Heating system pressure

The concept of pressure in the boiler and heating system refers to the same indicator. Different experts use different names for this indicator:

- Boiler pressure;

- Central heating pressure.

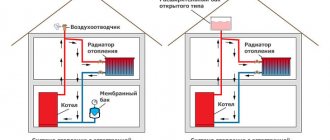

In most homes, owners use a combined system or sealed non-combined options. Sometimes installation specialists also refuse a collector tank. The heating in the central part is firmly sealed and is also under constant pressure. When heated, the operating pressure may increase. In addition, this indicator is influenced by the location of the circulation pump.

Operating pressure in the heating system of a private house

Operating pressure in the heating system of a private house

Most of the structures that are used in the heating process are closed options. Such devices do not have open ventilation holes where water can expand and contract with temperature changes. The system is tightly sealed and constantly under pressure - thus, it is possible to compensate for these moments.

In order for the heating system to work correctly, it is necessary to monitor such an indicator as operating pressure. In this case, you should understand what its optimal values may be.

Modern heating equipment has a special algorithm that turns off the system at low and high pressure.

The problem is that a deviation in one direction or another negatively affects the entire functioning process: if the indicator is too low, the boiler will simply turn off and residents will lose access to hot water. If the readings are significantly higher than normal, then an extra load is created on the entire device, which provokes early wear of the unit.

A few general but important notes

In order to be able to talk about the correct operation of the heating system and its setup and adjustment, you first need to make sure that your country house heating system is correctly designed, installed, and the heating equipment is correctly selected.

This approach is dictated by the fact that heating systems in private houses are often “sculpted” by teams of “shabashniks”. But how, what, and on what basis they do it often remains a big secret for homeowners. Therefore, I am forced to draw the reader’s attention to several, in general, truisms, without understanding of which it is not serious to talk about setting and adjustment.

Stage No. 1

The first thing you need to make sure is that the parameters of the boilers correspond to the parameters of the heating system. The arithmetic here is simple. For every kilowatt of boiler power there should be approximately 13 liters of water (coolant) in the heating system. Moreover, deviations in a larger direction are not as critical as in a smaller direction. In this case, by and large, it does not matter who the manufacturer of the boiler is or even what fuel it runs on.

The easiest and most reliable way to determine the volume of water in the heating system is to view the water meter readings by pouring liquid into the system (during the first test fire, when flushing the system). In addition, you can calculate the volume of water in the system. To do this, it is necessary to take into account its volume in the main devices: in the heating boiler, in heating radiators and in pipes. For example, during my first test fire, the water meter showed that 295 liters were poured into the system.

Thus, the specific volume of water in the system in my case was: 295/20 = 14.75 l/kW, which slightly exceeds the required value. But more is not less. Therefore, I did not change anything, and later regretted it.

If the volume of water is too small in relation to the power of the boiler used, it is advisable to adjust the volume of the coolant in accordance with the power of the boiler. The easiest way is to add the number of heating devices to the system.

When determining the boiler power, you need to take into account possible nuances and surprises. So, for example, I bought my boiler as a 16-kilowatt boiler.

When inspecting the equipment and documentation at home, it turned out that the boiler was equipped with a 20 kW gas burner. Accordingly, the boiler power is not 16, but 20 kW.

Owners of imported boilers may be in for another surprise. For example, a boiler with a power of 27 kW (at a nominal gas pressure of 18-20 mbar) in our gas networks at a pressure of 13 mbar will actually produce a little more than 20 kW. In winter, when the pressure drops even lower, the performance of the gas boiler will decrease even more.

After we have made sure that the volume of coolant corresponds to the power of the boiler, and have clarified the volume of water in the system, we can proceed to the next stage.

Optimal pressure in the heating system

The pressure in the structure must be distributed so that streams of hot liquid can move evenly throughout the house. If we talk about the average, the pressure gauge usually fluctuates in the range of 2-4 bar. The gas boiler is equipped with a special sensor, which should record deviations and indicators. This measurement system is needed in order to understand the appropriate pressure for pressurizing water at home.

- If we talk about an open system, then the indicators in the expansion tank and in the external environment will be the same and amount to 0 Bar.

- If we consider a closed system, then the pressure is increased artificially - this is how high quality work is achieved and a barrier appears for air to enter the coolant.

To calculate the optimal pressure indicators in a closed system, you need to multiply the height differences at the highest and lowest points by 0.1. Another 0.5 bar is added to the resulting indicator (this is the static pressure). If there is a cold coolant in the system, then it is better to immediately take 1.5-2 bar as the optimal value (the last number during the heating process).

Why raise the pressure?

The pressure in the supply line is higher than in the return line. This difference characterizes the heating efficiency as follows:

- A small difference between the supply and return makes it clear that the coolant successfully overcomes all resistance and transfers the calculated amount of energy to the premises.

- An increased pressure drop indicates increased section resistance, decreased flow velocity and excessive cooling. That is, there is insufficient water flow and heat transfer to the rooms.

For reference. According to the standards, the optimal pressure difference in the supply and return pipelines should be in the range of 0.05–0.1 Bar, maximum 0.2 Bar. If the readings of 2 pressure gauges installed on the line differ more, then the system is not designed correctly or needs repair (flushing).

To avoid high drops on long heat supply branches with a large number of batteries equipped with thermostatic valves, an automatic flow regulator is installed at the beginning of the line, as shown in the diagram.

So, excess pressure in a closed heating network is created for the following reasons:

- to ensure forced movement of the coolant at the required speed and flow rate;

- to monitor the condition of the system using a pressure gauge and recharge or repair it in time;

- Coolant under pressure heats up faster, and in the event of emergency overheating, it boils at a higher temperature.

We are interested in the second item on the list - the pressure gauge readings as a characteristic of the serviceability and performance of the heating system. They are of interest to homeowners and apartment owners who independently maintain home communications and equipment.

Adjusting the pressure in the heating system

If the heating system is not running, then the pressure in the boiler should vary from 1 to 1.5 bar, with the arrow itself pointing to the green zone.

If, during heating, the pressure begins to increase by 1 bar, then the expansion tank will also need to increase the pressure again. If a high indicator occurs due to overflow, then you need to bleed the radiator. As a result, the pressure gauge should again be in the range of 1-1.5.

On average, you need to top up the pressure no more than 2 times a year - if this happens more often, then you need to find out why the boiler does not hold pressure.

Adjusting the pressure in the heating system

High pressure in the heating system

High pressure in the heating system

In order for the boiler to operate at maximum efficiency, it is necessary to constantly monitor its pressure readings. If excess air gets into the case, it must be promptly removed from the radiator.

Most likely, you are faced with excess pressure and have found the following symptoms:

- The radiators are cold at the top or bottom;

- Too much noise from the pump or boiler.

It is necessary to check the equipment even if the pressure is constantly at a high level, even if excess liquid is regularly drained through the tap.

It is necessary to identify the cause of the problem, why there is a constant increase in pressure, as well as the place where the water is drained through the safety valve. If water flows directly through the protective pipe, and the pressure does not drop below 3 bar, then there are two possible main reasons for such malfunctions.

- Shut-off valves are open (or not closed tightly), but the filling circuit is connected. This situation provokes the heating system to constantly replenish. To prevent this from happening, you need to check that the circuit is completely turned off and the valves are closed. Experts recommend draining the water gradually until the cold pressure drops to 1.5 bar. If the water does not stop, but also passes through the safety valve, then it will need to be replaced (this must be done when the pressure drops sharply).

- If you see that the filling circuit is turned off, but the pressure does not drop even when excess water is drained through the tap, then the problem should be looked for in the plate heat exchanger. This part is a type of secondary heat exchanger (only combi boilers do not have them).

It is because of this problem that the pressure remains high - a leak forms in the plastic heat exchanger. It is located in the structure itself, where process water is separated from clean water through the use of metal parts.

When the equipment operates correctly, the water that the device heats is pumped through a secondary heat exchanger. As a result, clean water flows in a specific direction to the hot water taps. All tunnels are located close to each other - their walls are always in contact. Heating occurs precisely because of this touch, since the water heats up as it moves.

If the leak is between these two paths, then high-pressure water leaks into the direction of the heating system - the pressure rises throughout the entire structure. As a result, it can reach up to 3 bar, after which the safety valve will open. Due to the leak, the pressure gauge may only show 3 bar at all times, while water will still flow through the safety valve. If you encounter this situation, you will have to change the heat exchanger and safety valve.

Low pressure in the heating system

Low pressure in the heating system

There are several critical points when you should think about repairing the entire device.

- If the readings have shifted below 1, then most likely there is a leak somewhere and the radiators need to be checked.

- If the indicators have shifted even below the 0.5 mark, then you need to replace the parts and add water.

If a pressure drop is periodically observed in the heating system, then it is necessary to check three main places where this can occur:

- Safety valves and pipe. To check for problems in these parts, you need to inspect the entire route of fluid movement (you should start from the safety pipe). The end of the protective pipe can be found in the pipeline itself. It is the water that passes through the safety parts that can cause permanent problems in the system.

- Sometimes water can get from the general system into the condensate pan or through its pipe. This happens due to leaks in the inner wall of the heat exchanger, but in practice this can be found quite rarely.

- Internal leakage in the structure.

If the pressure drop occurs slowly enough, then after a certain period of time it will be necessary to make additional replenishment of the entire system.

How to increase pressure in a closed heating system

Measures to increase pressure in a closed system:

- It will be necessary to drain about 2% of the coolant fluid;

- According to the instructions, you need to adjust the pressure in the expansion tank. To measure pressure correctly, you can use a pressure gauge;

- At the top point of the circuit, experts recommend opening the valve and then starting to fill in coolant until the pressure returns to normal.

- Then the circulation pump is started so that all the accumulated gas comes out. In this case, it is necessary to periodically bleed air around the valve.

During deflation, to avoid air pockets, it is also necessary to gradually add coolant so that the pressure rises. As soon as the circulation pump starts, a person should see a difference in the indicator values. If the pressure rises too slowly or unevenly, then not all the air has been pumped out of the pipes.

Leak detection

How can leaks be identified and corrected? If the pressure in the system decreases, then you need to find a leak, that is, clearly determine the location of the malfunction. In this case, you need to inspect all the pipes to make sure they are tight . Particular attention should be paid to areas where fittings, couplings, and pipes are connected. Typically, this is where leaks occur.

This is due not only to strong pressure drops, but also to the fact that the installation was done poorly. But when puddles are visible under the areas where the pipes are located, the system requires a more thorough inspection. Repairs and replacement of individual sections may be required.

These inspections must be done regularly in order to promptly identify any faults and change pipes or their connections. But when the pipes are replaced, and the pressure in the heating system continues to decrease, more thorough troubleshooting work needs to be carried out. It is advisable to invite a specialist who, using special equipment, will identify the reason for the decrease in pressure.

In this case, you need to drain the water and fill the pipes with air using a compressor. The batteries and boiler are disconnected from the system, then all pipes are carefully inspected. In areas where leaks are observed, air whistling will be heard, accordingly, it is this area that needs to be repaired.

The repair needs to be done correctly , here you will need:

- replacing the section of pipe in which a leak was detected with a new section;

- if there is a weakening at the connection, then just tighten it; you will probably need to change the fittings for the pipe;

- a winding for compaction is used in the form of a tape, which is sold specifically for this purpose;

- the damaged section of the pipe, including the connection, is completely replaced with a new one.

If nothing was found during the work to identify leaks, then the problem is probably in the performance of the heating system itself, more precisely, the expansion tank and boiler. When installing water heating, you need to carefully inspect all the batteries; leaks and loose connections may also appear here. Auxiliary tools and materials will not be needed at this stage.

To carry out these works, it is advisable to call a specialist rather than buy completely unnecessary materials, because the likely cause of the malfunction is the incorrect installation of some component , the heating boiler itself. But, as a rule, after removing the leaks, the pressure in the system normalizes.

Heating boiler testing

Often, pressure disturbances in the heating system are associated with the boiler. In this case, you need to test it, namely, diagnose it, but only a specialist can do this. A decrease in pressure may be due to a reason such as the formation of microcracks in the heat exchanger . The pressure decreases slowly; it is necessary to recharge at certain intervals.

In this case, the heating boiler must be checked immediately by calling a specialist, and not put off repairs for a long time. Professionals advise testing the heating system before the start of the season, this will make it possible to avoid many problems during operation.

Expansion tanks are installed in closed water heating systems to compensate for temperature expansion. These are tanks divided into two parts by a partition. In one area there is a coolant, that is, water, in the second - gas. During expansion, the coolant creates pressure on the partition , occupying another part of the volume of the tank; during contraction, the opposite situation occurs. In this way, it is possible to control the overall pressure, preventing leaks and other malfunctions.

How to choose a tank size to maintain normal pressure

It is best to select an expansion tank and install it in the boiler room of the house itself, and the pressure in the tank must be 0.2 bar higher than the static pressure in the tank. Static pressure data can be calculated by multiplying 0.1 bar per meter by the height from the highest point of the heating to the expansion tank.

For water heating of a house, you can find out the volume of this expansion tank using the formula V=(e * C) * (Pmax+1) / (Pmax—Pgas) , where:

- V is the overall size for the expansion tank;

- C is the volume of all water in the heating system, in liters;

- e - temperature expansion for the coolant, indicated as a percentage. It is advisable to take with a small margin of 3.5%, this corresponds to the approximate temperature in the system at 90 degrees;

- Pmax is the highest pressure level. As a rule, it is designated equal to 3 bars;

- Pgas - gas pressure directly in the tank.

If a calculation takes place, most experts advise taking into account the safety factor; it is equal to 1.2-1.25. When purchasing a membrane tank, it is advisable to round up the calculation to the larger part; this will make it possible to maintain normal pressure in the system without worrying about its decrease, significant differences, leaks and other malfunctions.

Normal boiler pressure

First of all, the main sign of normal pressure in a heating system is its stability. If the system is not yet connected or paused, the pressure meter should be between 1 and 1.5 bar. If there is a slight deviation from the norm, then it is not a big deal. When the pump is turned on in the system, the pressure may also change slightly - this situation is not considered a problem. This effect occurs when the direction of the pump to the pressure gauge changes, as well as its placement relative to the measuring device.

When the system heats up, the pressure level increases - usually at the highest heating point the pressure can increase by at least 0.5 bar. Typically, for the structure to fully heat up, you will need to wait about 15-25 minutes.

The exact normal pressure indicators depend on the specific type of system.

Here, a lot depends on the volume of the heating system itself and the expansion tank - it is located in almost all sealed systems. If we consider a specific situation with a private house, then experts usually talk about the norm of 0.3-6 bar.

It is necessary to check the equipment if the pressure rises too quickly (more than 0.5 bar per cycle) - this indicates problems in the system.

Normal boiler pressure

Some general information

Even at the design stage of the heating system, pressure gauges are installed in different places. This is necessary in order to control blood pressure. When the device detects a deviation from the norm, it is necessary to take some action; a little later we will talk about what to do in a specific situation. If no measures are taken, the heating efficiency drops and the service life of the same boiler is reduced. Many people know that the most detrimental effect on closed systems is caused by water hammer, for damping which expansion tanks are provided. So, before each heating season, it is advisable to check the system for weak points. This is done quite simply. You need to create excess pressure and see where it shows up.

How to relieve pressure in the boiler if it is high

If the pressure inside the boiler has increased, then there are several methods. How can I get it back to normal?

- Drain the water from the equipment. This is one of the reasons why pressure readings can go off scale. This is only possible if the pump is operating correctly to specification. To solve this problem, you must first turn off the boiler so that it becomes completely cold. Find the place where the water is draining and select a vessel to collect it. Carefully open the drain and pour the liquid out into a plastic container. This must be done until the needle on the pressure gauge reaches the desired value (usually the green zone).

- Bleed the radiators. Another reason for too high pressure is an air lock in the radiator. To solve this problem. You must also first turn off the boiler and let it cool. Find a hole from which air is removed, and also prepare a container to collect water. Next, you need to carefully open the outlet valve - water and air bubbles will begin to leak out. After the process has stabilized, the valve must be closed and proceed to checking the next radiators. After all these procedures, the pressure sensor should be in the green sector. After each drain, be sure to close the hole tightly.

In radiators, air accumulates from a pump, which generates air flows. It is necessary to pay attention that if such pumping is necessary too often (more than once a year), then you should call a specialist to thoroughly check everything.

What to do if the pressure in the boiler is low

If too little pressure develops in the boiler, then first of all you need to check the safety valve. If it is already connected to the system, then when the pressure increases, it may not be tightly closed. This causes leaks. Also, the safety valve can wear out over time, so if a leak occurs, the damaged part must be replaced. After troubleshooting, you can continue using the equipment.

You can also take a few simple steps to restore your blood pressure readings.

If you turn the red part, the red valve will become disconnected, which could allow liquid to leak into the inside. If you turn it further, it will fall into place on its own. These actions will increase and stabilize the pressure in the system. If nothing works and the differences are too noticeable, then you need to replace the part with a new one.

Sometimes it is not possible to find the place of the water leak - in this case, most often the water flows under the floor. However, there are situations when the floor covering is solid - you won’t be able to fix the problem yourself, but some specialized companies can help raise the floor and fix this problem.

Pipe diameter and degree of wear

It is necessary to remember that the size of the pipe must also be taken into account. Often, residents set the diameter they need, which is almost always slightly larger than the standard sizes. This leads to the fact that the pressure in the system decreases slightly, which is due to the large amount of coolant that will fit into the system. Do not forget that in corner rooms the pressure in the pipes is always less, since this is the most remote point of the pipeline. The degree of wear of pipes and radiators also influences the pressure in the heating system of the house. As practice shows, the older the batteries, the worse. Of course, not everyone can change them every 5-10 years, and it is not advisable to do this, but it doesn’t hurt to carry out preventive maintenance from time to time. If you are moving to a new place of residence and you know that the heating system there is old, then it is better to change it immediately, so you will avoid many troubles.

Boiler pressure control

If the system operates stably, then there is no need to constantly check the pressure status in the boiler. Experts say that in this case it will be enough to inspect the heating structure only once a month. However, there are cases when this needs to be done additionally:

- At the beginning of the heating season. Before the start of winter, you should once again check the operation of the entire system, since during the cold season it plays an important role for the life support of residents.

- After bleeding the radiators. If you had to pump them additionally, then you need to control the stability of the pressure in the boiler - the needle should not move too low.

If the system works stably and there is no suspicion of problems, then it is enough to monitor this indicator with a pressure gauge in normal mode.

Air lock as a cause of increased pressure

Another possible reason why the pressure itself increases is the presence of air in the heating circuit.

Airing can occur due to:

- when the heating circuit fills with liquid too quickly, the system should be filled slowly, with the air bleed valves open. The valves are open until liquid flows from the highest point of the system;

- Mayevsky's taps are broken, change the taps;

- The impeller of the circulation pump is loose, which may allow air to enter, adjust the impeller.

Terminology issues

Network pressure is divided into two components:

- Static pressure. This component depends on the height of the column of water or other coolant in the pipe or container. Static pressure exists even if the working medium is at rest.

- Dynamic pressure. It is a force that acts on the internal surfaces of the system when water or other medium moves.

The concept of maximum operating pressure is distinguished. This is the maximum permissible value, exceeding which can lead to the destruction of individual network elements.