Equipment

The steam heating circuit in a private house consists of certain components.

- Steam boiler. Through it, water is heated to a temperature at which it turns into steam.

- Expansion tank. Due to it, steam is generated from the water supplied by the boiler plant.

- Radiator. These are structures through which heat is released into the space of the rooms. This is how the entire building is heated.

- A pipeline through which steam is supplied and condensate formed during its cooling is removed.

- Pump. This is a device that pumps steam inside the heating system.

- Steam regulator. It is important for normalizing the amount of coolant entering the heating system.

Warm floor system

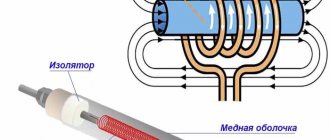

“Warm floor” has recently become increasingly popular. It is often created on the basis of electric heating, but if desired, water heating can also be used. Installing such a system is a complex and time-consuming procedure. Polypropylene pipes are laid under the floor covering (metal-plastic can also be used), through which the hot coolant will circulate.

“Water heated floor” system

It is also necessary to install a room thermostat - it will be used to regulate the temperature.

Collector group

Wiring and installation diagram of the regulator

This variation of the “warm floor” system has a lot of advantages compared to the electric one, the main ones being low cost and low energy consumption.

Peculiarities

The diagrams of steam heating systems are very simple and practically do not differ from those used when installing water equipment.

It is worth noting that when choosing a heating technology there may be some difficulties.

- Some people confuse water and steam coolants, believing that these objects work in exactly the same way.

- Many people refuse a steam installation because they consider it unsafe.

To understand that steam boilers will not cause harm and, on the contrary, will become a profitable investment, it is enough to competently approach the preparation of the project, its implementation in reality, observing existing standards and norms.

How to choose quality equipment

Food boilers are one of the types of heating equipment. They are installed in almost every professional kitchen to prepare first and second courses, vegetables, jelly and fruit and berry ingredients. Such equipment makes it possible

When choosing a digester model, you must first of all pay attention to the fact that there are two heating modes: maximum and minimum. It should also be taken into account that they differ in technical characteristics.

Depending on the characteristics of the catering enterprise, you can choose either a stationary or a tilting option. In the first case, the vessel is stationary, and the prepared food has to be laid out manually. The second is characterized by the presence of a rotary gearbox, which allows you to tilt the container at a convenient angle to remove the dish.

Operating principle

The heating scheme using steam heating is very simple.

- Heating of the water available inside the system occurs inside the boiler.

- When the boiling temperature of water is reached, it enters the cavity of the expansion tank.

- There, the liquid is converted into steam with a temperature of +120-130C.

- From there, the steam is directed through pipes and radiators connected throughout the house, and they are responsible for heating the room.

- Once the condensation process is completed, the steam flows back into the boiler. If necessary, the circulation will be repeated.

Even if the steam heating circuit is designed and installed with your own hands, the movement of water through the equipment is still carried out according to the standard principle.

However, the slightest violation in the assembly can cause a serious pressure drop, which leads to an accident and stop functioning. It is possible to prevent such consequences - it is enough to install special controllers that allow you to promptly release the discharge pressure. This reduces the likelihood of accidents.

Advantages and disadvantages of steam heating

The steam heating system operates on:

- Gaza;

- Coal;

- Firewood.

The best choice for houses built where there is no centralized gas supply is coal and firewood.

In general, this equipment, like any other, has its pros and cons, which must be taken into account if you want to equip your home with warmth and comfortable living conditions. The advantages include the following qualities.

- Affordable price, which is important for many consumers.

- Low heat loss, which makes the technology highly economical and reduces the cost of heating rooms.

- High level of heat transfer, which allows you to quickly heat even large buildings.

There are also disadvantages.

- Intense noise during boiler operation, when filling pipes and radiators with steam. The problem can be solved if the boiler installation is placed in a special room and the pipes are covered with sound-proofing material.

- High battery temperature. This may cause burns. Decorative grilles made from raw materials that are resistant to heating will help prevent such consequences.

- There is no smooth temperature control, and therefore, in order to cool the air in the rooms, you need to turn off the entire system. The solution is to choose modern boilers equipped with all the necessary functions.

- Low security. The solution is to select high-quality boiler equipment, order the design of the system from specialists with experience in this field of activity.

Preparing the boiler room for operation

Make sure there is the required amount of water and check the firebox for the absence of fuel oil. Ventilation of the firebox is also necessary to avoid ignition of accumulated gases. When fuel is supplied to the firebox, it is ignited by an electric igniter or from a burning source.

Steam should be distributed slowly to ensure uniform heating of parts of the boiler. Before steam rises, you need to make sure that the air valve is open. During heating of water and rise of steam, the tightness of hatches, manholes and covers is checked. Make-up pumps are turned on, automatic boiler systems are started, the fuel pump, fan are turned on and current is supplied to the ignition electrodes. Upon reaching a steam pressure of 1 kg/sq.cm. close the air valves and blow out the water indicators. After the steam reaches a pressure of 3 kg/sq.cm. inspect the flanges and manholes, squeezing their nuts. At a pressure of 5 kg/sq.cm. water replenishment and purging are switched on.

Tips for installation and operation

By following the recommendations below, you can avoid problems when using steam heating.

- It is prohibited to lay the pipeline using plastic pipes. When in contact with water heated to a high temperature, their internal cavity is subjected to high stress. If this part of the system is formed from unsuitable raw materials, it will lead to an explosion when pressure is built up. The best option is metal pipes, mainly galvanized or stainless steel.

- Installation of the system should be trusted only to experienced professionals. If you want to carry out the work yourself, then a qualified specialist should still supervise the process. This will prevent mistakes that could lead to an accident.

- When choosing a boiler, take into account how much steam it will produce. This figure is calculated in kilograms. It determines how quickly the house can be heated, which will allow you to choose an efficient, economical installation.

- For installation, you need to give preference to structures, pipes, radiators and components that: are made by well-known brands, have excellent technical characteristics, and ideal performance properties.

In addition, they must be: reliable, high quality, complying with the standards and GOSTs created for such products. The last fact will be confirmed only by license certificates.

A steam heating system can justify the investment, effort and patience, but its arrangement should be approached from the most correct side.

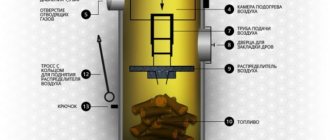

Fire tube boiler design

A simple operating principle determines the design. The body shape can be varied, but the most common is the cylinder shape. On one side there is a combustion chamber, and on the other side there is a smoke removal system. Combustion is supported by a forced blowing device.

Above the firebox there are heat exchangers that are in contact with the smoke exhaust duct. For increased heating efficiency, the heat exchanger is made of small cross-section pipes. The most common are three-pass fire-tube boilers. Its main difference from the conventional design is the presence of three smoke exhaust channels.

The first channel is considered to be the firebox, and the other two are located above one another. The fan provides the necessary draft, and there is also natural draft through the grates and ventilation holes.

In addition to the specified parts, the installations are equipped with the following components to improve their characteristics:

- air outlet channels;

- steam pressure gauge;

- coolant thermometer;

- control unit;

- pressure controllers;

- emergency protection.