Heating and providing a home with hot water are the most important factors for creating comfortable conditions for residents. In many cases, the best solution is a long-burning double-circuit solid fuel boiler. Such devices are reliable and easy to use.

A long-burning double-circuit solid fuel boiler is needed to create comfortable conditions.

Features of a double-circuit solid fuel boiler

Long-burning solid fuel double-circuit boilers combine at least two advantages: firstly, they provide both heating and hot water supply, and secondly, they allow you to significantly increase the intervals between visits to the boiler room.

Design

The design of such units is distinguished by the presence of two circuits.

The main elements of the device are the same as conventional ones:

- firebox;

- ash pan;

- heat exchanger;

- automation and control devices.

To ensure long burning, an automatic fuel loading system can be used, which includes a hopper for pellets or other bulk fuel, as well as a screw or pneumatic mechanism for supplying fuel to the burner.

Operating principle

The operation of boilers is based on a fairly simple principle: fuel, when burned, transfers energy to a heat exchanger, which, in turn, through a system of pipes, radiators, boiler and other devices, heats rooms and provides hot water for various domestic needs.

Boiler houses that heat not a private house, but entire cities work on the same principle. Thus, your own boiler is a mini-boiler room.

How is it different from a boiler with one circuit?

The number of circuits directly affects the number of possible functions. Each circuit is, in fact, a separate pipe that performs its task. If it is alone, then it performs one task, as a rule, heating the room. In most single-circuit systems, it is highly undesirable to withdraw water from circulation for other needs.

If there are two pipes, then the second one can provide hot water for the kitchen or shower. There are boilers with three pipes, in which case another circuit can be used, for example, for a heated floor system, which is an additional advantage during the heating season.

In the private sector, the most common multifunctional boilers are 2-circuit ones.

Principle of operation

The combustion chamber in these units, where the fuel combustion process takes place, acts as a heat exchanger in which the coolant is heated inside. The design of the combustion device is made of a fuel supply system, a smoke removal zone from which combustion products are removed, a grate, an ash pan for accumulating and removing ash with air holes.

While the solid fuel is smoldering, the released thermal energy heats the walls of the furnace. It is then transferred to heated water circulating through the water jacket from the walls and the internal capacitive heat exchanger.

The operating principle of a solid fuel unit assumes the presence of paired wall structures in its combustion space, between which there is a coolant for the heating system and hot water supply.

This firebox design is called a water jacket. Network water from the heating return pipeline enters the water jacket, is heated, after which the hot layers of liquid rise in the heat exchanger and then enter the heating system supply pipeline.

Moving along the heating circuit, hot water enters the heating devices installed in the rooms, gives off its heat through the radiator heating surface and, cooled, returns to the lower part of the water jacket.

Such a heating system can have natural circulation, for one-story houses, or forced circulation using an electric pump. It is well suited for multi-storey buildings with large heated volumes.

Advantages and disadvantages of boilers

A double-circuit solid fuel boiler has the following advantages:

- efficiency;

- reliability;

- long service life;

- low cost when compared with other heating boilers;

- wide selection of models;

- possibility of working without electricity and gas indoors;

- simplicity and ease of use;

- the ability to use various materials as fuel: firewood, coal, pellets, peat and others;

- easy availability of fuel and its low cost.

Disadvantages of solid fuel boilers:

- the need for pre-drying of the fuel;

- organization of fuel storage space;

- inability to adjust the temperature of hot water;

- periodic refueling of the boiler manually, this may be necessary several times a day;

- There is no automatic operating mode; such a boiler must be monitored.

The boiler also has some installation features; it is best to have this work performed by specialists; they will definitely be able to do everything in accordance with the rules and will give a guarantee. Features of installing a solid fuel boiler:

- It is not recommended to install the boiler on a wooden floor, but if this cannot be avoided, then it is necessary to make a good non-flammable stand.

- The boiler must be located at a distance of at least 20-25 cm from absolutely all foreign surfaces.

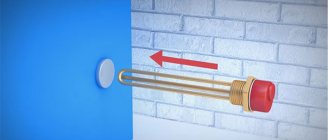

- The connection of all heating pipes must be done as efficiently and reliably as possible, since if water leaks, the boiler may fail.

- The outlet channel should be no more than one meter from the boiler to the chimney.

- It is possible to connect an additional tank to such a boiler - a boiler; it will be able to provide a stable water supply in the house, which will not depend on the water pressure in the system.

Operating rules

Heating units are complex devices with a high hazard class. The unit must be installed and operated only in accordance with the requirements and instructions of the manufacturer.

Ways to Increase Productivity

There are a number of methods that can significantly increase the efficiency of the installation.

Experts recommend periodically cleaning the unit.

Experts in the operation of heating systems recommend:

- Take time to prepare the fuel. Do not use undried firewood or damp coal.

- Ensure reliable ventilation of the room where the equipment is installed. Most solid fuel boilers use an open combustion chamber, so it is necessary to provide an uninterrupted flow of oxygen.

- Optimize the heating system of the room. To do this, you need to correctly calculate the number of radiators and the diameter of communications, as well as use the collector distribution of the coolant.

- Clean the unit periodically. Combustion products should be removed from the ash pan and ventilation lines should be cleaned.

- Check and, if necessary, improve the thermal insulation of the room. By sealing cracks and holes, you can greatly reduce your home heating costs.

- Use fuel that has increased energy efficiency. At the same time, it is not always economically justifiable to use the cheapest fuel. Thus, pellets, when burned, release more thermal energy than wood and coal.

- Install additional heat preservation equipment. For this purpose, thermal accumulators are often used. They are buffer containers filled with water. Circulation is provided by an electric pump. It takes water from the tank and supplies it to the boiler. There it heats up. The liquid is then returned to the storage tank. After the fuel burns out, the water container slowly cools, maintaining the air temperature in the room.

Types of boilers by fuel type

The simplicity of the boiler is inversely proportional to its ability to operate on any type of fuel. Complex systems are often capricious and have a number of limitations and requirements for the quality of the materials used.

Solid types include:

- firewood;

- coal;

- woodworking waste.

Wood burning

The most unpretentious devices run on wood. Often they can work on all other types. For some, the manufacturer indicates firewood as the main type, as well as the possibility of using others for minor technical modifications of the boiler.

Firewood is not a free-flowing substance, so it is impossible to use a traditional automatic fuel supply system here. This means that quite frequent manual reloading is required.

At the same time, the efficiency of such devices can be significantly increased due to various kinds of technological improvements, combustion principle, and fuel quality.

Pellet

Pellets are recycled waste from the wood processing industry. These are sawdust and wood chips pressed into granules. Due to this treatment, heat transfer and efficiency are higher.

Pellet boilers have burners, which are often not suitable for using other types of fuel, and are a metal structural element in the form of a bowl.

It is these units that are equipped with bunkers into which pellets are poured, as well as an automatic pellet supply system, consisting of a screw or pneumatic conveyor, and automation that determines the periods and intensity of supply. The bunker often has volumes from 200 to 400 liters, which allows the boiler to operate without human intervention for 3 to 7 days.

Negative aspects of long-burning double-circuit TT boilers

The main disadvantages are:

- high requirements for fuel quality;

- the need to allocate space for storing fuel reserves, which takes up a large volume;

- the inability to organize automatic supply of fuel to the firebox in inexpensive models that burn wood and coal;

- the need for regular maintenance - removing ash, cleaning ventilation lines;

- lack of automation responsible for controlling the water temperature in the heating circuit;

- inertia of the installation - the boiler cannot be turned off until the fuel burns out.

Criterias of choice

Despite the large range of manufactured models, it is not difficult to choose a boiler with a DHW circuit for your home. It is necessary to take into account several main features that are associated with the operation and configuration of the equipment:

- The presence of an installed heating element - an additional heating device as a backup heat source. After fuel combustion, the coolant cools over time. A special sensor is mounted on the return line, recording changes; it is connected to the heating element. After the liquid has cooled below the set temperature, the heating element is automatically switched on and the required water heating temperature is maintained. When the boiler is reheated, the heating element automatically turns off.

- Type of heat exchanger. Cast iron and steel equipment available. The latter option is about half the price, has a low weight and good resistance to temperature differences on the supply and return coolant circuits. The disadvantages include a relatively short operating time, no more than 20 years. The minimum service life of cast iron equipment is 50 years. Cast iron models are characterized by high thermal performance, unlike steel devices.

In addition to the characteristics described above, when choosing a boiler, you need to make a power calculation, as well as select a model taking into account the cost and manufacturer.

Power calculation rules

Traditional single-circuit equipment is calculated using the formula 1 kW = 10 m². Calculations allow you to select an approximate power value and can be used for rooms with a height of no more than 2.8 m. A boiler with a DHW circuit must be calculated taking into account the cost of heating water.

For a house with an area of 150 m², the calculation is made as follows:

- Only the heating system requires a 15 kW boiler.

- To heat DHW, additional power is required, which is equal to 50% of the total efficiency of the boiler.

- For a house of 150 m², a boiler with a capacity of 22-25 kW is required. Indicators are rounded upward. If the manufacturer does not have 22 kW boilers, then you need to choose a 25 kW device.

- The installed heating element is not used as the main source of heating and is used only for periodic operation.

Accurate calculations taking into account probable heat losses are made using a special calculator.

Types of solid fuel vehicles

Existing boiler models based on the type of solid fuel are divided into:

Regular. They burn fuel in the traditional way and can function on anything that burns. These are classic solid fuel cats.

Combined. They differ from conventional ones in that in addition they are capable of running on diesel fuel.

Gas generators. A special type of equipment that uses firewood in the main chamber and gases released when wood burns in another chamber as an energy source. Otherwise, these boilers are called pyrolysis boilers.

If you look at the drawing of a long-burning solid fuel boiler, what first attracts attention is the presence of two combustion chambers - for wood and gases.

The firewood compartment includes a fan that evacuates oxygen from the chamber.

Pellet. Pellets are a type of industrially produced solid fuel made from forest industry waste. They can be loaded into the boiler automatically.

Manufacturers of the TOP best solid fuel boilers with a water circuit

The Russian market for domestic boilers is saturated with solid fuel boilers of both domestic and Western production. Serious competition in the market forces manufacturers to make innovative changes in design and reduce consumer prices. According to buyers, the following brands have the greatest advantages.

Karakan 16TPEV 3 16kW

A double-circuit boiler that is popular in rural areas and uses any solid fuel. First of all, it gained popularity due to its deep firebox, which allows the use of firewood up to 50 cm long and a hob. For classical combustion boilers, it has a sufficient efficiency of 75%, producing 250 l/hour of hot water. The preparation of sanitary hot water is carried out using a built-in heating element with a power of 9 kW. When operating for heating, the boiler is completely energy-independent, with mechanical control via a thermostat. The weight of the unit is 120 kg.

Cost: 25,000-27,000 rubles.

Dragon Ta-15 Gv

One of the best double-circuit solid fuel boilers for heating a private home. A more advanced, efficient, practical and easy to maintain, but also much more expensive boiler. The efficiency reaches 88%, which was achieved by designing a combustion chamber with a longer gas removal time, due to which more heat is accumulated by the heat exchanger. Also worth noting among the features is the considerable volume of the firebox - 60 liters, the manufacturer claims 6-10 hours of burning of one bookmark. In practice, this is true, but when using coal with low ash content as fuel.

The design of the door allows for the additional installation of a liquid fuel burner, but we recommend doing this only as a last resort: the efficiency of burning gas, diesel fuel or exhaust in a large combustion chamber of a solid fuel boiler will be extremely low. Owners also note the cast iron grate. The only drawback is the extremely high price.

Cost: 53,500-62,000 rubles.

Wirbel ECO SKB 20

Development in Austria, production usually in the Russian Federation. An even more advanced model with complex gas removal, which accumulates more heat. The main serious difference is the organization of the second circuit through a storage boiler built into the main circuit with a capacity of 65 liters or more, which allows you to always have a certain supply of hot water in stock, but reduces efficiency if the boiler is used only for heating the house. It is also worth noting the reliability of the heat exchanger made of thick 5 mm furnace steel; in practice, such heat exchangers of other models last more than 15-17 years.

Water circuit - what is it and why is it needed?

The water circuit is a well-known heating system using radiators . It is necessary in houses with a not very good layout, it reduces heat loss from the window, and evenly heats the room.

Traditional boilers without a water circuit heat locally, and if there are more than two rooms in the house that are not in contact with the boiler room, a water circuit is simply necessary, because in its absence, remote rooms will not warm up sufficiently.

Heat loss in them will be very high, and temperatures often do not even reach optimal for living and long-term stay.

In addition, in houses with stove heating, corners often freeze . A water circuit will avoid this problem.

Heat exchanger

The reliability of the boiler is important - this is influenced by the material of the heat exchanger. Cast iron is durable, can last up to 20 years, but can be damaged by mechanical shocks and sudden temperature changes. Steel is resistant to such loads, but a steel heat exchanger will last about 6 years. Cast iron is recommended for private houses.

In addition, plate and tubular heat exchangers are distinguished:

- Plate ones are most common, they are characterized by their low cost and high heat transfer area. The disadvantage is the requirements for water purity. The circuit must include a water treatment system.

- Tubular ones have a small heat transfer area per unit weight, which is compensated by their massive construction and copper construction, which significantly increases the price.

Comparison with electric and gas boilers

Many people who build a house away from the city are faced with the choice of installing an autonomous solid fuel, gas or electric boiler.

In order to compare these options with each other, you will need to consider three important parameters: connection cost, service safety and ecology.

Connection cost. Although a solid fuel boiler is not cheap, its operation has the lowest cost indicators among all compared models.

The cost of a gas boiler is much cheaper than a solid fuel one, but in order to connect it you will need numerous permits from state supervisory authorities.

For this purpose, they will require the owner to provide a gas supply project, perform installation work to install the boiler and meter, and also pay for the connection.

Today, according to conservative estimates, it will take 600 thousand rubles and more to supply gas to a house, perform installation work and obtain an operating permit. Installing an electric boiler will cost much less, but it’s also not cheap.

In most cases, such a connection will require changing the power of the power supply line to 380 V. This will also require significant financial investments for the reconstruction of in-house electrical networks and coordination with the distribution zone.

However, it is not a fact that the electricity supplier will agree to replace the technical conditions. A solid fuel boiler does not require any approvals, and the funds spent on the purchase of boiler equipment will pay off in 2-3 years, while connecting to the gas network and installing a new power line no earlier than in 6-9 years.

Service security.

Everyone knows that gas boilers are the most dangerous, since if there is a violation in operation and the flame breaks away from the burner, an explosive mixture can be created in the house.

Electric boilers pose a danger due to the possible occurrence of fires in cable lines during overloads. In addition, an explosion of the steam-water mixture in the heat exchanger may occur if the circulation of the coolant is disrupted.

Any boiler needs to be serviced on time. Photo source: termo-star.ru

A solid fuel double-circuit boiler is also a source of a fire hazard, but the reality of its occurrence is much lower.

Since all structural components of the boiler unit are designed in such a way that the device is non-volatile. The built-in automatic protection, if the permissible parameters of the boiler operation are violated, shuts off the air supply to the firebox, after which the combustion process stops. In addition, today pallets are the safest fuel.

Ecology.

Here, in the first place are electric boilers, which have no emissions into the atmosphere at all, followed by solid fuel double-circuit long-burning boilers, and the list is completed by gas boilers, with the largest CO emissions.

Taking into account all the listed features of the types considered, we can conclude that the most convenient and easiest to operate is an electric boiler, followed by a gas unit, and a solid fuel unit is inferior to them in terms of these requirements.

But in terms of the cost level of the generated thermal energy, the best option is a solid fuel pyrolysis boiler, followed by a gas unit and the list is completed by an electric boiler. The heat cost of the latter unit is several times higher than that of a solid fuel unit.

Cost of basic options for solid fuel boilers

Solid fuel boilers are produced to operate on various types of fuel. The most commonly used wood species are pellets made from pressed wood chips and various types of coal.

The cost of boilers is from 30 to 200 thousand rubles. Photo source: avtokotel.ru

Recently, with the advent of biofuel from wood and agricultural waste, many users have switched to burning it in heating boilers. There are models that can run on any of these types of fuel.

The price of such modifications of heating units very much depends on the metal of the combustion chamber - cast iron or steel.

Wood-burning boilers today can be purchased for 55 thousand rubles. Coal units from 40 to 80 thousand rubles. Long-burning pellet double-circuit solid fuel boilers are the most expensive from 120 to 200 thousand rubles.