When building a house, the most important task is its thermal insulation, the quality and durability of which determines not only comfort, but also heating costs. In suburban housing construction, ecowool is becoming an increasingly popular thermal insulation material, the pros and cons of which will be discussed in detail in this article, along with issues of installation and the feasibility of use on different structures.

Ecowool can be used to insulate almost all parts of the house Source green-agency.ru

Positive and negative properties of insulation

Ecowool is a product of processing recycled paper. Only non-coated and non-glossy paper, mainly newspaper, is used for its production. It forms the basis of the future insulation. It is crushed and mixed with substances that make the material resistant to fire and various microorganisms.

Approximate composition of ecowool:

- about 80% - cellulose base;

- 7-10% – sodium tetrabonate (borax), which acts as a fire retardant and an additive that repels insects and rodents;

- 8-12% – boric acid, an antiseptic that protects the natural base from the appearance of mold and pathogenic bacteria in it.

The insulation looks like loose gray wool, often with colored inclusions (depending on the type of raw material). It differs from other cotton thermal insulation materials in its loose structure, since its fibers are short and poorly connected to each other.

This is what ecowool insulation looks like Source fasetwoinsulation.com

This material competes well with other modern materials for thermal insulation - mineral wool, sprayed polyurethane foam, expanded polystyrene. In some ways it is superior to them, but in some respects it is inferior. To make the right choice, you need to study ecowool insulation in more detail, compare the pros and cons with similar parameters of other materials and find out which of the advertising statements about it is true and which is a marketing ploy.

Advantages

The absolute advantages of ecowool include several of its properties.

- Low thermal conductivity.

It is comparable to the thermal conductivity of expanded polystyrene and better than that of mineral wool, which puts it on par with the most popular thermal insulation materials in terms of efficiency. With its help, heat loss is greatly reduced.

- High vapor permeability.

The positive difference between ecowool and other fiber insulation is that it easily passes air through itself and dries quickly when wet.

Ecowool does not require the use of vapor and waterproofing films during installation Source pikabu.ru

See also: Catalog of companies that specialize in home insulation

- Stable thermal conductivity indicators.

If mineral or glass wool, when saturated with water, sharply loses its ability to retain heat, then ecowool, due to its capillary structure and high vapor permeability, easily releases water vapor into the environment and retains its properties.

- High biostability.

Due to the presence of antiseptic substances in the material that neutralize pathogenic microflora, it does not become infected with mold. And borax scares small rodents away from it.

- No cold bridges.

Ecowool insulation does not have seams and joints, which are the main cold bridges when using sheet or roll insulation. If the correct installation technology is followed, the material creates a monolithic surface, filling the slightest cracks and voids.

- High level of sound insulation.

The low density and loose structure of randomly arranged fibers contribute to the fact that, in addition to excellent thermal insulation properties, ecowool has the ability to actively absorb sounds. A layer of such insulation can halve the noise level from the street or an adjacent floor, which can be used when building housing within the city or near busy areas.

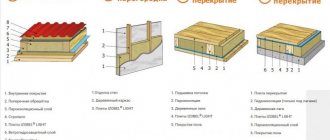

The material is suitable for soundproofing external walls and interfloor ceilings Source lkgstroi.ru

Questionable properties

The advantages of ecowool often include characteristics that raise doubts among developers. These include environmental friendliness, low price, non-flammability and some other positive parameters. How unconditional they are is worth understanding.

Those who know what ecowool is and how to work with it know that you can only insulate horizontal surfaces with your own hands. Insulating walls, roofs and other structures requires the use of expensive equipment, which can only be operated by specialists. And their services are not cheap, which makes ecowool insulation not the most budget-friendly method.

Loading ecowool into a blow molding unit Source sibecostroy.ru

One can also doubt the environmental friendliness of the material, knowing what it is made from. Printing ink for newspapers contains harmful substances such as lead, benzene, and toluene. Together with tiny particles of paper, they form the so-called library dust, to which many people are allergic.

About 20% of the raw material consists of fire retardant and antiseptic additives, which also cannot be considered absolutely harmless. Especially if, instead of regulated components, ammonium phosphates or sulfates are added to ecowool.

Advice! To reduce the risk of allergic reactions, poisoning and ammonia odors, you should buy well-known brands of insulation from reputable manufacturers.

Extra is one of the first domestic companies to master the production of ecowool Source zoon.ru

Where is ecowool used?

Ecowool is a very attractive material for insulation in many areas of construction. It is used as external and internal insulation and filler in so-called wooden sandwich structures. Thus, the use of ecowool is not limited to strict operating conditions.

The only limitation may be the requirements of SNiP for some buildings or structures where it is prohibited to use materials that do not belong to the NG group (non-combustible). Although ecowool does not support fire and does not ignite, the restrictions prescribed for “paper” apply. Despite this, when building owners really need certain high performance indicators, ecowool is used despite the requirements of building codes developed before the appearance of cellulose thermal insulation on the Russian construction market for sound and heat insulation:

- residential buildings;

- industrial facilities;

- outbuildings;

- country houses;

- shopping pavilions;

- cultural buildings;

- airports and train stations.

Particular attention to the material when arranging recording studios, cinemas, concert halls and when creating acoustic rooms.

The right ecowool has a loose fiber structure that can trap air without turning the room into a “thermos”. In a house that is insulated with ecowool, the air remains fresh, with an optimal balance of humidity. This guarantees the absence of the smell of dampness even during seasonal or periodic residence, when the owners of the house move into it, say, for the summer vacation period. - but again, as mentioned above, if the country house is not turned into a thermos by using “deaf” vapor barrier materials. The absence of rodents will be a bonus.

When creating a thermal insulation circuit with ecowool , you can thermally insulate the following building elements:

- Facade structures – using the wet-glue method on the surface of the walls or filling the formed cavities with dry ecowool. Insulation is carried out under further cladding or equipment of the curtain wall.

- Walls – by wet-glue spraying or blowing insulation into the wall cavity.

- Floors - a simple method of dry backfilling will provide a warm floor without additional heating equipment.

- Attics. By insulating the walls and ceiling of the attic with ecowool, you can get a full-fledged living space that is cool in summer and warm in winter.

- Attic floor for a cold attic. This insulation is performed using the dry backfill method. In addition to saving energy, it prevents the formation of condensation and frost in the attic. Warming up of the roofing material with the formation of ice and icicles will also be excluded.

- Roofs in a warm attic. Such measures significantly extend the life of the roofing material, protecting it from temperature changes and corrosion. Helps conserve thermal energy in the house.

In addition to the insulation effect, laying ecowool will significantly reduce the impact of noise on the inhabitants of the house. Interfloor ceilings and interior partitions with cellulose fiber-based heat insulation will contribute to the creation of acoustic comfort.

Video description

The extent to which the positive characteristics of ecowool declared by the manufacturer correspond to reality is described in the video:

Flaws

There are no ideal materials without flaws, and ecowool is no exception. It also has its downsides.

- Shrinkage of the thermal insulation layer.

Over time, the loose fibrous material shrinks, becomes denser, loses volume, and its thermal insulation properties decrease. On horizontal surfaces, this problem is solved by making the layer thicker than the calculated one and organizing high-quality ventilation to evaporate moisture. But with vertical insulation, it will no longer be possible to fill the resulting voids.

- Installation problems.

When purchasing ecowool insulation, you should find out in advance what it is and where it is used. As well as the way in which it is laid on different structures. If you want to insulate monolithic walls or fill the cavities of a frame house, you will need special equipment and experienced operators, which are not yet available everywhere. And when insulating floors manually, the compressed material, freed from packaging, must be loosened using a drill with an attachment. This creates a lot of pervasive debris and allergenic dust.

Before installation, the material is “beaten” with a mixer Source obustroeno.com

Specifications

The quality of insulation with environmental wool is determined by technical characteristics that meet the performance of a modern insulation product.

Might be interesting

The ecowool insulation medium does not affect metal coatings and does not cause corrosion. There is also no fiber shrinkage.

| density | 30-70 kg/m |

| thermal conductivity | 0.032-0.041 W/m*K |

| flammability | G-2 GOST(30244) |

| smoke generation | 2.14-4.18 GOST (12.1.044) |

| breathability | 80-120x 10¯⁶m³/msRA |

| vapor permeability | 0.3 mg/mm |

| acid index | 7,8-8,3 |

| sound absorption | 63DB at 50mm thickness |

| lifetime | 50-80 years |

Installation methods

Ecowool is laid manually or automatically by blowing the material under pressure. For automatic spraying, both dry insulation and mixed with water are used.

The simplest and cheapest manual method is also the most ineffective. Firstly, it is used only for insulating horizontal surfaces. And secondly, with manual distribution it is difficult to create an even layer of equal density and fill all hard-to-reach places.

By using a blow molding machine to spray dry ecowool, these problems can be avoided: the insulation, supplied under pressure, lies evenly and penetrates into all cracks and recesses. But this method is only suitable for horizontal insulation and insulation of frame buildings. In the latter case, the material is blown into the cavity between the outer and inner lining through specially made or left holes.

Dry spraying of ecowool in the cavity of the frame Source thermofloc-isolatie.nl

To insulate vertical structures and sloping roofs, only the wet-adhesive automatic application method is used. The material is mixed with water to obtain a liquid suspension and blown with special installations onto the insulated surface. The natural glue lignin contained in cellulose glues the fibers to each other and to the base.

Preparation for insulation with ecowool

There are different ways to insulate with ecowool, which you can read about on the Internet. For my house, I chose wet adhesive for the walls (external and partitions) and Sidox for the attic and lower ceiling.

What is sidox? This is a combination of the wet method and dry blowing into an open horizon. When the wool is slightly moistened during the installation process, due to which it “stands” better in the ceiling and is much less susceptible to shrinkage (since in ceilings the packing density of ecowool is low). It is curious that there is practically no mention of this installation method, common in Scandinavia, on the Russian Internet, in companies that deal with ecowool.

Insulation was planned to be carried out in 2 stages.

- The main external perimeter is external walls 150mm, attic 300mm, ceiling 250mm.

- Additional 50mm in external walls and partitions.

Initially, the attic insulation was planned to be 250mm. But “you can’t spoil the mess with insulation.” The extra 50mm was not at all expensive in terms of money, so it was decided not to save money and to pour it in “heaps”.

Almost everything was ready for the first stage:

- The outer perimeter is sewn with isoplate, access to the walls from the inside, for wet adhesive application - yes

- The bottom floor is done. There is a subfloor that will hold the insulation, counter logs are installed and fixed. OSB boards on the floor just need to be lifted and can be insulated.

All that remains is to prepare the attic.

After googling on the Internet for plans for preparing an attic for insulation with ecowool, the following was done:

- Wind screens in the attic were installed before the windows

- Kraft paper with limited vapor permeability Elt Craft VCL was attached to the lower belt of the trusses using a conventional construction stapler. The paper was attached along the trusses, with an overlap of approximately 15 cm, and an allowance was made for the walls in order to later connect the paper from the ceiling with the paper on the walls.

- Then, from below, across the trusses, the sheathing is attached with a 25x50 piece of timber (an inch spread out along the length, as on the façade sheathing).

The sheathing has a dual purpose. Firstly, insulation support. Secondly, the basis for further fastening of the ceiling panels during finishing. The sheathing pitch is 30cm (under the panels). From the attic side, all paper joints were additionally taped with reinforced tape.

First, we attach temporary bars to make it easier to drag and attach the paper to the ceiling

paper on temporary bars

view from the attic

gluing joints

preparing the opening for the attic hatch

attic hatch opening

loft preparation completed

Briefly about the main thing

The very name of ecowool hints that it is an environmentally friendly and harmless insulation material. In fact, one can argue with this statement, as well as with the fact that this is one of the cheapest and most effective thermal insulation materials.

But when compared with expanded polystyrene or mineral wool, it actually has many impressive advantages, in particular - excellent heat capacity, vapor permeability, resistance to harmful biological factors, and a high degree of sound insulation.

Disadvantages can be found in any material, the main thing is that they are not critical and can be leveled out by following the installation technology. In this regard, ecowool is a very worthy insulation material.