Any heating boiler is connected to at least four lines:

1) Power supply . Required for the control and safety automation system located inside the boiler, for example: ignition control. 2) Fuel supply line . For gas boilers, these are connections to the low pressure line or to the pipes of the gas holder (liquefied gas storage) 3) Heating system lines . If the boiler is single-circuit, then there are only two pipes: forward and return lines (output and inlet to the heat exchanger). If the heater is double-circuit, then two more pipes are added: cold water inlet and heated water outlet. 4) Combustion products emission line . The boiler must also be connected to a chimney that provides unhindered smoke removal, and if the boiler is installed in a closed combustion chamber, it must also be connected to the heating unit with combustion air.

Each of these connections must be made in compliance with the rules and regulations governing each type of connection. The electrical part must meet the requirements of the PUE . The water and fuel lines are regulated by the relevant SNiPs, which specify everything from the type of connection used to the choice of sealing materials. These connections must ensure absolute tightness and the ability to maintain it under conditions of high pressure, which is especially important for coolant pipelines.

Fuel gas connections, as you might guess, in addition to tightness, should also be made taking into account the organization of protection of the fuel line from possible mechanical damage. Checking the tightness of the gas system at home is carried out by supervisory services by pumping air into the system under a certain pressure. After the control period (at least one week) has passed, the pressure will be checked again. The pressure difference between the start of the test and its completion should be minimal. Only in this case will a permit to operate the heating system be obtained.

Buderus boiler connection diagrams

There are standard classic diagrams, illustrated in the installation instructions for Buderus boilers of one series or another. However, in practice, the diagrams almost always undergo changes to optimize the wiring, adjust to the geometry of the furnace room and the relative position of individual components of the heating system.

The heating systems of country houses, although similar to each other, are only in general terms. In reality, no matter how diverse the areas and layouts of buildings are, their heating systems are just as different. Departures from standard schemes can also be caused by:

- connecting the pool heating heat exchanger,

- placing a volumetric buffer tank to which you plan to connect alternative heat sources: solar collectors, solid fuel boiler or fireplace insert with a water circuit.

Complications of the circuit cannot be avoided when implementing the connection scheme for Buderus cascade boilers, when the system is designed to use several gas boilers operating together or alternately. A modern approach to constructing such systems is the use of special units - hydraulic arrows, which ensure equalization of temperatures and pressure of the coolant in several circuits connected to it.

The simplest solution

Solid fuel boilers Buderus Logano S111-2 deserve special attention, as they are the simplest option for residential premises and buildings for other purposes. They can be used as a separate installation or in conjunction with other heating equipment that operates on other types of fuel.

These units are ideal for both domestic heating systems with natural circulation and forced networks. Thanks to their small dimensions, they can be installed even in small rooms. The devices provide protection against overheating.

The appearance of Logano products is shown.

As for performance, there are 7 standard sizes, the power range of which varies from 12-45 kilowatts. Duration of combustion is ensured due to the impressive dimensions of the main chamber and ash pan. During operation, almost any solid fuel can be used. However, there are separate models designed for burning wood.

The manufacturer's warranty is two years from the date of use, but no more than 27 months have passed from the date of shipment from the main warehouse.

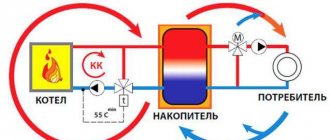

Connection diagrams for Buderus boilers to the boiler

Modern heating equipment is designed in such a way as to simplify the implementation of the main connections of the heating system. Buderus has a so-called quick installation system for this. Its functions are to ensure reliable, safe and accurate connection of nodes. For each gas boiler of one series or another, there are recommended lines of indirect heating boilers. For example, for the Logano G234 series it is optimal to use Logalux ST or Logalux SU tanks. And for Logano G124, the so-called Unit installation is provided, when a horizontal boiler of the Logalux L series is located under the boiler. This ensures, in addition to the convenience of connections, minimizing the length of the boiler heating circuit route and reducing the space requirements.

Familiarization with technical characteristics

Below we discuss the main parameters of the products of the most popular “Logano” series. The information is provided in the form of a comparative table to make it easier to make a choice. All models are made of steel or cast iron, as these materials have the most suitable properties.

Logano G221 products presented.

Having made preliminary calculations of the heating system for the building, you can familiarize yourself with the technical data of the boilers.

| Products | Power in kilowatts | Efficiency in percent | Pressure in bars | Material |

| S111-2 | 12-45 | 86 | 2,5 | Steel |

| S121-2 | 21-38 | 85 | 2 | Steel |

| G221 | 20-40 | 78 | 3 | Cast iron |

| G221A | 25-30 | 80 | 4 | Cast iron |

The Logano S121-2 boiler is demonstrated.

Recommendation! When operating boilers operating on solid fuel, it is necessary to use firewood whose humidity does not exceed 20 percent. Otherwise, the power of the devices will be noticeably reduced.

Connecting a Buderus wall-mounted boiler

The peculiarity of wall-mounted boilers is that it is, as they say, a boiler room in miniature. Inside one housing are the boiler itself and the hot water supply circuit, sometimes together with a small storage tank, a circulation pump and, of course, automatic control. Sometimes a small expansion tank is also placed inside. Naturally, all these nodes are combined and connected to each other already at the factory. But nevertheless, the boiler itself still needs to be correctly and reliably connected to the gas, chimney and pipes of the heating and hot water circuits. All connection operations are described in the installation instructions, and theoretically can be performed independently if you have the necessary skills. But do not forget that during the initial connection and commissioning you will still need to have an agreement in hand with a certified installation organization.

How the Buderus boiler works

The main feature is the reliability and durability of the German assembly. Therefore, domestic consumers highly appreciate any model. It is difficult to find negative reviews online.

Main components of the Buderus boiler:

- The main thing is the gas burner;

- A bithermic or standard heat exchanger is possible;

- A fan is used for turbocharging;

- The circulation pump is equipped with an automatic air removal system;

- A secondary heat exchanger made of stainless steel is used;

- A three-way valve is used;

- Built-in technology to control the operation of the fan and pump;

- A control board based on a sensor system is used;

- The kit includes pipes and pipelines for installation.

How a Buderus two-circuit boiler works:

- For maximum heating, the coolant first enters the first heat exchanger;

- It is sent to an additional heat exchanger to release excess heat to prepare hot water;

- To ensure the required temperature of the coolant, it is mixed with cold water based on a three-way tap. Now it moves along the heating circuit.

Important: This process is controlled by numerous sensors. They send corresponding signals to the control board. If problems are detected, an error code is displayed. In case of danger, the operation of the boiler is blocked.

The work of one contour model is no different. But it does not have additional technology for heating hot water to be supplied to the consumer from the tap.

Piping a gas boiler in the heating system

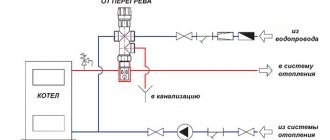

After the wall-mounted gas boiler has been installed and the heating device is placed on the wall, the first thing you need to do is connect it to the heating system. Depending on which model is installed, single-circuit or double-circuit, there are different piping schemes. We will look at the connection process using the example of a wall-mounted double-circuit gas boiler.

Photo 1: Connection diagram for a wall-mounted double-circuit gas boiler

As you know, a double-circuit boiler, in addition to heating, is capable of producing hot water for household needs. Structurally, this is realized by installing one bithermal or two separate heat exchangers. A double-circuit boiler does not produce very much hot water, but it is quite enough for 1-2 distribution points (for example, a kitchen faucet and shower).

A modern wall-mounted gas boiler is very compact and already contains within itself the basic elements necessary for the operation of a heating system with forced circulation, such as: a circulation pump, an expansion tank, a safety group. In the heating systems of small private country houses, this is more than enough, but if necessary, you can install an additional expansion tank or another pump.

At the bottom of any mounted double-circuit boiler there are 5 pipes. They are connected to: supply and return lines of the heating system, supply and return of hot water supply, main gas. The gas connection is usually located in the center and is colored yellow. All other lines can be located in any order, depending on the model of the gas boiler. Therefore, before starting tying, it is necessary to clarify the purpose of each of them in the operating instructions.

Photo 2: Piping diagram for a wall-mounted double-circuit gas boiler

The piping of a wall-mounted gas boiler is done with polypropylene or metal pipes. The cross-section of heating pipes is usually larger than DHW pipes 3/4 and 1/2 inches, respectively. The heating system is connected to the boiler through American nuts. Ball valves are installed on each line for the convenience of dismantling the gas boiler without draining the coolant and to isolate the boiler from the heating system if necessary. To ensure tightness, all connections must be made using plumbing FUM tape or flax.

Coarse filters must be installed in the heating return line and in the DHW supply line. For ease of washing and cleaning, they are also cut off by shut-off valves. Often, in order to increase the service life of the secondary heat exchanger of a double-circuit boiler, a magnetic fine filter is additionally installed at the DHW supply.

Return to contents

Electric boiler installation

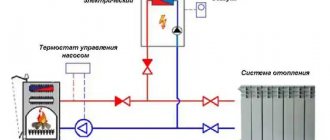

Installation of this equipment in a house does not require a chimney and approval from regulatory authorities. The only requirement is that the electrical wiring is in good working order. The connection diagram is quite simple. In addition to the boiler, it includes temperature sensors on the pipelines, a heating radiator, drain and shut-off valves, an expansion tank and a filter with a circulation pump. You will also need a voltage stabilizer, since electric boilers are sensitive to voltage drops, and they are inevitable in the electrical network.

When installing, you must try to isolate it from the water supply system so that if a pipe breaks, water does not enter the unit, causing a short circuit. The installation room must be thermally insulated to prevent the formation of condensation - it can also lead to serious damage. The boiler must be installed on a flat surface.

Connection

To connect equipment, couplings and adapters are used. First, you need to turn off the water supply in the water supply using ball valves. The connection is made in accordance with the installation diagram attached to the accompanying documentation. The circuit assumes the presence of grounding, installation of a circuit breaker, as well as an RCD for short circuit protection.

Cables must be installed in cable ducts, and the electrical part of the equipment is protected by a casing. The unit itself must be securely fastened. And only after that you can let water into the heating system and check the functionality of the equipment.

Connecting a wall-mounted boiler to the electrical network

Most modern wall-mounted gas boilers are equipped with sophisticated automation. It controls many processes, turning the heating boiler into an autonomous mini-boiler room, the operation of which requires virtually no intervention from the owner. Obviously, the control unit and various sensors require an electrical connection.

Double-circuit wall-mounted boilers are available in two versions: with a conventional socket and with a cable for connecting directly to the machine. In any case, they must be powered from the mains through an individual machine. If you purchased a model with a plug, then the individual socket for the gas boiler should be located next to it, but in no case under it. This is one of the safety requirements so that in the event of a coolant leak, a short circuit does not occur.

Review of the Logano boiler range and their costs

The Logano series of boilers is represented on the sales market by models with cast iron and steel heat exchangers. It should be noted that cast iron equipment weighs much more than steel. It is also more sensitive to sudden temperature fluctuations inside the combustion chamber.

Today, several Buderus models are popular:

- Logano S131;

- Logano S171 W;

- Logano G221/A;

- Logano G221;

- Logano S111-2;

- Logano S121-2;

- Logano S181 E.

Features of Logano S131

The model is a solid fuel boiler designed for heating a private house with a small area. Currently, this model is presented in one variation with a power of 15 kW.

The unit is partly a long-burning TTK. Using the settings, you can set the mode of slow burning and gradual smoldering of the fuel. Increased reliability is the main advantage of the presented equipment.

The combustion chamber has a volume of about 38 liters, the combustion time is more than two hours with this load. The main disadvantage is that the grate must first be dismantled to clean it. The efficiency of its operation depends, as a rule, on the quality of the chimney.

Prices for the Logano S131 boiler model

Logano S131

Logano S171 W

It is a complete pyrolysis boiler made of high-strength steel. Due to the fact that this material cannot provide reliable protection and heat retention, the manufacturer additionally used fireclay brick for the lining, which has good heat capacity and increased resistance to high temperatures. According to the characteristics specified in the technical documentation, with proper installation and installation, the efficiency of this model will be about 87%.

The unit is presented in several versions, differing from each other in power and volume of the loading chamber:

- 20 kW - 110 l;

- 30 kW - 110 l;

- 40 kW - 133 l;

- 50 kW - 133 l.

The coolant in all devices usually heats up to 70–85 ºС, and the period of continuous operation on one pad can last from 3 to 8 hours.

The equipment is equipped with the latest electronic automation, making it energy-dependent. This feature cannot be considered a disadvantage, since the control unit increases safety and efficiency. It is possible to configure the boiler so that in offline mode SMS messages are sent to the phone indicating the status of the device.

Logano G221/A

The design of models equipped with long-burning cast iron heat exchangers is reliable and simple. Typically, such boilers are installed in private homes and industrial premises with an area of no more than 400 square meters. m.

Not only coal and wood, but also coke can be used as fuel. Pyrolysis is the main method of burning wood. The operating temperature of the liquid in the heat exchanger does not fall below 90 ºС. The efficiency indicator is not higher than 78%. This model is represented by a whole line of devices of varying power: 20, 25, 32 and 40 kW.

The manufacturer presents Logano G221(A) as a highly efficient universal boiler that can operate without problems with various devices running on diesel fuel or gas.

The main advantage of the model is the presence of an improved special unit with automatic supply of fuel (pellets or coal) to the combustion chamber, which helps to increase the efficiency of the TTK in continuous mode.

Logano S181E

The unit is a long-burning pellet TTK. The design is equipped with a spare chamber, which ensures automatic supply of fuel: pellets and coal. A one-time download is enough for uninterrupted operation of the device for more than forty hours. During this time he works independently.

If a problem occurs, the automation instantly notifies the user via SMS about what happened. The company introduced three variants of models of different power to the market: 15–25 kW.

Prices for the Logano S181 E boiler model

Logano S181E

Logano G 221

The equipment belongs to the TTK, which are used for heating industrial and residential premises with an area of up to 410 square meters. This device is safe thanks to the upgraded protected heat exchanger, adapted for sealed systems.

Models G221 are low-power cast iron boilers operating in the range from 20 to 42 kW. The compact model can last at least 30 years. A distinctive feature is a very spacious firebox, which allows you to reduce the frequency of adding fuel. The efficiency of G221 is about 78%, but for conventional TTK this is considered a good indicator.

The design allows for the door to be placed on the right or left. If we add to this the modest dimensions of the case, then the unit can be called quite convenient for installation and maintenance in a fairly cramped room. G221 is a simple-to-use equipment, and yet, it has a thermostat that regulates the draft in the firebox, which prevents the water in the heat exchanger from boiling.

Logano S111-2

This model is made of steel and costs much less than cast iron. It is corrosion resistant due to the use of special alloys. The unit is available in seven versions with different power levels - from 12 to 32 kW. These heating devices are more popular among owners of country houses. The efficiency is 74-76%.

Prices for boiler models Logano S111-2

Logano S111-2

Logano S121-2

This long-burning TTK model is fundamentally different from all models in that it does not just burn wood, but reuses the pyrolysis gases released. As a result, equipment productivity increases significantly without increasing fuel consumption.

However, to control these processes, it is necessary to clearly control the air supply to the main chamber and to the pyrolysis burners. Automation is responsible for this. The S121-2 series is represented by four types of boilers of different power: from 18 to 38 kW. This range is enough to choose a suitable model for heating a country house of any size, up to 360 m2. The owners note that the filling burns out almost completely, leaving only a small ash residue, which reduces the cleaning time of the unit.

Purchasing equipment can cost the following approximate amount:

- Logano g221 20 – 115,000 rubles;

- Logano g221 25 – 125,000 rubles;

- Logano g221 40 – 140,000 rubles;

- Logano g211-20D – 70,000 rubles;

- Logano g211-32D – 100,000 rubles;

- Logano s111-2-WT-12 – 70,000 rubles;

- Logano s111-2-WT-24 – 95,000 rubles;

- Logano s111-2-WT-32 – 10,000 rubles.

A fairly wide range allows the buyer to choose the most suitable option for himself.

Choosing a chimney for a gas boiler

Any wall-mounted gas boiler needs a chimney. Depending on the model, this can be either a traditional chimney or a small horizontal chimney that can be led outside directly through the wall of the house.

Photo 4: Installation of a coaxial chimney for a turbocharged boiler

In double-circuit boilers with an open combustion chamber, the combustion process occurs with the help of air from the room in which the heating device is installed. Typically, such models are installed in specially equipped boiler rooms. To remove combustion products, they are connected to traditional chimneys for gas boilers made of ceramic or stainless steel.

Wall-mounted boilers with a closed combustion chamber (turbocharged) use outside air in their operation. It is supplied inside the device through one of the channels of the coaxial chimney. The second channel is used to discharge flue gases into the atmosphere. A coaxial chimney is very easy to install and you can connect a gas boiler to it yourself.

Return to contents

Connection to the gas main

The process of connecting a gas boiler to a gas pipeline must be carried out exclusively by qualified specialists from the gas service or another organization licensed to carry out this type of work. Independent connection to the gas main is illegal and, at best, threatens the owner of the premises with a considerable fine, and at worst, it can lead to tragedy.

The first stage in the process of gasification of a facility is contacting the gas service. After submitting all the necessary documents, individual technical conditions (TS) will be developed for you, the fulfillment of which is necessary to connect to the gas main.

Once you have the specifications in your hands, you can safely start looking for a certified specialist who, in accordance with the requirements of regulatory authorities, will design a gas pipeline and connect your heating boiler to it.

Photo 5: Connecting a wall-mounted boiler to the gas main

Gasification of the premises can be carried out using underground and above-ground methods. For the underground section, corrosion-resistant polyethylene pipes are used, and the above-ground part is made of steel pipes, which enter the room directly at the location of the gas heating boiler, at a distance of 1.2-1.5 m from the floor.

Attention!

When using several heating devices, gas supply to each of them is carried out separately. Laying gas lines indoors is strictly prohibited.

When accepting installation work, you should pay special attention to the fact that all connections must be sealed using tow or paint. The use of sealing tape or FUM is not allowed due to the low degree of tightness of the connection. A gas filter must be installed on the shut-off valve to protect the heating boiler from small debris and condensate. It is recommended to connect the gas boiler directly to the shut-off valves using steel pipes. It is possible to use a special corrugated stainless steel hose, but pipes are still preferable, since their use does not reduce the cross-section of the gas channel.

For more information about connecting and piping wall-mounted gas boilers, see the following video:

Its service life, operating efficiency, and the safety of its owner depend on how correctly the wall-mounted gas boiler is connected. We hope that our short overview of the main stages of connection and strapping was useful to you.

FAULTS AND REPAIRS

REPAIR OF GAS HEATTER

BOILER SPARE PARTS