The heroes of our review today are heating boilers produced under the Sibir brand. We will analyze in detail how they compare favorably with competitors and which ones have disadvantages. The owners, who agreed to leave their review especially for kotlydlyadoma.ru, will tell us about the intricacies of their work.

Novosibirsk produces solid fuel boilers “Siberia” of two series “Gefest” and “KVO”. Let's look at each of the models in turn and find out what advantages these devices have among their Russian counterparts.

Features of Siberia boilers

Siberia-Hephaestus boiler

The NMK plant has been operating since 1995 and is based in Novosibirsk. The heating boiler Siberia is presented in two versions: Hephaestus and KVO. All gas appliances in the series are standard classic units and have a simple design. It includes the boiler itself and the water jacket supplied with it. Due to the minimum number of parts and compact sizes, the devices can be located in any part of the house.

Upon closer examination, you should pay attention to the grate, cross beams and cover. All Siberian boilers are created using universal technology and consist of almost the same elements. The grille is designed to increase the area of thermal volume and achieve maximum effect. The beams are placed in the path of flue gases to direct heat into the heating system. The lids are equipped with holes for coal and have a standard shape.

Which fuel to choose

Coal is a chemical compound containing a number of hydrocarbons and impurities with a low combustion rate. These substances are formed in the lower chamber of the boiler after combustion. This is slag and ash that needs to be regularly cleaned out of the ash pit. Moreover, each species, depending on geography and period of occurrence, contains a certain level of carbon. It is the age and the ratio of flammable and non-flammable components that determine the quality and grade of the solid fuel mineral.

There are several types:

- The youngest of the subspecies is lingitis. It is a loose stone structure. It often crumbles and crumbles. Ineffective for heating houses. However, it is considered the cheapest and is used for energy production in thermal power plants.

- Anthracite is the variety that warmed up most deeply when buried. It is a transitional form from coal to graphite. The amount of carbon reaches 95%. The most effective among all varieties.

- Hard coal is the result of the transformation of bitumen masses. Divided into several grades depending on carbon content, from 75-95%. Humidity reaches 12-15%.

- The brown subspecies, unlike other varieties, is formed from peat and includes up to 70% carbon. It has a characteristic white color. Can be used as fuel or raw material. Also includes a large number of volatile compounds.

Different grades

Due to its minimal weight and significant carbon content, it is anthracite that has the maximum specific heat capacity. Indicators can reach 9 thousand Kcal/kg. Coal, due to its lower content of flammable substances and higher humidity, has up to 5.5 thousand kilocalories per kilogram. Brown has an even lower rate of 3 kcal/kg. Therefore, anthracite is considered the optimal choice.

Specifications

Design of a solid fuel boiler

Before choosing a suitable boiler model, you need to study its technical characteristics in detail. Each model has its own designation. For example, KVO 12 TPE: the number indicates power, the letters indicate a device with an electric heating element operating on solid fuel. The thermal performance of devices is measured in kilowatts and varies between 12-20 kW, efficiency is 70%, standard pressure cannot be more than 0.1 MPa. Using devices from both series, you can heat rooms with an area of 120 to 200 m2. The maximum temperature value should be at least 95 degrees, the nominal value should range from 60-80 degrees.

The diameter of the Siberia boiler chimney should be 150-200 mm, the power of the unit is 2 kW. Compliance with all technical requirements during installation and operation ensures stable operation of the boiler. Drinking water with a GOST 2874 value is used as a heat carrier, the hardness of which cannot exceed 0.7 mg. The water treatment option must be selected by the project company. In addition to water, it is allowed to use household heat carriers permitted for residential premises.

For safety reasons, it is prohibited to use antifreeze containing ethylene glycol and other liquid components not intended for heating systems.

Advantages and disadvantages

The NMK plant produces boilers from high-quality raw materials.

Each Siberia heating boiler, regardless of the model, has its pros and cons. In the list of advantages, consumers include high-quality raw materials from which the devices are made. The main advantage of the units is also their reliability and durability, a large assortment and choice of options, affordable prices and the ability to purchase the desired model in every region of the country.

Products of the brand are able to function properly in any weather conditions, including extreme heat and frost. Each boiler is accompanied by the necessary documents: certificates of conformity, instructions for use. A standard solid fuel boiler of the Siberia brand has practically no drawbacks, with the exception of minor difficulties during the installation process, which depend on the characteristics of the room.

What coal is best to heat a boiler?

The manufacturer initially carries out thermal calculations and adapts the design of the combustion chamber and heat exchanger to the specific type of fuel. Therefore, in order to increase the efficiency of a household boiler, it is enough to use coal of the grade and fraction specified in the operating instructions.

What brand of coal to burn?

Coal contains carbon and non-combustible impurities, which form ash and slag after combustion. The ratio between carbon and impurities depends on the type of fuel chosen. Coal has (depending on the brand) different degrees of moisture, loose or hard structure, and age of formation.

To effectively heat a coal boiler, you need to have a good understanding of the characteristics that distinguish this or that type of fuel:

- Lingite – this type of fuel has a loose structure and a large percentage of ash residue. Lingite is used in industrial power plants. This type of fuel is not suitable for heating a house.

Hard coal – has a calorific value of 5500 kcal/kg. The percentage of carbon is at least 75%. Ash content from 2 to 4%. Most classic-type household boilers are heated with coal. For gas generator type equipment, not suitable due to humidity above 20%.

Brown coal – calorific value is only 3000 kcal/hour. When burned, a large amount of ash residue and coking substances are formed. Humidity is at 50%. Brown coal is not recommended for heating domestic boilers, due to the rapid clogging of the chimney and heat exchanger.

Anthracite – the humidity threshold is within 7%. It has high specific heat values, equal to 9000 kcal/hour. The share of ash carried away by gases from the coal boiler is no more than 7%. Manufacturers of heating equipment recommend heating gas-generating boilers with Anthracite. Coal is divided into several grades according to size: fist, nut, seed.

Is it possible to burn with coal briquettes?

Coal briquettes are made by pressing small fractions (dust). Special organic or mineral compounds are used as a binding element. The latter greatly increase the ash content of the fuel, but are cheaper. The most popular are coal briquettes, in which coal tar acts as a binder.

Heating with compressed coal has the following advantages:

- Easy to install in the combustion chamber.

- Good flammability.

- High calorific values, identical to anthracite.

- Easy storage and transportation - briquettes have a regular geometric shape, so they are easier to store and take up less space.

The only disadvantage of compressed coal is its high cost, which is approximately one third higher than the price of lump raw materials. The advantage is the ability to fire the boiler on coal, without contamination by combustion products.

How to burn with coal dust

The safest and most effective method of burning dust is considered to be using a special burner device.

Is it possible to burn with charcoal?

With all these advantages, charcoal has one serious drawback. The cost of a kilogram of purchased charcoal will cost almost 2 times more than the cost of hard coal. You can somewhat reduce the cost of raw materials by establishing its independent production. To obtain 1 ton of charcoal, you will need to burn about 10 m³ of wood.

Types of boilers Siberia

Steel heating boiler Siberia KVO 10 kW

The NMK enterprise produces solid fuel units KVO and Hephaestus. Each series includes a set of models that have their own characteristics, differences, advantages and disadvantages.

Siberia KVO

Steel appliances of the KVO series are created for owners of country houses and dachas who are looking for budget household units. The list of devices in the series includes five types, marked with numbers 10, 12, 15, 20 and 25 according to the number of kW of power. All of them are made of heat-resistant steel, some are supplemented with cast iron elements. Each boiler is equipped with special parts:

- water-tube grate of grate type;

- cross beams with heat carrier;

- lid combined with the hob;

- additional heating element for 3 kW, installed separately.

The connections for flue gases, supply and return lines in models of this series can be located on the right or left wall for more convenient installation. The operating principle of such boilers does not differ from standard combustion appliances; they operate on wood or coal, which heats the coolant inside the heat exchanger.

Siberia Hephaestus

Solid fuel boiler Siberia Hephaestus KVO 15 TE

Devices of the Hephaestus series have been produced since 2014, they are new products in the field of heating equipment. Consumers can purchase a unit of one of three types with a capacity of 15, 20 or 30 kW. The firebox of each boiler is surrounded by a water jacket, the grate is complemented by a deep ash pan that can accommodate a large amount of waste. Boilers of this type have their own characteristics:

- the ability to supply a 4 kW heating element as an additional heating source;

- the presence of supply and return pipes for more convenient piping and installation work;

- the ability to install a mechanical traction regulator;

- water tanks in grate bars to improve operational efficiency.

Double-circuit and single-circuit boilers of the series function similarly to standard water heating devices. This is a good option in terms of cost-quality ratio, suitable for those who stick to a budget when creating an indoor heating system.

Hephaestus boilers are not suitable for heavy loads and are of a lightweight type.

How to properly light a boiler

How to clean soot from a coal boiler

The composition of soot includes a non-combustible residue that turns into slag during the combustion process. An additional problem is that under the influence of high temperatures, low-quality coal leads to increased formation of condensation, an acid that can corrode the metal of the heat exchanger.

Boiler cleaning is carried out in several stages:

- It is necessary to remove the ash from the ash pan, a chamber located immediately under the firebox and which is a spacious box closed with a sealed door. The ash pan is removed and the ashes are poured out.

- Cleaning of slag is carried out with a special tool, the appearance of which resembles a curved awl. Sludge is removed around the perimeter of the heat exchanger and from the grate.

In addition to regular boiler cleaning, measures are taken to prevent increased soot formation. The main reason why the heat exchanger becomes clogged with soot is insufficient combustion temperature of the fuel. Layer-by-layer stacking of firewood mixed with coal can solve the problem of increased soot formation.

How to clean the chimney pipe of a coal boiler

Proper operation of heating equipment includes measures to reduce soot formation in the chimney during boiler operation, as well as regular maintenance and cleaning of pipes. SNiP stipulates the need to carry out routine maintenance at least twice a year.

Pipe cleaning is carried out in the following ways:

Mechanical cleaning method - proper cleaning of chimneys is carried out using a special brush. Flexible plastic rods are mounted on the rod. If necessary, the brush can be extended using flexible bars that can be connected. Cleaning is carried out from the roof. Soot is removed through special inspection wells. The largest layers of soot accumulate on the bends and adapters of the chimney

During cleaning, they receive the most attention. Cleaning chemicals are available as fuel additives. It is enough to place the bag in burning coal to effectively clean the chimney

Chemicals are used as preventive measures and cannot completely replace the need for mechanical cleaning. Reducing soot emissions from coal combustion. Preventing the appearance of soot is the best measure to combat deposits on the walls of the chimney. As a preventative measure, several methods are used. A soot trap is installed, the required coal combustion temperature is ensured, the chimney design is changed and a deflector is installed to improve draft characteristics.

All of the above measures are aimed at maintaining the performance of both the boiler itself and the chimney. Acidic condensate leads to rapid burnout of the heat exchanger and chimney.

Proper operation of a coal boiler includes: proper choice of fuel, kindling and maintaining combustion in the chamber, preventing increased soot formation and regular maintenance of the heating unit and chimney.

Installing the device yourself

The floor and walls near the boiler must be protected with non-combustible materials.

The boiler and other elements of the heating system must be installed taking into account compliance with safety rules. The device is mounted at certain distances from combustible elements, maintaining a distance of at least 500 mm from the walls of the boiler. There must be at least 1200 mm of space from the top of the floor-standing boiler and the ceiling, and at least 1250 mm from the wall in front of its door. If a wood-burning or heated floor is made of flammable materials, a fire-retardant coating is made of sheet steel laid on a layer of asbestos cardboard, which is impregnated with a clay solution.

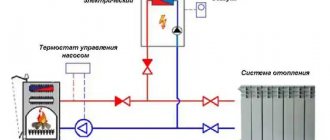

Valves or safety devices are placed in a part of the output manifold device without intermediate elements. In this case, the supply pipes cannot be less than 32 mm. The heating system is installed so that the air is completely removed when it is filled, and the coolant is eliminated through the drainage when the device is emptied. The heating element unit must be connected using a cable with 30 A circuit breakers, the cross-section of the copper wire in which must be at least 4 mm2.

How to remove ash

If the boiler is heated exclusively with wood, then cleaning up combustion products is quite simple. After burning out, the ash will fall down through the cast iron grate. After which it can be removed from there using a spatula. However, it is advisable to remove flammable objects and liquids.

When using coal, the burnout time is significantly longer. Therefore, it is extremely difficult to clean a slagged niche in a timely manner. To prevent this effect, it is necessary to additionally lay layers of coal with layers of wood. Or by significantly increasing the temperature in the boiler. This can easily be achieved by increasing the draft, so either activate the fan or use boosting techniques.

The use of solid raw materials as an element for heating has several advantages over firewood. Heating with peat or carbon analogues makes ignition much easier, and solid fuel minerals will burn at a higher temperature. The use of combined materials helps. Using firewood in combination with coal is the best option for a private home.

Operating principle

Due to their simple design, Siberia units allow you to save a lot and reduce fuel costs. They work on the principle of using a closed firebox, which limits the flow of air into the chamber. By creating the effect of “oxygen starvation” during operation, the fuel burns 3-5 times longer than in standard mode. Just a couple of loads of fuel will be enough for one day if firewood is used. With the help of coal, the boiler can operate for more than two days.

Siberia boilers have a high efficiency, reaching 90% - this is an ideal indicator for solid fuel appliances.

Features of the Kuban stove

The temperature of the stones in the oven reaches 650 degrees. The stones themselves are closed, the heater is inside the heating chamber and flames are blazing on all sides. As a result, the water that enters the heater using a special dispenser begins to evaporate very quickly and, as a result, weightless steam is formed. The oven can also be open, in which you can select steaming modes to suit your taste.

- The oven is equipped with a door with which you can adjust the temperature

- The presence of a dispenser allows you to evenly distribute water inside a closed oven

- The heater can be open, which allows you to combine evaporation modes

- The heating chamber is super-rigid and has a special shape

The Kuban Teplodar stove has the best performance characteristics and is a very reliable device. With this stove, the steaming process will turn into a real pleasure and will please even the most demanding steamers.

Operation and Maintenance

During use of the system, the level of the coolant in the open tank cannot fall below its height. By adding coolant, it is maintained at the optimal level. Water from the heating system cannot be used for domestic purposes; this can stop circulation and reduce the liquid level. Before turning it on, it is necessary to open the dampers on the chimney, check whether the tap on the return line is open, and also take into account the presence of draft.

During ignition, the device is heated with dry wood, loading it inside the firebox up to half its height. Hot coals should completely cover the grate; the coal is loaded gradually when the firewood is perfectly lit. Coal fuel must be placed into the firebox through the door in small portions, without leaving the hole open for a long time. After the coal is ignited, the ash pit door is left in a position that ensures complete combustion of the fuel. During initial ignition, dark liquid may leak from under the ash drawer.

You need to clean the grate at least once a day. Do not allow a large accumulation of water inside the firebox; cleaning is carried out at least 1-2 times a day.

How to melt correctly

The algorithm of actions looks like this:

- It is required to place sheets of dry paper at the bottom of the firebox. Then, a small layer of wood chips, logs, preferably fruit varieties. To speed up the combustion, it is necessary to arrange them in a pyramid.

- Set the paper on fire. Then close the door, but leave the ventilation hole open. Due to which you can regulate the rate of combustion of firewood. Moreover, depending on the volume of oxygen, the fuel will burn faster or slower.

- After complete combustion of the wood, you need to place a layer of small coal, up to 15 cm, on the resulting pile of ash.

- When it burns sufficiently, you can pour a larger mineral on top in the form of a pillow. The height can reach 60 cm. Before doing this, be sure to move the hot stones apart so that the coal does not bake.

If you use fuel of insufficient quality, coking may occur. Therefore, if you are not sure of the quality of the purchased raw material, put it in the form of a sandwich, mixing it with firewood. Several layers of logs, successively mixed with stone, make it possible to sufficiently warm up the installation and release heat into the premises.