Here you will find out why a water heated floor does not heat: possible problems and their manifestations, the reason for poor operation, uneven and long heating times, and also what causes a breakthrough.

Despite the fact that built-in heating systems and, in particular, water heated floors are considered the most reliable, durable, and efficient, sooner or later you may encounter problems.

Having studied them in advance, it is easier to determine why the water heated floor does not work and take measures to eliminate the malfunction.

Malfunctions of water floors

The main reasons why a water heated floor does not work well are due to defects during installation. Insufficient heating may be due to low boiler power or improper operation of the water pump.

- When the circulation pump is running, it vibrates slightly and makes a little noise. If there is power and no signs of operation, the failed pump can be easily replaced with a new one.

- The system may not turn on if air gets into it. This problem can be resolved with the help of repair specialists.

- If the boiler power is low, the heat may not be enough for high-quality floor heating. It is necessary to install a boiler with a power reserve or turn off part of the heating (in rooms not in use during this period).

- If the floor gets warm in places, the vapor barrier is not done correctly. It will have to be redone. Poor quality vapor barrier leads to increased dampness in the room and the formation of mold, which is very harmful to health.

Reasons for the failure of a properly functioning heated floor

- Often at the beginning of the heating season, when the heated floor is turned on, the circulation pump may not work because it may “boil” during long periods of inactivity in the summer.

By the way, a note for you. For prevention in the summer, it is necessary to turn on the circulation pumps for 10 minutes once a month to maintain their functionality.

- A lack of electricity in the network will also stop the pump and lead to a lack of coolant circulation in the system.

- Check that the automatic air vents are open and that the system is not air-filled.

- Clogging of the mechanical cleaning filter of the heating system leads to difficult passage of the coolant through it, as a result of which the floor may not warm up properly.

- Pay attention to flow meters, valves, and in general it is necessary to check all the taps, because if you have small children, they can screw up anything.

- If it is left idle for a long time during the cold season, for some reason (often a power or gas outage), the water may freeze.

Also, malfunctions during operation can occur, as already mentioned above, with automation. But this problem needs to be considered separately.

Cozy living conditions in most cases evoke associations with warmth. But even careful handling of the heating system does not guarantee stable heating of the floor covering

. For some, the heated floor does not work due to incorrect installation or influence received during operation. In such a situation, you will have to establish the cause of the failure, and then remove the resulting breakdown.

Stable heating operation – guarantee of comfort

Water heated floor does not heat

It's hard to admit, but it's true. Warm floors do not bring joy, but disappointment. Don’t rush to scold him, maybe there’s something wrong with him that can be fixed.

1. The heated floor circuit does not work.

a) In the distribution panel, ball valves are installed on each circuit. Look, all the handles should be located along the pipes (open).

b) The circulation pump does not work. Most often they are located near the boiler (in the distribution panel). Its operation is accompanied by slight noise and slight vibration. If not, it should be replaced if power is supplied to it.

c) Air has entered the system. You cannot do without the help of a specialist. An unpleasant situation, but fixable.

2. The floor temperature is low, insufficient to heat the room.

a) There is not enough boiler power. Try reducing the temperature in other rooms, in those where it is possible, but you are rarely or rarely present. Maybe it's time to clean the boiler, carry out preventative repairs, and inspect the temperature sensors.

b) They laid a carpet and put in additional furniture. Underfloor heating requires open floors, the more the better.

c) Air has entered the system. This happens when the air did not completely block the pipe, but partially.

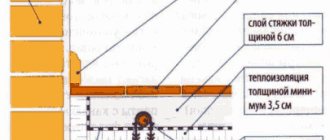

d) During installation, you “saved” on insulation and now you warm the ground or your neighbors from below. Here you need to make a choice: either redo the floors completely with normal insulation, or install additional heat sources (supply warm air through ventilation, additionally install radiators, gas convectors, etc.).

3. The heated floor does not heat evenly (spots). This is the most unpleasant case. If attempts to free the system from air are unsuccessful... Your vapor barrier is done poorly or is missing altogether. In this case, the floor works to dehumidify rather than heat the room. How can I check this? With the heating running, place a 1*1m piece of plastic film on the floor and tape it around the perimeter to the floor. If after a day (or earlier) perspiration appears on the film, the joints of the tiles darken from moisture - the floor must be redone in accordance with the technology. I do not recommend installing an additional heat source. Dampness from the floor and heat will lead to the appearance of fungus and mold, with an unpleasant odor.

Teleos-Bud LLC Terekhov Alexanderwww.teleos.kiev.ua

Hydraulic floor failure

If the floor does not heat well, the reasons for this can be very different. In most cases, owners blame the equipment manufacturers, saying that they have become the owner of a low-quality product. In reality, failure often occurs due to incorrect installation. Mistakes made in this case become the basis for failure or unstable operation of the structure.

Loss of functionality of the hydraulic floor

is connected with several points.

It happens that the floor stops working due to a breakdown of the hydraulic circuit .

In such a situation, first carefully inspect the distribution panel. In the middle of it there are toggle switches responsible for supplying the coolant inside the heating circuit. If the installation process is done according to the rules, the toggle switches in the open position are turned along the pipes. Another reason why heating stops working is the failure of the circulation pump. If everything is good, during operation you will hear an insignificant background noise and feel a slight vibration. If no sounds are heard from the equipment, and the electrical supply of the house does not cause reproaches, then the pump will have to be repaired or replaced with a new one.

The floor is not warm enough. Coolant temperature is low

A typical and common problem that owners of city apartments and private houses are forced to face when complaining about the unsatisfactory performance of the heated floor is uneven heating. During normal operation, the water circuit must completely and evenly heat the concrete screed or floor covering, creating the necessary conditions for heating the home.

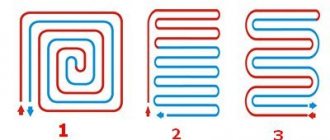

In this case, the problem is uneven coolant flow through the water circuit. Due to the fact that pipelines can have different lengths, due to the same intensity of coolant supply, the degree of heating of each pipe is different. Usually, before starting, the levels of electric drives are set in the collector cabinet to the required position.

Before starting the system, the optimal parameters calculated for each circuit are initially set. By measuring the temperature of the coolant in each water circuit, the electric drives are set to the appropriate position. Consequently, the heating temperature of the coolant in the system changes, and the degree of heating of the water circuit also changes.

The solution in this situation is as follows. We are looking for a water circuit in which the coolant does not heat the water floor in accordance with the set temperature, then we manually increase the flow of boiler water.

Conclusion

Many heating problems are not difficult to identify and fix on your own. However, in difficult situations it is better to seek help from specialists. Even though the price for their services can be quite high, it is still cheaper than replacing a damaged heating system.

For more information on this topic, watch the video in this article.

If you need to buy a SVP tile leveling system in Moscow, our specialists will definitely contact you and answer all your questions. We will be glad to mutually beneficial cooperation! We sell parts of various designs: (wedges and clamps in various quantitative variations), designed for different seam widths. Call or write to us, our conditions will pleasantly please you! We will be glad to mutually beneficial cooperation! See you in touch!

Electrical floor problems

An electric heated floor consists of a heating cable and a thermostat. Therefore, why the system does not work depends on their proper functioning.

If the heated floor stops heating, the heating cable may have been damaged during pouring of the screed or during installation. To check the integrity, you need to disconnect the terminals on the thermostat side and measure the voltage between the heating conductors. The discrepancy with passport data should not exceed 5%.

- If the temperature sensor turns off when the floor heats up weakly, it indicates incorrect installation. The sensor either touches the cable or is close to it. The floor temperature can differ from the set temperature by no more than two degrees. It can be measured using a special thermometer.

- The thermostat or temperature sensor may be faulty. You must first make sure that the terminal connections of the circuit elements are reliable. Then the output voltage is measured, it should be equal to the supply voltage. Having determined the malfunction, the broken unit is replaced.

For such a system, you can repair the heated floor yourself, without resorting to the help of specialists. You only need basic knowledge of electrical engineering and certain measuring instruments.

Film floor failure

Low floor

appears due to the following reasons:

- Poor contact in the electrical circuit. To connect the film to the electrical power supply, cables are used that are connected to a copper bus located along the edge. The connection is made using a specialized clamp. If the contact crimp is insufficient, the floor covering will not heat up. Poor contact can result in metal oxidation. By returning contact, you will restore the functionality of the structure;

- Thermostat failure due to a malfunction or lack of power. This can be determined by measuring the voltage;

- Poor operation. If from the very beginning the system was planned as an additional one, it will not be able to work as the main one, since the external water thermostat will be installed incorrectly. During installation of the key system, an appearance is established that responds to the temperature of the floor covering . When it decreases, the device will work and the temperature will increase.

We carry out the installation process carefully

If the heated floor does not work, there is no need to give up. You can restore his ability to work by establishing the cause in advance. When calculating failure conditions, consider the design features and operating principle of the heating system itself. If some parts can break a hydraulic floor

Why the water heated floor does not heat; faults and their elimination

Water heating built into the floor is a rather complex system of interconnected components. If the water heated floor does not work, the reasons may be different.

First of all, you need to know the basic elements of this type of heating:

- Pipes are lines through which coolant circulates, transferring heat to the floor surface.

- Bypass.

- Circulation pump.

- The manifold and electric drives of the inlet group, which serve to regulate the flow in the circuits, as well as a balancing valve, designed to mix heated water and water that has already given off heat.

- Thermostats and thermostats that allow you to regulate and maintain the set temperature. In the event of a breakdown, both cooling and critical overheating of the system are possible.

It is worth taking into account possible flaws in installation. Eliminating such a malfunction as, for example, an insufficient amount of insulation and high heat loss, will be problematic, because you will have to lift the floor covering of the warm water floor, dismantle the screed and pipes.

Also, if a warm water floor does not heat, the reasons may lie in incorrect calculations during the design and, as a result, incorrectly selected system components according to the parameters. It often happens that there is not enough energy for proper heating. In this case, the problem is low network voltage or insufficient boiler power.

However, we will consider the most typical breakdowns, places and causes of their occurrence, as well as ways to solve the problem.

Pipeline damage

A breakthrough of a water heated floor manifests itself in a leak and often a sharp drop in pressure in the pipes. A leak not only reduces the amount of coolant in the system, but is also fraught with destruction of the floor, flooding of neighbors and damage to property.

After determining the location of the leak, you need to carefully dismantle the floor covering and screed locally. The method of eliminating a leak comes down to excision of the damaged section of the pipe and replacing it with a new, intact one. The technology depends on the type of pipes used.

Before dismantling the coating and cutting out the pipe, you must first shut off the coolant supply to the circuit (at the collector), and then completely drain the water from the circuit. After repair, the circuit starts up. It is mandatory to check the solder or connection for leaks.

Before heating a water heated floor, it is necessary to de-air it.

Uneven heating

In cases where a water heated floor does not heat well, the reasons may lie in the uneven distribution of the coolant in the circuits. This is due to the fact that the contours, as a rule, have different lengths. If the rate of water supply at the collector to each loop is the same, then the coolant will take longer to pass through a longer circuit. Accordingly, in such loops the water cools faster.

In this case, you will have to be patient, because the time it takes for a water-heated floor to warm up depends on many factors (the design and thickness of the “warm cake”, the temperature and intensity of the water supply, the temperature outside the windows, the flooring material, what power the heater is chosen for the warm floor). water floor, etc.).

Automation tools will help to facilitate control and adjustment, namely temperature sensors and servos on the collector valves connected to an external thermostat - an analyzer that sends commands to the collector to regulate the water supply to the loops.

Sources

- https://eurosantehnik.ru/ne-rabotaet-ne-greet-vodyanoj-teplyj-pol.html

- https://ZnatokTepla.ru/teplyj-pol/pochemu-ne-greet-teplyj-pol.html

- https://samelectrik.ru/pochemu-teplyj-pol-ne-nagrevaetsya-i-kak-reshit-etu-problemu.html

- https://teplota.guru/teploizolyatsiya/ne-greet-teplyj-pol.html

- https://netholodu.com/teplyj-pol/elektricheskij/nagrevaniya.html

- https://netholodu.com/teplyj-pol/vodyanoj/neispravnosti.html

Combination of heated floors and radiators on one collector group

Radiators and underfloor heating pipe loops have different hydraulic resistance. By installing heating radiators on a heated floor collector, it may turn out that the radiators heat, but the heated floors do not. There is simply no circulation in them.

The coolant circulates through radiators because they have less resistance. You can tighten the radiator taps, thus creating resistance on them and the warm floors will begin to work. But then the power of the radiators will decrease significantly and their power will not be enough.

There is one collector for the warm floor, another for the radiators

Of course, you can calculate and select suitable radiators. But it will be much cheaper to install manifolds for radiators and manifolds for water heated floors.

Reason 1. Lack of thermal insulation

The most common reason why a heated floor does not cope with the functions assigned to it is that you simply forgot to install the thermal insulation properly, or did not install it at all. Often, a regular polyethylene foam backing is used as thermal insulation. And the substrate is simply not intended for thermal insulation of heated floors. Instead, you need to use polystyrene foam 5-10 cm thick.

How to fix it?

Keep one thing in mind. You will already have to overpay for heated floors. But perhaps the situation will be corrected by a higher temperature supply to the heated floor and the use of more powerful heating equipment. But don't overdo it. The maximum temperature should not exceed 70 degrees. And it shouldn't be permanent. Otherwise, the pipe will quickly become unusable.

Lack of calculation of heat losses

This mistake is made most often. Warm floors are made “by eye”. Installers roll out pipes as they see fit or as they are used to. Remember: any heating system is needed in order to compensate for the heat losses of the building. That is, any heating system replaces the heat that the house loses due to temperature differences.

This is important to understand.

In order to ensure that the power of the warm floors is sufficient and you do not freeze in winter, you need to calculate the heat losses.

An example of part of the calculation of heat losses of a private house

I've seen people who make heated floors + radiators. Although if you do the math, it may turn out that radiators are not needed. Or needed, but not so much. Or there will be few of them. Any of these options is either discomfort or lost money.

Extra radiators cost money, plus you have to pay for their installation. You don’t need to rely on your neighbor’s house; it may not be as insulated, or it may have a different house structure, different windows, ceilings, and so on.

I won’t tire of repeating: count the heat loss. It is this figure that will give you an understanding of the power of the heating system you will be making.

Why the heated floor doesn't work reasons why the heated floor stopped working

For complete comfort, many residents of megacities order a heated floor system. But after installation, you may suddenly discover that the heated floor does not work. Naturally, you can’t repair water floor heating yourself, but what first steps should you take?

The heated floor does not work: reasons and methods for solving them

The first thing you need to look at if the system is not functioning is the switch. It will help you understand why the heated floor does not work. There may simply be no electricity due to a tripped circuit breaker. It happens that the line is damaged and this leads to its sudden operation. Modern underfloor heating systems (most models) are equipped with special screens that show with a set of symbols that they are turned on. It's also a good idea to check the voltage using the terminals. However, a high-quality turnkey heated floor should not suffer from accidental breakdowns or accidents.

Often, even when there is voltage in the system and normal operation of the switch, it is noted that the heated floor does not work. Then the whole issue may be in the elements of the underfloor heating system, the regulator, or even the sensor. You need to know which of these elements are where. After all, when purchasing, you were not only interested in which heated floor is better, but also in what each of the devices does. The system is checked like this. Current resistance is measured. The value should be equal to the resistance of the cable selected as the heating element.

Measuring cable voltage is easy. You can perform this procedure for heating film. The voltage is divided by the resulting resistance. The resulting value is the current that is in the underfloor heating system. If you multiply it by 220 volts, you can get the power that a heated floor system needs. These values are also specified in the system passport. They need to be compared. If the resulting figure differs by a large amount, then perhaps you are dealing with a short circuit or simply damage to the insulating layer. This can also manifest itself in uneven operation of heated floors.

Since underfloor heating involves a high cost of work, it is not recommended to fix the problems yourself. More harm could be done. It’s better to call our specialists from , who will quickly determine the cause and fix the breakdown. At low power levels, the cause of the malfunction may lie in breaks. Naturally, you won’t be able to fix them yourself.

By the way, some unscrupulous sellers of this system not only do not say exactly how much a heated floor costs, but also do not provide a passport for it, so it is impossible to compare the data. In such cases, you have to take the average value.

If the data obtained indicates that there is no voltage at all, then we can conclude that there is a short circuit. The difficulty of repair lies in the fact that it is impossible to identify a fault in the concrete screed. After all, you will have to take out the cable and replace it. You will have to completely remove the screed and re-install it. In this regard, film flooring allows repair work to be carried out quickly and easily.

Often the reason lies not in the floor itself, but in the sensor. After inspecting the floor, we move on to it. A sensor is essentially a resistor, that is, it has resistance. Based on the resistance and temperature indicators, it is easy to calculate how correctly the system temperature sensor works.

If the regulator is damaged, you will know about it from the messages on the monitor. By the way, damage to the regulator is the most easily replaceable incident, since this element of the system is not located in the floor or under a concrete screed. It is enough to simply pull it out of the tube and replace it. The most unpleasant thing that can happen is that the small section of the wall to which it is attached is damaged. By the way, the price of this element is very reasonable.

The regulator is checked using a multimeter. You will also need to set the maximum temperature for the system. The terminals should show voltage. If you switch to the minimum temperature, the voltage in the terminals should disappear.

It is not recommended to carry out any repair work if the heated floor suddenly stops working. It’s better to call our company’s specialists, who will quickly and efficiently complete all the work for you.

Incorrectly selected flooring

This is a sore subject for me. We made warm floors, and the customer laid an engineered board on top. First he complains about the lack of power in the heating system, and then about the cracking of the engineered wood.

Warm floors work well with laminate

Most floor coverings can be combined with warm floors. But you need to calculate warm floors for laying this particular floor covering. That is, you need to decide on the floor covering before installing warm floors .

Heating is not at full strength

Sometimes consumers do not immediately notice that there is something wrong with their floor heater. It's on but doesn't heat well

An electric heated floor, depending on its type, has heating parameters set by the manufacturer.

On average, if the installation was carried out correctly, then for:

- Infrared film floor heating time will be 10-15 minutes;

- heating mats filled with glue will reach the temperature set by the thermostat in 6-8 hours;

- a cable floor “recessed” into a thick screed will take a day to warm up.

If the system took longer or did not reach the specified parameters, the reason for this may be:

- Incorrect installation of the temperature sensor. If it is placed too close to the heating element of the structure, it will cause the thermostat to turn off before the floor covering warms up.

- The sensor itself may fail, so it must be checked without turning off the thermostat.

- The cause may be low voltage, which can be avoided by installing a stabilizer.

- The floor can take a long time to warm up if the heat loss is higher than the system can produce. This can happen if there is no thermal insulation.

- Initially, incorrect calculations can significantly reduce the power of a heated floor.

As practice shows, in order not to wonder in the future how long it takes for an electric heated floor to heat up, you need to make the correct calculations at the stage of its installation and lay the system taking into account all the layers of the “pie”.

Types of heated floors

Heated floors are figuratively divided into 3 groups depending on the heat transfer components used:

A hydraulic heated floor transfers heat specifically to a concrete surface from metal-polymer pipes, in the middle of which a hot coolant flows. For the system to function, the hydraulic circuit is connected to the main heating system or the coolant is heated using a boiler.

Hydraulic heated floor

In an electrical system, a separated wire acts as a heating element, laid according to a given pattern on the heated surface. This can be a long product, or ready-made mats, in which the wire is laid with a certain step from the very beginning. To maintain the required temperature operating conditions, the system is equipped with a thermostat.

Infrared models are among the most progressive. They can actually be placed under various floor covering

. According to doctors, the infrared radiation generated has a good effect on human health.

Attention! Almost all types of heated floors have their own specifics. The reasons for failure in each specific case are determined individually depending on the operating principle of the system.

Infrared coating

Infrared film floors are the most modernized heating method. However, during their installation certain nuances may also arise.

The system is connected to the network by wires attached to a copper bus running along the entire edge of the film. They are connected using clamps. If there is insufficient contact, oxidation of the metal occurs. Gradually the chain breaks and the floor may stop heating. To correct the situation, the contact must be replaced and securely fastened.

- Film floors regulate the degree of heating using a thermostat. Accordingly, its failure leads to improper operation of the floors. This is an easily repaired unit.

- If the quality of heating deteriorates, the heated floor is checked by measuring the current consumed by the device. A deviation from the specified value in the passport of more than 10% indicates a breakdown of the heating elements. A broken tape can only be replaced. You can temporarily increase the heating temperature of the remaining elements using a thermostat. However, this is a temporary measure.

There are a number of reasons for failure that are common to all types of floors:

- Initially, you need to check that the heated floor is connected correctly to the network. Only after making sure that the input voltage is present can you further look for a breakdown.

- The main reason for heat loss is a small layer or complete absence of thermal insulation. The heat goes down (it warms the neighbors or the ground), rather than warming the floor. During installation, it is necessary to take into account the operating conditions of the floors.

- By measuring the resistance of a heated floor, you can easily calculate its power. By comparing the calculated value with the rated value, we can confidently say about the presence of short circuits and insulation damage (power greater than the rated value) or cable breaks (power less).

Underfloor heating is considered a low-temperature heater. The maximum surface temperature is 30°C. At higher temperatures, the floor covering (laminate, parquet) may deteriorate.

When using two heat sensors, heating the room is more efficient

No damper tape

You may remember from school that when heated, a substance expands, and when cooled, it contracts. It’s the same story with underfloor heating screed; when heated, it expands. To compensate for the expansion of the screed, a damper tape is installed around its perimeter.

The green thing nailed to the wall is called damper tape

You can buy ready-made damper tape. It is sold in many stores. We make it ourselves from centimeter-long polyethylene foam (foamed polyethylene). If we find one for sale. This is the cheapest way.

To compensate for the expansion of the heated floor screed with a damper tape, it is necessary that the maximum area of one fragment of the screed be no more than 40 m².

Causes of electrical system malfunction and its repair

There are several reasons for floor damage. Most often, this is a failure of heating elements, thermostats and temperature sensors.

The principle of location of the heated floor temperature sensor

Lack of power

If the electric heated floor does not work, the first thing you need to check is the presence of power. Information about this comes from the thermostat to which the heating elements are connected - the presence of voltage is indicated by the corresponding indicator or glowing icons reflecting the operating parameters of the system. If the display “shows no signs of life,” you will have to find out the cause of the breakdown by visual inspection and using a special tool - a multimeter, which determines the presence of voltage at the input contacts.

Multimeter

Important! The reason that the heated floor does not heat up to the set temperature may be low network voltage. The problem can be solved by installing a voltage stabilizer.

When detecting voltage at the input using a multimeter, you need to make sure that it reaches the heating cable or infrared film. First, you should refer to the system settings and make sure that the heating temperature is not set to minimum by mistake. After setting the temperature, check how well the wires are connected to the terminals - low or no heating is possible precisely because of the lack of contact.

Mechanical thermostat panel

When the connection and settings have been checked, but the floor still does not heat, check the voltage at the output - at the area where the heating system is connected to the thermostat. If, when turned on, the voltage in this place does not correspond to the network parameters, then the thermostat is replaced.

Touch floor heating thermostat

Advice. Direct connection of the heated floor to the network allows you to identify a malfunction of the thermostat. If it starts to heat up, then the reason is in the regulator.

Damaged cable

In an electric floor system, failure of the heating element is possible as a result of damage to the cable during installation. This causes it to burn out after some time. The cable can be damaged during floor repair work using a cutting tool or drill.

Damage to the thermal mat is determined using a thermal imager

To remove the heating mat for repair, the floor covering is dismantled. If it is a tile, then you can use a hammer to break the element directly above the breakage point.

How to remove tiles from the floor? This work is dusty and quite labor-intensive, but breaking is not building, and it can be done much faster than installing a ceramic coating. How to do it? Read in the special article.

It is important not to damage the thin mat that may be located immediately under the tile in the adhesive solution. To properly break the tile, blows are made starting from the center, moving towards the edges of the tile. To avoid damaging adjacent tiles, hammer blows should be directed towards the center of the tile being dismantled, and not away from it.

Removing tiles

After removing the tiles, carefully knock off the screed or dried glue to get to the heating elements and find out the reason for their failure.

Removing the adhesive layer and freeing the cable section in need of repair

The cause may be loss of contact in the coupling. This occurs if a sharp turn of the heating cable is made before or after the coupling. As a result, very large mechanical tensions are formed at this turn, and when the cable operates, it turns out that it pulls itself out of the sleeve connections.

A cable bend radius that is too steep can cause cable breakage.

To cut the coupling, it is heated using a hair dryer.

The coupling is heated using a hair dryer

They cut it off using a construction or stationery knife, freeing the problem area, which was identified using a thermal imager.

Removing the coupling

The problem with heating mat couplings is poor insulation between adjacent connection sleeves, resulting in the cable tearing itself out under mechanical stress. Therefore, it is extremely important not to allow the cable to turn sharply after the coupling.

Damaged area

Result of repair before placement in the coupling

Table 1. Cable repair (cold ends)

| Illustration | Description |

| The area where the broken or damaged cable is located is freed from decorative covering and screed. | |

| The wires at the ends must be stripped and connected using sleeves with a suitable diameter. | |

| The sleeves are crimped with special pliers. The sleeves in the insulator allow you to shorten the length of the coupling, which does not need to be extended to the side. | |

| The shielding braid is connected with insulation wire. When connecting the cold end to a heating cable, connecting the braid with a wire without insulation, you can get a decrease in the insulation resistance between the screen and the heating core with subsequent breakdown. | |

| To prevent the sleeve from affecting the heat shrink or puncturing it, the insulation wire is wrapped with electrical tape. | |

| Apply adhesive heat shrink. | |

| Heat it using a hair dryer. | |

| During the heating process, glue is released. As a result, the coupling becomes airtight and is not afraid even of immersion in water. The completion of the process is indicated by the glue protruding along the edges of the coupling. After this, it is necessary to allow the coupling to cool completely so that when it is moved, the glue does not peel off. |

Video - How to lay and connect an electric heated floor

Sensor failure

Damage to the temperature sensor results in insufficient heating of the system. When operating correctly, the floor heats up to maximum power and turns off automatically, otherwise the shutdown will not occur and energy costs will increase. When using a damaged temperature sensor, it is not possible to lower the floor heating temperature. There is no need to repair the sensor - it is easier to replace it with a new one.

Heated floor temperature sensor

During the installation of a heated floor, the temperature sensor is laid inside the corrugated tube, so there is no need to dismantle the floor covering and screed. It is enough to remove the broken sensor from the tube and install the working element in its place.

Video - How to make a future replacement of the temperature sensor

Incorrect installation

The conclusion about incorrect installation comes after checking all elements of the system and confirming their serviceability. If the floor heating temperature does not exceed 30 degrees, the reason is sought in the following:

- There is an error in calculating the heating power, which results in weak heating of the system.

- Poor quality insulation of the room, resulting in significant heat loss.

- Incorrect installation of heating elements, non-compliance with cable spacing, too thick layer of screed or incorrect location of the temperature sensor (too close to the floor surface).

Scheme for laying a warm electric floor in a bathroom

The only way to correct the operation of the system is to dismantle it and reinstall it, taking into account all the requirements, if installing the temperature sensor to the required height does not help.

Installing a temperature sensor

Among the common mistakes when installing electric heated floors are the following:

- Despite manufacturers' warnings, sometimes the heating cable is placed under heavy furniture and plumbing fixtures.

- When laying cables, materials are used that are characterized by low thermal conductivity - gypsum beacons when pouring the screed, construction waste caught in the screed, in the form of fragments of plasterboard, aerated concrete and other materials.

- The cable can be damaged after laying it, before pouring the screed, when walking on it, moving equipment, materials, tools, therefore, immediately before pouring the screed, check the functionality of the system again.

- A common cause of cable damage is the use of a spatula or grinder when jointing joints during the process of laying floor tiles, when it is necessary to remove excess hardened glue in the spaces between the tiles. Often the cable is laid directly into the layer of tile adhesive, so it is quite easy to damage it.

Coolant layout diagram

When laying a heated floor, it is necessary to have a diagram of the location of the coolant. It will be useful for subsequent repair work and operation of the system.

Use of low-quality materials

There is nothing wrong with a customer's desire to save money. Problems begin when the customer tries to buy the cheapest materials.

Let me give you an example. I sell materials to the customer and install a heating system. The customer tells me to sell him the cheapest materials. I earn, for example, 10% from materials.

A year later, the customer’s half-inch faucet leaked. I sold the cheapest faucet, from Leroy Merlin for 50 rubles. I earned 10% or 5 rubles from it.

I would never buy such a faucet in my life

The customer says: replace the faucet under warranty. I spend money on gasoline, spend my time traveling to the customer (we do projects with a distance of up to 1,000 km), drain the heating system, change the tap under warranty, fill the heating system and start it up.

Is this beneficial for me? Of course not. I earned 5 rubles, and then spent, at best, a thousand. Because he didn’t install a faucet for him for 300 rubles, which will stand for 10 years. And he installed a cheap one, which after a year leaked, or burst, or soured. Or maybe the ball turned in it or +100500 other reasons.

And it’s good that when the tap burst, no one was flooded and the customers noticed it in time. You need to save wisely. You can save on some things, but you don’t need to save on others, even if money is tight.

Reason 2. The system power was not calculated

It is generally accepted that the average heat loss in a home is 100 W per square meter. But often in some rooms they can significantly exceed this value. This is why the warm floor does not work at the proper level.

How to fix it?

First, calculate the heat loss of each room. The Internet is full of ready-made calculators. Compare the heat loss figure with those rooms where your heated floor does not work. Next, try adjusting the contours of the heated floor on the collector with priority to those places where the heated floor does not heat.

You do everything through experimentation. Do not hurry. Remember that the inertia of the floor is 2-3 hours.

In extreme cases, you will have to upgrade your heating system.

Incorrect pipe installation

This error occurs due to inexperience. This includes everything related to the quality of laying pipes for water heated floors. I saw how the pipe is attached to the mesh with binding wire. The pipe may expand and break at the attachment points.

It is better to use nylon ties, but they should not be tightened all the way. I saw how they fastened a pipe to the foam with staples, and then they came off when the screed was poured. This is not because the staples do not hold well, but because they were rarely installed.

Common heating problems

General scheme of operation of autonomous heating

The principle of operation of any heating system is the effective transfer of thermal energy from the energy carrier (gas, solid fuel, diesel, etc.) to water in pipes. The task of heating devices (radiators, radiators, pipes) is to transfer the resulting heat into the room.

And if the heating radiator does not heat, the reasons for this may lie both in the design itself and in the parameters of the system as a whole. Let's consider the common reasons for a decrease in the efficiency of a heating system:

- Low efficiency of the boiler heat exchanger. The water does not heat up to the required temperature;

- A particular radiator does not heat well. Possible reasons: improper installation, formation of air pockets;

- Changes in the technical characteristics of the system - an increase in hydrodynamic resistance in certain sections of the pipeline, a decrease in the bore diameter of pipes, etc. Most often, the consequence of such phenomena is that the heating circulation pump gets very hot.

In some cases, not one, but several of the listed problems arise. Often the main one is the root cause of the appearance of the following ones. Thus, the formation of an air lock affects the increase in hydrodynamic resistance, and as a result, an increased load on the circulation pump occurs.

Decorative grilles should not be installed on a heating radiator with poor heating or covered with a panel. Thus, the already low efficiency of its work will be artificially reduced.

Radiator does not heat up

Heating radiator design

Most often, problems with normal heat transfer occur in heating radiators. This is explained by their specific design - the coolant does not move through one pipe, as in a transport line, but is distributed over several.

In what cases does the heating radiator not heat? There are several factors that directly affect the correct operation of the battery.

Air locks in heating

Installed Mayevsky faucet

There are several reasons for the appearance of air locks in the heating system - excess temperature, water evaporation, etc. It is important that the consequence of this is the appearance of places in the line that are not filled with coolant. Most often these are heating radiators. To eliminate them, it is necessary to install a Mayevsky valve - an air valve that releases excess air from the device.

How to determine why a radiator does not heat well? The simplest method is a temperature difference on the surface. At the point where the air lock forms, it will be significantly lower, thereby preventing the normal passage of the coolant. To eliminate it, you must perform the following steps:

- Using a screwdriver or a rotary lever, the Mayevsky tap is opened;

- Add water to the system until the coolant begins to flow out of the tap along with the air;

- Shut off the water supply.

After starting the heating system, the surface of the radiator should heat evenly. Otherwise, repeat the procedure.

For normal heating of the radiator, you need to install an adjustable thermostat. Depending on the set temperature, it will automatically adjust the volume of coolant.

Improper installation and limescale deposits in pipes

Radiator connection installation diagrams

The efficiency of the radiator depends on the correct installation of the radiator. It should not be inclined relative to the plane of the floor and wall. If this condition has not been met, then the question will inevitably arise - why the radiator does not heat.

To check the correct installation of the radiator, you can take a standard building level. If the upper plane of the battery has deviations, re-installation should be performed. It is best to use new reinforced fasteners for this.

If after this the question of why the heating radiator does not heat remains unresolved, it is recommended to flush the heating system.

This problem is relevant for old pipes and radiators made of steel and cast iron.

Over time, a limescale layer accumulates on the inner surface, preventing the normal flow of coolant. There are several ways to perform the washing procedure:

- Hydraulic. A special pump is connected to the system circuit, which creates high water pressure. Under the influence of this force, the scale is broken into small fractions and retained in the pump filter;

- Chemical. Special additives act on limescale, which loses its uniformity and flakes off from the inner surface. Subsequently, hydraulic flushing is performed to remove residual debris.

Experts recommend using a comprehensive method to solve the problem in which the radiator does not heat up. After checking the correct installation, the system is flushed, and then filled correctly with the Mayevsky tap open.

If a two-pipe heating system does not heat due to clogged pipes, you need to carefully choose a cleaning technology. For pipelines made of polypropylene, chemical cleaning cannot be done.

The boiler does not heat the radiators

Boiler heat exchanger before and after cleaning

Often, a two-pipe heating system does not heat due to the low heat transfer rate of the boiler exchange circuit. This leads to a decrease in temperature and, as a consequence, a loss of efficiency of the entire system. Not every boiler model provides an easy way to dismantle the heat exchanger. If the heating does not heat well due to the appearance of plaque on the internal elements of the boiler, you can perform flushing without this procedure. To do this you will need a pump with a filtration system. The cleaning procedure is as follows:

- Disconnecting the boiler from the general heating system;

- Connection to the inlet and outlet pipes of the pump hoses;

- Filling a special cleaning liquid into the boiler heat exchanger;

- Using a centrifugal pump increases the speed of fluid passing through the boiler.

After this, the radiators should not heat up poorly. Particular attention should be paid to the flushing fluid. It should not harm the metal elements of the boiler and system. Therefore, at the end of the procedure, the entire system should be rinsed with distilled water.

To avoid the appearance of scale, before pouring water into the heating system, you need to reduce its hardness level. The use of running water is not recommended as it contains large amounts of calcium and magnesium bicarbonates. They are the main source of limescale deposits not only in the boiler heat exchanger, but also in pipes and radiators.

The best way to clean the heat exchanger is to dismantle it. This way you can not only remove the entire volume of scale, but also ensure its integrity. After this procedure, the heating system should not heat poorly.

Pipelines: reasons for low heating

Determining air pockets in batteries using a thermal imager

Failures in the heating mode are typical for a two-pipe heating system. In this case, the supply line that distributes the coolant to the radiators does not heat. Identification of the “problem” area can be done by measuring the temperature on the surface of the pipes or a thermal imager.

Natural circulation

Pipe slope for heating with natural circulation

What can cause such problems? If the heating does not heat well, the slope of the line may not be observed. This only applies to natural circulation systems. According to the standards, the slope of the pipes should be 10 mm per 1 m.p. In addition, the direction is taken into account - from the accelerating riser to the radiators. For the return pipe, the slope must be towards the boiler.

At the first stage, it is necessary to measure this indicator using a building level. If it meets the standard, but the heating radiator does not heat, there is a possibility of air pockets forming. In this case, an integrated approach is recommended, which includes the following steps:

- Measuring the angle of inclination. If necessary, change it to the required value;

- Flushing pipes to remove limescale;

- Filling the system with coolant with open Mayevsky taps on the radiators.

This technique will eliminate the low heat transfer rate of the heating system.

To improve circulation, a circulation pump can be installed in open systems. If it overheats, you need to install an additional one. This is often necessary for branched heating systems.

Lack of heating system testing

After installing heated floors, tests must be carried out. In common parlance they say pressure testing. This is when water or air with excess pressure is pumped into the heating system and leaks are checked.

We pressure test all the systems we install: heating, water supply and sewerage

If air is pumped into the system, then such testing is called pneumatic; if liquid is pumped in (usually water), then such tests are called hydraulic.

When liquid is pumped in, the leak is more visible than when pressurizing with air. A significant disadvantage of hydraulic pressure testing appears in winter; the system may freeze.

We have had cases where in winter the crimping of an insulated Swedish stove was done with a car compressor

Or water was pumped into the heating system in the spring, but the house was not completed before winter and the water needs to be drained. Then someone drilled the pipe and remained silent. You finish the repair, fill the system, and it leaks. And the tiles or laminate are already laid.

It is better when the heating system is under pressure, and if someone drills a pipe, you will immediately see on the pressure gauge that the pressure has dropped.

Such mistakes are much easier to correct during the construction stage than when the finishing has already been done.

To avoid damaging the water heated floor pipe when pouring the screed, create double the operating pressure in it. This will save the pipes from being crushed or crushed.