One of the most important stages in the finishing of any building is the protection of all its structural elements from loss of internal heat. Effective thermal insulation significantly reduces the cost of maintaining a comfortable temperature in living and working spaces. The issue of selecting the optimal insulation is important both for large projects and for private country houses.

One of the popular bases for creating heat-insulating materials is foamed polystyrene, produced using various technologies. Its characteristics provide reliable protection of all elements of the building. One of the representatives of this class of insulation is products under the Termite brand.

Technical characteristics of Thermit polystyrene foam extrusion boards

Thermal insulation “Termite” has a lower thermal conductivity coefficient compared to other materials that are used in construction for insulation and sound insulation. “Termite” insulation lightens the weight of erected structures, helps save on space heating, and increases the life of the building, since repairs when using it will not be needed for many years. Its service life without loss of thermal insulation qualities is more than 50 years.

The use of this material allows you to reduce costs for materials and labor . “Termite” combines characteristics due to which it is often used in low-rise construction.

1 sheet has a size of 1190x590x30x mm, which facilitates transportation to the construction site and work with insulation.

Strength and rigidity

Strength and rigidity are the main characteristics of insulation that determine its choice. “Termite” has a rigid structure. It can withstand loads of up to 25 tons per 1 m² . The slabs are also resistant to rodent attacks.

Flammability

Thermite slabs are resistant to fire, so their use when carrying out thermal insulation work will provide additional protection against fire. The insulation does not spread flame over the surface; it is a self-extinguishing material , which is important in the construction of housing and various national economic facilities.

Basic material properties

The basis for Termite insulation is polystyrene. In the nomenclature under this name there are materials based on conventional polystyrene foam or polystyrene foam and extruded polymer. The second option is the most popular in modern construction, because its properties differ significantly from those of classic foam plastic.

Thermal insulation based on extruded polystyrene foam is characterized by a monolithic structure with a large number of absolutely closed pores, the diameter of which does not exceed several tens of microns. This structure provides the material with high resistance to heat loss, strength, durability and low permeability.

Due to its cross-linked spatial structure, Termite insulation is chemically inert. It also does not support combustion.

The strength of the material is sufficient to withstand light loads, as well as the pressure of rodents.

What is the difference between Thermit XPS and Thermit EPS

XPS and EPS thermal insulation have significant differences. XPS is not moisture absorbent and has high compression resistance . Foam plastic can be sufficient for installing thermal insulation on walls, insulating a balcony or ceiling, and for arranging the foundation, floors in industrial buildings, and insulating soils, XPS insulation will be the best choice.

These types of thermal insulation differ in price. EPS insulation is less expensive, so it is often easier to purchase quality EPS extruded polystyrene foam. Plaster is easily applied to the foam, and it attaches well with glue.

Features of a septic tank

The main element of this design is a plastic rectangular tank. It consists of several interconnected chambers through which wastewater passes. Here it is filtered clean and also clarified due to the presence of bacteria.

This septic tank has several important advantages:

- energy independence, because power sources are not needed during operation;

- similarity of the main characteristics with the popular Tank equipment;

- resistance to various external factors due to the presence of stiffeners and significant wall thickness;

- no need to use additional fasteners or concreting the pit;

- increased productivity;

- tightness of the case, possible due to the absence of seams;

- affordable price;

- the need to pump out only once a year, which makes operating the system quite convenient;

- strength and durability of the structure.

Among the shortcomings, it is worth noting the lack of a deep cleaning and odor filtration system. However, this is precisely what makes autonomous operation of the equipment possible.

Thermit SP

Thermit SP building boards are suitable not only as thermal insulation, but also as a base for the installation of structures to which finishing is applied (room partitions, walls, ceilings, floors). They can be easily mounted, processed, rounded when making columns, arches, steps.

(sandwich panels) are used as cladding for window and door slopes and for leveling walls. They are also used as outdoor advertising.

Construction of partitions

To create partitions from THERMIT SP building board, you can use a wooden or metal frame. You can also install a partition without a frame on a solution in a floor U-shaped profile (if the partition does not reach the ceiling), or use a U-shaped profile on both the floor and the ceiling (if the height of the partition to the ceiling is no more than 2500 mm, that is, the maximum THERMIT SP slab height). The advantage of THERMIT SP is that when installing partitions, additional thermal insulation and waterproofing are not required. The slabs weigh very little, but at the same time have great load-bearing capacity. Instead of a standard partition, it is easy to implement any design solution with THERMIT SP slabs - for example, build a decorative partition in the form of a rack.

Roll Thermit SP n1 – pipe insulation

This is insulation, on which a coating is applied on one side, and on the other there are notches, their depth depends on the diameter of the pipe. “Termite” is used as thermal insulation for pipes with a diameter of 58 to 630 mm, through which substances having a temperature of -50...+75 ° C are transported, for insulation of pipelines when laid in a semi-buried and fully buried way.

The main features of high-quality extruded polystyrene foam

The main parameters that indicate product quality are regulated by GOST 15588-2014. They can only be fully tested in laboratory conditions.

Meanwhile, some indicators, and, first of all, the structure, can be assessed independently. To do this, you need to cut a piece of slab with a sharp knife and carefully examine the cut.

High-quality material has a uniform fine-cell structure.

Non-compliance with the requirements of the standard is indicated by the presence of pores and cells that are visible to the naked eye. Such a stove will not last more than three years.

You can also check the strength properties without special equipment. It is enough to press your finger firmly on the sample.

If the material is defective, you will hear a cracking noise made by collapsing cells. High-quality material can easily withstand such a load without damage.

To assess the level of water absorption, two samples should be placed in water for a day. After this time, you need to place the products on a napkin and press on each of them. A puddle will form around defective polystyrene foam, while quality polystyrene will only slightly moisten the fabric.

Reviews

Despite the detailed description, reviews about Termit insulation are mixed.

Dmitry, Krasnoyarsk: “This insulation is best suited for home improvement. I chose it to insulate the loggia. Good, durable, comfortable slabs. But insulation also has its drawbacks - reinforced insulation is expensive. Polystyrene foam costs 150-160 rubles per sheet, and reinforced plastic costs 1,100-1,200 rubles. To save money, I purchased high-quality foam. I’m happy with the choice and the result.” Leonid. Irkutsk: “I used SP sheets in the bathroom. They are easy to work with even for a beginner. Leveled the floor and walls. The tile lay easily on them. All communications were hidden under insulation. The interior of the bath turned out stylish.”

Official promotional video:

Roof insulation with Tepofol

The technology of insulating structures with Tepofol is unique and is not suitable for installing other thermal insulation materials. It compares favorably with its competitors with the following advantages:

- Saving money. The combination of the characteristics of the heat insulator makes it possible to eliminate the installation of continuous sheathing and the use of membranes for protection from wind, steam and water. Thus, the owner of the facility significantly reduces the cost estimate than choosing fiber or foam materials.

- Speed. The sheathing for Tepofol insulation is assembled from timber and boards in steps of the width of the canvas and in the middle to prevent sagging of the insulator. No other interlayer membranes with insulation are needed. This allows installation work to be carried out in a short time.

- Seamless. The main feature of the technology is the construction of a continuous thermal insulation carpet. This is done using a regular hair dryer. The edges of two panels are attached to one board (width 100 mm) overlapping with mounting lugs (lock connection). The joint area warms up a little and the edges are fastened together under slight pressure.

Fastening the canvases with a construction hairdryer Source yandex.net The canvas itself is fixed to the sheathing with the usual dowel-nails, which are popularly called “parachutes”. This is a self-tapping screw and a threaded plastic head with a wide head. Regarding installation, representatives of TEPOFOL LLC note one similar point with mineral wool. For more practical/dense laying, the cutting of the blanks is carried out with a small margin. Elastic material is easy to compress and takes the desired shape without loss of quality.

Choosing a detergent for washing membrane items

When purchasing a jacket with a membrane in a store, they may immediately offer to purchase a detergent for washing and impregnating the top layer of the product. Manufacturers of high-quality clothing not only indicate all the useful care information on the label, but also produce a line of washing gels.

As an alternative to special products, you should opt for liquid gels to remove stains from delicate types of synthetic fabrics or children's clothes intended for washing.

The peculiarity of the membrane is that dirt must be removed from it quickly, and most importantly, with the obligatory removal of the cleaning solution. Large granules of washing powder are not suitable for this purpose, since they clog the gaps in the membrane layer and are difficult to remove when rinsing. Liquid laundry detergent dissolves well in cool water, effectively removes dirt and is easy to rinse.

Carrying out installation work

When performing thermal insulation, all the rules that are mandatory for installing mineral wool apply. Depending on which element of the building is being insulated, the progress of work and the design of the insulation “pie” will vary somewhat.

Pitched roof

Insulation of roof slopes makes it possible to use the attic space under the roof as a full-fledged living space. The best material for thermal insulation is Hitrok light.

The composition of the roof structure from the inside of the room to the street will look like this:

- clean interior lining of the room;

- ventilation gap;

- vapor barrier;

- insulation;

- roof sheathing;

- vapor-waterproofing layer;

- ventilation gap;

- counter-lattice;

- roofing covering.

Most often, insulation work is carried out from the inside. During construction, they strive to erect a rafter system and cover the roof with a roof as quickly as possible, so as not to depend on the vicissitudes of the weather.

Floor by joists

The design of floors made along logs provides for the presence of cavities into which it is possible to install Hitrok light thermal insulation. The insulation is installed from the side of the room. It is laid in a dense layer between the joists.

Structurally insulated floors consist of several layers:

- finishing floor;

- vapor barrier;

- a layer of thermal insulation installed in the space between the joists;

- waterproofing;

- horizontal base (concrete floor or planks).

Internal partitions

The design of insulated internal partitions is somewhat simpler:

- external finishing;

- plasterboard mounted in two layers;

- thermal insulation;

- frame made of wooden or metal posts.

Two types of thermal insulation of the Hitrok brand can be used as filler in partitions - light or block. The characteristics of these materials are quite similar.

Two layers of plasterboard provide sufficient vapor barrier for mineral wool. When using other materials (osb, plywood, chipboard) as a base for a final coating, it is advisable to use protective membranes.

The insulation installed in the frame, due to its low density and fibrous structure, provides, in addition to thermal insulation, also noise and sound insulation of the room.

Frame walls

Insulation of frame walls is similar in principle to insulation of internal partitions. The design uses the same brands of insulation. The difference lies in the greater thickness of the thermal insulation layer and the implementation of an additional external insulating layer for protection from atmospheric moisture.

Frame wall structure:

- interior finishing;

- ventilation gap;

- vapor barrier;

- insulation installed between the frame posts;

- protective insulating membrane;

- outer skin.

Types of penofol

Manufacturers offer different penofol options for different functionality. The generally accepted classification divides it into three varieties:

- A type – one-sided penofol (aluminum film is applied to one side of the polyethylene after foaming). This type is used more often as an additional heat insulator with foam; Penofol type A

- B type – penofol foil-coated on both sides, has universal use, including for autonomous insulation;

Penofol type B C type – self-adhesive. On one side there is a layer of reflector on aluminum, on the opposite side there is a moisture-resistant adhesive on polyethylene foam, which is protected by a sticker. This penofol is more convenient for finishing areas that are difficult to reach. No special installation tools are required during installation.

Penofol type C

In addition to these standardized types, the developers have also prepared modifications that occupy a separate niche in the building materials market:

- ALP type - penofol with lamination, on the foil side there is a plastic film. This type of material is used for insulation of agricultural buildings operated in a not too aggressive environment;

- M or R types – one-sided foil with a corrugated “top”;

- AIR – penofol used to prepare air exhaust structures;

- Super NET (from the word “Network”) - the main task of this type of penofol is insulation and steam protection for air vents, pipelines or heating mains.

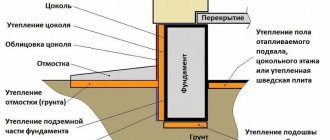

Areas of application

TERMIT insulation is widely used in various fields. It is actively used for insulating walls, roofs, ceilings, basements, etc. Due to the fact that this material has low thermal conductivity, it is ideal for the construction of roads, railways, and gas and oil pipelines. In the refrigeration industry, extruded polystyrene is also in great demand. The use of this insulation allows you to save energy spent on heating structures, reduce their weight, extend the service life of structures and minimize the costs of various building materials.

Ability to conduct heat

The foam consists of many air-filled polystyrene bubbles in a ratio of 2% film to 98% air. The general appearance of this material resembles foam, which is why it is called expanded polystyrene.

The air inside polystyrene bubbles retains temperature excellently, which is why polystyrene foam is the best heat-insulating material.

Mineral wool has greater thermal conductivity. In order to improve the performance of extruded polystyrene foam in terms of heat retention, it is necessary to increase its density. For example, cover the walls in several layers.