Reducing the percentage of heat losses in heating communications in enterprises, utilities and private homes will save the lion's share of funds spent on heating the coolant. In this regard, any thermal insulation methods always remain relevant, especially when it comes to pipeline insulation. In heating systems of individual residential buildings, the main way to maintain a stable temperature of the coolant inside the pipes is to insulate the heating pipes. Insulating material is installed from the outside of the pipeline.

Expert opinion

Konstantin Alexandrovich

For every homeowner whose heating boiler is located at a distance from the heat exchangers (for example, in a separate utility room, outdoor boiler room), information about the main types of thermal insulators that are used to protect the pipeline from negative external influences, and about insulation of heating pipes will be useful. on the street. Materials for thermal protection can vary significantly, as well as their installation methods. Often, all the work can be done with your own hands. But you will need to carefully study the technology.

How to insulate heating pipes with your own hands

Sequence of actions in the form of step-by-step instructions:

calculation and purchase of thermal insulation material;

wrapping the pipe with foil tape or foil. The foil acts as a heat reflector;

installing insulation around the pipe. Sectional hard (casing) or soft insulation is simply “put on” the pipe. As for soft materials, they need to be cut into pieces equal in width to the diameter of the pipe. Next, wrap it around the pipe and secure it with tape, wire or plastic clamps. Hard insulation is the hardest part. From it you need to create a box around the pipe (or use pipe shells of the appropriate diameter);

inspect the insulated pipe for the presence of “cold bridges” and eliminate them;

secure the heat-insulating material to the pipe using plumbing or metallized tape;

if necessary, cover the heat-insulating material with protective material (film) and seal the joints with tape.

The costs of insulating heating pipes, despite their initial value, are quickly recouped by saving on bills for heating the house.

Insulation of water supply pipes in a private house is an important step in creating a comfortable microclimate and reducing the cost of heating premises in private and apartment buildings. In this article we will consider the insulation requirements for polypropylene pipes and whether it is necessary to insulate heating and plumbing.

In private houses, communications have two vulnerable areas for freezing. These areas are located on the street when laying communications from the well to the house or in an unheated basement. If you have not insulated the basement, then it is necessary to protect the pipes in the basement of a private house from heat loss. Let's look at how and how to insulate communications on our own, and tell you what materials to use.

Is it necessary to insulate polypropylene pipes in a private house? If you didn’t do this during construction, then protecting communications from heat loss is simply necessary. If a country house is rarely used in winter, then communications may freeze, regardless of what material is used for the water supply pipe - metal-plastic, HDPE or galvanized steel.

How to insulate pipes in a private house with your own hands

When a cold water pipe enters a warm room, condensation will always form on it. If the pipe is insulated, you will protect the room from possible dampness. Heating at home also requires thermal insulation, so as not to waste excess heat in a given room, but to redirect it as much as possible to living spaces, reducing your heating costs.

Protection of external communications

Insulation of heating pipes on the street is necessary if the boiler unit and radiators are installed in different buildings. Laying an external pipeline will cost less than installing an underground network, and covering communications with heat-insulating materials will help avoid heat loss and extend the life of the pipes. This way they will not require immediate repair or replacement.

When choosing how to insulate pipes outside the house, preference should be given to moisture-resistant materials and the installation of a hard casing to protect against mechanical and other external influences.

How to insulate outdoor heating pipes with your own hands

To choose the right pipe insulation, you need to know what types of thermal insulation for heating pipes exist, and what are the features of each of them.

By installation method:

rigid sheet insulation. These include: polystyrene foam and polystyrene foam. Despite the high thermal insulation properties, the installation of such insulation is quite complicated from the point of view of ensuring the tightness of the insulation;

roll insulation. These include: polyethylene (used as an additional component of insulation), foil penofol, wool (mineral and glass wool). The use of rolled materials requires the arrangement of their reliable fastening to the pipe;

segmental (shell) insulation. There are two types of such insulation: hard - shells made of polystyrene foam, polyurethane foam (PPU) or polystyrene foam, and soft - polymer pipes. The advantage of segment materials is that they hold their shape well, are easy to install and provide the required level of tightness between the heat-insulating material and the heating pipe;

sprayed insulation, incl. thermal paint. Penoizol has proven itself to be an excellent sprayer, as it allows you to insulate even small cracks. Thermal paint has the same property. The only disadvantage of these materials is that they are quite expensive and applying them yourself is problematic.

By type of insulation:

polystyrene foam and polystyrene foam. They have the best characteristics in terms of maintaining the original temperature of the coolant. Their use in the form of a shell simplifies installation and provides reliable protection of the system;

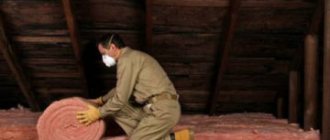

wool (mineral, glass wool). Can be used as a roll or sectional material. Regardless of the type and configuration, cotton wool insulation for heating pipes has a significant drawback, which is that cotton wool is hygroscopic. Those. it needs additional protection from moisture. When wet, cotton wool loses its properties. Therefore, sections often have additional protection in the form of a foil layer. But cotton wool is great for insulating pipes in the basement or attic.

foil penofol. Due to its small thickness, it is used primarily for insulating pipes indoors.

foamed polyethylene – (EPE, PPE) polyethylene foam for pipes.

Thermal insulation materials

Let's start the article with an analysis of insulation materials, because the modern building materials market today offers a fairly wide range of them. And the question of how to insulate heating pipes is relevant today.

There are both traditional materials and completely new ones, but they are all still in use, so it makes sense to consider at least the basic ones.

Mineral wool

This is a traditional insulation that has proven its relevance over many years of its use.

Things to note:

- Firstly, these are high thermal insulation characteristics.

- Secondly, the ability to use this material for finishing pipes through which coolant passes at a fairly high temperature.

- Thirdly, it is a non-flammable material.

- Fourthly, this heat insulator can come into contact with oils, acids and other aggressive environments, and at the same time it does not lose its qualities.

- Fifthly, the price of this material is quite low.

Various insulation materials for heating pipes

But it has, perhaps, only one drawback - it is hygroscopic. Mineral wool insulation quickly absorbs moisture, and at the same time sharply reduces its characteristics. That is why it is imperative to insulate it with waterproofing materials. For example, roofing felt or tin.

Expanded polystyrene

Expanded polystyrene has become an alternative to mineral wool insulation because it is quite cheap and at the same time easy to install. It is made in the form of two half-cylinders, which are used to compress the pipe.

The two parts are usually held together with clamps or self-adhesive tapes, or with wire. But, as in the case of mineral wool, polystyrene foam insulation must be waterproofed.

Expanded polystyrene - excellent thermal insulation

But if we compare these two insulation materials, then experts currently give preference to the second one. And the main reason is that the waterproofing process can be done with your own hands, without resorting to the services of specialists.

Penoizol

In its composition, this material is very similar to polystyrene foam, only it is used for application in liquid form. This heat insulator can be called this - insulation for heating pipes in the open air.

What are its advantages?

- Easy to apply.

- Seamless thermal insulation.

Insulation with penoizol

But it has one minus - it is impossible to apply without a special device. Therefore, you will not be able to insulate heating pipes yourself in this way. By the way, insulating the loggia in your own apartment with foam insulation is a very correct decision.

Foamed polyethylene

But this heating pipe insulation is extremely popular among home craftsmen. You don't even need instructions. The thing is that it is produced in rolls.

It is lightweight, convenient and easy to work with, there is no need to use any additional materials or devices, you simply wrap it around the pipes and fasten it with tape or wire.

The advantages include the durability of the product, its environmental friendliness, and let’s add that it is a non-flammable product, and this is of no small importance today. Thus, an insulated heating pipe is a guarantee of its effective thermal insulation.

Polyurethane foam

In this case, it is necessary to talk about two materials at once:

- Polyurethane foam. Many may doubt that it can be used as insulation for heating pipes. But practice has long proven that polyurethane foam can be used if there is a need to thermally insulate a small section of the pipeline.

- PPU shell. This insulation gets its name because it is produced in the form of two half-cylinders or in the form of several segments. By covering a pipe for insulation in this way, it is as if you were laying it in a shell.

Shell for insulation

Penofol with foil layer

This insulation appeared on the market recently, but immediately began to gain popularity. What is he like? There are two components used here. The first is aluminum foil, onto which the second component is applied - foamed polyethylene.

It is produced in rolls, it is perfectly protected by aluminum, foamed polyethylene is an excellent heat insulator. It is clear without words that using it to insulate pipes will not be difficult.

Foamed polyethylene

Foil foamed polyethylene

This is a flexible insulation that is produced in the form of pipes of various sizes, with a cut in the middle (this is done for ease of installation).

When insulating a pipeline with this material, pieces of insulation are applied to the pipes along the entire length and secured with construction tape. The joints or pipe connections must be covered with insulation of a thicker diameter. Therefore, before starting work, you need to approximately calculate the required amount of insulation of different sizes.

This brand of insulation is very convenient; it can be easily cut, and the remaining pieces can be used elsewhere, making one long part from several pieces.

Basic requirements for pipe insulation

Today, the choice of materials for thermal insulation is quite wide, so it is very easy to get confused when choosing. Be sure to focus on the basic requirements and characteristics of pipe insulation.

The selected material for thermal insulation work must meet the following parameters:

Today, for thermal insulation of outdoor heating systems, many insulation products are produced that meet all of the above criteria. Below we will consider in detail the most popular and suitable materials.

Expanded polystyrene

Expanded polystyrene for pipes

This insulation is made in the form of two shells of different sizes; they are fastened together using special grooves, but for a reliable connection they must be additionally secured with special glue or tape.

When connecting on pipes, the halves of the insulation are connected to each other and the two parts are shifted in different directions by several centimeters. The next link is also connected, and the remaining ends are joined together, resulting in a kind of “overlap” of one connection onto another, which provides a better bond.

To insulate awkward areas and corners, shaped shells that have unequal dimensions are used.

In order to carry out high-quality insulation with this material, you need to calculate in advance the length of the pipeline, the number of joints and bends. This is necessary to purchase the required number of connecting parts.

Installation and Operation Basics

The joints should be coated with glue to reduce heat loss.

Before installing the shell, the pipes must be inspected to eliminate the risk of leaks. Then the pipeline should be cleaned of traces of corrosion and coated with primer twice.

Insulation segments should be installed with longitudinal seams offset by 5-10 cm. To ensure a higher quality of insulation, the joints should be taped with foil or regular tape.

Having covered the pipeline with a protective casing, secure the insulation with clamps, wire or steel tape. Then, roofing material, fiberglass or roofing felt is wrapped over the shell, if there is no factory protective coating. The protection is also secured with plastic or metal clamps. The joints are coated with glue to reduce heat loss.

In an 8-hour working day, two people can insulate up to 150 m of pipeline.

What to consider when performing thermal insulation

Before you begin insulating a structure located in the basement of an apartment building, you should understand the basic requirements in order to get the expected result and avoid numerous problems.

- Maximum service life.

- Self-extinguishing ability.

- Availability of water-repellent properties.

- Easy to install.

- Low cost.

- Environmentally friendly.

- Low thermal conductivity.

Thermal insulation in an apartment building

Which materials are preferable?

Today, the variety of materials with which you can easily and quickly insulate water supply in the basement is impressive.

Among the effective and most popular are the following:

Mineral wool

Elements made on the basis of mineral wool will cope with temperature changes. With its help, you can insulate not only pipes in the basement of an apartment building, but also those located outside or in the ground. You can see what mineral wool looks like in the photo below.

Polyurethane foam

Ideal for insulating basement water pipes and attics. In essence, it is the outer shell of the water supply system. This design minimizes heat loss and adds strength. This heat insulator is not afraid of chemical influences and does not rot. But it has one drawback - high cost.

Expanded polystyrene

This material is characterized by a high level of rigidity. Expanded polystyrene insulation is sold in the form of a part of a pipe that has protrusions for fastening.

This heat insulator is best suited for internal insulation of a heating system.

Styrofoam

Polystyrene foam is good for insulating heating and water supply systems on ground and basement floors. Has a low level of moisture absorption. Foam plastic is also very durable and can be used for more than two decades.

Foam rubber

The heat insulator has a number of advantages. It is elastic, temperature resistant and not afraid of fire. Due to the fact that it is fire resistant, it is suitable for insulating external pipelines.

Liquid heat insulator

High-quality material that can compete on an equal footing with others. For example, one layer of paint can replace a 5-centimeter layer of polyurethane. In addition to its insulating properties, liquid thermal insulation can protect metal from corrosion and give pipes a good appearance. But it is not used for thermal insulation of plastic pipes.

Regardless of the material you choose, the main thing is that the insulation is effective and there are no problems with tearing or other damage on cold days. More detailed instructions for installing a particular heat insulator can be viewed in the video on the Internet. It is worth noting that working with insulation is not difficult; you can easily do it yourself.

If you find an error, please select a piece of text and press Ctrl+Enter

.

7901

Hello. Today I want to talk about how to insulate heating pipes inside and outside construction sites with my own hands.

. The topic is of considerable interest, since proper thermal insulation can reduce the level of heat loss when transporting coolant from the thermogenerator to the heating device. I hope you find the instructions in this article interesting and useful.

Main types of heat insulators

The choice of insulator is influenced by climatic conditions, budget and specific needs of the buyer. The best option for tubular and roll thermal insulators is selected based on these criteria.

Mineral wool

Insulation of pipes using foamed polyethylene and mineral wool

Mineral wool is a popular material for insulation. It has good durability and practicality.

There are several types of mineral wool:

- Made from basalt. It is highly resistant to heat (up to 600°C). Does not enter into a chemical reaction with pipes, does not emit harmful substances when heated.

- Fiberglass. The base is quartz sand. Used only for external finishing of external pipes. There are temperature restrictions - up to 200°C.

Mineral wool has a high percentage of moisture absorption, which reduces its insulating properties. To avoid this, waterproofing must be used. Roofing felt is used as a waterproofing material, the sheets of which are wrapped around the highway. This is the simplest and most convenient method of insulation. Rolled mineral wool is purchased for pipes.

Popular brands of materials include Energoflex, Jermaflex, Vilaterm and others.

Styrofoam

For the external finishing of pipes, specially shaped foam is produced that follows the geometry of the pipeline. The most common form is a ring consisting of two parts. The material almost does not absorb moisture, but additional waterproofing is still required. The rigid foam shell adheres well to the pipe. Available in gray and blue.

Foam insulation

Foam rubber insulation

For the manufacture of such insulation, the following are used:

- rubber;

- expanded polystyrene;

- polyurethane.

The insulation is made in the form of a cover, which has a cut for easy installation. This cut needs to be glued after installation to prevent moisture from getting inside.

Reflective pipe wrap

Foil insulation for pipes

Penofol is used for the external reflective winding of street pipes. The principle of operation is to reflect heat from the mirror surface of the insulation. Mineral wool, foam rubber, Porilex and other insulation materials can be used as such materials, which must be covered with foil on top. Fixation is carried out with a strong wire.

The main functions of insulation of pipelines of this type:

- reflection of warm currents;

- wind protection;

- do not allow cold and moisture to pass through.

Thermal insulation paint

Heating main covered with coating insulation based on perlite

The insulation method using heat-insulating paint is highly effective with minimal weight. Only a few millimeters of paint is enough to cover the pipe. Allows you to replace thick layers of other insulation for finishing.

Spray insulation

This is one of the best ways to insulate pipes. The process occurs quickly, the insulation is high-quality and reliable. Due to the absence of seams and joints, the possibility of moisture or wind getting into the pipes is eliminated.

The main disadvantage of this finish is the difficulty of installing insulation of heating pipelines. To work you need some experience and professional tools.

How to insulate pipes in the basement with your own hands

Glass wool

Fiberglass insulation from Isover, Knauf and Ursa. The material is most often used for insulating metal-plastic pipes. A positive characteristic is the low density of the material; its use requires additional insulation using rolled waterproofing materials (fiberglass or roofing felt), which requires additional costs of finance and time.

Basalt insulation

Basalt insulation in the form of cylinders made of basalt fiber. The shape allows the insulation to be installed without the construction of special trays, due to its cylindrical shape, while the cost of the insulation can be high. The top protective layer of waterproofing can be made of foil insulation or glassine.

Foam insulation

Polystyrene foam is the most common material. Expanded polystyrene shells can be used to insulate pipes without an external coating and do not require laying trays. The insulation can be reused many times, and the performance characteristics of expanded polystyrene satisfy all the requirements for insulation of water pipes.

Advantages and disadvantages of individual insulation materials

All types of insulation have their advantages and disadvantages. Therefore, it is worth talking about the pros and cons of insulation separately.

Mineral wool

This is a classic insulation material that occupies a leading position among rolled materials in popularity. And there are several reasons for this:

- high thermal insulation rates;

- resistance to aggressive environments;

- does not rot;

- not afraid of rodents;

- can be used when insulating heating pipes with high coolant temperatures;

- low cost.

The biggest disadvantage of mineral wool is that it is hygroscopic, that is, it absorbs moisture. Therefore, when using it, a waterproofing device is required, since if it gets wet, it will lose all its properties.

Penoizol

Unlike rolled materials, using penoizol you can achieve seamless pipeline insulation. The advantages include:

- excellent thermal insulation - 12% higher than that of cotton wool and 8% higher than polystyrene foam;

- no additional fastening or waterproofing required;

- biologically stable (not afraid of rodents and insects).

The main disadvantage is the need for special equipment to apply it.

Expanded polystyrene

The polystyrene foam shell is pressed against the surface of the pipes and secured with tape or clamps. Each section has grooves, thanks to which a tight connection is achieved. Withstands compressive and tensile loads.

But, since the material is hygroscopic and is destroyed under the influence of carbon liquids, it will require the creation of waterproofing. Another disadvantage is the difficulty of installation when turning the main line. To give the insulation the desired shape, you have to trim it.

Polyethylene foam

This is a new generation material. The closed cell structure provides it with such advantages as:

- low thermal conductivity;

- moisture resistance;

- does not rot;

- easy installation.

Available in the form of canvas (may have one or two-sided foil coating) or tubes. Polyethylene foam is cut into strips and wrapped around the pipe. The presence of a foil layer allows you to create additional thermal insulation and a waterproofing layer.

Thermal insulation paint

A relatively young type of thermal insulation. A special formula created by Russian scientists allows you to achieve optimal results even if you apply it in a thin layer. Apply thermal paint with a brush or spray. For hard-to-reach places, this is simply an irreplaceable option. The main disadvantage is the high cost, which is several times higher than the cost of other insulation materials.

As you can see, the choice of material for insulating heating pipes on the street is great

When choosing, the first thing to pay attention to is the characteristics of the material, then the complexity of installation. Last but not least, look at the price.

Remember that cheap insulation can quickly become unusable and then the money will be wasted.

Video: Thermal insulation of pipes: comparison of types

Is it necessary to insulate heating pipes and what benefits does it give?

Thermal insulation for heating pipes allows:

reduce heat loss in places where pipes pass along the ground, are mounted by air (ground) or are located in an unheated room;

prevent freezing of the liquid, which is the coolant (freezing is fraught with a pipe break);

reducing the likelihood of corrosion on the surface of the pipe (for metal pipelines);

saving money on heating your home.

Thus, the more reliably the heating system is insulated, the more heat the user will receive (the higher the efficiency), and the less he will have to pay for gas for heating (or for electricity, if an electric boiler).

Due to the fact that the coolant moves through the heating system, the task of pipe insulation is reduced to minimizing heat loss and preventing rupture of the system due to freezing.

A popular solution in this case is the use of thermal insulation materials. This is the most cost-effective and easiest insulation method from the point of view of independent implementation.

Thermal insulation of external pipelines: choice of material

For central and autonomous heating systems, a common problem is a decrease in the temperature of the coolant as it moves through the pipeline. First of all, this applies to external sections of the heating network, but also inside the building in some areas, thermal insulation of heating and hot water supply pipes is required to avoid heat loss.

You can buy a shower for your bathroom at AlmetaGroup. Variety of materials

Communications inside the house, as well as within your own land, can be insulated yourself by choosing the right materials. By insulating the heating main and hot water pipeline, you will achieve:

Who should pay for replacing pipes in the basement - Pravoved.RU

Hello, I live on the first floor, the apartment is divided into three rooms, a hot water pipe in our basement burst (that is, there is no water only in our apartment, there is water in the whole house), the management company says that the residents must replace it themselves. The question is, should we pay money to replace the pipe, or should the management company do it?

Victoria Dymova

Support employee Pravoved.ru

Similar questions

- After replacing the pipes of the in-house heating system, who should eliminate the consequences (if the wallpaper was damaged during a gas weld)? 23 August 2016, 14:56, question No. 1354083 5 answers

- Replacing pipes and faucets in a communal apartment June 14, 2015, 20:38, question No. 871057 2 answers

- At whose expense should it be necessary to replace the pipe from the central water supply to the water pump in the private sector? 28 July 2022, 13:34, question No. 1708933 1 answer

- Who should pay for heating pipe repairs? February 10, 2022, 21:20, question No. 1534698 1 answer

- Should we pay to replace the pipe or should the housing department replace it for free? 16 July 2016, 13:56, question No. 1316494 1 answer

Features of each

No matter how many materials claim to be universal, each one has installation and operation features that determine their scope of application.

Expanded polystyrene

The insulation for PPU and PPS pipes has structural locks for reliable connections and to prevent the formation of cold bridges. PPU shell is recommended for thermal insulation of networks laid in the ground. Insulation made of PPS, polyurethane foam for pipes is characterized by low resistance to sunlight. Under direct sunlight, the structure of the thermal insulation is destroyed. The shell made from polyurethane foam has zero moisture absorption, high biochemical stability, and extreme fire hazard.

The shell of PPU, PPS can withstand a large static load without compressing under the weight of the earth, maintaining its thermal insulation properties.

cold lock

Basalt based

Basalt wool shell

Thermal insulating shells made of basalt are best used when insulating an external pipeline. The main argument confirming this is the excessive water absorption of the material. Saturation with water leads to a complete loss of thermal insulation properties. It is restored only after the basalt fiber has completely dried. The use of hydrophobic impregnations has a slight effect on this indicator.

We insulate communications in the basement heating pipes

The problem of insulating communications in the basement, as a rule, is not familiar to ordinary city residents. But it is very often encountered by all those who live outside the city or have a dacha (or private house) for seasonal residence. Insulation of pipelines is not only useful, but also often a necessary measure, protecting the entire building from many potential problems.

Materials for thermal insulation

Today, a variety of materials can be used to reduce heat loss and insulate heating pipes. The choice of one or another heat insulator for basement pipes will depend, first of all, on the specific requirements of the owner of the house, operating conditions and pipe sizes.

There are a huge number of thermal insulation materials on the modern market, but not all of them are suitable for heating pipes.

This point must be taken into account before purchasing this or that thermal insulation material.

Of course, the most common and traditional thermal insulators, which are used everywhere, include fibrous insulation, including mineral wool.

It can be used in a variety of conditions, and almost always the thermal insulation will be quite effective.

Materials based on mineral wool can potentially withstand extremely high temperatures, so they can be used in basements and boiler rooms.

Mineral wool.

What can be identified from the main advantages of this heat insulator?

- high level of resistance to chemicals;

- safety for humans and the environment;

- minimal water absorption (but with serious exposure to water, the insulation will lose its properties);

- small price.

Basalt wool.

Mineral wool, according to experts, is excellent for thermal insulation of external pipelines, as well as heating systems in the basement of a private house.

In recent years, derivative materials have been increasingly used: basalt wool and glass wool, which also have good performance and performance characteristics. Materials of this type are suitable for most country homeowners.

Insulation with polyurethane foam

Recently, more and more people have begun to pay attention to modern heat insulators. And one of the most popular and effective is polyurethane foam (PPU)

This type of material is excellent for pipes and is, in fact, the outer shell for a water pipe (“pipe within a pipe”).

Polyurethane foam significantly reduces heat loss.

This type of design not only minimizes thermal energy loss, but also gives the pipes a high level of strength.

Positive characteristics of polyurethane foam:

- the material does not contain any compounds hazardous to humans;

- high level of resistance to climate impacts;

- increased mechanical strength;

- neutral to electricity and biological influences.

Polyurethane foam insulation materials will not rot or be destroyed by chemical exposure. The only obvious drawback of the material is its high cost. In fact, only this can be considered a reason to refuse thermal insulation from polyurethane foam in the basement of a private house.

Ready-made polyurethane foam shells.

It should be noted that insulating pipes with polyurethane foam is not so easy to do with your own hands, so it is better to hire specialists for this work. In the basement of a private house, the use of polyurethane foam often does not look like a very profitable option: the cost of a single installation (for example, for one or two pipes) will be quite high, so there is no urgent need for it.

Indoor insulation

Do-it-yourself insulation of heating pipes indoors will only be necessary in the case of unheated buildings. This refers to various basements, attics, and so on.

Be sure to pay attention to the fact that in such rooms there may be an increased level of moisture, and there are often rodents that can damage the finishing material.

To thermally insulate pipes in unheated rooms, you can use any of the above materials; in some situations, you may not even need an additional layer of waterproofing (if the room is closed).

The most convenient way to use finishing in such cases is with covers made of expanded polystyrene foam. But this is quite an expensive pleasure, so most people still prefer mineral wool.

As for insulating pipes in the attic, when choosing a material, be sure to pay attention to the thermal insulation characteristics. It must be resistant to heat.

Basalt cylinders

Thermal insulation material is a hollow product made of stone basalt wool, having a cylindrical shape. They are available coated with aluminum foil or uncoated. They come in different diameters and thicknesses, 1-1.2 m long. You can find basalt cylinders with a tongue-and-groove lock or an even joint that needs insulation. The material is resistant to aggressive environments, bioresistant, and easy to install. Due to hygroscopicity, it requires insulation.

Are you interested in insulation for heating pipes? Its price will depend on the characteristics and properties of the thermal insulation material. The estimated cost of the most commonly used products on the construction market is as follows:

basalt cylinders – from 50 rubles per linear meter;

polyurethane foam - from 10 rubles per linear meter;

heat-insulating paint – from 230 rubles per 1 liter;

energyflex - 10 rubles per linear meter, and more;

foam shell - 30 rubles per linear meter and more.

Remember that you should not save on thermal insulation material. To ensure that your home is always warm and cozy, use high-quality products from trusted manufacturers.

Contrary to all stereotypes: a girl with a rare genetic disorder conquers the fashion world. This girl's name is Melanie Gaydos, and she burst into the fashion world quickly, shocking, inspiring and destroying stupid stereotypes.

Unforgivable Movie Mistakes You Probably Never Noticed There are probably very few people who don't enjoy watching movies. However, even in the best cinema there are mistakes that the viewer can notice.

15 Cancer Symptoms Women Most Often Ignore Many signs of cancer are similar to symptoms of other diseases or conditions, which is why they are often ignored.

Pay attention to your body. If you notice

7 Body Parts You Shouldn't Touch with Your Hands Think of your body as a temple: you can use it, but there are some sacred places that you shouldn't touch with your hands. Research showing.

Our ancestors slept differently than we do. What are we doing wrong? It’s hard to believe, but scientists and many historians are inclined to believe that modern man sleeps completely differently than his ancient ancestors. Initially.

10 mysterious photographs that will shock Long before the advent of the Internet and the masters of Photoshop, the vast majority of photos taken were genuine. Sometimes the pictures captured were truly incredible.

Production methods and types of coatings

For the needs of industrial and civil construction, new heating mains are manufactured so-called. pre-insulated pipes. In this case, the prepared polyurethane foam fills the space between the object being insulated and a special formwork having a larger diameter. The result is a finished product, on the surface of which a protective polyurethane foam layer has already been applied.

Polyurethane foam shells are manufactured in accordance with industry standards and specifications. Depending on the operating parameters determined by the area of application and the pumped media, they are available in two types:

| Brand | Temperature range, °C |

| CT1 | from 100 to 120 |

| CT2 | from 100 to 150 |

Polyurethane foam shells can be produced without coating or have a protective layer: foil, fiberglass, glassine, galvanized steel, which depends on the operational and strength characteristics of the structure. Without additional protection by a casing, shells are used indoors or serve as the bottom layer of insulating “pies.”

Main types of thermal insulation coatings for pipes:

- Foil (foil paper). It is used indoors and to protect internal communications. Not suitable for heating mains with ductless or ducted installation.

- Reinforced foil (armafol). Recommended for economical insulation of networks, both internal and external. Protects against the effects of precipitation under conditions of significant temperature changes.

- Moisture resistant or fiberglass. Suitable for all types of pipelines laid outdoors by air. Provides a durable outer insulating layer and reliably protects against ultraviolet rays. Withstands mechanical loads and is considered optimal in terms of strength properties.

- Glassine (bitumen paper). The roofing material is resistant to ultraviolet radiation, but is inferior to fiberglass in strength.

- Galvanized steel casing. Used for open-laying trunk networks, process lines, gas and oil transportation systems. It serves as both ultraviolet and anti-vandal protection, and in terms of cost it is even preferable to fiberglass.

The variability of insulation will help ensure the required quality and reduce your costs

Polyurethane foam shells for pipes can withstand more than 1 thousand freezing cycles without changing consumer properties. And if you follow the recommendations for transportation and storage, it allows you to increase the service life of technological communications.

Why insulate pipelines

To begin with, let’s take a closer look at whether the material should be used for insulation of heating pipes or for thermal insulation of heating networks, and if necessary, why and where exactly.

The heating system of any building is designed as follows: the air inside the room heats the coolant (water) circulating through pipelines to the radiators.

Giving off its heat through the walls of the pipes, the water returns back to the boiler, which heats it again. This is in general terms.

However, heat transfer is not necessary over the entire length of the pipe. For example, if the boiler room in your house is located far from residential premises (or even in a separate building on the street) that need heating.

During transportation from the boiler to the area requiring heating, the water will lose some of its heat. As a result, more energy (fuel), and therefore more money, will have to be spent on heating the air for living rooms.

Often boiler rooms are located in basements, where the temperature is significantly lower than in a living room. So Energoflex insulation for heating pipes in the basement will give serious results in saving fuel.

But thermal insulation for heating pipes for an apartment is no longer so important and irreplaceable. The only caveat is that insulation of heating risers is important: in this case, more heat will reach the battery

In addition, the pipeline also needs mechanical protection from possible damage. First of all, this concerns areas along the street - it is their isolation that needs to be thought about first of all.

Which thermal insulation to choose for heating pipes Review and description

At first glance, insulation of heating system pipes is only important for large boiler houses serving a large number of consumers. But even in a private home, losses can be significant. Just imagine: a conventional (aka equivalent) square meter of pipeline with a temperature difference between inside and outside of 10 °C produces about 70 W/h. As the gap ∆t increases, losses increase proportionally, and this can only be avoided with the help of good insulation.

The need for pipe insulation

It’s one thing if the heating pipeline is located in residential premises and transfers energy to them - in this case it becomes a kind of radiator of a small area and does not need protection. But when the circuit is laid in a concrete screed, the heat may be used for other purposes. In the open air, energy is completely wasted, and in a cold basement, the temperature difference can provoke condensation and corrosion of metal communications.

Any insulation for heating pipes must have fairly high technical characteristics:

- Density ≤ 400 kg/m3.

- Thermal conductivity ≤ 0.037 W/m∙°C.

- Heat resistance – not lower than +130 °C.

- Water absorption is no more than 1% when it comes to steel pipes.

- The flammability of the insulation is NG or G1.

- High electrical resistivity of the insulation.

- Resistance to aggressive chemicals and biocorrosion.

Thermal insulation for heating system pipes is simply necessary if they are not located in heated rooms. Refusing it can lead to unpleasant consequences, and the total losses will not be so harmless. In the worst case scenario, unprotected sections of the circuit will simply freeze and depressurize—the entire affected section of the route will have to be replaced. So there is no escape from thermal insulation. That is why we will devote our review to choosing suitable options for heating pipes.

A clever meter that saves electricity Pays for itself in 2 months!

How to insulate pipes in a private house

You should think in advance about how to insulate water supply pipes in a private house, how to insulate a columnar foundation, and what thermal insulation material to use for various materials. Requirements for the materials used should take into account the ease of installation of insulation, long service life, water-repellent characteristics, environmental and fire safety of the material.

You should not have any difficulties in your work; anyone can handle this issue. No special skills or special tools are required to insulate pipes. Check out the video instructions at the end of the article on this topic, and you will understand

Insulation of heating pipelines is an important aspect in the creation of energy-saving technologies, and this issue is acute these days.

At the moment, a large number of insulating materials and methods for their optimal use in various industrial fields have been developed.

But energy needs to be used rationally not only in industry, but also in everyday life. Insulating heating lines is not only desirable, but also becomes a vital necessity.

In general, the process of thermal insulation is aimed not only at maintaining the temperature at a stable level, but also at protecting the heat carrier from freezing during cold periods.

Thermal insulation materials are of the following types:

- piece;

- in rolls;

- combined;

- for filling;

- casing

Depending on the technical characteristics and insulation parameters, these materials are used in the following networks:

- ventilation;

- cold and hot water supply;

- technical equipment;

- steam heating.

The choice of protective material must be approached with great responsibility, because it is the key to warmth and comfort in people’s homes.

The types of most effective insulating material are as follows:

- Thermal insulation paint

. It is considered one of the achievements of Russian science. One layer of this coating can replace several centimeters of polystyrene foam and mineral wool. At the same time, this material does not harm the environment and is resistant to high temperatures. This type of pipeline insulation is used in difficult production conditions. - . This material is characterized by low thermal conductivity and fire resistance. For these reasons, it has found wide application in the protection of heating systems. But, this type of protection refers to expensive building materials.

- Insulation with polyurethane foam

. They began to use it for thermal insulation only recently, but they have already appreciated its practicality. - Expanded polystyrene

. This is practically the same pinoplast. This option is affordable and easy to install. - . It is a shell shaped like a pipe.

Insulation underground

When laying heating pipes underground, it is important to take into account the following nuances:

Laying heating pipes underground is quite an expensive pleasure, since in this process it is important not only to use high-quality materials, but also to be especially careful.

The most effective and common option for thermal insulation is the use of finishing material in combination with rigid casings. There are only two options here:

Both of these options are united by a plastic or metal pipe covering the insulation layer and the frame itself.

Heating pipe insulation technology

The choice of pipe thermal insulation and the method of its installation are influenced by the location of the pipeline.

Insulation of heating pipes on the street

External thermal insulation of pipes is the most difficult method of insulation, since in the open air it is not only the pipes that need protection, but also the insulation itself. For outdoor installation, non-hygroscopic materials or other materials are used, but reliably protected from moisture by a film or casing.

In addition, it is advisable to use the densest and thickest insulation outdoors. Another requirement is the use of a material that is resistant to ultraviolet radiation, bad weather and mechanical damage.

Insulation of heating pipes in an unheated room

Basement, cold attic, boiler room - a feature of such rooms is the absence of heating radiators. But since the pipes are filled with coolant and are located in an environment with minimal humidity, there are no special requirements for either the thermal insulation material or its thickness.

Insulation of heating pipes underground

The specificity of installing heating pipes underground is that they must be laid below the freezing level of the soil, which is a depth of one and a half to two meters. If you do not adhere to this requirement, the coolant will cool greatly while it passes through the heating main located in the ground. In order to reduce heat loss, you need to take care of high-quality insulation of the underground pipeline.

Experts say that the optimal solution in this case would be to use a cable pipe heating system. But due to the high cost, users prefer enhanced thermal insulation of heating pipes.

Good insulation of underground heating pipes requires the following requirements:

insulation of insulation from moisture in the soil;

eliminating the possibility of deformation of the insulation, because in this case, its properties are reduced. This is especially true for soft thermal insulation materials;

According to reviews, the optimal solution is thermal insulation of heating pipes using.

Note. Users recommend using a combined insulation system for pipes that are laid above the ground freezing level, namely: a combination of cotton wool and a hard polyurethane foam shell with a protective fiberglass coating. Ideally, even at the laying stage, use factory multilayer ones.

Need for isolation

Thermal insulation for heating pipes is needed everywhere, from huge factories and enterprises to small country cottages. The price for insulation included in the project at the very beginning will help save a lot of money on pipeline repairs and fuel costs in the future.

Insulation shell - connection structure

Thermal insulation of heating pipes outdoors and indoors is carried out to protect against freezing, metal corrosion, as well as the formation of condensation. Work on insulating hot water pipelines is carried out to reduce heat loss, as well as save money on fuel; in addition, the service life is increased.

If you purchase high-quality products, they will also protect your pipes from bacterial and chemical attack.

Worn heating main insulation

Materials for insulation work

In construction stores, thermal insulation materials for heating pipes are available in a wide variety; they have different qualities and characteristics. There you can see on the shelves mineral wool in mats, cylinders, polyethylene or rubber heat-insulating tubes, liquid thermal insulation and many others.

We will consider the most popular materials:

Foamed polyethylene. The insulation consists of notched tubes made of high-quality polyethylene foam. The thermal insulation created from this product is environmentally friendly, highly resistant to sudden temperature changes, moisture accumulation and chemical influences.

This product is used as an insulating shell; it is used for cold and hot water supply pipelines, in air conditioning and refrigeration equipment;

Pre-insulated pipe

Foamed rubber. This technical insulation can be in the form of plates or tubes. Rubber itself, in addition to its excellent thermal insulation properties, has increased fire safety, therefore, it belongs to the group of self-extinguishing materials.

This insulation is absolutely waterproof and resistant to the formation of fungi and condensation. Foamed rubber in the plates may have a protective foil coating that reflects heat. This product is widely in demand for insulating equipment and pipelines for various purposes;

Insulation: mineral wool. It is produced in mats and has a wide range of uses. This material is convenient for performing work aimed at insulating large equipment and pipes.

Thermal insulation of heating pipes in the basement

The mats themselves are made pierced, foil or laminated. Such products provide good sound and thermal insulation of equipment for a long time;

Thermal insulation cylinders. The production of these products is carried out from basalt mineral wool. On the market, such insulation can be found in three variations: cylinders with a galvanized surface, cylinders with a foil surface and cylinders without a coating.

This insulation forms a protective shell and envelops pipelines, and its materials have high fire resistance and water resistance. In addition to good thermal insulation of pipelines, it reliably protects chimneys;

Foil insulation – foamed polyethylene. It has the appearance of a canvas and is an excellent material for insulation purposes. This material is used both outside and inside buildings. Polyethylene itself has hydro-, steam- and insulating properties.

Thanks to the foil, it reflects heat well and does not lose its qualities as a result of chemical and thermal influences, is environmentally friendly and durable, and is suitable for absolutely any pipes and equipment;

Polystyrene half-cylinders

Liquid thermal insulation. It is a new invention in this area and is also called thermal paint. The instructions for use suggest that it can be applied to pipelines of various shapes and diameters.

The result is a thin protective coating that provides good insulation, protection against corrosion and condensation. Having applied such insulation, there is no need to apply other materials. The main advantage is the possibility of application even in the most inaccessible places;

Protective coatings for pipes. This includes materials such as: fiberglass, fiberglass, foil canvas, foil insulation. They have good thermophysical properties and are not afraid of temperature changes.

Foiled polyethylene foam

Polyurethane foam

This insulation is applied by spraying. A specially prepared composition is sprayed onto the installed pipeline. It reliably adheres to the surface and, when foaming, forms a dense protective mass with high strength.

Due to the fact that this insulation does not tolerate exposure to sunlight, insulation of pipes located in the open air with it must be accompanied by their protection: winding with roofing felt or aluminum foil.

For high-quality insulation of pipes, insulation materials can be combined. For example, in a boiler room and outdoors they can be covered with mineral wool or basalt insulation. And in the house, the connections to the heating radiators are made of foamed polyethylene, which looks more aesthetically pleasing.

Scope of application

Insulation of sewer and water pipes reduces the risk of plastic rupture in winter.

Shells for insulating pipes made of polyurethane foam or other material are used to maintain a constant temperature of the environment circulating inside the pipeline, to protect people from burns at high or low pipe temperatures. This material is used for insulation:

- sewer pipes;

- cooling lines;

- hot and cold water supply networks;

- chemical synthesis systems;

- pipelines in the oil and gas industry.

High speed and ease of installation distinguish the shell from insulating materials of other form factors. Due to its high insulation efficiency, environmental friendliness, and ease of use, shells for pipe insulation are popular in public and private construction and industry.

Thermal insulation for outdoor heating pipes

A variety of insulation materials makes it possible to choose exactly the one that is best suited for a specific location of application (outdoors, in the ground, in the basement, in the attic) and budget.

The selection of a heat insulator is carried out taking into account the following factors:

heating system pipe diameter;

operating conditions (location of the heating system);

average heating temperature of the coolant;

thermal conductivity indicator of insulation (the lower, the better);

water absorption rate. Shows the ability of the insulating material to perform its functions in a humid environment;

resistance to combustion, biological and chemical activity, ultraviolet radiation and other environmental factors;

life time;

ease of installation (provided that sufficient tightness is ensured);

price.

PPU shell - types of protective coatings

To protect the surface of polyurethane foam insulation from exposure to UV radiation, mechanical damage and other external factors, the PU foam shell is made with various types of protective coatings:

| The covering material based on aluminum foil and fiberglass has mechanical and chemical strength, is not affected by moisture, protects against negative ultraviolet radiation, significantly increasing the service life of the PU foam shell. The foil “smoothes out” thermal inhomogeneities, reducing the likelihood of heat losses, and gives a finished look to the insulated objects. Used for internal communications. |

| Fiberglass protection provides higher resistance of the polyurethane foam shell to atmospheric, biological, physical and chemical influences; fiberglass is a difficult-to-combustible material, is not subject to rotting processes, and additionally gives the insulated objects an aesthetic appearance. Recommended for indoor and outdoor use. |

PPU shell coated with galvanized steelThe steel coating provides a high degree of protection for the polyurethane foam shell from mechanical damage and other environmental factors, and gives additional rigidity to the insulating layer. This type of protective coating is used for indoor and outdoor applications. |

Do I need to protect pipes from the cold?

The coolant that enters the radiators of our apartments arrives at a temperature slightly lower than it was in the boiler room. If the boiler room is located at a distance from the house, this heat loss is even more noticeable. According to statistics, a quarter of the total amount of heat that comes from the boiler room to the radiator is lost along the route of the pipeline. Most of the pipeline is located in the open air and is not always insulated. Heating the street is undesirable for any consumer. Therefore, protecting the pipeline from the cold is a vital necessity.

The warm water that flows inside can protect the pipeline from freezing, but the heat loss is significant. Insulating pipes will help maintain the temperature of the coolant inside the pipe, heat loss will be significantly reduced, and the pipes themselves will be protected from atmospheric influences: temperature and humidity changes. Corrosion processes in insulated pipes will be insignificant, this will lead to long-term use.

It will be especially important to carry out thermal insulation work in areas where the pipeline runs along the street or in basements. Timely insulation will reduce the financial costs of heating an apartment or house.

An insulated pipeline is less susceptible to breakthroughs, therefore, there will be no need to do expensive repair work in winter.

Installing your own boiler room in a multi-storey building will not solve this problem, because the pipeline is located in the basement, where cold air is present, and heat loss is inevitable.

The use of high-quality thermal insulation materials will allow the consumer to obtain a comfortable air temperature in the apartment, regardless of what radiators he has: cast iron, aluminum or bimetallic.

So, the purpose of insulating the heating pipeline is as follows:

- increase the temperature in the consumer’s premises;

- save money on the purchase of this coolant;

- prevent freezing of the pipe and, as a result, repair work;

- protect pipes from adverse environmental influences.

Thermal insulation of pipelines in a building

If the heating boiler is installed at a large distance from the radiator closest to it, and the pipeline passes through an unheated room, it is recommended to choose a method of thermal insulation so that the temperature of the coolant does not decrease.

It is important to insulate heating pipes in the basement, as well as in places where the pipeline passes through the walls, so that energy is not wasted on heating building structures. For interior work, use a safe heat insulator that is resistant to combustion and does not emit harmful substances.

Source

Thermal insulation for stoves with stone wool

Stone wool is one of the ways to provide thermal insulation for a stove.

According to the specified technical characteristics, thermal insulation for furnaces can easily withstand temperatures of 700 degrees, and with a short-term increase, it may not melt even at 900 degrees

The main advantages of mineral wool slabs are that they do not shrink after installation, and most importantly, they are completely protected from possible exposure to moisture. Also, mineral slabs are not sensitive to the effects of alkalis and acids; in general, this material has excellent performance characteristics.

It is worth noting that the use of mineral wool for thermal insulation not only increases the resistance of equipment to high temperatures, but also significantly reduces heat loss during the operation of the furnace, which means that the amount of fuel consumed can be significantly reduced.

Dimensions and diameters

The size and thickness of the insulation layer are selected depending on the operating conditions

The shell is used for thermal insulation of above-ground and underground communications. The protective casing is formed from two or more segments connected to each other. The larger the diameter of the shell, the more segments there are. The shell is made of a soft and flexible material, for example polyethylene foam, and can be made in the form of a cylinder with a longitudinal section. Shells made of relatively dense material, designed for small diameter pipes, up to 2 inches, consist of semi-cylindrical segments. If the pipe diameter is from 2 to 3 inches, there are already 3 segments. For larger diameter pipes, shells consisting of quarter-circle segments are designed.

The thickness of the insulation from which the shell is made varies from 9 to 90 mm. Insulation with a larger diameter and thickness will cost more. Based on this parameter, the shell is selected taking into account the requirements for thermal insulation efficiency.

Length dimensions also range from 1 to 2 m. The latter characteristic is determined by the ease of transportation, manufacturing and installation.

Insulation of pipelines according to SNiP

When carrying out work on equipment and installation of pipelines, it is necessary to comply with SNiP standards.

What is SNiP? These are building codes and rules for organizing construction production, compliance with standards, technical specifications and departmental regulations.

Basic norms and rules for thermal insulation

Heating networks are one of the main elements of centralized heating supply. You should strictly adhere to the rules and regulations when drawing up a pipeline thermal insulation project.

Subject to compliance with SNiP, thermal insulation of pipelines will be carried out efficiently without violating standards.

Thermal insulation of pipelines SNiP is provided for linear sections of pipelines, heating networks, compensators and pipe supports.

Insulation of pipelines in residential buildings and industrial buildings requires strict compliance with design standards and fire safety systems.

The quality of materials must comply with SNiP, thermal insulation of pipelines should be aimed at reducing heat loss.

The main tasks of thermal insulation, features of the choice of materials

The main purpose of thermal insulation is to reduce heat loss in heating systems or hot water pipelines. The main function of insulation is aimed at preventing condensation.

Condensation can form both on the surface of the pipe and in the insulating layer.

In addition, according to safety standards, the insulation of pipelines must ensure a certain temperature on the insulation surface, and in case of stagnation of water, protect it from freezing and icing in the winter.

Insulation of pipelines also increases the service life of pipes.

According to SNiP standards, thermal insulation of pipelines is used both for centralized heating and reduces heat loss from intra-house heating networks. What to consider when choosing thermal insulation:

- Pipe diameter. It depends on what type of insulator will be used. Pipes can be cylindrical, half-cylinders or soft mats in rolls. Insulation of small diameter pipes is mainly carried out using cylinders and half-cylinders.

- Coolant temperature.

- Conditions in which the pipes will be operated.

PPU shell parameters

- shell length 1000 mm;

- diameter of insulated pipe: from Ø18 mm – Ø1420 mm;

- thermal insulation thickness: from 22 mm – 300 mm.

Polyurethane foam bends significantly speed up the process of installing thermal insulation for a rotary section of the pipeline.

Parameters of PPU bends

- diameter of the insulated pipe: from Ø 22 mm - Ø 1020 mm;

- thermal insulation thickness: from 30 mm - 300 mm;

- rotation angle 45˚,90˚.

According to the customer's technical specifications, it is possible to manufacture polyurethane foam shells and bends for pipelines of any diameter with different thicknesses of thermal insulation!

PPU shells and bends are used for thermal insulation:

- gas and oil pipelines;

- hot water supply and heating lines, both above-ground and underground;

- pipelines for various purposes, chemical and food industries;

- pipelines for technological purposes;

- communications laid in the far north and permafrost areas.

Advantages of polyurethane foam shells:

- High thermal insulation efficiency due to the low thermal conductivity coefficient of polyurethane foam;

- Moisture resistance and biochemical resistance of polyurethane foam to solvents, oils, acids;

- Environmental safety and durability of polyurethane foam, service life more than 30 years;

- Quick installation of polyurethane foam shells by fastening with ties, staples, wire, or special polymer adhesives;

- When performing the work, no special tools or personal protective equipment are required; polyurethane foam can be easily processed with a knife;

- Possibility of repeated use of polyurethane foam shells in case of dismantling;

- Thermal insulation work can be carried out at any time of the year;

- Wide temperature range of application of polyurethane foam from -180°С to +120°С.

Criteria for choosing insulation

There are quite a lot of selection criteria, but they are all determined by significant factors. Let's go through the points so that everyone can choose insulation for a specific situation.

- Price. Yes, the first point is always the price. The question is not so much about the cheapness of the design, but about the specific insulation budget. A specific amount must be allocated that must be met, and only then the remaining parameters come. The cheapest option would be to fill it with expanded clay, but you need to install a separate box under it, which is extremely inconvenient, but cheap.

- Thermal loads. You need to know the temperature of the coolant in the supply line. The insulation must withstand this temperature without any kind of deformation.

- Impact of pests. If you are firmly convinced that you do not have pests, then you don’t have to look back at this point. If they are, you will have to treat the insulation with an antiseptic or use mineral wool. Remember, any modern insulation must be biologically inert. This means that despite any impact, bacteria or fungi will not grow in the insulation.

- Hygroscopicity. Insulation that absorbs water is not the best option. It will have to be covered with additional covers to protect it from moisture. But, if there are no other options, you can also use hygroscopic insulation.

- Shrinkability. Good insulation should not “shrink” over time. In practice, shrinkage means that after a certain period of time the insulation will have to be replaced. The absence of shrinkage extends the service life of the insulation.

- Easy to install. The easier it is to install the insulation, the better. But among other indicators, this one ranks last. If, after you have gone through all the points, there are still a few options left, you can think about ease of installation.

Installation nuances

First of all, when installing the shell, it is necessary to determine the diameter of the pipeline - so that you can select the appropriate diameter of the shell.

If it is larger than that of the pipe, the insulation will hang on it. If it is larger, the insulation will have gaps: the shell segments simply will not meet.

To fasten the segments (we will consider this option, and not the whole shell - it is the most relevant) the following can be used:

- Wire - in this case, the applied thermal insulation is wrapped with it.

- Glue – joints (both longitudinal and transverse) are lubricated and glued together.

- Groove - halves are connected to each other with a latch. Adjacent segments can be connected either with a latch or with glue.

- Adhesive tape.

The first option is good because it allows you to get a detachable connection: if necessary, you can simply unwind the wire, get a “bare” pipeline, and after completing the inspection (or work) you can put the insulation back.

The glued segments will only have to be cut. However, they can then be glued together, but the quality of the connection will be significantly lower. And every extra gap is a bridge of cold.

Stages of work

Thermal insulation of this type is installed as follows:

- The pipeline is cleared of old and unnecessary insulation (if used and not required).

- The areas that need to be insulated are measured.

- The number of shell segments is calculated.

- The insulation is installed from one “obstacle” (this could be a flange, turn, joint, fittings) to another.

- Each segment is attached using the chosen method (glue, groove, wire, or a combination thereof).

- If several fastening methods are used (for example, groove and tape, or groove, glue and tape, or any other combination), a second (third, fourth) fastening tool is used.

- Each segment is installed so that its transverse joint (cut) does not coincide with the joint of the adjacent one.

- If surface protection is used, it is installed and the joints are sealed.

- If necessary, areas that could not be insulated with a shell are separately insulated (by other methods: heating cable, rolled materials, spraying, paint).

What thickness of insulation is required?

Surely, an interested reader will have a question - what should be the thickness of the insulating layer in order to be guaranteed to protect the water pipe from freezing.

The answer to this is not so simple. There is a calculation algorithm that takes into account the mass of initial quantities and includes several formulas that are difficult even for visual perception. This technique is set out in the Code of Rules SP 41-103-2000. If anyone wants to find this document and try to make an independent calculation, you are welcome.

But there is an easier way. The fact is that experts have already taken on the brunt of the calculations - in the same document (SP 41-103-2000), which is easy to find with any search engine, the appendix contains many tables with ready-made insulation thickness values. The only problem is that it is physically impossible to present these tables here in our publication. They are compiled separately for each type of insulation, and are also graded by location - ground, open air or room. In addition, the type of pipeline and the temperature of the pumped liquid are taken into account.

But if you spend 10–15 minutes studying the tables, then you will probably find an option in them that is as close as possible to the conditions that interest the reader.

It would seem that that’s all, but we need to dwell on one more important nuance. It only applies to cases of water pipe insulation with mineral wool

When it came to this thermal insulation material, a series of mineral wool disadvantages included its tendency to gradual caking and shrinkage. This means that if you initially set only the calculated thickness of the insulation, then after some time the thickness of the insulation layer may become insufficient for complete thermal insulation of the pipe.

Therefore, when performing insulation, it is advisable to lay out a certain reserve of thickness in advance. The question is - which one?

This is easy to calculate. There is a formula that, I think, makes no sense to demonstrate here, since the online calculator we offer is based on it.

The two initial values for the calculation are the outer diameter of the insulated pipe and the recommended value of the thermal insulation thickness found from the tables.

One more parameter remains unclear - the so-called “compaction coefficient”. We take it from the table below, focusing on the selected thermal insulation material and the diameter of the pipe to be insulated.

| Mineral wool insulation, diameter of insulated pipe | Compaction coefficient Kc. |

| Stitched mineral wool mats | 1.2 |

| Thermal insulating mats "TEKHMAT" | 1,35 ÷ 1,2 |

| Mats and sheets made of super-thin basalt fiber (depending on the nominal pipe diameter, mm): | |

| → Du | 3 |

| ̶ the same, with an average density of 50-60 kg/m³ | 1,5 |

| → DN ≥ 800, with an average density of 23 kg/m³ | 2 |

| ̶ the same, with an average density of 50-60 kg/m³ | 1,5 |

| Mats made of glass staple fiber with a synthetic binder, brand: | |

| → M-45, 35, 25 | 1.6 |

| → M-15 | 2.6 |

| Glass spatula fiber mats “URSA”, brand: | |

| → M-11: | |

| ̶ for pipes with DN up to 40 mm | 4,0 |

| ̶ for pipes with DN 50 mm and above | 3,6 |

| → M-15, M-17 | 2.6 |

| → M-25: | |

| ̶ for pipes with DN up to 100 mm | 1,8 |

| ̶ for pipes with DN from 100 to 250 mm | 1,6 |

| ̶ for pipes with a diameter of more than 250 mm | 1,5 |

| Mineral wool slabs with synthetic binder brand: | |

| → 35, 50 | 1.5 |

| → 75 | 1.2 |

| → 100 | 1.1 |

| → 125 | 1.05 |

| Glass staple fiber slabs brand: | |

| → P-30 | 1.1 |

| → P-15, P-17 and P-20 | 1.2 |

Now, armed with all the initial values, you can use the calculator.

Calculator for the thickness of pipe insulation with mineral wool, taking into account material shrinkage

Interesting feature. When making calculations, it can sometimes turn out that the final result is less than the tabulated insulation thickness. In these cases, nothing needs to be changed - the value found from the tables of the Code of Rules is accepted as true.

Scope of application of PPS casing

The scope of application of polystyrene foam (EPS) insulation affects all sectors of industrial and municipal services; the technique is the most promising and can be used for insulation in the following cases:

- When insulating and protecting main pipelines running underground and on its surface from the effects of negative temperatures.

- For protection and thermal insulation of water, heating and sewer pipes in public and private sectors.

- When insulating air ducts of ventilation and air conditioning systems.

- To protect pipes supplying cold water from freezing when organizing individual water supply in country houses.

- When insulating wells and casing pipes.

Methods for installing polyurethane foam shells

Installation of polyurethane foam shell is simple and does not require special skills. Two workers per shift can insulate at least 300 meters of pipeline. The material is easily processed with a regular knife, which allows you to quickly trim the inside of the shell for a thick weld or other protruding parts of the pipeline.

There are 2 installation methods: sealed one-piece, using glue and quick installation without gluing the PU shells.

Installation using polyurethane glue

Vipol PK-200 glue is applied to the end of one of the shells being joined, after which the adhesive surface is treated with water using a sprayer. Then 2 shells are installed with technological fixation within 24 hours using bandages. The result is that the PU shell is securely secured with a seamless, permanent connection. More details

Quick installation

Quick installation is carried out by attaching the PU shell to the pipe with plastic ties, steel or polypropylene tapes, or binding wire. This fastening method leaves access to damaged pipes, fistulas and cracks, and makes it possible to reuse the PU foam shell. More details

Attention! The insulated pipe must be treated with anti-corrosion primer. When installing the PU shell, the pipe must be dry! The presence of moisture under the shell will cause a greenhouse effect and, as a result, severe corrosion of the metal

Projects with our participation Certificates of conformity

Proper installation of the polyurethane foam shell will ensure the reliability and durability of the thermal insulation, so we recommend that you familiarize yourself with the following information:

Recommendations for installing polyurethane foam shells Recommendations for working with polyurethane glue

A detailed description of all the products offered by our company necessary for the installation of polyurethane foam shells can be found in the “Products for Installation” section.

We remind you that to obtain information about prices for our polyurethane foam products and place an order, simply send a request to [email protected]

or call any of the phone numbers listed on the website.