Double-circuit wall-mounted boilers "Baksi" - gas equipment for individual heating from an Italian company. They are compact, convenient and reliable. However, malfunctions also occur in the operation of the Baksi boiler, and it is worth finding out about their elimination in advance.

Boilers from this manufacturer have many advantages. The main advantage is cost-effectiveness. Their service life is quite long, and during operation they make virtually no noise. Using this heating device, one can also note its high performance and ease of operation. In addition, Baksi boilers are sold at affordable prices, and representatives of all segments of the population can afford them.

Work algorithm

produces metal combustion chambers for its boilers. From the outside, the part is protected by a heat-insulating layer. Just above the chamber there is a copper heat exchanger. When the heated room becomes warmer or colder, the thermostat turns on. Its work is automated. The thermostat sends a signal to turn on the water pump. It begins to pump water by creating a vacuum in the pipes. Then warm water enters the pipeline.

When turned on, the boiler power increases gradually. This happens before the water temperature rises to the required value. Then the heating mode switches to modulation mode. When the coolant cools, the temperature sensor gives a signal to open the inlet valve. This starts the electric ignition, and the water temperature again reaches the desired level.

If the room does not require additional heating, the boiler starts operating in DHW mode. It consists in the fact that cold water enters the secondary circuit through a three-way valve, which, in turn, blocks the heating line. Gas is supplied to the burner using a special valve , and the power of the device gradually increases. When the water is already heated to the desired temperature, its adjustment mode is activated.

Pump noise

A common cause of problems is pump operation. Typically, it has three positions to raise the water column to a certain height, which depends on the power of the device. The uniform movement of the coolant along the thermal circuit is not accompanied by noise effects.

If you hear strange sounds that sound more like mechanical sounds, you should check the operation of the pump.

If it fails: water gurgles in the heating pipes of a private house; a hum appears; cracking is possible; The boiler begins to make noise and knock.

In this case, you need to turn off the pump, and if the sounds stop, then the reason has been found. Cracking and noise are mechanical damage: this means that the graphite sliding bearings have worn out or dirt has gotten into the housing.

Scale settles on the inner walls of the pump due to poor-quality coolant and has a destructive effect on its components.

The check is simple: just remove the pump; lower its working part into a container of water; when turned on, it must pump water; if this does not happen, it must be repaired.

Important! The pump cannot be turned on without water.

Malfunctions and causes of their occurrence

The good thing about boilers is that if problems arise, you can handle the repairs yourself, without having to call in specially trained people. True, it is acceptable to do this only if the malfunction is typical and can be eliminated according to the diagram. For those who have never had the opportunity to repair gas equipment, it is better not to repair Baksi boilers with your own hands, but to call a specialist. Typical unit malfunctions include the following:

- the burner does not light or constantly goes out;

- ignition does not work;

- there is a knocking sound in the combustion chamber when the boiler is operating;

- exceeding the permissible temperature inside the device;

- the maximum water temperature becomes lower;

- the occurrence of loud noise during operation;

- failure of temperature or pressure sensors.

The reasons for the malfunction of the Baksi boiler may be as follows:

- water getting inside the boiler;

- insufficient quality of the coolant used;

- weakening or sudden change in gas pressure;

- power surge in the network;

- initial inaccuracies in equipment installation.

Troubleshooting Tips

The following points can be used as instructions for troubleshooting the Baksi gas boiler:

- The burner is not operating at full capacity. Such an error in the operation of gas equipment can occur in a situation where the pressure inside the system is not adjusted correctly. A similar problem also appears if the gas modulator is damaged. Or the diode bridge may be faulty. You can cope with this problem by adjusting the system parameters according to the equipment operating instructions.

- The heater turns off immediately after being turned on. This problem occurs in gas appliances due to low pressure in the gas pipeline. Possible solution: it is necessary to adjust the gas pressure down to 5 mbar.

- The coolant does not heat up when turned on. To fix it, you should recheck the gas valve. It is possible that the minimum and maximum values have changed places.

- Modulation mode is faulty. This problem can be solved by reinstalling the valve.

- Temperature sensors show incorrect data. In this case, you should also remove the sensor and replace it with a new one.

- The hot water supplied to the taps is not heated enough. To restore water heating, you need to make sure that the three-way valve is fully open. Sometimes this happens if this device is damaged. To be sure that the malfunction is caused by the valve, you need to wait a little until the system cools down. After this, the shut-off valves should be closed. Then switch the device to hot water supply mode. If the heating system becomes hot as a result, it means that the problem was in the valve and it needs to be replaced.

- Sharp shocks are heard when the burner is ignited. Uncharacteristic noises can occur due to various factors: one of them is too low pressure in the gas pipeline. Another thing happens due to improper transportation of the boiler, when the igniter is displaced and the distance from it to the gas supply becomes greater or lesser. The solution to this problem is to set the correct distance. It should be approximately 4-5 mm.

- You can adjust the gap between the igniter and the burner on a Baksi gas boiler as follows: the front panel is opened and removed from the device. When this is done, the flap is removed from the inspection hole. There is an igniter there. To give it the correct position, you need to unscrew the screw with which the electrode is attached to the boiler. The igniter must be removed, carefully bent and then returned to where it was, and then the damper must be closed.

- A strong decrease in coolant temperature. This often happens due to dirty filters. The only way to eliminate them is to clean them. Sometimes filters need to be replaced if they are severely clogged. It is also worth checking for damage to the pipeline. If, for example, radiators are clogged or exposed to low temperatures, only repairs will help. The damaged segment will need to be replaced or cleaned.

Scale formation

A high salt content in water leads to scale deposits on the walls of the device. When heated, the salts will make themselves known by hissing. Because of this, the device heats up much more slowly. The radiator needs to be cleaned once a year. To do this, you will need a reagent, a special pump through which the reagent is poured into the device and rinses it from the inside.

In radiators, water does not move as quickly as in pipes, and the sedimentation of suspended matter is many times higher. Regular cleaning of radiators is necessary. You can flush the entire system at once or separately the radiators using a compressor unit. To flush, the radiator is connected to the compressor, and dirt is cleaned from it with water pressure.

Sometimes it is enough to simply flush the system with strong water pressure. Chemical reagents are used in cases where the situation with scale deposits is extremely advanced.

Under the influence of chemicals, cracks may form in radiators that were clogged with salts. In order to prevent an emergency, before starting the system, all equipment must be checked for readiness for operation.

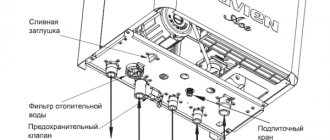

Cleaning the primary and secondary heat exchangers

First, you need to remove water from the heating device. There is a tap on the right side of the boiler; if you unscrew it, the liquid will be drained. It would also be a good idea to drain the heating system. For cleaning, a special washing device is used. The pipes are connected to the pipes of the gas boiler. Then the cap on the flushing device is unscrewed, and then the cleaning liquid must be poured inside. After this, you can connect the device to the network.

Cleaning the heat exchanger is a slow process and can take several hours.

During this time, it is necessary to switch the direction of the rinsing fluid. After two to three hours, you should stop cleaning. After this, the tap is opened and the water is drained, and then the hoses are removed. When doing this, you need to be sure that all the liquid has flowed into the device. After all the manipulations, the boiler is reconnected to the heating system. The pipes are filled with coolant. Washing the device parts should dissolve the scale, which will increase the life of the system and optimize its operation.

Similar to the primary one, to clean the secondary heat exchanger, you need to attach a flushing device to the boiler. After connecting it to the network, you need to close the gas tap and move the hot water tap to the open position. Then turn on the cleaning device so that the reagent moves along a short circuit.

To install Baksi gas equipment, you should definitely use the services of gas service workers. They will also help in case of a malfunction in the boiler. Parts of heating devices from this company can also wear out over time, so sooner or later repairs will still be inevitable.

BAXI Forum

The largest professional forum BAXI in Russia

- 08/30/2021 — The BAXI 3Q seminar book has been published. 2021 (18 MB). Download

- 04/16/2021 — The conference has been moved to a separate subdomain. Now we are at forum.baxi.ru.

- 11/15/2019 — A separate section on the forum has been allocated for discussion of the ZONT device.

- 07/19/2019 — The BAXI seminar book 3Q was published. 2019 (119 MB). Download

- 06/20/2019 — BAXI Energy voltage stabilizers are on sale.

- 04/16/2019 — Sales of BAXI Eco Nova boilers have started.

- 11/16/2018 — The BAXI 4Q seminar notebook was published. 2018 (8 MB). Download

System errors

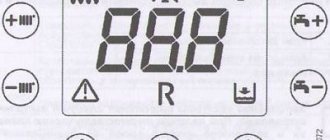

When a malfunction occurs in the Baksi double-circuit wall-mounted gas boiler, an error code is displayed on its electronic display, which can mean one of two things: either blocking the operation of the heating device or turning on the standby mode.

In the first case, you need to manually restart the boiler. The device can be blocked when problems are detected affecting the main parts of the system, which can cause harm not only to the equipment, but also to the health of its owner. Such errors include excessive heating of the boiler, insufficient or reverse draft, as well as its absence. If gas does not flow into the storage tank, the equipment also becomes blocked. Sometimes this problem resolves itself, and then the device turns on automatic startup mode.

Code E01 - burner sensor

Code E01 appears on the display when the sensor monitoring the burner operation reacts. This error can be caused by a number of reasons:

- gas stopped supplying to the burner;

- there is no correspondence between zero and phase;

- sensor is disabled;

- the sensor needs cleaning or repair;

- malfunction in the ignition device;

- the gas supply valve has failed;

- the electronic board does not work;

- there is not enough air to maintain the flame;

- There is not enough gas pressure for combustion.

Having seen such a signal on the display, you first need to check whether the flame sensor is working correctly. Then see if gas is supplied to the device. If there are no problems, you should press the R button or switch the toggle switch to neutral mode, which is also indicated by this letter.

If the sensor is triggered involuntarily, the boiler will continue to operate as usual. If the error repeats, it is better to ask for advice from a gas equipment repair specialist. This fault code indicates problems in the chips, and trying to fix the problem yourself may lead to undesirable results.

E10 - water cycle indicator

Code E10 relates to sensors that monitor the operation of pumps and regulate the water cycle in the system. Such a cipher can diagnose the presence of the following problems:

- pressure decreased;

- the conductivity between the relay and the board is broken;

- the pressure switch does not function properly;

- malfunction of the pump sensor;

- the pump itself needs repairing;

- the heat exchanger is dirty.

Having noticed the E10 code, there is no need to rush to deal with the problems yourself. You can replace the pump yourself; it is not very difficult. It is also easy to clean clogged filters yourself. Other faults are best left in the hands of a qualified worker.

E96−98 - electronic board problems

The remaining Codes E96, E97, E98 indicate problems in the operation of the electronic board. If they appear on the display, the owner should not take any action and immediately call a repairman, because only an experienced specialist can deal with them without outside help.

Fixing problems with household appliances is a kind of treatment . There are simple diseases that a person can get rid of on their own, but for complex diagnoses it is better to consult a doctor. But both can be prevented with timely prevention. This also works in the case of preventing malfunctions of the Baksi wall-mounted double-circuit gas boiler.

Why is it important to fix the problem immediately?

Even small pops are warning beacons indicating that the equipment is faulty. If the problem is not solved immediately, it will get worse in the future. The boiler may turn off, in addition to popping noises, an open flame comes out of the boiler, etc.

Despite the fact that modern equipment is equipped with good protection systems, the owner must still use it competently, maintain it in a timely manner, remove blockages, etc. Then the boiler or column will work for a long time, efficiently and without failures.

If you find that the boiler slams when turned on or makes noise during operation, and the reason cannot be determined, contact the experts. They will advise you on this issue, and if necessary, they themselves will diagnose and eliminate the cause of incorrect operation. Call.