An important step in almost any construction is thermal insulation. This is especially true for residential buildings. In the modern world, there are a lot of different materials for home insulation on the construction market. They all have different properties and characteristics and have their pros and cons. But today we will talk about a relatively new technology for insulating houses. The topic of our review today is liquid insulation , its types, characteristics, advantages and disadvantages. We will tell you everything you need to know about liquid insulation for your home, and also help you choose the best one.

So, what is liquid insulation? Let's start by conditionally dividing all liquid thermal insulation materials into two main, fundamentally different types. The first type is warm paints , and the second is foamy substances. How these types differ, in what cases it is better to use them and which brands are better to use, we will talk about all this further. To make it easier for you to navigate, we note that foam mixtures include: penoizol, polyurethane foam, polystyrene foam and other similar materials, which are often called liquid foam. But thermal paints have a more accessible application from the point of view of everyday issues, and in many external features they are similar to facade mixtures. Let us remind you that we examined most types of solid insulation in the last article, solving the question of which insulation is better, so we recommend that you familiarize yourself with this material.

In this article, we will look at examples of specific brands of liquid insulation that a group of experts have identified so that you can choose the best liquid insulation for your needs. If you know any other brands or options for insulating houses, be sure to share your opinion in the comments.

Liquid insulation

What is liquid wall insulation?

In addition to the fact that liquid insulation allows you to apply insulation in a fairly simple way, even after hardening this insulation is a durable monolithic, porous layer. And it performs the role of thermal insulation . Thanks to its structure, which has many air-filled microspheres, the insulation performs its functions many times better than its analogues. It is believed that just a few millimeters of liquid insulation have the same effect as a 5-7 centimeter layer of conventional insulation, for example, mineral wool, glass wool or polystyrene foam.

On the modern building materials market, various types of liquid insulation are sold, which are better suited for different purposes. The difference between these insulation materials is that they are produced from different raw materials, and the technology for applying the insulation also differs. Here are the varieties:

- Ceramic compositions.

- Expanded polystyrene or penoizol.

- Sprayed ecowool.

Of course, as with any choice of materials, for example, brick, we must understand that each brick is suitable for its own purposes, for example, clinker brick is used for the facade of a house, white sand-lime brick is good for its frost resistance, and fireclay brick is needed when building a fireplace or stove. Liquid insulation is no exception, so each type of insulation has its own pros and cons, and their scope of application also differs.

Where is liquid insulation used?

The scope of application of liquid insulation is quite diverse. This material is used for not only various construction tasks. Often such compounds are used in automotive production to protect metal from corrosion. Liquid insulation is also used for various products that must work by maintaining heat within certain values.

Where is liquid insulation used?

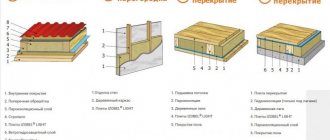

But still, the main area of application of such compositions is construction, namely the insulation of the following parts of the house.

- Stan.

- Paula.

- Floors.

- Ceilings and roof coverings.

- Pipe

In other words, liquid insulation is considered more versatile than any other insulation that we talked about in the last article. This versatility is associated with the method of applying the insulation; it is this that allows the use of liquid insulation where it is simply not possible to use any other.

The main pros and cons of liquid insulation

Liquid insulation has many fans among professional builders. This is due to the fact that such insulation has several undeniable advantages, namely:

- Universal use on surfaces of any configuration.

- Very low thermal conductivity due to the porous structure, which is very important for thermal insulation. The basic properties of any insulation can be found in this article.

- The material has high resistance to external physical influences.

- The material has good fire resistance.

But unfortunately, like any material and technology, liquid insulation also has disadvantages that can complicate some work and not perform the necessary functions. The main disadvantage of liquid insulation is precisely its method of application. This is due to the fact that some liquid insulation requires special equipment. This creates the need to contact specialists. This means that it is not always possible to do the work yourself. This means that another expense item will appear. But construction is already a costly business, so some consumers choose more traditional insulation, even despite all the obvious advantages of liquid insulation.

DIY application technology

Applying liquid insulation does not require any professional skills or expensive equipment (with the exception of liquid foam). To work, you will need a roller (brush or spray). When using a roller, you will also need a container to evenly rub the mixture over its surface. The process itself includes the following steps:

- We prepare the surface (clean the walls from excess mortar, sweep with a brush and wash with water).

- We prepare the material (if necessary, dilute it to the desired consistency).

- Pour paint into the roller container.

- Dip the roller in paint and roll it out on a special area until the mixture evenly saturates the roller.

- We carefully apply the insulation to the wall, no need to press hard. The first layer is applied from bottom to top.

- Subsequent layers are applied after complete polymerization of the first, usually after 24 hours (to find out the exact values, see the instructions for the insulation).

When drying any of the layers, it is necessary to avoid getting them wet, since most liquid thermal insulators are water soluble. Because of this, the impact of water on insulation that has not completely hardened can cause its complete or partial removal from the surface.

Application technology - video instructions:

Subscribe

TOP best types and manufacturers of liquid insulation

A group of our experts has prepared a list of the most common and high-quality liquid insulation materials. They tried to display as efficiently as possible all the pros and cons of these liquid insulation materials. After you get acquainted with each insulation in more detail, you can make a final decision whether it is worth using it to insulate your home and, if so, which one.

Liquid foam

It is believed that one of the most common options for liquid insulation can be called liquid (filled) foam . Its structure is a fine-mesh material, and most importantly, it has no odor. Therefore, most builders prefer to use it for internal insulation of the house. But nothing will stop you from using liquid foam outside the house.

Liquid foam. Roof insulation

Liquid foam is very often used in the construction of high-rise buildings. It owes such popularity not only to its thermal insulation properties, but also to its high elasticity. In addition, builders like that this material can be made directly on the construction site and poured under high pressure into hollow profiles. When dry, such liquid insulation guarantees a fairly good level of thermal insulation. Experts who work with this material praise its high strength, environmental friendliness, good thermal insulation properties, and most importantly, that it can be poured into any, even hard-to-reach places.

In addition, liquid foam is a durable material and lasts quite a long time. This is due to the fact that this material is resistant not only to mechanical stress, but is also not afraid of mold and mildew, since it has a porous structure and allows the walls of the house to breathe. In addition to everything, liquid foam can easily withstand any temperature conditions. The complex of these properties makes this material so popular and ensures its service life of more than 65 years .

Liquid foam

Most often, wall insulation using liquid foam is done using penoizol or polyurethane foam . Both of these options have the properties and characteristics of liquid foam. But it is not possible to apply penoizol to finished walls. It is used at the stage of wall construction, covering them with material. And also to use penoizol you need quite heavy equipment.

There are 2 types of polyurethane foam , the first with open cells, the second with closed cells. The first type has less reliable waterproofing, but has much better sound insulation. It is possible to apply polyurethane foam vertically using the same equipment as for liquid foam. And if you purchased the material in cylinders, then you only need a mounting gun

Liquid foam

Liquid insulation "Polinor"

A type of polyurethane insulation is liquid insulation "Polinor" . This insulation is produced in very convenient and small-sized cylinders. one such cylinder will be able to cover one square meter of surface, given that the thickness of this layer will be 6 centimeters. In construction stores you can find “Polinor”, the price of which fluctuates around 500 rubles , depending on the modification. Therefore, this type of insulation is considered very affordable, and most importantly, easy to use. Typically, "Polinor" is used to insulate the following surfaces.

- Facades, internal walls made of various building materials, for example, concrete, brick, gas silicate blocks.

- Lag floors or any other coverings with a non-load-bearing structure.

- Various types of attics and attics.

- Pitched roof and its internal surfaces.

- Foundation, basement and ground floor.

Liquid insulation Polinor

Due to the fact that this insulation is in liquid form and can be used on almost any surface, it is often used for thermal insulation of pipes outside the home. But there is also a drawback to this packaging option. Due to insufficient pressure, such insulation is not suitable for insulating empty spaces. Therefore, when using it, you must remember that it should be applied only by spraying . There are many videos on how to properly use such a cylinder. But in principle there is nothing complicated, and instructions are written on the cylinder itself.

Technical characteristics of liquid insulation "Polinor"

Let's take a closer look at the technical characteristics of the Polinor liquid insulation. This will help you understand whether this type of insulation is suitable for your needs.

- The thermal conductivity of this liquid insulation is in the range of 0.023 - 0.025 W/μ

- When the insulation hardens, its density will be at least 28 kg/m³.

- Closed cells in the structure of the material are at least 70%.

- If you immerse insulation in boiling water for 90 minutes, it will absorb only 2% moisture.

- The maximum permissible operating temperature is 121°C.

- The service life is approximately 45-50 years.

What does Polinor look like?

Among other things, Polinor is not only moisture-resistant, but it is also resistant to most chemicals. But you still need to know that there are substances that can adversely affect this liquid insulation. These chemicals include chloroform, methylene chloride, dichloroethane, and concentrated solutions of hydrochloric acid. Due to exposure to these chemicals, Polinor swells. You also need to remember that contact with sulfuric and nitric acids is extremely undesirable, due to the fact that they can corrode polyurethane.

Liquid insulation "Corundum"

What is liquid insulation “Corundum” , what is its feature and why was it in our TOP? We will now answer all these questions. Firstly, Corundum insulation is a mixture that includes an acrylic binder and ceramic microspheres with a diameter of 0.01 to 0.5 millimeters. Inside these spheres there is rarefied air. And the binding acrylic component of the mixture is made using catalysts and fixatives.

Application of heat-insulating paint “Corundum”

Secondly, liquid insulation “Corundum” is used not only for insulating residential buildings; this amazing material is very often used to protect industrial equipment and pipelines. Externally, ceramic heat insulator resembles ordinary paint and looks like a white suspension. After applying such a solution to the surface, it dries to create a very reliable and elastic polymer coating.

Thirdly, this material not only creates thermal insulation for the surface, like any other insulation, but also protects the metal from corrosion . And this is a very significant addition to the already very good properties. Due to the versatility of application, several different versions of heat-insulating paint “Korund” are produced. Let's look at each in detail.

Types of heat-insulating paint "Corundum"

Types of heat-insulating paint "Corundum"

- "Corundum Classic" . A universal material with high efficiency. Used for insulation of any surfaces. Treatment with such paint will prevent condensation from appearing and greatly reduces heat loss. The price of such a paint modification is approximately 375 rubles/liter.

- "Corund Anticor" . An indispensable modification for those who need to work with rusty metal. This composition can be applied to rust; it is only important to remove the loose layer of rust itself. The composition of such heat-insulating paint has very powerful anti-corrosion properties. The most important thing is that it not only preserves traces of corrosion, but prevents its occurrence. In addition to these important functions, this modification also has excellent thermal insulation properties. The average price of such paint is 435 rubles/liter.

- "Corundum Winter" . If you need to apply paint in harsh conditions, then this modification is a must-have. This material can be worked at a temperature of -10°C; for comparison, for conventional compositions the value is +5°C. The thing is that the modification of this material does not freeze and does not polymerize at subzero temperatures. It's all about the composition of such paint; it contains acrylic polymers, dispersed foam glass microgranules, flame retardants, inhibitors, pigments and rheological components. This paint will cost you 540 rubles/liter.

- "Corundum Facade" . And this modification was specially developed for application on concrete surfaces. Its feature is increased heat-reflecting properties. Experts also point to the high vapor permeability of such material and resistance to atmospheric influences. There will be no particular difficulties when working with this paint, since it can be applied in thick layers. After completion of the work, such paint does not interfere with the use of decorative facade coatings. The best option for home. Such heat-insulating paint will cost 400 rubles/liter.

Liquid insulation "Armor"

Here is another liquid insulation called “Armor” . The name is very symbolic. It is a homogeneous white suspension. After this composition dries, it forms a dense matte film that protects the surface from most external influences. Thermal insulation properties are created by retaining heat inside ceramic microgranules. And the acrylic base gives the composition elastic properties. Other necessary properties that are needed for such heat-insulating paint are achieved by adding catalysts, as well as antiseptic and anti-corrosion additives.

Popular types of thermal insulation paint “Armor”

There are various modifications of thermal insulation paint. They also differ from each other in various properties that are inherent in each type, and in the final price.

- The most common "Classic"

- "Antikor"

- "Winter"

- "Facade"

- "Wall"

- "Light"

So that you can compare the heat-insulating paint “Armor” with other analogues and make a choice based on your specific tasks, let’s take a detailed look at the main technical characteristics of this paint.

- Thermal conductivity value: 0.0012 W/μ.

- Vapor permeability indicators: from 0.001 to 0.013 mg/m·h·Pa.

- Density when the paint dries: 0.558 g/cm3.

- When applying a layer 1 mm thick, per 1 m2 you will need 1 liter.

- The paint dries from 2 to 26 hours.

- The temperature at which the paint can be used (maximum value) is +200°C (+140°C for inexpensive options).

- The service life of such paint is about 14-17 years.

Application of heat-insulating paint “Armor facade”

Thermal insulating paint "Armor" has a practically unlimited scope of application. It can be used for any vertical, inclined and horizontal surfaces, and can also be used both outside and inside buildings. Experts recommend using this paint for insulating roof slopes, ventilation, facades, various tanks, floors, refrigerators, water heaters, as well as any other similar surfaces and objects.

Warm paints

Unlike foaming polymers, thermal paints contain ready-made additives that provide thermal insulation. The most common are ceramic microspheres, fiberglass particles, perlite fillers or foam glass. Acrylic dispersion is used as a binder; water-based mixtures are also common.

Corundum

Multicomponent heat insulator on a polyacrylic base. Ceramic microspheres of different densities are used as a filler in its composition, which allows you to create a thin porous coating.

This is a white suspension, similar in consistency to regular facade paint. Once hardened, corundum forms a durable coating that is resistant to cracking due to its ductility. This allows the mixture to be used as insulation in a fairly wide range:

- Thermal insulation of walls, window and door openings;

- Insulation of floor coverings and roofs;

- Pipelines for any purpose, as well as steam pipelines and air ducts in air conditioning systems;

- Refrigeration systems (thermal insulation of refrigerators, thermal boxes and trailers).

One common application is the insulation of cold water supply lines. A layer of thermal paint prevents the appearance of condensation and corrosion on metal pipes.

Depending on the surface being treated and the required degree of insulation, several types of insulation are available:

- Classic . A universal mixture to protect almost any surface. Retains all performance qualities over a wide temperature range (from -60° to + 200°C) for at least 15 years. A twenty-liter bucket costs about 8,000 rubles . This is enough to cover up to 40 m2 of surface with a layer of 2-3 mm.

- Antikor . As the name implies, this composition can be used to protect metal elements from corrosion, including those elements that already have rust (the main thing is to remove loose fragments). The mixture has high thermal insulation properties, and its cost does not exceed 450 rubles per liter.

- Winter . Unlike conventional mixtures, when applied, the ambient temperature should not be lower than +5°C, Corundum Winter insulation can be used even in cold weather (down to -10°). This is the most expensive product in the line (the cost exceeds 500 rubles).

- Facade . The priority use of this mixture is insulation of external surfaces made of brick, cinder block or concrete. The material is weather-resistant and quite vapor-permeable. Cost - about 400 rubles / liter.

Akterm

The Akterm range of mixtures includes more than 15 products, many of which are highly specialized and designed to solve specific problems.

Among the thermal insulation compositions, the most popular are the following:

- Standard . An effective material on a water-dispersed basis, used as a thermal insulation and waterproofing agent in industrial and domestic conditions. Price – 340 RUR/l.

- Vulcan . Used to insulate surfaces whose operating temperature reaches +500°C. Can be applied to metal and concrete (brick, cinder block, penoizol, etc.). Price – 450 RUR/l.

- Nord . An organic based mixture that can be applied at ambient temperatures from -35°C. Compatible with various surfaces, it is resistant to aggressive environments and has anti-corrosion properties. Price – 360 RUR/l.

- Facade . Weather-resistant insulation with high energy-saving parameters. It is used for thermal insulation of walls on the street side. Price – 340 RUR/l.

- Anti-condensation . A water-dispersed mixture to prevent the appearance of condensation and mold formations. Price – 340 RUR/l.

- Metal . Operating temperature can reach 190°C. Applied to metal surfaces, it protects against condensation, freezing and corrosion. Price – 350 RUR/l.

- Concrete. A product for indoor use, a millimeter layer of which has barrier properties (prevents heat leakage on one side and cold penetration on the other). Prevents the formation of mold and condensation. The finishing layer is strong enough that it can be decorated (wallpaper, paint). Price – 340 RUR/l.

Astratek

Liquid polymer insulation. Thanks to special additives and low-density fillers, it has good thermal insulation properties at a relatively affordable cost. Currently the range includes the following products:

- Station wagon. Standard mixture for indoor and outdoor use. Can be applied to metal, wood, concrete materials and even plastic. Cost – 415 rubles/l.

- Metal. Designed for thermal insulation of metal surfaces. Prevents corrosion and condensation. Operating temperature – up to 260°C. Cost – 445 rubles/l.

- Facade. The priority use of this mixture with high viscosity is outdoor vertical structures. Significantly reduces heat loss and can be used both for reconstruction and in new buildings. Cost – 430 rubles/l.

- NG. Non-flammable heat-resistant material for insulating fire-hazardous structures (class KM0). Applied to plastered or brick substrates, can be used indoors and outdoors. Operating temperature – from -60°C to +200°C. Cost 445 RUR/l.

- Station wagon. The prefix BC means all-season, which allows you to work with the mixture at temperatures from -30°C. Otherwise, the properties of the mixture are identical to the “Universal” brand. Cost 495 RUR/l.

- Acoustic decor. Decorative heat-insulating mixture that reduces the intensity of penetration of external noise. Price 445 RUR/l.

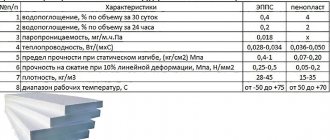

Thermal insulation properties of liquid and traditional insulation materials

If you have not read the material on the question of which insulation is better, then let us very briefly look at the thermal conductivity coefficients of the main and most common thermal insulation materials.

- Mineral wool : 0.06 – 0.07 W/(m*K). The difference in values is very dependent on density.

- Sheet foam : 0.037 – 0.05 W/(m*K). Also, when using sheet foam, there will be heat loss at the joints.

- Penoizol : 0.06 W/(m*K).

- Expanded polystyrene : – 0.03 W/(m*K).

- Polinor : 0.025 W/(m*K);

- Thermal insulation paints : from 0.0012 to 0.025 W/(m*K). Of course the manufacturer and modification matter.

You also need to understand the fact that during the actual operation of the material, its thermal conductivity will differ for the worse due to a number of different reasons.

Comparison of thermal conductivity of various materials

Your benefits

is, first of all, a manufacturer. We work without intermediaries.

Advantages of purchasing goods from us:

- no extra charge for certified branded insulation materials

- fast delivery on time

- production of coatings under contract

- personalized service

- professional installation services in the capital

- discounts for bulk orders

- the opportunity to release a product under “your” brand

We cooperate with wholesale and retail clients from all over Russia. Delivery of products anywhere in the world is possible. The main office of the company is located in Moscow. Shipment within the region - within 1-2 days after order confirmation. Leave a request on the website and you will receive a unique offer from our company.

Pros and cons of liquid insulation

Liquid insulation - advantages

- Can be applied to surfaces of almost any shape and material.

- Liquid insulation is resistant to atmospheric influences.

- Quite a small price for installation work.

- Due to the fact that the insulation is initially liquid, when it dries, it forms a monolithic layer without joints, compared to sheet insulation.

- There are no problems with coordinating home insulation with regulatory agencies. After applying the paint, the appearance of the house remains the same.

- It is not necessary to thoroughly prepare the surface for applying insulation. The solutions have high adhesive properties.

Liquid insulation - cons

- If stored and transported incorrectly, problems may arise with the composition and its properties.

- Compared to traditional insulation, it has a relatively short service life.

- It can be quite expensive if you use some liquid insulation materials.

- Many mixtures require specialized application equipment.

Video description

The video talks about SHUTTLE liquid thermal insulation:

Ecowool

An environmentally friendly product stands out against the background of thermal insulation materials. This is the only material that cannot be classified as a liquid insulation material in an unambiguous sense. But one of the methods involves using a ready-made mixture to prepare a working solution.

Spraying Ecowool Source myuspehlife.ru

Initially, the heat insulator consists of cellulose fibers in loose form:

- rejected products from printing factories;

- waste from the pulp and woodworking industries, from the production of corrugated and cardboard packaging;

- heterogeneous raw materials from recycled waste paper.

The raw materials are pre-treated with antiseptic drugs and fire retardants. Boric acid can make up up to 12% of the total volume. It provides resistance to moisture, fungi and mold. As a result, the insulation has a capillary structure, and not porous, unlike its analogues. About 8% is sodium tetraborate, a fire retardant substance that improves the fire resistance of the finished product. It also works as an insecticide that resists the appearance of settlements of certain insects.

The preparation of the solution for spraying is based on the lignin contained in the raw material. This natural substance becomes sticky when in contact with water. Spraying and simultaneously compacting natural fibers occurs using a special installation. Floors, walls, ceilings inside the building, and roof structures on sides protected from moisture can serve as a working base.

Industrial insulation with Ecowool Source stroyportal.ru

How to choose the right liquid insulation?

After you have finally decided what exactly you need to insulate, and there are a lot of nuances, if it is insulating a house, then first you need to decide which side you will do it from, and only after that select the material. For example, most manufacturers produce special “Facade” paints for insulating the facades of houses. Therefore, if you already clearly know what exactly needs to be insulated, the choice becomes simpler.

What about the paint itself and how not to make a mistake and choose a damaged one? We have already said that if stored improperly, the properties of liquid insulation can deteriorate, so when purchasing liquid insulation, first of all you need to pay attention to the production date and clarify the storage conditions. As with any product, it is still better to prefer well-known brands . They have already proven the quality of their products in the market.

How to choose thermal insulation paint

Here are the points that experts recommend paying attention to when purchasing:

- Find out the weight of a bucket of paint . The density of the composition greatly affects the thermal insulation properties; the higher the density, the lower the thermal insulation properties. Therefore, after weighing a ten-liter bucket of paint and seeing a weight of more than 6.5 kg, it is better to refuse to purchase such a composition.

- Hold the paint up to light . In the composition, light microspheres should rise to the top. Therefore, a thicker top layer of insulation indicates higher thermal insulation properties of the composition.

- a small amount of paint between your fingers . If the material is of good quality, then you will feel a fairly high amount of rough microgranules. If you don’t feel this effect, then most likely the paint is of low quality.

- The paint must be white . If the color is changed, this indicates gross violations in the manufacturing process. But there are paints with mineral color additives and this point does not apply to them.

When choosing and purchasing heat-insulating paint, experts do not recommend relying only on price. It is necessary to choose a paint that will perform its tasks, but the price is still of secondary importance.

Selection rules

First of all, you should decide on the place where the thermal paint will be applied. Usually, the jar with the product is labeled by the manufacturer. Look carefully at what surface this product can be applied to.

Carefully inspect the contents of the jar. It should be uniform, there should be no plaque or any inclusions. It is desirable that the color be white, but light shades of gray or beige are allowed. Otherwise, the product will not meet the declared qualities.

The density of the product should not be ignored. A low indicator of this criterion will give greater heat transfer. In addition, you should familiarize yourself with the service life and interaction with external environmental indicators. For example, ultraviolet light, fire or water.

Not all liquid thermal insulation has an easy application method. Make sure that the product not only meets the required protection and density parameters, but is also convenient to use.

Since there are a large number of manufacturers of this insulation on the market, it is better to give preference to a time-tested brand. This way you can be sure of the quality and reliability of the purchased product.

How much does liquid insulation cost?

But the price of liquid insulation varies. Because everything depends on the material itself, the composition of this material, the method of installation (application), the area of application and, of course, on the manufacturer’s brand. Therefore, it is difficult to name any general price for liquid insulation and the price varies very significantly, if you look at it objectively. To be prepared, the cost of any liquid insulation must be obtained directly from the seller or manufacturer.

For example, in the famous construction store you can buy goods at the following prices.

- “Magniterm Standard”: 4100 rubles per 10 liters;

- "Polynor": 468 rubles per cylinder.

Briefly about the main thing

The group of liquid insulation materials includes thermal paints and polymer foaming compounds. This also includes moistened ecowool, as it is applied by spraying.

The main advantage of the materials: high energy efficiency of thin-layer coating. The main disadvantage is the total cost according to the estimate. More often, spraying is carried out using special equipment that is not purchased for home use. Therefore, we have to hire craftsmen. If you purchase the material in gun cylinders, you can do the work yourself. But here there is a large consumption of expensive foam.

The insulation technology consists of 3 stages: surface preparation, application of insulation, decorative finishing. The base must be clean, strong and “healthy”. A sheathing is installed under the sprayed compositions. The finish can be anything: painting, paneling, plastering, cladding. Less commonly, thermal insulation coating is used as an independent coating.

Instructions for use: expert advice

There are no difficulties with applying thermal paint. Experts recommend adhering to the following recommendations when working:

- The surface of the wall must first be sanded to clean off the protrusions and remove excess masonry mortar.

- When processing ferrous metal, the coating is degreased and dust-free. Gloss is removed from non-ferrous metal products and primed.

- Mixing of the thermal paint is carried out immediately before application - downtime is unacceptable. Kneading time – up to 10 minutes.

- Liquid thermal insulation is applied in layers. The thickness of the coating depends on the brand of paint. Between applying layers, take a day off to allow complete drying.

Ceramic thermal paint is a new technology in home insulation. So far it is not popular, and its thermal characteristics have been criticized. However, in some cases, liquid insulation has proven effective, for example, in the thermal insulation of pipes. The material is practically not used in frame house construction.

Flaws

- In severe frosts, slopes in a panel house completely freeze if applied incorrectly or if the manufacturer's recommendations are not followed.

- When using TSM Ceramics, cracks may appear on the facade of buildings, since this manufacturer simply moves the dew point and does not protect the house from heat loss at all.

- Liquid thermal insulation Izollat, Asstratek is prohibited from being applied to the facade, but can only be used for waterproofing metal structures.

- When water is diluted above the specified standards, the thermal insulation simply flows off the walls.

What is the difference between internal and external wall insulation

Wall with external insulation

This application technique is considered the most effective because heat is retained in the house, while the internal area does not change in any way.

An important advantage is the increased ability of external walls to retain heat. Walls that are insulated from the outside cool down much more slowly than walls that are insulated from the inside.

Undoubted advantages:

- Minimal heat loss;

- Inside the insulation, as a rule, there is a dew point. In rare cases, it can accumulate at the outer edge of the wall;

- The wall will never be wet;

- The steppe maintains a certain temperature along the entire perimeter, there are no jumps;

- The coating reliably protects the wall from seasonal and daily temperature fluctuations; it is not affected by precipitation, which is considered the main cause of its destruction.

External insulation

Internal insulation

This method is considered the simplest, but in terms of functionality it is significantly inferior to the previous one.

This manifests itself in:

- Heat losses up to 10 percent.

- Dew point. It is located in the space between the inner wall and the insulation or in the insulation itself, which will undoubtedly lead to condensation beginning to accumulate and dampness appearing in the room;

- Walls are not able to retain and accumulate heat.

IMPORTANT! At the stage of performing thermal insulation indoors, it is more rational to use a vapor barrier film over a heat-insulating ball to prevent steam from entering the insulation.

The place where the thermal insulation will be adjacent to the structure must be sealed with foil adhesive tape. In this case, it is advisable to make an overlap of several centimeters.

Internal insulation

Results

When considering liquid thermal insulation as an option for insulating your home, you have to make a difficult choice between convenience and high cost. Indeed, simple tile foam or mineral wool will cost several times less: however, installing them is much more difficult than liquid insulation (this will inevitably thicken the base). When it comes to insulating hard-to-reach areas or surfaces with complex configurations, thermal paint is unrivaled.

5/5 — (11 votes)