No matter how modern and powerful the heating system is, without high-quality reliable thermal insulation its effectiveness is reduced to a minimum due to large heat loss. Expanded clay and mineral wool are most often used to insulate walls, roofs, floors or ceilings of residential buildings. It is impossible to say categorically which material is better. Both heat insulators have their positive and negative sides. Their heat-saving function depends not only on physical and technical indicators, but also on compliance with the rules for installing thermal insulation.

What is expanded clay

Expanded clay is a loose, porous, fairly lightweight building material. The main difference between expanded clay and other similar building materials is the use of special types of clay containing about 30% quartz as a base.

Expanded clay is produced by firing low-melting clay rocks that can quickly swell when heated to 1050-1300C for 30-40 minutes. As a result of thermal shock, round granules with a melted surface are formed.

We can say that expanded clay appeared thanks to defective clay bricks, when burned, sedimentary clay rocks swell. The release of gas and the transition of clay rock into a pyroplastic state during heat treatment is taken as the basis for the production of expanded clay. Most often, expanded clay is used to fill concrete structures and thermal insulation of foundations, floors, and roofs.

What types of expanded clay are there?

Depending on the size and shape of the granules, they are distinguished:

- Expanded clay gravel. Oblong granules.

- Expanded clay crushed stone. Granules in the form of cubes with sharp corners.

- Expanded clay sand. Small granules, less than 5 mm in size.

The quality of expanded clay is affected by the size of the granules, bulk density, bulk density, porosity, and strength. The porosity of expanded clay comes in different structures, and its insulating properties depend on this. The more pores, the higher the heat-saving function of expanded clay. On the outside, the granules are usually brown in color, but on the break they are black.

Depending on the size of the grains, expanded clay is divided into fractions. According to GOST 9757-90, the following fractions of expanded clay are distinguished: 5-10, 10-20 and 20-40 mm. Material with granules smaller than 5 mm is classified as expanded clay sand.

Performance characteristics of expanded clay

Thermal conductivity

High thermal insulation ability. The heat-saving properties of the material depend on the type of processing. Even a small expanded clay layer under the floor significantly increases the level of thermal insulation. The thermal protection of a 100 mm thick expanded clay layer is the same as a 250 mm thick layer of wood.

Weight

Due to its lightness, expanded clay insulation is used at all stages of the construction process. The weight of one cubic meter of expanded clay reaches 250 kg.

Sound protection

Expanded clay is characterized by a high degree of soundproofing. The soundproofing properties of expanded clay are important in housing construction.

Strength and Durability

Thanks to “hardening”, as a result of firing the clay and forming a strong sintered shell, the material becomes chemically inert, resistant to mechanical damage and temperature effects (frost resistance, at least 25 cycles).

It is not susceptible to rotting, damage by rodents and damage by fungus and mold.

Flowability

Expanded clay is used to fill spaces of any volume and geometric shape.

Environmental Safety

Expanded clay is a completely natural material. Does not contain toxic impurities.

Water resistance

Expanded clay is not susceptible to moisture. The water absorption of the material is 8–20%. Any insulation needs protection from moisture and vapor barrier. But even when moisture gets into the expanded clay layer, its granules act as drainage, thanks to the ventilated gaps. And the moisture gradually evaporates.

Affordable price

The material is relatively inexpensive. For example, one cubic meter of expanded clay gravel (fraction 10-20) can be purchased for 1,450 rubles, the price with delivery is 1,500 rubles. Expanded clay is sold both in bulk and packaged in bags.

Properties of expanded clay as insulation

Expanded clay is a porous building material in the form of small granules. It is obtained by firing clay with a quartz content of about 30%. The material is environmentally friendly, durable, easy to use and durable; it is most often used for insulating foundations, ceilings, walls, ceilings, floors and roofs.

Expanded clay as insulation has many advantages, including:

- High levels of noise and heat insulation - it dampens impacts and retains heat well.

- Frost resistance - the material is not afraid of low temperatures.

- Fire resistance - the insulation does not burn.

- Strength and durability - the service life of the material is much higher than other insulation materials; over time, its properties remain unchanged.

- Low price.

The thermal insulation characteristics of expanded clay as insulation depend on the size of the granules, volumetric weight, and strength. It is used as an additive to concrete or bedding.

Expanded clay as floor insulation

When arranging floors, you can use expanded clay as insulation or sound insulator, the basis for creating a screed. The order of its installation varies depending on the technology used. The sizes of expanded clay granules as floor insulation are selected depending on the operating conditions and the expected loads on the structure - for the attic you can take a fine-grained one, but for a bathhouse you need to use a coarse one.

Using expanded clay as floor insulation, you:

- you create a reliable insulating layer that is light in weight and therefore does not place significant loads on the building structure;

- choose a material that does not burn, does not rot, or deforms;

- fill all voids due to flowability and small particle sizes;

- reduce construction costs.

Expanded clay as wall insulation

The walls occupy a significant area of each building, so heat loss through them can be very large. To avoid them, you can use expanded clay as wall insulation. It is used as a layer on external walls made of bricks or blocks, as a backfill for brickwork.

The main advantages of the material in comparison with other heat insulators:

- biological harmlessness;

- good heat and sound insulation (due to porosity);

- fire resistance;

- light weight;

- resistance to mold and fungi (without additional processing).

Expanded clay as wall insulation is an inexpensive, practical, non-toxic material that lasts much longer than other insulation materials. So why pay more?

A comfortable, warm home is every person’s dream. To make it this way, you will need to think through an insulation system. Most modern developers rely on expanded clay for insulating walls, ceilings and floors, since this material has good performance properties, is always on sale and is relatively inexpensive.

Physical and technical characteristics of expanded clay

Bulk density

Expanded clay is assigned different grades depending on the size of the bulk volumetric mass. The total number of expanded clay grades varies from 250 to 800; the grade number indicates the bulk density of the material.

For example, expanded clay gravel 250 has a bulk density of 250 kg/m3. Analysis to determine bulk density by fraction is carried out by pouring expanded clay into measuring containers. The smaller the granules, the greater the bulk density.

Moisture absorption

This indicator expresses the percentage of dry filler weight. Unlike other fillers, expanded clay is protected from moisture penetration inside due to the presence of a burnt crust. The correlation coefficient of high-quality expanded clay is not lower than 0.46. The defective material has low granule porosity, which significantly increases the ability to absorb and retain moisture.

Deformability

The deformation coefficient is determined by the porous structure of the material. As a rule, after the first test cycle, the vast majority of material samples show a reliable shrinkage result. The permissible value of the deformation coefficient is no more than 0.14 mm/m.

Thermal conductivity

The thermal insulation properties of expanded clay are greatly influenced by the glassy phase of production. The higher the glass content, the lower the thermal conductivity of the material. Good quality expanded clay has a thermal conductivity of 0.07-0.16 W/m, which allows you to save up to 80% of heat.

Expanded polystyrene or granulated foam

Polystyrene foam, both pressed and loose, consists of many small grains (granules or balls). If polystyrene foam in granules is not compressed, the material will be free-flowing, which significantly reduces its density and increases the thermal impermeability of expanded polystyrene chips. This also increases the volume by weight. Such heat-insulating material is used only on horizontal surfaces or in a closed inclined space, from where the polystyrene foam insulation cannot spill out. This material is also used to fill the cavities and crevices of structures by blowing them in with a compressor so that the crumbs are packed as tightly as possible.

But even with this technology for laying loose thermal insulation, it will shrink over time. A few more negative aspects that builders will encounter when using polystyrene foam in granules:

- High flammability (flammability group G4);

- Combustion toxicity;

- Low biological resistance;

- Thermal conductivity coefficient is 0.032-0.044 W/m•H/K.

The insulation is sold in polyethylene bags.

Styrofoam crumbs

Expanded clay production method

Clay shale is fired in metal kilns in the form of drums with a diameter of 2-5 m and a length of up to 70 m. The drums are located at an angle of inclination. Shale granules are poured into the upper part of the furnace, they flow down the drum, where the nozzle for burning fuel is located. The firing time of the granules in the oven is 45 minutes.

There are double-drum ovens, in which the drums are separated by a threshold and rotate at different speeds. In such kilns, it is possible to process lower-quality raw materials and obtain expanded clay crushed stone or gravel at the output, which is not inferior to the material obtained in single-drum kilns.

Material properties

Since expanded clay is a material that has a natural base, it has strength and durability that synthetic materials do not have. Its service life is an order of magnitude higher than wood insulation. Another advantage is that rodents do not grow in its layer.

Expanded clay is produced by melting and firing clay. To do this, only certain varieties are selected, pre-dried and crushed.

Raw materials are loaded into a drum-type oven, which rotates at a certain speed. Heated air is supplied to the oven. As it moves down the drum, the clay begins to stick together into lumps, sinter, and rotation gives it a rounded shape.

The quality of expanded clay and the size of its granules are achieved by regulating the temperature of the heated air and the rotation speed of the furnace. As a result, the output is an environmentally friendly material with excellent thermal insulation, soundproofing, fireproof and frost-resistant characteristics.

Kinds

Several types of expanded clay can be used as insulation - crushed stone, gravel, sand.

But crushed stone has sharp edges, and sand is heavy. Therefore, gravel is more suitable for roof insulation. It allows you to fill all cavities and create a high-quality thermal insulation layer. For the best effect, expanded clay gravel is mixed with foam chips. It is possible to use expanded clay of several fractions at once.

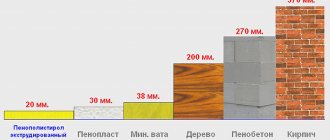

A layer of 10 cm of insulation is comparable to 25 cm of wooden beams, 60 cm of expanded clay concrete slab, and a meter of brickwork. But it is better if the layer exceeds 15 cm, then the maximum effect is obtained. In addition, such insulation is 3 times more economical than wood, and 10 times more economical than a brick wall.

Where is expanded clay used?

- Economical bulk insulation for walls, floors, building floors, basements, pitched roofs, as well as for the installation of heat and water supply networks. Good quality expanded clay gravel reduces heat loss in a building by 70-80%.

- Filler for lightweight concrete (expanded clay concrete). Production of expanded clay concrete blocks.

- Decorative material and at the same time a heat insulator for soil and lawns.

- Drainage material and thermal insulator for earthen road embankments in areas of water-saturated soil.

Application area

- When constructing buildings to provide thermal insulation. In addition, it can be used as insulation. Capable of protecting the foundation from freezing and providing high thermal insulation of roofs.

- Used for filling lightweight concrete.

- Used for the manufacture of lightweight expanded clay blocks.

- Expanded clay is used to create drainage, as well as to provide thermal insulation for roads, especially in cases where work is carried out on soil saturated with groundwater.

- Used for insulation of heat pipes. In addition, in the event of an accident or scheduled repair work, expanded clay will not create problems with access to the pipe.

- Used for growing various plants without soil.

- Used in landscape design for lawns. At the same time, expanded clay insulates the soil and creates good conditions for the development of roots.

- Can be used as a holding bedding in flower pots.

Methods for insulating floors with expanded clay

In modern construction, there are different ways to construct a subfloor. One of the frequently used ones is floor screed with expanded clay, which is performed both dry and wet.

Wet method

The use of expanded clay as a filler for concrete mortar adds strength to the structure. As a result of the penetration of the solution into the porous structure of the granules, the adhesion force of the concrete increases.

The content of cement and construction sand is 1:2 or 1:3. In the first case, a durable hard surface is obtained that can withstand heavy loads. Add enough water to obtain a fairly thick, homogeneous mass. Ready-made sand-cement compositions are available for sale, which are diluted with water in accordance with the instructions.

How to calculate expanded clay consumption

Calculation of expanded clay for floor screed is carried out taking into account the required thickness of the thermal insulation layer. Before you buy expanded clay and other screed materials, you need to calculate their quantity.

Usually they adhere to the following proportion: for 1 sq.m of screed 30 mm thick, 17 kg of cement and 50 kg of sand are required. Expanded clay consumption depends on the thickness of the insulation layer and the material fraction and is approximately one 50 kg bag, which is enough to construct a screed with an area of 4-5 m2.

Calculation of expanded clay for heated floors

The use of expanded clay allows you to use concrete mortar more economically. Laying a “warm floor” has its own characteristics, since the concrete-expanded clay coating experiences not only mechanical loads, but also temperature influences. In this case, the proportional content of cement and sand will be 1:2.

The amount of expanded clay depends on the thickness of the thermal insulation layer, for example, with a layer thickness of 10 mm, 0.01 m3 of material per 1 m2 is required. It is difficult to calculate in advance the exact consumption of expanded clay; often the required amount of material is determined experimentally during the construction process. A plasticizer is added to the concrete mixture for “warm floors” at the rate of 150-200 ml per 1 m2.

Procedure for laying expanded clay

Thermal insulation with expanded clay requires strict adherence to technology.

The procedure for insulating with expanded clay:

- Clean the floor. If the floor is made of wood, then remove all structures except for the mounting beams.

- Place beacons around the perimeter of the room, maintaining a small gap from the wall.

- Cover the surface with a 100 mm thick layer of sand and compact it.

- Pour expanded clay over the sand layer. The minimum thickness of the expanded clay layer should be at least 150 mm. It is determined taking into account the load on the floor.

- Level the surface of the expanded clay layer along the beacons using fishing line.

- Cover with a waterproofing film to protect the expanded clay insulation from moisture penetration.

- Pour concrete solution. Laying concrete requires care so as not to disturb the level of expanded clay. For 3-4 weeks, the floor is regularly moistened with water to avoid cracks.

Dry method

The peculiarity of dry screed technology is that no concrete mixture is used. The design consumption of expanded clay is 0.01 m3 per square meter of floor with a layer thickness of 10 mm. However, the calculation of expanded clay for dry screed is made for a layer thickness of 30-40 mm, which means that per 1 m2 of area, at least 0.03-0.04 m3 of material will be required.

In practice, the consumption of expanded clay may differ slightly from the calculated one due to various reasons: floor slope, change in screed area after installing beacons, etc.

Insulation under a concrete base

Dismantling and removal of old floor screedCleaning the floor

Floor waterproofing

The joints around the perimeter of the floor must be closed, so the film is placed on the walls. The damper tape is attached last at the level of the future screed. Now you can start insulating.

Damper tape.png

Step 1. Installation of beacons

Beacons must be metal; it is best to use T-shaped aluminum slats. Mix a little cement or gypsum mortar to fix the beacons, take the first strip and lay it under the wall opposite the doorway on the mortar. Be sure to check the location of the guide with a level and, if necessary, press it into the solution or, conversely, lift it. The height of the beacons should not exceed 10 cm, and the distance between them should be from 0.5 to 1 m.

Installation of floor beaconsBeacons

Step 2. Backfilling insulation

A mixture of expanded clay of different fractions is used to fill the space between the beacons and level it with a rule or a piece of plywood. Particular care should be taken to fill corners and joints where voids may form. After this, the expanded clay is carefully compacted so as not to damage the granules.

Filling with expanded clayFilling with expanded clay

Step 3. Reinforcement

A metal mesh with large cells is laid on the insulation, leaving 4-5 cm indentations from the walls along the entire perimeter. The mesh should not have any dents or bulges or protruding sharp edges.

A mesh is laid on the expanded clay

Step 4. Making the screed

For the screed, take 3 parts of sifted sand and 1 part of cement, mix thoroughly with water to a uniform thick consistency and pour in portions onto the floor between the guides. Level the screed using a long rule, running along the beacons and removing excess mortar. Now you need to wait for the concrete to dry completely and you can lay the floor.

The screed is laid directly on the expanded clay, without additional insulation. Leveling the cement screed

Insulating the floor of a country house with expanded clay

A country house can be insulated with expanded clay. The insulation layer must be at least 30 cm. When laying expanded clay directly on the ground, the floor will be cold. A more effective method is double flooring. A subfloor made of tightly fitted boards without gaps is attached to the beams. The flooring is covered with thin durable paper - glassine, which is used instead of roofing felt. Expanded clay is poured from above to the level of the middle of the beam. Then the finishing floor is laid.

Insulation materials require protection from moisture generated both inside the house and penetrating from the external environment. For this purpose, waterproofing membranes are used.

What is mineral wool

Mineral wool is one of the most common heat insulators, used in various types of insulation. Mineral wool is a soft, coarse-fiber building material. Mineral wool insulation is produced from metal waste and carbon alloys of minerals.

Mineral wool is widely in demand in construction due to its durability, simple and quick installation, and fire resistance. The disadvantage of this insulation is its reduced moisture resistance. To protect against dampness, the material is impregnated with special compounds.

The property of mineral wool such as breathability is especially valued. Due to its ability to “breathe”, mineral wool is often used to insulate wooden houses. Mineral wool insulation form: slabs, rolls, mats of various lengths and thicknesses. The choice of slab size depends on the conditions of thermal insulation installation and the upcoming tasks.

For summer houses, the insulation dimensions will be smaller. So for a panel country house you will need sheets 50 mm thick. Houses for year-round use require more thorough insulation; in this case, the required thickness of the mineral wool layer reaches 200 mm.

Insulation materials

In general, the floor in a bathhouse can be insulated with any insulation material. There are rooms with different operating modes and the floor structure may be different. Let's look at the most common materials that can be used to insulate a bath.

Foam glass (foam glass). Not to say that it is widespread, but it is an ideal option in all respects for any room. Foam glass does not get wet, is not afraid of moisture, frost, can withstand temperatures up to 100°C without problems, does not emit anything, does not burn, does not support combustion. It, like ordinary glass, melts at a very high temperature and does not emit anything. It has very good thermal insulation characteristics; a small layer is needed to achieve the required degree of protection. The material has low vapor permeability and this must be kept in mind when choosing a floor design. There is only one drawback - the price. Foam glass comes in the form of blocks, granules, and you can also find scraps. The most expensive blocks are (about $350 per cube), the cheapest are scraps (about $40 per cube). Blocks can be placed between the logs, granules and trimmings can be used as backfill. This is a much more effective (but also more expensive) replacement for expanded clay. New technologies bring new materials. For example, foam glass is almost ideal as insulation

Expanded polystyrene (not foam). The best option is extruded polystyrene foam. It can be placed in the screed or between the joists. It has excellent thermal insulation properties and does not absorb water (or rather, it does, but in a very small amount). Up to a temperature of 95°C it is environmentally safe, but above that it begins to release not the most beneficial substances. In relation to floor insulation in a bathhouse, it can be installed in any room. The floor is not walls and it simply has no chance of heating above 40°C. But polystyrene foam is flammable and vapor-proof. That is, good ventilation is needed. How to insulate floors in a bathhouse and with what depends on how you are going to make them

Mineral wool. Stone wool can only be used in dry rooms. She will work great here. It is better to insulate the floor in a bathhouse using a different material. If you want mineral wool, look at glass wool. The humidity in the bathhouse is still high. If wet stone wool freezes, it does not restore its properties after freezing, but immediately loses them by 40%. So after two frosts there will be nothing left. Just trash that doesn't affect anything at all

Glass wool is very itchy, but is not afraid of moisture, which is very important in a bathhouse

Working with glass wool is difficult and difficult. It pricks even through overalls. But she is not afraid of getting wet. It also slightly reduces its properties when wet, but after drying the characteristics remain almost unchanged.

We suggest you read: How to rejuvenate your skin in a bathhouse From old memory, many still remember such insulation as expanded clay. Until there was an alternative, it could still be considered insulation. Now, to replace a layer of mineral wool with a thickness of, for example, 8 cm, you need to pour 40 cm of expanded clay. Yes, it is cheap, but it is afraid of water, which makes it completely unattractive.

Performance characteristics of mineral wool

- Mineral wool is a fire-resistant material.

- Provides a high degree of sound insulation, which is especially important in residential buildings with thin walls.

- Not subject to deformation from exposure to high and low temperatures.

- Acceptable price. The cost of the material depends on the release form and size. For example, a set of mineral wool in rolls based on fiberglass for heat and sound insulation of various structures from two mats measuring 8200x1220x50 mm costs RUB 1,375.00.

Disadvantages of mineral wool insulation: the material is fragile and not moisture resistant. Mineral wool cannot be called an environmentally friendly insulation. Its particles, when inhaled, have a harmful effect on the human body.

These disadvantages are neutralized by proper handling of the material and compliance with thermal insulation installation technology.

Use of car sound insulation in apartments.

This misconception is similar to the previous myth about thin structures. The argument usually given is: “It works in machines!” Indeed, car soundproofing materials are quite thin (usually only a few millimeters thick) and actually work: cars become noticeably quieter! There is a great temptation to use similar materials for the apartment: soundproofing the ceiling, walls and floor.

However, what works in cars will not work in an apartment. The reason is simple: in a car, noise is created by a vibrating sheet of metal less than a millimeter thick, and in an apartment the source of noise is a massive thick wall or ceiling 15–20 cm thick (or even more).

And the mechanisms for dealing with noise from a thin sheet of metal and from a thick massive wall are fundamentally different! If in the first case it is enough to simply dampen the metal with any viscous membrane (the mass and thickness of which is several times greater than the similar parameters of the metal), then in apartments the sound insulation can only be increased with multilayer cladding, and this is a certain thickness.

Thermal insulation of the floor with mineral wool on joists

One of the ways to insulate a floor is to lay it on joists.

Floor insulation using joists is carried out on the ground. The underground space with this method will be cold. If the house is brick, then it is necessary to insulate the foundation of the house. This is caused by the high thermal conductivity of the brick and the possibility of the formation of cold bridges. Thermal insulation using the joist method is often carried out in wooden houses, since wood has lower thermal conductivity.

Modern insulation materials are very effective. But sometimes their use leads to freezing of the base in wooden buildings. This opposite effect is associated with the high tightness of modern heat insulators and the obstacle to heating the underground space due to the heat of the house. Therefore, when insulating a wooden house with modern materials, thermal insulation of the base is also required.

The procedure for floor insulation by joists

- Compacting the soil.

- Laying a layer of crushed stone bonded with bitumen mastic. Bitumen is used for waterproofing.

- Installation of brick columns with a longitudinal interval of 2 m and a transverse interval of 60 cm.

- Waterproofing of columns.

- Laying wooden logs with a cross-section of 100x50 mm, which is sufficient to withstand the load on the floor.

- Fixing a windproof layer at the bottom of each joist. First, a metal mesh is attached, and a wind-protective film is attached to it. This is necessary so that the insulation layer does not fly apart under the influence of air currents under the floor of the house. This film is vapor permeable.

- Laying mineral wool insulation on film between the joists. Mineral slabs with a windproof coating are now being produced. In this case, metal mesh and film are not required.

- Covering the insulation with a layer of vapor barrier.

- Sealing joints between sheets.

- Flooring made of planks.

If the floor is wooden on a concrete base, then remove the boards and everything under them and clean the concrete surface. If the boards are in good condition and they are planned to be re-laid after insulation, then note the order of their arrangement and carefully remove them.

Then spread the waterproofing film. Logs with a cross section of 50x50 mm are laid on top at a distance of 50 cm from each other. Insulation is placed between the joists. An overlapping vapor barrier film is attached on top with small slats. The final stage: laying the finished floor.

When insulating the floor with mineral wool, it should be taken into account that the height of the floor will rise by approximately 50 mm.

Insulating the attic with mineral wool

To prevent the attic from being empty, it can be insulated and turned into an additional attic room or storage room. For thermal insulation of the attic space the following are used:

- Organic derivatives (polyurethane foam).

- Mineral wool materials.

- Bulk dry insulation (expanded clay).

For high-quality thermal insulation of the attic, all three types of materials are used and combined.

Mineral wool is well suited for insulating all surfaces of the attic: floors, walls and roof. Insulating an attic with mineral wool requires the additional use of external wind- and water-insulating polymer film. It is advisable to treat the metal surface of the roof with oil paint to prevent condensation during the cold season of the year.

Mineral wool has a loose structure and allows steam to pass through well, so the inside of the insulation is covered with a vapor barrier layer of foil polyethylene.

Mineral wool is used in the form of rolls and mats. The seams between individual fragments of insulation are carefully sealed with metallized adhesive tape.

Mineral wool is placed between the roof rafters, and on the floor - between the joists of the supporting structures. When performing thermal insulation work, it is very important to take into account the increased load on the support columns due to the weight of the insulation.

Therefore, before starting insulation measures in the attic, you should make sure of the strength of the supporting structures and the roof itself, and, if necessary, replace outdated worn parts.

Thermal insulation of the attic with expanded clay

Expanded clay is an excellent material for insulating attic spaces. The dry, loose expanded clay layer creates a well-ventilated space and at the same time retains heat. Expanded clay is usually used to insulate attic floors, and in some cases, for thermal insulation of gables and the roof itself.

The loose expanded clay layer allows moisture and air to pass through well, which is why a wind- and moisture-proof polymer layer is needed on the outside. It is recommended to leave a small ventilated gap between the roof and the expanded clay layer to allow moisture vapor to escape outside.

From the inside, the expanded clay layer needs vapor barrier protection. Expanded clay is filled into a special frame. This hides some of the space inside the attic. A special box is made on the floor, expanded clay is poured into it, and wooden or tile flooring is laid on top.

Expanded clay insulation is often supplemented with mineral wool or polyurethane foam, especially in the area of pipes where ventilation is most required. Expanded clay is poured into these places and carefully covered on all sides with moisture and windproof membranes.

So which is better: mineral wool or expanded clay?

Thermal insulation of buildings with mineral wool and expanded clay is considered the most common due to several factors: relatively inexpensive price, a fairly simple installation process and quite decent insulation quality.

The choice of one or another insulation depends on the specific construction conditions, financial and technical capabilities. In addition, expanded clay and mineral wool complement each other perfectly and are often used in combination. Expanded clay and mineral wool are time-tested materials that have become traditional in construction. And it seems that they are not going to give up their positions in the foreseeable future.

Alternative types of insulation

Expanded clay is not the only widespread thermal insulation material used in roofing structures. Let's look at the most common options:

Expanded polystyrene, better known as a type of polystyrene foam. The thermal protection of such material is much better than that of cotton insulation. The layer of polystyrene foam insulation will be much thinner. Polystyrene foam does not absorb water and is quite rigid and durable. The use of specialized additives allows for increased fire resistance. But, if the material does catch fire, toxic gases will be released that are dangerous to human health and life. Unlike expanded clay, mice and rats love to chew foam.

Basalt wool and mineral wool. The fibrous structure of this type of insulation ensures its high saturation with air. This allows them to be used as a thermal insulation material. When laying fiberglass, you will need additional protection: gloves and a respirator. Disadvantages include susceptibility to rotting, as well as high cost.

Polyurethane foam. Foam insulation manufactured directly on the construction site. Application is carried out with a special gun. The expansion of the material after application allows you to create a monolithic insulating structure. It is lightweight and fire resistant. The service life is about half a century. The disadvantage is the need to use specialized equipment and an experienced team for high-quality work.

Ecowool. A material containing 80% cellulose fiber and 20% fire-resistant and antiseptic additives. Has good heat and sound insulation. Ecowool forms a seamless coating that eliminates the formation of cold bridges. Service life - more than 50 years.