Every motorist knows the problem of cold in the garage with the onset of winter. Repairing a car turns into a test of strength, and the risk of developing a fever increases significantly. The problem is solved by installing a heated floor in the garage, and whether it will be electric or water depends on the specifics of the room and the personal preferences of the owner. You can install the insulation yourself, without the help of specialists. To do this, you just need to familiarize yourself with the stages of the work and prepare the necessary materials.

Types of heated floors

It is not at all necessary to warm up the garage to “home” temperature, unless, of course, you plan to live in it. Instead of 18-20 degrees, 15 will be enough to feel comfortable. For this purpose, preference is given to water or electric flooring. They differ from each other in the installation principle, characteristics and design, but they have the same task - heating the room. If you are just planning to build a garage, then the option of floor insulation needs to be considered at the design stage.

Water

An economical option for insulating a garage is laying a water-heated floor. However, it requires installation or insertion into an existing heating circuit, and this is not always possible.

At the initial stage of laying the floor, some financial investments will be required, which will fully pay for themselves in the future due to energy savings. Installing a boiler in a detached garage, without a central heating system, is not profitable from an economic point of view, but is sometimes still used when other options are not possible.

What is a coolant water circuit? In autonomous systems, the heat source is a gas, electric or solid fuel boiler. Heated floor devices may be different, but they all work on the same principle: water heats the pipes, then heat is transferred to the screed and floor covering. The heated floor releases heat into the air and the garage space is heated.

Electric

Structurally, an electric floor is simpler than a water floor, but its operation requires a large amount of electricity. In this heating option, heating occurs due to heat release in a flexible conductor under the influence of electric current flowing through it. The conductor heats the screed adjacent to it, from which heat is released into the air.

There are two types of electric floor:

- cable, the main element of which is an electrical cable. It can be single-core, double-core and self-regulating;

- infrared. The heat source is a flexible or carbon rod emitter that generates waves in the infrared range.

You can install an electric heated floor in your garage.

Installing an electric heated floor will not cause any difficulties, but if the winter is very frosty, the amount of your electricity bill may be an unpleasant surprise. To reduce costs, you need to pay special attention to the thermal insulation of the walls and ceiling of the garage. To do this, lay a layer of insulation no thinner than 60 mm.

Pros and cons of heated floors in the garage

Before deciding to install a TP in the garage, you need to evaluate all the advantages and disadvantages of such a device. Here they take into account the region of residence, weather conditions, financial capabilities and characteristics of the premises. The general advantages of water and electric heating options are as follows:

- maintaining temperature at a certain level;

- large heat transfer area, increasing heating efficiency;

- uniform heat distribution;

- the possibility of installing an automatic system, which gives the advantage of remote heating control.

The disadvantages of heated floors in the garage are:

- frost will constantly appear on the outside of the garage door;

- metal parts of the gate can freeze to each other;

- evaporated moisture in the air will condense on cold structural elements and form icing.

It is necessary to highlight all the pros and cons of each type of heated floor. The electric option is good because:

- only one socket is required for connection;

- simple installation;

- complete set with a small number of elements.

- heating up to +28 degrees makes the operation of the room safe.

The disadvantage of electric flooring is its high cost. Electricity costs a lot, and this type of garage heating will increase costs. There is also a disadvantage of such a floor in subsequent repairs. If the insulation breaks or the wiring is damaged, you will have to disassemble the entire surface to find the location of the breakdown.

The advantages of a water floor are its low cost compared to the electric option. It is also easy to install and maintain. Such a heating system will last for decades. You can connect the water heated floor in the garage yourself. The disadvantage of a TP with a coolant is the need to connect it to a centralized circuit. If there is none, then arranging a water structure can cause difficulties.

To do or not to do?

On the one hand, you get the opportunity to always maintain a comfortable temperature in the garage even in the coldest period. In this case, the heat will be distributed evenly over the entire area of the room, which is impossible when using autonomous convectors.

However, there is a downside to everything: due to the temperature difference, frost will appear on the gate, and condensation will invariably appear inside the room. It also makes sense to use underfloor heating in your garage if you use it frequently. Periodic switching on will not give a noticeable result in warming up, and the potentially high efficiency of the system will remain unrealized.

And one more point, no less important: all installation work must be carried out in full compliance with the requirements of SanPin. Therefore, studying them carefully is your obligatory task.

Requirements for heated floors in a garage

Installing underfloor heating is one of the most effective methods of heating a room. Like all repair processes, installation of heated floors requires compliance with certain rules. First you need to draw up a diagram according to which the garage will be heated. With its help, you can calculate the amount of material required and the power of CO.

The requirements for installing an electric heated floor in a garage are as follows:

- the distance between heating elements should be at least 4-5 cm from furniture, central heating system risers and household appliances;

- to effectively heat the room, underfloor heating elements must cover at least 75% of the entire garage area;

- The control unit is placed at least 50 cm from the floor.

Electric heated floor in the garage

Before making a heated floor in the garage, you should find out whether the wiring already installed will withstand the increased load. If you have no knowledge in this area, it is better to take the advice of specialists.

The requirements for installing a water-heated floor in a garage are slightly greater, and some of them are met in accordance with building codes and regulations.

- The distance between the heating circuit and the wall must be at least 15 cm.

- The temperature of the heated floor in the garage should not exceed 30 degrees.

- The temperature difference in different parts of the room should be at least 10 degrees.

- The maximum permissible water temperature in the circuit is up to 55 degrees.

- Warm water floors are laid only on a flat base. The permissible error is 5 mm.

- To prevent heat leakage, thermal insulation in the form of foil material up to 10 mm thick is laid in the lower parts of the garage.

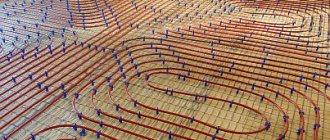

- The loops of the circuit are laid in one of the following ways: “single coil” or “spiral”. But it should be remembered that the first option is suitable for local heating of some part of the garage.

- Installation of pipes is carried out according to the markings on the heat insulator. It is done using anchor brackets, which are attached in increments of 30-40 cm.

- When screeding, the pressure in the pipes must be 0.3 MPa.

If these requirements are not met, the water heated floor in the garage may not work correctly, and if electric heating is installed, there will be a risk of a fire hazard.

What material is best for thermal insulation?

An example of insulating a screed floor with foil-coated polystyrene foam.

Today, stores offer a huge number of different materials for insulation. Its choice depends on the characteristics, as well as on the structural features of the garage.

The most common materials can be classified into one of two types:

- Foamed polymer materials. These include polystyrene foam, polypropylene foam and polyurethane foam. They can be purchased in blocks, slabs or panels. Such materials are among the most affordable (especially foam plastic), they are easy to install, and they are airtight. The features of such materials include the need to equip a ventilation system, this will avoid the accumulation of condensate;

- Materials based on mineral fibers. This type includes glass wool and mineral wool. Typically they are sold in rolls, mats or slabs.

Less common is the insulation of garage floors with expanded clay, roofing felt and other materials.

The criteria for choosing a material as insulation include health safety, fire resistance, level of load resistance, sound insulation, etc. When choosing insulation, these features should be taken into account. You can learn more about the topic of thermal insulation in the garage in the video.

Electric floor installation technology

Having decided to install an electric heated floor in the garage, you need to think through all possible options for saving energy. To do this, pay attention to the area of the room, existing insulation, the quality of thermal insulation of doors and windows, as well as the type of floor. The less heat leakage, the less electricity will be required for proper heating.

Tools and materials

When preparing the necessary tools and materials for installing the heating element in the garage, the first thing people pay attention to is the heating element. There are several options:

- heating mat - a flexible tape completely ready for installation, with woven cores;

- resistive cable - is a single- or two-core element that heats up to a certain temperature;

- self-regulating heating element. Installation of such a cable is rational only if there is an air gap between the floor and the objects installed on it to remove heat;

- infrared cable with film - consists of two layers of dense polyethylene, between which heating elements are laid;

- infrared rod - consists of flexible emitter rods laid between two conductors with a pitch of 9-10 cm.

In addition to heating elements, you will need the following materials:

- connecting wires;

- mechanical or electronic thermostat;

- RCD

- ground cable;

- damper tape;

- screed materials;

- fasteners.

The tools you will need are:

- perforator;

- chisel;

- metal scissors;

- Screwdriver Set;

- roulette;

- level;

- level.

When everything you need is at hand, you can begin preparing the floor.

Preparatory work

Any garage sits on the ground, so to prevent some of the heat from escaping into the ground, the floor needs to be prepared.

- Pour the first layer of screed, making it as even as possible

- After the first layer has dried, a layer of thermal insulation made of penoplex or polystyrene is laid. The layer is 7-10 cm.

- If a heating cable is used, a tape is mounted under it to ensure secure laying of the wire. If mats are used, then it is not necessary to glue the tape.

The preparatory work includes insulating the floor with penoplex.

The heating wire is laid in a zigzag with a step of 25 cm. Crossing or bending the heating cable is unacceptable.

Installation instructions

Anyone can install a heated floor in a garage with their own hands, even without experience. The heating cable is laid as described above and fixed using special clamps on the mounting tape. The turns of the wire are laid parallel to each other without excessive tension. The junctions of the wires and contacts are insulated with bitumen mastic.

After the heating elements are laid, you need to install a temperature sensor. To do this, a small recess is made in the thermal insulation at a distance of about 50 cm from the wall and 30 cm from the floor, into which a corrugated pipe with a diameter of 2 cm is placed. The thermostat is placed in it. The pipe allows you to replace the sensor after pouring the screed.

Connections to underfloor heating elements are made with copper wire. The system can only be connected to the network through its own residual current switch. After connection, the system is checked for functionality. If everything works properly, fill in the final layer of screed.

Laying a water floor

A heated water floor in a garage can be laid on any existing base. Installation begins with design: calculation of thermal power and circuit length, selection of materials and control devices.

Materials and tools

On sale you can find standard water floor kits with automatic temperature control. Typically, such systems are designed to heat a room from 60 to 80 square meters.

For work you will need the following materials and tools:

- metal-plastic pipe;

- plasticizer;

- heat-insulating mats;

- three-way mixing valve;

- circulation pump;

- thermostat;

- fittings for plastic pipes;

- servomotor for mixing valve.

To install a water heated floor in a garage, you will need heat-insulating mats.

You will also need a standard set of tools for installing a heated floor in a garage with your own hands.

Calculations

The calculation consists of a pipe laying diagram. It is important to consider the distance between the turns and their length. If the heat exchanger in the garage will be the only source of heat, it is recommended to take steps of 10 cm. If there are other heating elements, then installation can be done in steps of 30 cm.

To calculate underfloor heating with coolant, special calculators and formulas are used. Independent calculations can be performed using averages, which are often used for installing floors in garages. The calculation includes:

- cross-section of the metal-plastic pipe - 1.6 cm;

- circuit length for heating a garage with an area of 60 sq. m. — 70-80 m;

- circulation pump power - at least 2 l/s.

At walls and gates, pipe loops are laid in smaller increments. Closer to the middle it increases. The supply pipeline is laid closer to the outer walls.

Preparatory activities

Preparatory work before installing a water transformer includes cleaning and leveling the base surface. To do this, the floor is poured with a layer of concrete screed and left until completely dry.

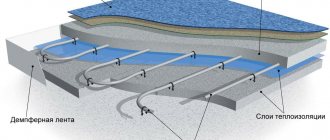

A heat-insulating material no more than 3 cm thick is laid on a flat floor surface. It is secured on top with a damper tape around the perimeter. In this way, the thermal expansion of the screed is compensated.

The next layer will be the laying of dense polyethylene film and reinforced mesh, to which the heating pipe will be attached.

Installation stages

The installation of pipes through which the coolant will move is carried out in one of the following ways: “snail” or “snake”. Next, the following connection steps are performed.

- The pipe is attached to the reinforcing mesh using plastic clamps.

- A valve is installed to drain water from the system.

- The operation of the system and its tightness are checked. For this, coolant is pumped under pressure 2.5 times higher than the operating parameter. If the pressure does not drop within 24 hours, then the system is sealed.

- A layer of screed at least 10 centimeters thick is poured on top.

- The floor is covered with film to ensure proper hardening of the screed.

- After a month, you can conduct a test run of the system.

As a decorative finish for the garage floor, you can use porcelain tiles or paint the surface.

DIY installation

Since the installation of any TP (both water and electric) is carried out approximately the same way, we will describe the general scheme. It is assumed that the old screed (if there was one) is no longer in the garage, and everything has already been removed from it.

This is roughly what the floor “pie” looks like: bedding (not visible in the photo), insulation, heated floor, reinforcing mesh and concrete screed

How to do TP correctly:

- We draw up a floor plan and a TP layout diagram.

- We start with waterproofing. We choose any material and lay/fuse it with an overlap on the walls (if we also repair them). If we are working not on floors or concrete, but on soil, we first tamp it down, and then add a backfill of sand and crushed stone. We leave only the required height for the concrete screed.

- We lay thermal insulation. We determine the height ourselves, it depends on how cold it is in your region, what is under the garage (ground, floor, whether there is a basement, whether it is heated and insulated), and what your budget is. A common solution is a 5 cm layer of extruded polystyrene foam (labeled EPS, can be foil). An alternative is a bulk heat insulator (expanded clay, perlite, vermiculite) in a layer of 10-20 cm.

- We lay the heated floor itself (collector, mats or heating cable). We connect it (to the heating network or to a socket/electrical network and to the regulator), and check its functionality.

- We lay reinforcing mesh on top. To prevent the mesh from coming into contact with the TP, we place pieces of excess polystyrene foam under it or spread cement mortar.

- We install the guides and fill the screed.

After pouring, we wait for the screed to dry completely, and “inhabit” the updated garage.

How to properly make ventilation for a spray booth (for painting a car)?

How to arrange ventilation in a chicken coop: a review of schemes for poultry houses of different sizes

Related Posts

Safety considerations

Any construction activity increases the risk of injury. To prevent this from happening, when laying the TP you need to follow some safety rules:

- It is better to install an electric heated floor using plastic rather than metal reinforcing mesh;

- the electric floor is not checked without ensuring the quality of the contact insulation;

- installation of a water TP eliminates contact of water with the electrical network.

If all processes are carried out correctly, the garage will become a comfortable room for doing what you love.