Installing a gas boiler allows you to forget about cold water in radiators and taps. Double-circuit models are capable of simultaneously operating for heating and hot water supply (DHW) of a room. But what to do if the boiler does not heat the water? If you encounter a similar problem, our recommendations will help you find the cause and fix the problem yourself.

Self-diagnosis system

The purpose of automatic self-diagnosis and protection systems is to detect and correct various breakdowns at the moment they occur. After fixing any kind of defects, the equipment stops, with a breakdown code displayed on indicators or LCD screens. Finding problems in equipment that is not equipped with self-diagnosis is much more difficult, although the procedure for checking the internal filling does not change. Self-diagnosis allows you to quickly identify and find faults in the Navien boiler.

During the search process, the system sends requests to numerous sensors and nodes: all received results are analyzed and stored. If serious breakdowns are detected, a report about them is instantly transmitted to the indicator board. Initially, such systems were developed for gas workers, since they make it much easier to troubleshoot a Navien gas boiler and fix them. However, if you have minimal skills in servicing boiler equipment, you can repair Navien appliances on your own. Before you begin self-repair, you need to check whether the warranty period has expired. If the warranty is still valid, it is better to send the boiler to a service center for a free repair.

What malfunctions occur

To repair the Navien heating boiler yourself, you need to read the special manual. It will help not only decipher the type of breakdown, but also eliminate it in the most effective way.

List of problem codes with the Navien boiler and their interpretation:

- 01E. The device overheated, and this was recorded by the temperature sensor.

- 02E. Indication of an open circuit in the flow sensor and a drop in the coolant level in the circuit.

- 03E. The signal confirming the presence of a flame has disappeared. In this case, the combustion can continue.

- 04E. This code has the complete opposite meaning of the previous designation: in this case, there is confirmation of the flame, although in fact it is absent. E

- 05E. Failure of the circuit responsible for controlling the degree of heating of the coolant in the heating system.

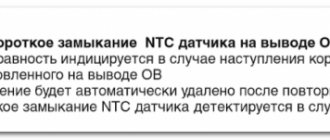

- 06E. This code also indicates a malfunction of the temperature sensor (the circuit is closed).

- 07E. Signal about failure of the temperature sensor in the DHW circuit.

- 08E. Malfunction of the Navien gas boiler in the same unit due to a short circuit.

- 09E. Alert about fan failure.

- 10E. The appearance of malfunctions in the smoke removal system.

- 12E. Flame extinguishment in the burner.

- 13E. The heating circuit flow sensor has shorted.

- 14E. Gas has stopped flowing from the main line, which is why the Navien boiler does not turn on.

- 15E. A general indication of errors in the operation of the control board, without specifying the problematic element.

- 16E. The equipment has overheated.

- 18E. Malfunctions in the operation of the smoke exhaust sensor.

- 27E. Air pressure sensor (APS) malfunctions.

The manufacturer itself does not provide any instructions for repairing the Navien gas boiler. The calculation is made that repair activities are the responsibility of service centers exclusively. In our country, people’s thinking is somewhat different, so many of them are accustomed to troubleshooting household appliances on their own.

User manual

Navien gas boilers are operated automatically, with minimal human intervention.

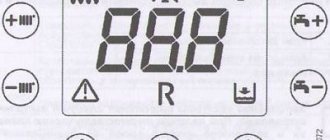

The owner only needs to observe the readings on the display and respond in a timely manner to the appearance of an error code.

In addition, the user determines the operating mode - summer or winter:

- Summer mode is determined only by DHW heating.

- Winter mode starts the heating system simultaneously with the supply of hot water.

The display has a button with a corresponding icon (symbol of a snowflake or sun).

If it is necessary to adjust the extract air temperature or other parameters of the heating system, the winter operating mode must be turned on. Exhaust temperature is adjusted when the radiator icon is flashing.

If it lights up steadily, the display shows the current temperature . By pressing the “radiator” button so that the icon flashes, press the “+” or “-” buttons to change the set coolant temperature.

The icon stops flashing after a while (a few seconds), and the boiler will begin to heat or cool the coolant in accordance with the instructions received.

No need to heat

The first step is to clean the heat exchanger. At home, it is common to use citric acid, toilet bowl cleaners and special liquids (if available). Before cleaning the Navien gas boiler, you need to dismantle the heat exchanger and pour a suitable solution into it. After a short pause, it is washed out with high pressure of water.

A similar procedure should be carried out with the DHW circuit heat exchanger if problems are observed with heating hot water. In case of particularly contamination, it is easier to install a new exchanger. To prevent scale build-up, it is recommended to have a system for cleaning and softening your tap water.

Excessive power as the most common cause

In a simplified form, the required boiler power is calculated based on experience: for every 10 m2 of an average house with 2 bricks and a ceiling height of no more than 2.7 m, 1 kW of thermal power of heating equipment is required. It is also recommended to take into account a reserve of 15-20% so that the boiler does not work at the limit or the heat transfer is sufficient during the most severe frosts in the region.

This calculation method is sufficient for any typical private home. For example, for a house with an area of 200 m2, a boiler unit with a capacity of 22-24 kW is required.

How to calculate the required boiler power Individual calculation, formula and correction factors

If, with insufficient power, everything is clear - the boiler simply cannot provide heat transfer corresponding to the heat loss of the house in cold weather, then according to practice, owners often do not take into account that excess power is also bad, especially if the boiler has primitive automation and one- or two-stage burners. Most often this happens to owners of small houses (60-100 m2), who purchase boiler units with a capacity of 14.16 or even 20 kW.

The boiler lights the main burners, which quickly, in 2-5 minutes, heat up the missing few degrees of coolant temperature and turn off. And since modulation (power adjustment) of the flame is not provided for by the design of the burners, nothing can be done at the level of boiler settings.

One of the simplest mechanical room thermostats.

However, there is another fairly simple solution - installing a room thermostat, which will regulate the boiler’s operating mode depending on the room temperature, and not the constantly changing temperature of the coolant. The thermostat will block the ignition of the boiler until the room temperature drops below a predetermined critical level, thereby extending the ignition and extinguishing cycles to 1-2 cycles per hour. The cost of the cheapest room thermostats, and this will be quite enough to solve the problem, starts from 800 rubles.

If the boiler is a double-circuit boiler, it is necessary to install the thermostat exclusively according to the instructions, otherwise incorrect operation may occur both in the heating mode and in the hot water supply heating mode.

Troubleshooting error 03

There were some obstacles in the way of the signal about the presence of flame entering the system. The cause of this malfunction of the Navien boiler may be a cessation of gas supply or a failure of the flame presence sensor in the burner. Often, problems of this type arise after repairs to a gas pipeline. Error 03 is also displayed when problems occur with ignition.

Elimination procedure:

- Checking the gas supply.

- Testing the serviceability of ignition.

- Cleaning the ionization sensor (it often gets dirty).

When using liquefied gas, you must ensure that the gearbox is in good working order. If the boiler is fully operational, the cause of error 03 may be improper grounding.

Typical Navien Ice boiler breakdowns

Although the devices in this series are famous for their impeccable performance, they sometimes fail. When installing a Navien Ice boiler in your home, it is recommended to arm yourself with information about its most typical faults (there are not very many of them). For example, for the 24 K model, the most typical error is 10. The design of this double-circuit boiler uses a closed combustion chamber, which leads to periodic problems with smoke removal. Most often this happens due to fan breakdowns, which need to be replaced from time to time.

Typical malfunctions of the Navien gas boiler also include error 02: it indicates rapid heating and equally rapid cooling of the boiler. This usually occurs due to the appearance of air pockets in the circuit system or due to a breakdown of the flow sensor. All air must be bled from the heating circuit.

How to stop a leak with your own hands

How to repair a leak - the leak repair algorithm is the same for both solid fuel boilers, such as Don, KChM, and gas boilers, for example, AOGV, Alixia 24, Ariston, Deu, Arderia, Electrolux.

- Turn off the device.

- Drain the water.

- Wait until the boiler cools down completely.

- We will describe how to remove the heat exchanger below.

- Solder and eliminate the fistula.

What does a heat exchanger look like - it is a metal or cast iron body, heated by a burner flame and transferring thermal energy to the liquid that is inside it.

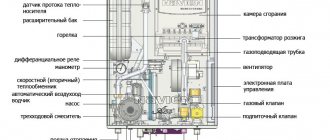

To disassemble it and solder it yourself, you need to remove the front panel, protective casing and combustion chamber protection using a long screwdriver. Then disconnect the sensor wires and the pipelines suitable for the heat exchanger, try not to damage the pipes and pipes, hold them with a wrench.

In order to connect everything correctly later, you should first take a photograph of the inside of the heat generator. Then disconnect the fan and smoke detector. When removing the heat exchanger, do not use force or make sudden movements; do everything with extreme caution.

If you find a gap between the circuits in the tube, it is impossible to repair such a hole; you will have to change the heat exchanger. The heat exchanger cannot be welded; soldering with a gas torch should be used.

Soldering the heat exchanger

In order to do soldering yourself, you must first clean the place where the fistula has formed. This can be done using fine sandpaper. Soldering is carried out using an oxygen gas mixture with solder containing the same chemical elements from which the heat exchanger is made.

Tin cannot be used in this case, since such repairs will again lead to the formation of a fistula after some time. After soldering, a protective coating, for example, a layer of aluminum, should be applied to the problem area.

The control board is faulty

This error, which is difficult to accurately diagnose, is designated by code 15E. It is almost impossible to understand how the control board works without special education. The most correct algorithm of action in such a situation is to invite a specialist who can use testing to determine and eliminate the causes of the problem.

The place where the Navien gas boiler is repaired is chosen by the foreman: in particularly difficult cases it is necessary to transport the boiler to a service center. To avoid problems of this type, it is strongly recommended to equip the supply networks of the Navien boiler with a voltage stabilizer.

Error 01

There is no need to panic, because this code quite often indicates the appearance of ordinary air pockets in the circuit or filter. The procedure for bleeding air from a Navien boiler is carried out according to standard recommendations. Next, you need to check the functionality of the circulation pump.

It is important that it rotates and that the coolant flows well through the impeller. It happens that the reason that the Navien boiler does not start is a physical breakdown of the impeller. A more complex option is problems with the circulation pump, the elimination of which requires rewinding or complete replacement of the equipment. The most reliable model of pumping apparatus is considered to be products from the Grundfos brand.

Error 04

A little about fault 02 has already been said: it consists of a rapid rise in temperature and an equally rapid drop. The same applies to error 03. When the self-diagnosis system detects error 04, the functionality of the flame sensor and its power supply is checked. It is strongly recommended to avoid any contact of this assembly with surrounding metal elements. It happens that this code is displayed when the system board breaks down. In such cases, it is either repaired or replaced.

Errors 07 and 08

The purpose of double-circuit boilers is to provide homes with both heat and hot water. They consist of two circuits and a set of sensors. As a consequence, in this case there is not one temperature sensor, but two. One is designed to control the temperature of the heating circuit, and the second monitors the degree of heating of hot water. The appearance of codes 07 and 08 on the monitor indicates that the hot water in the Navien boiler does not turn on. Diagnosis and elimination occur in the same order as in the previous case.

Why does blood pressure drop?

The cause of a drop in water pressure in the system can only be a leak. At the same time, it can be both in the boiler itself and outside it - in pipelines, radiators, etc.

It is necessary to open the feed valve, start the boiler and carefully inspect the entire system, step by step. If no leaks are found, the boiler must be inspected. When looking for the cause, you should be guided by the rate of pressure drop.

Perhaps the water goes into the expansion tank, in which the membrane has ruptured. Another reason could be a worn safety valve. If it is connected to the sewer, the leakage will not be noticeable.

Error 09

These fault codes are the most common. They signal that the fan has reduced its efficiency or has stopped. To accurately determine the cause, the integrity of its windings and the continuity of their resistance are checked. It is also necessary to make sure that there is an interturn short circuit. If the damage is serious, it is better to change the device. If no problems were found on the fan, you should ring the control board. This procedure will require certain skills: if they are absent, it is better to seek help from specialists from the service center.

Workmanship

The strength of the boiler depends on the quality of the welded joints. If a weld seam has cavities or irregularities, sooner or later this seam may leak. The void located inside the seam is considered especially dangerous. Ideally, the seams should be X-rayed, but not all manufacturers do this.

Although heating boilers are pressure vessels and must be subject to increased manufacturing requirements, defects sometimes occur. And, as a rule, it drips from the heating boiler after the warranty expires. It is not always possible to weld the boiler inside and stop the leak.

It depends on how the heat exchanger is designed. In models where a bithermal heat exchanger is installed (the secondary and primary are in the same housing, heat exchange occurs thanks to the two-in-one design), this is problematic. But, even if you did this, as practice shows, this will not help you for long.

Error 10

An indication that problems have arisen with the removal of combustion products. A potential cause is a broken fan. The condition of the chimney duct, which requires regular cleaning, deserves a separate check. It is very important that its length complies with regulatory standards. Quite often, the cause of error 10 lies in a malfunction of the air pressure sensor. The most undesirable situation is regular malfunctions of the Navien boiler board. You need to check the most harmless option, when the wind simply gets into the chimney. Naturally, you need to know what to do if the boiler blows out in a strong wind, and how to get rid of this problem.

Error 16

This code indicates that the heating equipment has overheated: in such cases, the Navien boiler hums when hot water is turned on.

Potentially possible reasons:

- Exceeding the coolant heating norm.

- Lack of fluid in the circuit.

- The control board has malfunctioned.

- The three-way valve is acting up.

- The DHW temperature sensor has failed.

- The gas supply rate has been exceeded. This reason why the Navien boiler is humming is quite rare. Its elimination is carried out by simply screwing on the valve.

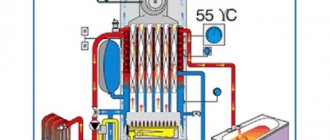

Use a water heater

A water heater embedded in the hot water supply circuit acts as a buffer tank. Its purpose is to equalize the temperature of hot water and smooth out possible temperature surges. The storage water heater and the gas boiler heater are set to the same operating temperature.

Even if the hot water taps are turned on simultaneously at different points of its intake, all users will initially receive water from the storage tank. The time spent waiting for a comfortable water temperature is reduced. Unproductive water consumption is reduced.

Turning the hot water supply on and off at any point of intake causes a temperature difference in the water leaving the gas boiler. However, this water enters the lower part of the water heater, and when it leaves the upper part, the temperature jump is completely smoothed out.

Connecting the water heater through a ball valve allows you to switch to a conventional gas boiler operating system at any time, which can ensure uninterrupted hot water supply in the event of a water heater failure.

Using a bypass jumper with a tap in close proximity to the boiler allows you to exclude the boiler from the hot water supply system. If the boiler is under maintenance, using the existing water heater will ensure uninterrupted operation of the hot water supply system.