designed for warm water floors. This approach will not only save time, but will increase service life and save up to 20% on energy spent on heating the room.

It is better to purchase a substrate for a warm water floor in specialized stores, which will protect you from purchasing low-quality products.

Adviсe

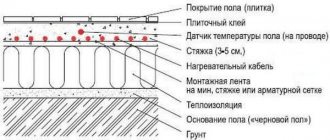

One of the most modern trends in solving the issue of thermal insulation at home has been the installation of a “warm floor” system. Nowadays, manufacturers have brought to the market three main options for underfloor heating - water, infrared and cable. The water method is used for large areas. This technique involves circulating hot water through pipes built into the floor. Such a system has a number of limitations:

- it cannot be used in multi-storey buildings, as it creates additional pressure on the floors;

- in the event of a breakthrough, there is still a risk of “flooding” the neighbors below, which will lead to large expenses for troubleshooting;

- high cost of materials, as well as installation work.

The infrared floor is a polymer film, which is divided into identical squares, each of which contains special plates responsible for high-quality heating.

It is better to install such a system under laminate or linoleum. If you use it under tiles, it bonds quite quickly with the adhesive solution.

Cable is an electric floor that can function year-round. In order to reduce energy costs, special thermostats are built into the design. The structure itself is assembled from two- or three-core cables or electrical mats.

This method is optimal for tiles, as it helps them heat up quickly and retain heat.

The “floating floor” technology is very popular; Isover coating is used for it.