If you are planning to build a house for yourself and are choosing insulation, then this article is especially for you. In this article we will introduce you to the insulation material - Ecowool.

In the photo there is a 15kg Ecowool briquette (Donskaya Ecowool, Tula)

In the photo there is a 15kg Ecowool briquette (Donskaya Ecowool, Tula)

Table of contents:

- A little history

- Ecowool composition

- What is Borax

- Boric acid

- Ecowool insulation cost

- Thermal conductivity Ecowool

- Air permeability Ecowool

- Energy efficiency Ecowool

- Capillary activity of Ecowool

- Fire safety Ecowool

- Environmental friendliness Ecowool

- Rodents and mice in Ecowool

- Ecowool - antiseptic

- Noise insulation Ecowool

- Heat capacity of ecowool

- Ecowool shrinkage

The history of ecowool

Ecowool is the Russian name for cellulose insulation. In world practice it is called “Cellulose Insulation”. Ecowool appeared in Russia in 1993, but in world practice it became known already at the beginning of the last century. In 1928, the first production of this insulation was created in Germany. Today, this insulation is well known and popular in many countries around the world. This insulation is especially popular in countries located in northern latitudes, in the humid climate zone:

- Finland

- Sweden

- Norway

- Germany

- Canada

- USA and other countries

According to the Russian information portal Wikipedia, in Finland, cellulose insulation accounts for up to 70% of the total market for insulation used in individual housing construction.

Popular manufacturers and prices

The high quality of ecowool is guaranteed by trusted manufacturers who do not allow the replacement of antiseptics and fire retardants with cheap analogues. Among them there are several of the best.

Isofloc. German with its products has earned numerous positive reviews from builders from all continents. The price for a 15 kg bag is about 660 rubles.

Termex. Finnish brand, known in Russia since 1988. Products are of high quality, which is facilitated by well-established process control.

Equator. Russian manufacturer of insulation made from waste paper. Production is fully automated, which allows us to obtain high quality products. Price for 1 kg - 34 rubles.

Nanovata. Another Russian enterprise with an unclear name, producing ecowool under the Alfagreen brand. Good quality is provided by equipment from Finland and the USA. A package weighing 15-17 kg can be purchased for 550 rubles.

What does this insulation consist of?

Ecowool 81 % recycled cellulose (newsprint paper), 7 % of Borax anti-friction agents (flame protection) and 12 % of natural antiseptics Boric acid (protection from rodents, mold, insects)

Ecowool composition

This is what ecowool looks like up close, it is a fibrous crushed material, gray in color, some inclusions may be present in the form of scraps of newspaper waste paper, sometimes you can even make out the text.

Fiber structure Ecowool

It has no smell and does not generate dust. Ecowool can be compressed, it takes a fixed shape, this can be used, for example, when installing this insulation into small cracks yourself. In addition, there is no need to fear that it will fall out of the holes through which it was mounted. It holds its shape and will not fall out anywhere.

Conclusion

Based on the results of comparison with other thermal insulation materials, we can highlight the positive and negative aspects of ecowool.

Advantages:

— Seamless application does not form cold bridges.

— Adhesion to the frame provides increased heat and sound insulation.

— Thermal conductivity does not increase when wet

— Good vapor permeability (0.35 mg/(m h Pa)

— Filling hard-to-reach places by blowing cotton wool

— Environmentally friendly - does not contain formaldehyde resins, consists of 80% cellulose

Same composition in all countries

I would like to especially draw your attention to the fact that despite the wide geography of application of this insulation, in almost all countries, including Russia, the manufacturing technology of this material, its composition, are almost the same - it includes three components: this is cellulose - newspaper waste paper, this is borax and boric acid .

If everything about waste paper is very clear, then about borax and boric acid, not so much. Let's look at them in more detail:

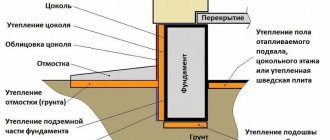

General principles of thermal insulation

The correct technology for thermal insulation of floors consists of five main stages:

- dismantling old floors;

- installation of rough (technical) floor;

- laying insulation and securing it;

- laying a hydro-vapor barrier over the insulation;

- installation and securing of the finished floor.

Each specified stage must be carried out with the utmost care. If errors are made during the installation process, correcting them may require large amounts of time and money. Therefore, it is not recommended to carry out work without prior preparation, in a hurry and without due care.

So, what is Borax?

Sodium tetraborate (“borax”, “borax” (from Latin borax

)) is an inorganic compound, sodium salt of boric acid with the chemical formula Na2B4O7, the most common and used boron compound, forms several crystalline hydrates, and is widely used in industry.

In the photo "Bura"

Sodium tetraborate (Borax) is used:

- as a raw material for the production of boric acid and various boron compounds

- in the production of enamels, glazes, optical and colored glasses, various ceramics

- when soldering and melting metals in flux

- in the paper and pharmaceutical industries

- in the production of building materials as an antiseptic component for the production of cellulose insulation ecowool

- as a disinfectant and preservative

- for preparing buffer solutions

- in analytical chemistry (as a standard substance for determining the concentration of acid solutions)

- for qualitative determination of metal oxides (by pearl color)

- in photography - in slow-acting developers as a weak accelerating agent

- as a component of detergents

- as a component of cosmetics

How to make ecowool with your own hands, equipment and blowing of ecowool

Ecowool is one of the types of thermal insulation materials. This is a cellulose insulation that consists of an antiseptic and recycled cellulose. Cellulose fibers make up almost 80% of the material itself. It creates an excellent homogeneous seamless layer of insulation. What is ecowool insulation, reviews about it - we will talk about this in our article.

Definition of ecowool. Its advantages

Ecowool consists of fibers that contain lignin, a substance that, when moistened, imparts stickiness. This material is completely harmless and absolutely non-toxic.

In addition, all its components are non-volatile, which means that they cannot harm the environment and people.

There are other advantages:

- good thermal insulation and sound insulation material;

- not susceptible to rotting and fungus;

- in the event of a fire, it is not susceptible to fire for a long time;

- trouble-free installation;

It should be noted that in ecowool, as in all thermal insulation materials, rodents appear that consider it as their food.

This material contains substances such as boric acid and borax. They reduce the fire hazard and provide good protection against fungi and rot. The low cost of wool is associated with simple installation and inexpensive raw materials from which it is made.

Do-it-yourself ecowool. Laying methods

Ecowool can be installed by both professionals and amateurs. There are the following installation methods:

Blowing ecowool with your own hands confronts a person with certain problems. This method is used to insulate floors and flows. Ecowool is easy to install with your own hands; no special equipment or special skills are required.

Manual installation includes several stages.

First you need to prepare the insulation by pouring it into a container such as a bucket or basin. The next stage, “fluffing,” is carried out using a drill.

Blowing ecowool with your own hands requires direct manual installation, which consists of filling it into the ceilings. But there are situations in which additional blow molding equipment is required. After filling the insulation, it must be closed. To do this, you can use sheet materials, for example, plywood.

With the mechanized laying method, equipment specially designed for this is used. And wet-glue processing is usually carried out by professionals.

It is the last method that is of the highest quality.

Having considered what ecowool is with your own hands, the equipment that is used in this process is also worth considering:

- blowing installation - necessary for uniform supply of insulation;

- corrugated hoses - supply ecowool to the place of insulation;

- pump set;

- special nozzles for blowing.

This equipment is necessary when it comes to mechanized insulation of a building.

Recommendations for do-it-yourself insulation

Using ecowool, you can insulate your walls yourself. floors, ceilings, attics and roofs. On construction sites you can find out more specifically what ecowool insulation is, reviews about this process and recommendations.

But we will give some basic recommendations in our article:

To determine the density, it is necessary to take into account the material consumption

It is important to know that when insulating with your own hands, the material consumption is much higher than with mechanized insulation. Density control can be calculated using a formula and thereby reduce material consumption. To insulate different floors, there are standards for the thickness of the floor. The thickness of the ceiling for the floor is 15-20 cm, for attic floors - up to 30 cm, the thickness of the ceilings between floors is 15-20 cm. If the ecowool insulation process is carried out manually, then it must be taken into account that the material consumption may be slightly higher than originally envisaged. When insulating materials such as concrete, brick or iron with ecowool, it is necessary to prevent the possibility of the ecowool absorbing condensed moisture. Likewise, when insulating a roof, it is imperative to protect the insulation from penetration of under-roof condensate.

This can affect not only the quality of the building's thermal insulation, but can lead to gradual destruction. This thermal insulation material is excellent for insulating residential buildings and utility rooms, as well as for insulating individual building elements.

Boric acid

Boric acid (orthoboric acid or lat. acidum Boricum) is a weak, monobasic Lewis acid, often used as an insecticide, antiseptic, and fire retardant.

In the photo "Boric acid"

Application

- Boron fertilizer

- Used in laboratories to prepare buffer solutions

- In medicine - as an independent disinfectant for adults, and also in the form of a 2% solution - for washing the skin after contact with alkalis

- Also, various combination preparations are produced based on boric acid (ATX group D08AD), for example Teymurov’s paste

- Registered in the food industry as food additive E284

- In jewelry - as the basis of fluxes for soldering gold-containing alloys

- In everyday life - extermination of cockroaches, ants, bedbugs

- In the production of ceramics, fiber optics, fiberglass, glass

- As a fire retardant to protect wood

- As part of electrolytes for copper and nickel plating

Cost of insulation - Ecowool

For correct calculation, let's take the insulation thickness of 100 mm. The price will include all work and the material itself.

Horizontal surface - 190 R/m2

Sloping and vertical surfaces from 240 R to 350 R/m2

The approximate cost of insulating a house with a total area of 120-150 m2 on a turnkey basis (thermal circuit) ranges from 100 to 200 thousand rubles. The price is comparable to all types of insulation with basalt or mineral slabs.

Insulation calculator

Ecowool calculation calculator

Do-it-yourself ecowool production

Ecowool is a cellulose insulation made from recycled waste paper. Its composition contains 81% cellulose fibers, which allows it to perform its functions perfectly. In modern construction it is used to create a seamless thermal insulation mass, but for full operation it contains boric acid and borax. Borax is intended to make the material fireproof, and boric acid is intended to resist fungi, mold and rodents.

Ecowool goes on sale in the form of an unmolded mass of cellulose fibers. For transportation and storage, bulk material is compressed and placed into special high-density briquettes. Before use, it is unpacked and dried, and during drying it increases in volume by about 3-4 times. The technology for making ecowool is so primitive that it can be made at home.

How to make ecowool yourself

To produce cellulose insulation, you will need waste paper and a powerful shredder that will process recyclable materials. By its principle, the chopper should work like a regular coffee grinder. Often an old activator washing machine is used that has undergone a slight modernization.

Recycled raw materials are loaded into a shredding machine, where they are preliminary and completely crushed using different knives. Next, the finished cellulose material must be fluffed and dried. Any fan unit is suitable for these purposes. Here cellulose is mixed with boric acid 12% and borax 7%.

Ecowool - waste paper after the shredder

Ecowool installation methods

Installation of cellulose insulation can be done manually or by machine. The manual method is less expensive and is recommended only for backfilling floors during the construction of upper floors and dry backfilling into walls. It is actively used by developers due to its low cost.

The mechanized method is a more productive solution and has a number of advantages:

- installation speed;

- economical insulation consumption;

- no risk of errors.

The main feature of mechanized laying is the use of blow molding equipment. Based on this, there are several types of installation, namely dry, wet and wet-adhesive.

- Dry method - designed for insulating horizontal and inclined walls. The main task is to fill closed planes located in walls, fill ceilings between floors and non-demountable structures.

- Wet method - designed for insulating house walls and various vertical surfaces. Wet ecowool is perfectly strengthened on any walls, creating a single mass.

- The wet-glue method differs from the wet method in that glue is added here to enhance the adhesion of the insulation. The advantage is slight deformation during drying and the absence of dangerous chemical compounds. The technique is perfect for thermal insulation of ceilings and other horizontal surfaces to which there is no direct access.

Advantages and disadvantages of ecowool

It is worth highlighting the advantages of cellulose insulation:

- Excellent thermal insulation. Compared to mineral wool, the advantage is 11-12%.

- Low breathability and elasticity. Unlike mineral wool and polystyrene foam, it better blocks sound waves, protecting the house from unnecessary noise.

- Fast drying. This way, the insulation helps maintain the natural level of humidity, creating comfortable living conditions.

- No toxic substances or phenolic binders.

- Homogeneity of mass. Thanks to its composition, after installation, ecowool creates a seamless layer that fills the entire volume, without forming cold bridges and voids, which cannot be said about mineral wool and polystyrene foam.

- Thanks to the processing, ecowool does not burn and is not susceptible to mold and mildew.

- No smell.

Thermal conductivity Ecowool

Thermal conductivity is the ability of material bodies to conduct energy (heat) from more heated parts of the body to less heated parts of the body through the chaotic movement of body particles (atoms, molecules, electrons, etc.).

The thermal conductivity coefficient of ecowool is 0.039 (W/m*K)

For understanding, below are data on the most common types of insulation.

Thermal conductivity table

The table shows that the thermal conductivity coefficient of ecowool is higher than the average result.

In what cases and why is insulation from below correct?

It is better to insulate the floor above a cold attic from above, but the thermal protection of the floor above the basement is technically more competent to perform from below. This has its reasons:

- there is no reduction in the height of the room on the ground floor;

- there is no need to choose dense rigid insulation that will withstand the loads from residents, furniture and equipment;

- protection from freezing not only of the floor, but also of the entire wooden floor;

- displacement of the dew point (the line on which condensation falls) to the surface of the ceiling from the thickness of the structure, which prevents rotting.

But when carrying out work in a private house or dacha, some difficulties may arise specifically related to work from below:

- the need for more reliable fastening of the insulation;

- the difficulty of working in low subfloor conditions;

- the need to work on the ceiling leads to rapid fatigue of workers;

- restrictions on types of insulation.

Air permeability of ecowool

Thanks to the technology of seamless application and the dense fibrous structure of the material, ecowool has low air permeability. The absence of joints and cracks determines the future tightness of the entire building.

A house insulated with cellulose fiber is 40% more energy efficient

There is a video on the Internet devoted to a comparative analysis of this “tightness” parameter. In America, they took two houses, identical in design, one house was insulated with mineral wool, the second house was insulated with cellulose insulation. And when we compared the tightness of the thermal insulation circuit of these 2 buildings, we were surprised to find that the tightness of a house insulated with cellulose insulation was 40 percent higher than the figure for a house insulated with traditional fiberglass. Here is the link to this video.

How to lay insulation manually

If you want to save on installation work to insulate your home, you can apply the insulation yourself. Do-it-yourself ecowool takes a lot of time to install. Blowing in the wall ensures greater density of insulation and filling of cavities with ecowool. When laying insulation manually, the consumption of ecowool is correspondingly reduced.

Before direct application, the insulation is laid out from the bags into a specially prepared trough, after which it is mixed with a mixer to give the material the required density and consistency. To do this, you will need to purchase a construction mixer or drill with a suitable attachment. Thermal insulation should be installed using personal protective equipment to protect the respiratory tract and mucous membranes of the eyes from dust.

High capillary activity of ecowool

Ecowool has high capillary activity

What it is? What does this give?

There are 2 mechanisms of moisture transfer inside the insulation:

- Capillary

- Diffusion

Thanks to wood fiber, ecowool uses both of these mechanisms; mineral types of insulation have only one - diffusion . Ecowool mainly consists of cellulosic wood fiber. When moistened, the fiber is able to absorb moisture and distribute it throughout the entire volume of the insulation. Due to the different molecular structure, basalt insulation cannot distribute moisture.

The photo shows the structure of the molecules of ecowool and mineral wool

This is a rather complex phenomenon and it gives rise to great controversy regarding the use of vapor barrier when insulating with ecowool. Proponents of the idea that a vapor barrier is not needed precisely mean this additional mechanism of moisture transfer, which works in the opposite direction and ecowool has the ability to dry not only outside, but also inside.

Capillary activity provides a number of advantages to ecowool,

compared to insulation materials that do not have

capillary activity.

Insulation technology options

You can fill the surface with ecowool in different ways. On an industrial scale, wet material is sprayed onto the prepared wall. The fibers are placed into the frame using a compressor. A cottage, bathhouse or garage can be insulated manually, but in this case it will take more time. Ultimately, much will depend on adherence to technology and the qualifications of the master.

Excess ecowool needs to be removed

- Wet method. The adhesive filler in this embodiment is lignin. Wet fibers adhere well to any substrate. The insulation layer should be within 50-60 kg/cub.m. This method is good for insulating block or brick walls. The sheathing is made of timber or profile (the first option is preferable). The insulation is applied using a professional installation. Loose cotton wool at the very outlet of the nozzle is impregnated with water and released to the surface under pressure. The wet method is easy and fast, indispensable for large volumes. The only disadvantage can be considered the presence of professional equipment. For complex surfaces such as a ceiling, adhesives are dissolved in water on the underside for strength, which help the linin to enhance adhesion. The excess is cut off and reused after drying. Actually, there is no waste with any installation option, since the wool is suitable for reuse.

- The dry method involves filling the lathing cells on the wall, floor, and ceilings with dry ecowool. You can loosen the insulation using a nozzle for mixing solutions in a container of a suitable size. All surfaces are filled with bulk, compacting the cotton wool until the forces are absorbed. When applying, they are guided by a simple formula: m = S* L*p, where m is mass, S is area; L – layer thickness; P is its density. The backfill method is convenient for insulating floors where it is possible to compact the layer to 35-45 kg/cub.m. In frame house construction, when insulating wells, this method is used less often, since it can be compacted to 60-65 kg/cu. m. is not always possible.

Calculations for insulation with a compressor

When applied horizontally, the distribution is close to 45 kg/m3. m. , with vertical – 65 kg/cubic. m. With the industrial method of insulation, ecowool is applied in layers, using a professional installation. The frame must be covered with film or kraft paper. A hole is left in the upper part for the supply hose. With the flow of forced air, the fibers fill everything, including hard-to-reach places. Then the hole is closed. Instead of a professional compressor, craftsmen use a homemade installation based on a garden vacuum cleaner.

Video - Technology of applying ecowool wet or dry

Pros of high capillary activity

- When moistened, the insulating properties of the insulation are preserved.

- Due to the redistribution of moisture through the capillaries, there are no zones of local waterlogging.

This is important when there is some kind of defect in the vapor barrier.

3. Condensation does not form in Ecowool.

4. Ecowool, due to the capillary mechanism, can affect the humidity of the room air. It absorbs excess moisture and releases it when the room becomes dry, that is, like wood fiber, it is a passive regulator of air humidity in the room.

If you do not plan to install supply and exhaust ventilation, then this property will significantly add comfort to your home.

Eco-friendliness of ecowool

There is a lot of controversy about the environmental friendliness of ecowool. There are extreme supporters that it is very environmentally friendly. Others say that it is not at all environmentally friendly, let's try to figure it out.

Ecowool consists of three components:

- Newspaper waste paper

- Borax

- Boric acid

“Ecowool is full of lead because it’s made from newsprint.”

As for newspaper waste paper, it means there is no lead in the newspaper since it has long been produced in a way that eliminates the presence of lead in the equipment.

“Printing ink is harmful to health”

The harm caused by printing ink is greatly exaggerated; it has its own hygienic certificate, on the basis of which newspapers are produced. Millions of people read, touch, enclose every day and no one has yet gotten sick, much less died, from contact with printing ink. So we can say with confidence - “This is a myth”

Roof insulation with ecowool

At the preparatory stage, the roof is waterproofed and the load-bearing capacity of the rafter system is checked. If necessary, it is reinforced with wooden beams and metal profile structures. The attic is cleared of debris, and protective screens are installed in places where cables are laid to ensure access to them after laying the wool. Before blowing, you should analyze all the spaces that need to be filled: those formed by the side rafter beams (the thickness of the layer will be identical to the width of the rafters), the upper windproof board, the lower vapor barrier. The insulator exerts a certain pressure on the base, so it is important to check the gap between the vapor-permeable membrane. Lay only high-quality material on the timber and without sagging. The counterbar should create a gap of 45 mm. At the bottom, the material is fixed with a 20-40 mm beam.

Prices for different types of bars

Bar

Layer cake when insulating the attic

Insulating the attic roof requires compliance with the following rules:

- thermal insulation must be protected from excess dampness;

- ventilation in this technology is mandatory;

- The cotton wool is laid in a uniform monolithic layer.

The roof pie consists of a roofing covering, frame, waterproofing layer, ecowool, vapor barrier and finishing material from the inside. The geometry of the roof is quite complex, so wet technology is recommended. Insulation instructions:

- Cover the roof frame with film. At the joints, the sheets are connected with construction tape.

- Spray a layer of ecowool on the surface. It is applied from bottom to top to prevent the top layers from slipping.

- After the insulation has completely dried (up to 2 days), it is covered with a vapor barrier film. The canvases are secured with a stapler.

- The roof is sheathed along the sheathing with plasterboard, siding, and wood.

Features of attic insulation

Video - How to insulate a roof with ecowool

Borax and boric acid in ecowool

Borax and boric acid are non-volatile natural chemical components. The scope of application of these two materials is completely different, and now discussing the harm of borax and boric acid on human health will take a lot of time.

Borax and boric acid are non-toxic and non-volatile compounds, they are quickly eliminated from the human body, but perhaps the most decisive argument in favor of not exaggerating the harm of the presence of this chemical in ecowool is the fact that all countries in Europe and America use this technology and the recipe for making this material.

In these countries, hygiene requirements are more stringent, and despite this, ecowool is widely used in this particular composition. In addition, ecowool contains no phenols, formaldehydes, or any carcinogenic binders. Ecowool does not contain microscopic allergenic dust, which is present in many types of insulation.

Laying ecowool manually

The advantage of ecowool insulation is that it has a smaller thickness with equal thermal insulation.

If a horizontal surface requires insulation, then manual laying of ecowool can be used. The insulation is distributed in even layers between the floor joists. Each layer of material must be carefully compacted so that no voids remain. The amount of ecowool for floors is 35-50 kg per 1 m³ of space. The blow molding machine determines the required amount of thermal insulation automatically.

The manual laying method is used in small areas, since the work is time-consuming and quite labor-intensive. Cotton wool particles may not get into hard-to-reach places, and the remaining unfilled gaps will contribute to the penetration of drafts. This method can also be used to fill cavities along walls and around pipes.

Despite the need to use blow molding equipment for laying ecowool, this method of insulation has a number of positive properties that distinguish it from other thermal insulation. This is an environmentally friendly material, non-flammable, moisture-resistant, bio-resistant, and has high thermal insulation properties. The warranty on the material is at least 50 years.

Ecowool antiseptics wood

The presence of borates contributes to the preservation of wood in contact with Ecowool and prevents the growth of bacteria.

An example of roof insulation with mineral wool

Borax and boric acid are highly toxic to certain types of microorganisms, in particular most types of mold and mildew, so mold stops upon contact with this chemical compound and does not spread further

“Why are borates used and not some other chemical compounds?”

In Germany in 1985 The Institute of Construction Technologies recognized that borates are one of the most effective means of protecting wood from mold and mildew, which is why borates are present in ecowool.

Negative aspects of cellulose

In order to get a complete picture of this insulation, let’s consider the disadvantages of ecowool.

- The use of specialized equipment, since manual installation is quite labor-intensive.

- The personnel performing the work require fairly high qualifications.

- The presence of a large amount of dust during installation of insulation.

- When the composition is wet sprayed, its drying time can reach 72 hours, which is not always convenient and sometimes even unacceptable.

- Shrinkage of cellulose wadding. Over time, the installed thermal insulation can lose up to a quarter of its volume, which will lead to the formation of uninsulated niches.

- Significant absorption. In order for the fiber to dry, it is necessary to create conditions for good ventilation.

- When vertical blowing, it is necessary to create a frame from reinforcement or wooden beams.

In fairness, it is worth noting what disadvantages there are of ecowool, among those pointed out by experts and people who have already encountered it in their homes. There are cases of an allergic reaction “to library dust”, expressed in the form of urticaria.

However, these are isolated cases and only individual intolerance to any component of this material can lead to negative consequences.

Also, some Internet users are concerned about the presence of boric acid in the insulation, which under certain conditions may end up in direct contact with a person. Let us remind you that its content in the material is 12% . This concentration generally does not pose a danger to the human body. The objectivity of this information remains entirely with those who distribute such data on online forums.

Ecowool has a high degree of noise absorption

Ecowool is a very good noise-absorbing material in terms of absorbing high and medium frequencies. It works no worse than basalt or fiberglass.

An example of soundproofing a room with Ecowool. Installation was carried out by Ekovata-MSK

When absorbing noise, one must take into account the fact that ecowool is a seamless technology, and in acoustics, as in heating engineering, there are requirements for the tightness of the circuit - any gap or leak is a so-called sound bridge, which significantly impairs the sound insulating ability of the enclosing structure.

The process of insulation of blown Ecowool.

- We pour Ecowool into our construction trough, about halfway.

- We mix it well with a drill with a mixer attachment, the ecowool rises to the edges of the trough.

- We insert the corrugation into the hole in the wall so that it does not touch the bottom by 30 centimeters. To do this, you need to immediately measure the required size on the corrugation and stick electrical tape there as a mark so that you don’t have to measure every time.

- We seal the gaps between the hole in the wall and the corrugation, for example, with a fingerless glove already put on the corrugation and one person holds the corrugation on the sawhorse.

- We turn on the blower at 3-4 speeds and suck in the Ecowool a little at a time, this is done by the second person, i.e. Blowing is carried out by 2 people.

- Judging by the sound and intensity of suction, we understand that Ecowool is already higher than the hose in the wall. We stop the vacuum cleaner and the man on the trestle pulls out the hose half a meter, seals it with a glove and blows it out again. This is done until the hose is pulled out almost completely. The last stage is when we insert the hose only 1 cm and compact the Ecowool until it stops.

Seal the holes in the wall.

After blowing in the walls, we attach the round pieces from the OBP that remain from the hole for the corrugation to square pieces of oilcloth with a stapler, apply them to the hole and fasten this oilcloth with a stapler to the wall.

The heat capacity coefficient of ecowool is 3 times higher than any insulation

Ecowool has a high heat capacity . Its heat capacity coefficient is three times higher than that of mineral insulation. This may be useful for you if, say, for some reason the heat source turns off and your house will cool down more slowly than if it is insulated with mineral wool.

Well, or on a hot sunny summer day on the second floor under an attic roof, insulated with ecowool, it will be a little more comfortable than if there was mineral wool.

Example of roof insulation with Ecowool

Density and weight

The higher the density of the insulating material, the greater its weight per unit area. With greater weight, the requirements for supporting structures increase. This is especially true when installing a roof. Also, in the case of ecowool, the density is affected by the uniformity of application.

Read about the features of choosing insulation for a roof in the article: “How to insulate a pitched roof.”

- Basalt mineral wool – 25 – 50 kg/m3 depending on the brand

- Fiberglass – 15 – 20 kg/m3

- Ecowool - 35 kg/m3 for horizontal structures and 65 kg/m3 for horizontal ones.

Thus, from the point of view of numbers, the materials do not differ much, but at the same time, applying ecowool to vertical surfaces with insufficient density can lead to subsequent shrinkage. Due to the specifics of application, the density in different areas is not the same.

Ecowool shrinkage

The most common and popular question when the choice falls on this type of insulation. Let's take a closer look here.

To begin with, let's divide the structural elements of the house into 3 groups :

- Horizontal (Floor, attic, ceiling)

- Inclined (Roof, attic)

- Vertical (Walls)

Let's highlight 2 main methods of applying ecowool

- Dry blowing

- Wet glue method

Horizontal surfaces

In this case, the floors are insulated with ecowool. With the help of a regular backfill, it is called “free backfill”, even when ecowool is simply poured onto a hemmed base with a certain layer of insulation and a heat-insulating layer is obtained. Here the density of Ecowool will be about 35 kg/m3.

Insulation of a 200mm floor using the dry backfill method.

With this method of insulation, shrinkage will be about 7-10%. Accordingly, the actual insulation thickness will be approximately 180mm .

Cannot be applied using wet glue method

Sloping surfaces (attics, roof slopes)

It is insulated using the “dry blowing” method. For high-quality non-shrink insulation of the roof with ecowool, it is necessary to properly prepare the base. Let us highlight the main stages of preparation:

- Under an insulated roof, it is necessary to use a vapor-permeable diffusion membrane to allow excess moisture to escape into the ventilation gap. The membrane should be well tensioned, without sagging or damage. Cut-offs must be installed along the lower perimeter of the roof.

Example of a roof before insulation

2. An internal diffusion membrane or vapor barrier is stretched along the straps. To create a rigid internal base and achieve an ecowool density of 50 kg/m3, it is necessary to attach a special retaining plastic mesh over the membrane. and the photo is a prepared roof without insulation

The photo shows a prepared roof without insulation

3. Fill the prepared base with ecowool using dry blowing. There is no need to close the holes in the mesh and membrane.

The process of installing Ecowool insulation on the roof

With this method of installation and preparation of the roof, ecowool is guaranteed not to sag even after a large number of years.

The wet-glue method is not applicable for roof insulation

Video description

The extent to which the positive characteristics of ecowool declared by the manufacturer correspond to reality is described in the video:

Flaws

There are no ideal materials without flaws, and ecowool is no exception. It also has its downsides.

- Shrinkage of the thermal insulation layer.

Over time, the loose fibrous material shrinks, becomes denser, loses volume, and its thermal insulation properties decrease. On horizontal surfaces, this problem is solved by making the layer thicker than the calculated one and organizing high-quality ventilation to evaporate moisture. But with vertical insulation, it will no longer be possible to fill the resulting voids.

- Installation problems.

When purchasing ecowool insulation, you should find out in advance what it is and where it is used. As well as the way in which it is laid on different structures. If you want to insulate monolithic walls or fill the cavities of a frame house, you will need special equipment and experienced operators, which are not yet available everywhere. And when insulating floors manually, the compressed material, freed from packaging, must be loosened using a drill with an attachment. This creates a lot of pervasive debris and allergenic dust.

Before installation, the material is “beaten” with a mixer Source obustroeno.com

Vertical surfaces (Walls)

Walls are insulated in two ways:

- Dry blowing method

- By wet-adhesive spraying method

Let's look at each of them separately.

Method of dry blowing into walls

For this method it is necessary to create a rigid base, both from the outside and from the inside. It is necessary to ensure the presence of horizontal cutoffs along the perimeter of all walls at a height of approximately 1.5 meters from the floor.

Horizontal cut-off at 1.5 meters from the floor

Next, sew up the walls with any slab material:

- CSP (cement particle board)

- OSB (Oriented Strand Board)

- Beltermo (Insulating fibreboards)

On the other side, sew up with a membrane and a special retaining mesh

The photo shows an example of a wall sewn from the inside

Next, ecowool is blown into the prepared base under a pressure of 65 kg/m3 . With this method of application and preparation of walls, shrinkage of ecowool is guaranteed not to occur.

Wet glue method

With this method of applying ecowool, there is no need to make additional cuts and install a rigid base of the walls on both sides. It is enough to stretch special holding threads inside the walls; they will protect the ecowool from subsequent shrinkage.

Application of ecowool using the wet-glue method

Ecowool consumption with this method is 30-40% higher than with dry blowing. After ecowool has dried, the density will be approximately 55 kg/m3 .

In custody:

Today in Russia there are dozens of enterprises that produce Ecowool, but there is still no GOST or a single standard that would strictly regulate the quality of the material and the technological process. Manufactures operate on the basis of technical specifications that they write for themselves, so the quality can vary greatly.

2 types of Ecowool enterprises in Russia:

the first group is the one that works on a high-performance automated expensive imported production line, for example, Finnish, which specializes in the manufacture of equipment for the production of Ecowool.

The second group of productions are those productions that operate on budget lines of domestic production. In this production chain, as a rule, there may not be automation, no Baratov additives, no dust collection systems, and not a sufficient number of steps for crushing waste newspaper into the required fiber.

Installation methods

Ecowool is laid manually or automatically by blowing the material under pressure. For automatic spraying, both dry insulation and mixed with water are used.

The simplest and cheapest manual method is also the most ineffective. Firstly, it is used only for insulating horizontal surfaces. And secondly, with manual distribution it is difficult to create an even layer of equal density and fill all hard-to-reach places.

By using a blow molding machine to spray dry ecowool, these problems can be avoided: the insulation, supplied under pressure, lies evenly and penetrates into all cracks and recesses. But this method is only suitable for horizontal insulation and insulation of frame buildings. In the latter case, the material is blown into the cavity between the outer and inner lining through specially made or left holes.

Dry spraying of ecowool in the cavity of the frame Source thermofloc-isolatie.nl

To insulate vertical structures and sloping roofs, only the wet-adhesive automatic application method is used. The material is mixed with water to obtain a liquid suspension and blown with special installations onto the insulated surface. The natural glue lignin contained in cellulose glues the fibers to each other and to the base.