Heating gas boilers have a complex structure. Their design includes combustion chambers, gas burners for boilers, and they are equipped with automation. Double-circuit equipment also includes boilers that heat water for household needs. Regardless of the brand and model of a gas boiler, its most important part is the burner. The efficiency of the entire heating system at home, as well as saving fuel resources, largely depends on it.

How to choose?

What you need to pay attention to when choosing a burner device for a boiler:

- productive power - noise level during operation (applies to supercharged models) - type of heating equipment for which the burner is purchased - type of fuel - pros and cons of this device - provide for possible malfunctions in the operation of the local gas supply line.

Taking these factors into account, you can choose the most suitable burner device for your boiler so that it operates as efficiently as possible without the burden of frequent preventative maintenance.

Combustion chamber of heating equipment

Gas boilers differ primarily in the design of the combustion chamber. It comes in two types:

- open;

- closed.

The open chamber is a fairly simple combustion device. It looks like this: above the burner there is a heat exchanger in the form of a coil of thin copper tubes. Thanks to the open design, the air required for the combustion reaction is supplied to the point of ignition of the gas from the environment.

As a rule, there is enough air from the room (provided good ventilation is organized). But there are wall-mounted models with air intake from outside, for which a special hole is mounted in the wall. Open combustion chambers require a chimney.

Most often it is installed for models of floor-standing gas boilers, and was also used to complete an old-style boiler (in this case, ignition was carried out by a pilot burner).

Combustion chamber design diagrams

The closed combustion chamber is distinguished by the design of the heating block. The heat exchanger is located above the burner. The unit body is closed, combustion air is pumped by a fan installed in the chamber. Coolant is passed through the double walls of the chamber, heating it, increasing the efficiency of the boiler. The gas is burned almost completely, the combustion products are removed by a coaxial pipe under air pressure.

Compliance with the requirements

As mentioned above, in the burner natural gas is mixed in air, and the resulting mixture burns. As a result of exposure to high temperature, a chemical reaction is triggered, the products of which are carbon dioxide and water.

Of course, the whole process is accompanied by the release of a decent amount of thermal energy, which is spent on heating the coolant located in the heat exchanger. This is another key component of a gas boiler. All products obtained during the combustion process enter the chimney and are discharged outside the room.

This is a rather dangerous item, so a number of specific requirements are imposed on it in order to make the operation of the heating boiler as safe as possible.

The requirements in this case are as follows:

- The design should be as simple as possible , since this greatly increases the degree of reliability of this element.

- The burner must make a minimum amount of noise. The fact is that gas boilers are usually installed directly in a residential building, where this indicator plays an important role.

- The longer the service life of the part, the better.

- If the boiler design involves the use of different types of fuel , then it is better to purchase a universal burner. Here they make sure that it can easily switch from one type of fuel to another.

- Ideally, the burner should emit a minimum amount of harmful substances , for example, nitrogen oxide, carbon monoxide, due to which the environmental friendliness of the boiler increases several times at once. However, this will only work if the design of the chimney along with the hood is done correctly.

Types of burners

According to their design and functional differences, burner devices are divided into:

By purpose:

- for high power industrial equipment

- for household equipment.

By fuel type used:

- devices for natural gas;

- devices for liquefied gas;

- universal devices.

By flame adjustment:

- single-stage – capable of operating on/off;

- two-stage (as a variation - models with smooth modulation) - operate at full power, when the desired temperature is reached, the flame is reduced by half;

- modulating - boilers with a modulating burner are characterized by smooth adjustment of the flame power.

According to the operating principle:

- injection/atmospheric. They operate by supplying air from the room. They are installed respectively in open combustion chambers. Also used for old-style boiler models.

- fan/supercharged. They work in isolated combustion chambers. Combustion air is supplied by a fan. According to their design features, they are divided into: - vortex (round-shaped nozzle holes) - direct-flow (shape of a narrow slot with a round/rectangular cross-section).

- diffuse-kenetic. Air enters two simultaneously: one is mixed with gas fuel, the second is added directly to the chamber during combustion.

Combined versions

Combined burner

When using a modulated burner, the fuel can be gas, fuel oil, or diesel fuel. Under these conditions, no technical changes to the equipment are necessary.

Options for burning different fuels have been introduced into one block. This advantage is relevant for owners who do not yet have mains gas. This option is also useful for saving fuel.

These heating burners have total automation to control the combustion mode, fire intensity and other actions of the boiler. Thanks to intelligent automation, user participation in controlling gas equipment is minimized.

True, these burners have significant shortcomings that significantly reduce their popularity:

- very complex device;

- low efficiency;

- It is a very complicated operation to reconfigure the device when changing fuel. A professional from the gas service should work here;

- colossal prices.

As already noted, burners may differ in the method of fire control.

Gas burner device for a boiler

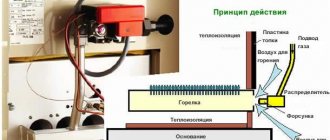

Atmospheric and fan burner devices differ in their structure. This is due to the different ways in which oxygen is supplied to the chamber during fuel combustion.

Atmospheric burner device.

Air enters the combustion chamber directly from the room. Nozzles are located inside the burner channel. Gas is supplied to the nozzles, mixing with air, which also has access here. At a short distance from the nozzles there are outlet slots through which the finished fuel mixture is supplied. An area of reduced pressure is created between the nozzles and outlets, which promotes a constant supply of air for mixing.

A pilot burner is constantly running in the combustion chamber to ignite the main device.

Fan burner device.

The device block consists of:

- engine;

- fan;

- automatic control unit;

- gearbox;

- air pressure switch;

- fuel mixer.

Air is forced from outside by a fan and supplied to the combustion chamber to form a fuel substance. The air to gas ratio can be adjusted using a damper and a fan.

Automatic

Preparing the fuel mixture and supporting the combustion process are fairly simple tasks, and are solved by the design of the burner itself, the shape of the nozzle, and the output nozzles. The automation unit in any heating boiler is responsible for other tasks:

- igniter combustion support, ignition using a piezoelectric element or a spark gap;

- thermal power adjustment;

- handling any emergency situations.

Among the latter are taken into account:

- lack of draft for atmospheric burners or problems with the operation of the fan for inflatable burners;

- low pressure in the gas line;

- extinguishing of the igniter or burner flame;

- exceeding the permissible temperature of the equipment.

The response to emergency situations is always the same - shut off the gas supply and, if possible, signal the user about a problem.

Burner flame

One of the indicators of proper burner operation is the color of the flame. Gas equipment is characterized by an even bluish flame without admixtures of other colors. The presence of yellow or red splashes indicates that the burner is not working well, which reduces the efficiency of the heating equipment.

First of all, this applies to injection burner devices, but sometimes it is also typical for fan burners. The flame may simply lack oxygen. Also, dust and other small debris can get in with the air, which will clog the device, reducing the efficiency of the boiler. All this directly affects the flame. If it hums, the burner is loud, or the fire has changed color, you need to adjust the correct operation of the device.

In what cases is it necessary to adjust the burner flame?

An atmospheric gas burner for heating equipment often fails. It is equipped with models of both wall-mounted and floor-standing boilers. The injection burner of floor-standing equipment reduces its efficiency for various reasons:

- Burner power is too high. This happens when a high-power burner is purchased for small heating equipment. At the same time, there is not enough space for combustion, the air flow for such power is weak, which leads to the transition of the flame from blue to yellow, sooting of the combustion chamber and chimney.

- If the chimney is poorly cleaned, the boiler draft deteriorates. At the same time, waste combustion products are poorly removed, and the air flow is small. This worsens combustion and the flame turns yellow.

- A defect in the burner itself does not make it possible to correctly adjust the complete combustion of the fuel.

- Due to pressure changes in the gas supply system, well-regulated equipment can release large amounts of unexhausted gas into the chimney. Partially it settles with soot and soot. A large layer of soot reduces traction and increases fuel consumption.

- Starting heating equipment after repair.

- The presence of extraneous noise during operation of the boiler or gas burner.

- Changing the type of fuel.

You may be interested in learning about the operating principle of a double-circuit gas boiler >>>

Blitz tips

- Recently, combination burners have been gaining popularity. These are some of the safest structures, but at the same time they are very complex. Their efficiency is quite high, but the price also makes itself felt.

- The burner of a gas boiler should be cleaned if the gas consumption in the room begins to noticeably increase, if there is some kind of unpleasant odor, if, despite all the indicators remaining unchanged, the air temperature in the heated room begins to noticeably decrease.

Equipment setup

Floor-standing gas boilers with an atmospheric burner can be configured independently. Pressurized systems are regulated by an automatic control unit and do not require additional configuration.

Scheme of actions for setting up single-stage equipment:

- Install the device on the boiler.

- Connect to the gas pipe.

- Check for absolute tightness.

- Remove the burner housing.

- Using a pressure gauge, measure the gas pressure at the inlet.

- Connect to electricity. Make sure that the jumpers and phases are connected correctly.

- Place a gas analyzer in the chimney pipe.

- Start the device.

- Using a pressure gauge, take pressure readings at the outlet of the burner block. Pressure readings must correspond to the parameters indicated in the data sheet.

- Adjust the air flow using the air damper.

- The gas analyzer readings must also comply with all gas equipment installation standards.

Setting up gas equipment should be carried out by specialists. The simplest open-type boilers can be configured independently if you have certain skills and knowledge of the design of the burner unit. The efficiency of the boiler, its level of efficiency, and fuel consumption depend on the quality of the burner. It is possible to superficially determine that the equipment is malfunctioning by the changed burner flame.

With your own hands

The easiest way to make the first type of burner, since it can be made from scrap materials.

To make it, you will need to use the following materials (almost all of them are available):

- The valve from an empty oxygen cylinder (it will serve as a nozzle here). What kind of valve it will be is not at all important; you can use the most common VK-74.

- In order for the gas stream to be directed as narrowly as possible , you will have to build a small cap that will be placed on the valve. Carefully make a small hole in it and place a jet there (a part from a blowtorch would be perfect).

- The injector will be the simplest - it will require a steel pipe, the thickness of which will not be higher than 2 mm. It is better to make it about 100 mm in length. The most reliable way to secure it is by welding. However, in this case, you will have to maintain a certain distance that should remain between the cap and the nozzle. This is done to ensure that a sufficient amount of fresh air enters there.

- To ensure that the flame ignites quickly , a piezoelectric element is installed next to the nozzle. You can do without it, and light the burner with matches and a piece of paper.