Solid fuel boilers are gaining popularity again today. The reason for the increased interest in this type of heating equipment lies in several aspects. The greater power and autonomy of solid fuel mechanisms, compared with gas and electricity, provide the consumer with ample opportunities for equipping an autonomous heating system in the home. Installation of a solid fuel boiler is especially important for residents of those areas where there is no centralized gas supply. In terms of choosing a heating device and heating system, the fact that for installation on solid fuel does not require obtaining official permission from the supervisory and control authorities is captivating.

The installation of the heating boiler is carried out taking into account the design data. Further, the working heating system is subject to registration by the Ministry of Emergency Situations authorities responsible for stove heating and the safety of objects heated by solid fuels. Schematically, the installation and connection of solid fuel heating units is as follows.

Having assessed all the obvious advantages of individual heating using fossil fuels or wood waste, the pros and cons of solid fuel appliances, you can safely begin installing heating equipment in a private home. The only thing that is of interest in this situation is how to connect a home solid fuel boiler to other devices and to the heating system itself

Let's consider the features and nuances of connecting equipment of all types.

What is special about connecting a solid fuel boiler? Important nuances

At the moment, quite a variety of schemes for connecting solid fuel boilers to an individual heating system are used in everyday life. In each individual case, the type of boiler, what fuel is supplied to the heating device and what its power is taken into account. The main tasks and requirements that are set for heating devices are space heating, operation of the hot water system, the required level of comfort and operating conditions.

How to connect a solid fuel boiler to the system, if already at the development and planning stage there was a desire to establish interaction between a solid fuel boiler and an electrical appliance. When it comes to directly installing the unit and connecting it to all elements of the entire heating complex, a lot of questions arise.

A correctly drawn up thermal diagram is the key to successful installation and connection of equipment. A smart decision would be to order the development of the project from a specialized institution. If you decide to do everything yourself, you will need certain technical knowledge, skills and the participation of professionals. The reason to turn to the services of specialists is that the connection diagram of a solid fuel boiler is significantly different from the gas autonomous heating and electric heating scheme that is familiar to us all.

Moreover, the subsequent operation of the entire heating system and the profitability of individual heating depend on how correctly the solid fuel heating device is connected.

Important! It should be remembered when working with solid fuel units that the operating temperature of the boiler varies in the range of 60-900C, no less and no more. Painstaking and careful adjustment of the heating temperature is required to reach operating mode due to the inertia of boiler equipment of this type.

For example: you use a heating device in operating mode at a temperature below the permissible limits. The temperature of the coolant in the return circuit is below 55 0C (dew point) leads to the formation of an excessive amount of condensate, which begins to flow out of the boiler. Firstly, a large amount of soot is formed on the walls of the firebox, which settles on the heat exchanger and accumulates on the walls of the chimney, reducing its cross-section. As a result, precious efficiency indicators of the heating device are lost, and difficulties arise with its maintenance. Secondly, the boiler room takes on an untidy appearance.

* Installation of the boiler is preceded by work related to connecting the heating equipment to the piping system. The scheme, despite the complex and expensive equipment, should be simple and understandable. To connect the product, the heating configuration must meet the following minimum requirements:

- there must be a large and small circuit through which water circulates;

- the pipeline must have good permeability;

- installation of the pipeline must be carried out in accordance with the parameters specified on the specification.

Ventilation plays an important role in home heating. The device must be connected to a ventilation system, the construction of which is carried out strictly in accordance with existing norms and standards. Properly equipped exhaust hood and ventilation not only help improve the efficiency of the boiler, but also guarantee the safe operation of a complex unit in a residential building.

Single-circuit and double-circuit heating boiler.

A single-circuit boiler has a fairly simple operating principle. During installation, it is connected to the chimney. For the normal functioning of the system, the presence of normal natural draft is sufficient.

Often, single-circuit boilers are installed, which in their design have an open combustion chamber, which requires the creation of certain conditions in the room.

During its operation, the boiler uses air from the room. That is why it should be installed in a separate room. It is worth noting that when a single-circuit boiler operates, substances and gases harmful to the human body accumulate, this is the main reason for the need to equip a room with a boiler with a chimney or hood. If all the above conditions are created, the risk of explosion will be eliminated and will also ensure the safe use of the equipment.

A double-circuit heating boiler differs from a single-circuit analogue in its universal purpose: it maintains the degree of coolant in the heating circuit and heats water for domestic needs. Single-circuit generators can also indirectly heat water. The heat transfer process is carried out during the passage of the coolant through the secondary heat exchanger.

The main difference between a double-circuit boiler and a single-circuit boiler is the direct transfer of thermal energy to water. The main feature is that when hot water is consumed, the coolant is not subject to heating, and parallel operation of two circuits is excluded. Practice shows that the operating mode of the boiler is not important for houses with high-quality thermal insulation, it follows that with thermal inertia, the heating circuit will be the same for any type of heating. An impressive volume of hot water can be obtained by combining a single-circuit design and heating columns.

A double-circuit boiler should not be designed in combination with a natural circulation system, since after heating of the coolant stops, the movement of the liquid quickly stops. The secondary heating process takes quite a long time, and the heat in the radiator is distributed unevenly.

The main advantage of the scheme is the ability to operate in natural circulation mode. The booster of the collector in this case is a pipe through which the coolant moves to the upper filling.

Traditional connection diagram for solid fuel boilers

The basis of almost any autonomous heating system used today is the connection of a heat accumulator to a solid fuel boiler. It is this connection that is the key to the safety of the entire heating complex. Preliminary thermal calculations allow the coolant to be easily supplied to a special container that performs storage functions. If necessary, while the main mechanism is cooling, the heating system takes coolant of the required temperature from the heat accumulator.

A heater with a heat accumulator can operate in a constant operating mode, maintaining the highest possible efficiency, while saving precious fuel.

For reference: at the design stage, you can calculate the volume of the storage tank, taking into account the power of the device. Such calculations are important, first of all, to calculate the number of times the boiler is loaded with fuel to heat a living space for two or three days.

Often, it is with the help of an expansion tank that the temperature of the coolant in the heating circuit is adjusted. Below is a diagram of connecting a heat accumulator to a solid fuel boiler and the place of a heat accumulator in the entire unified heating system of a private house.

The expansion tank is a mandatory element of the entire system, on which hot water supply is based. The hot water supply circuit is placed in a heat accumulator, where the heated coolant gives off its heat to running water circulating through the DHW circuit. Without an expansion tank it is impossible to install a heated floor connection. Long-burning boilers together with a heat accumulator are ideal for arranging heating systems of the “warm floors” type. Due to the expansion tank, the required temperature of the coolant is created, which then enters the pipeline laid on the floor. Heating "warm floor" in this form has maximum efficiency.

For calculations: the volume of the heat accumulator is taken at the rate of 25-30 liters. capacitive volume per 1 kW of boiler power.

Connection diagrams for solid fuel boilers together with an expansion storage tank represent a complex of complex and expensive equipment. Despite the high cost of such heating schemes, the investment and your efforts will pay off soon.

Two-pipe system with top wiring

In a two-pipe heating system with overhead wiring, the expansion tank is placed at the highest point.

This two-pipe scheme is very similar to the previous one, only here it is provided for the installation of an expansion tank in the very top part of the system, for example, in an insulated attic or under the ceiling. From there, the coolant goes down to the radiators, gives them part of its heat, and then is sent through the return pipe to the heating boiler.

Why is such a scheme needed? It is optimal in multi-storey buildings with a large number of radiators. Thanks to this, more uniform heating is achieved, and there is no need to install a large number of air vents - the air will be removed through the expansion tank or through a separate bleeder that is part of the safety group.

Advantages and disadvantages of a two-pipe system with top wiring

There are a lot of positive features:

- it is possible to heat multi-storey buildings;

- saving on air vents;

- you can create a system with natural coolant circulation.

There are also some disadvantages:

Using vertical wiring will lead to additional difficulties when installing hidden heating.

- pipes are visible everywhere - this scheme is not suitable for interiors with expensive finishing, where elements of heating systems are usually hidden;

- in tall buildings it is necessary to resort to forced circulation of the coolant.

Despite the disadvantages, the scheme remains quite popular and widespread.

Features of installation of two-pipe systems with top wiring

This scheme eliminates the need to locate the heating boiler at the lowest point. Immediately after the boiler, the supply pipe is diverted upward, and an expansion tank is installed at the highest point. Coolant is supplied to the radiators from above, so a lateral or diagonal radiator connection scheme is used here. After this, the cooled coolant is sent to the return pipe.

Other connection diagrams for a solid fuel heater

We connect the device to the main line with admixture

The design of the heating system in this case includes the following elements:

- heating equipment safety group (thermostatic valve, safety valve);

- expansion tank (heat accumulator);

- a circulation pump that supplies coolant to the entire system;

- shut-off valves.

This scheme is different in that it has an additional mixing circuit and taps, with the help of which you can easily volume the coolant in the mixing circuit. This type of connection allows you to keep heating radiators at a comfortable temperature, despite the fact that the heating boiler operates in optimal mode.

For example: in a pyrolysis boiler the water temperature is 70-80 0C, the heating system for living rooms produces a coolant temperature for the batteries of no more than 65 0C.

Connecting a solid fuel unit with a hydraulic boom

This type of connection is used in situations where the heating system has more than one circuit. The hydraulic distributor or hydraulic arrow performs the task of a fuse, excluding the hydraulic action of the circulation pumps installed on each circuit. The hydraulic arrow simultaneously acts as a sludge catcher and degasses the entire heating complex.

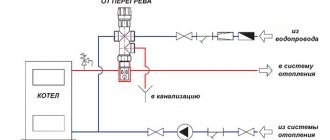

The connection diagram for a solid fuel boiler with a hydraulic boom in a house consists of the following elements:

- control devices;

- expansion tank;

- two circulation pumps independent from each other;

- hydraulic boom;

- heating radiators;

- distribution combs (dirt collectors).

*

Mandatory rules for operation

- It is prohibited to use substances that emit toxic substances for kindling (gasoline, diesel fuel, scraps of chipboard, laminate);

- the width of the passage around the boiler must be at least 1 meter;

- fuel and flammable substances must be kept at a distance of at least 40 cm from the unit;

- equipment must be regularly inspected and slag and ash removed before each kindling;

- Clean the firebox and ash pan daily to avoid clogging the chimney.

With proper operation of the equipment, your home will always have a comfortable temperature.

Connecting a solid fuel boiler with an electric or gas boiler

The heating system can include a whole set of heating devices, the task of which is to complement each other if necessary. Coal or wood boilers are used as the main source of the heating unit, while an electric or gas unit performs auxiliary functions.

Connecting an electric boiler to a solid fuel boiler is carried out in order to combine all the main units into a single automated heating system.

Note: electric boilers usually duplicate the work of traditional wood-burning boilers. When the combustion in the furnace of the main boiler weakens, this happens especially often at night, the electric heating device starts up.

The electric heating device also serves as a trigger for the solid fuel boiler.

The connection is made through a buffer tank, which plays the role of a hydraulic separator and a heat accumulator. The attenuation of the flame in the boiler furnace leads to the fact that the temperature of the coolant in the expansion tank begins to drop, therefore, the electric heating is automatically turned on. When the main boiler resumes operation, the reverse process occurs. The heated coolant flows back to the sensor and the electric heater turns off. What kind of device should work is decided by automation.

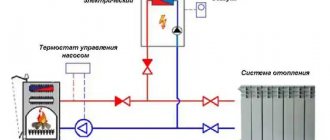

An approximate diagram is shown in the figure below

The system is viable and highly efficient, however, such a set of heating devices has a very high cost. Basically, a similar scheme is used for heating large residential buildings.

What does the heating boiler piping consist of?

Knowing what the boiler piping should do, we can easily guess what is included in its composition and select the appropriate equipment. Such equipment is located directly next to the boiler (on the walls and floor of the boiler room) and on it:

1 - filter; 2 - circulation pump; 3 - ball valves; 4 - expansion tank; 5 - boiler; 6 — pressure gauge; 7 — air vent; 8 - safety valve; 9 - system refill-drain unit

Let's look at the piping, starting with the return line.

1. The coolant approaches the circulation pump and enters the filter:

- which stands in front of (!) the pump.

2. The pump, as can be seen from the diagram, is located in front of the boiler. There are ball valves on both sides of the pump so that you can change the pump or clean the filter without draining the coolant from the entire system. Replacing the pump is quite simple, since it is secured with union nuts.

In general, the main requirement when installing a boiler is to provide fairly easy access to the pump and other piping elements.

3. There is an expansion tank between the pump and the boiler. The expansion tank can be installed anywhere in the system, but it is preferable as shown in the diagram.

4. Then the coolant enters the boiler, heats up and enters the supply pipe.

5. At the boiler outlet, a safety group is required: automatic air vent + safety valve + pressure gauge. The boiler may also have a thermometer to monitor the temperature in the boiler.

6. A ball valve with a fitting on which you can attach a hose and feed the system from the water supply. Or drain the coolant from the system.

The above are mandatory elements that must be included in the boiler piping.

The wall-mounted boiler has all the same devices, only they are already inside the housing.

If you are not familiar with any of the listed equipment, you can find complete information about it in the section on heating equipment.

How to connect your unit to ventilation and chimney

Connecting a solid fuel boiler to a chimney is one of the key tasks, the solution of which determines the subsequent functionality of not only the heating device, but also the entire heating system. Your home, in which you want to have a comfortable microclimate and coziness, must be protected from harmful combustion products.

For those who want to make a chimney with their own hands, there are some practical tips.

- the chimney pipe must have a diameter no less than the cross-section of the outlet pipe;

- when the chimney has a rectangular shape and the boiler outlet pipe is made round, it is necessary to compare them in terms of the flow area.

- the length of the chimney from the first bend should not exceed two pipe diameters. The chimney should have a minimum number of turns and bends.

- for better draft, the horizontal section of the chimney in relation to the heating boiler is located at an angle of 450 (an inclination angle towards the boiler of 30 and 15 degrees is allowed).

In the latter case, compliance with the angle of inclination is not necessary if the heating boiler is equipped with a blower.

In the video you can get the necessary information on how to install the chimney of a solid fuel boiler.