- Catalog

- Water heated floor

Mixing units and valves (equipment for the preparation and circulation of underfloor heating fluid)

Manifold blocks (modules of distribution and control valves)

Pipes for water heated floors (pipes for built-in heating systems)

Automation for controlling water heated floors (control and regulation devices)

Accessories for water heated floors (additional fittings, fittings and instrumentation)

Construction materials for water heated floors (materials for “wet” and “dry” installation of heated floors)

Manifold cabinets (distribution cabinets)

Standard kits for installing heated floors (technical specifications)

Water heated floor - comfort and efficiency

Modern standards and requirements for buildings are aimed at reducing heat loss and increasing the energy efficiency of heating systems. This is a prerequisite for the further development and implementation of built-in heating systems, primarily water heated floors (underfloor heating).

Thanks to energy efficiency and the ability to create the most comfortable temperature conditions for a person in rooms, water-heated floors have firmly entered the arsenal of engineering equipment in a residential building. Currently, heating based on water-heated floors is provided in many residential buildings under construction and reconstruction.

Liquid floor heating system

Underfloor water heating is considered more economical than heating a house using radiators. Warm air that comes from the floor rises from bottom to top. This creates a comfortable microclimate in the room. Cooling down, the air flow rushes to the walls and returns again to the floor or leaves the room due to ventilation.

On the floor and at the level of an adult’s head, the air warms up to a comfortable temperature. The temperature regime is programmed for each room separately or for the entire system as a whole.

With radiator heating, a warm flow of air immediately rushes upward from the appliances to the ceiling. Cooling down, it begins to sink down towards the floor. In this case, the floor covering remains cold and the ceiling is warm, which is not always convenient for household members. In addition, radiators may be incompatible with the design of the room. With water heating, all pipes are hidden under the floor. How does the “warm floor” system work?

- Initially, you will need to organize a heating source, stove or boiler. For a wood or liquid fuel stove, it is recommended to equip a boiler room.

- A separate room is not provided for an electric or gas boiler of low power. Boilers are installed on the floor of the house or mounted on the walls.

- Inside the furnace or boiler there is a water circuit, a heat exchanger. It is initially filled with water.

- The heat exchanger heats up in the firebox, forcing water to circulate through the pipeline.

- Hot liquid enters the pipes.

- Giving off heat, it returns back to the boiler.

We recommend: How to install Onor heated flooring?

Automatic control is connected to the system in order to be able to regulate the operating mode of the heating equipment. Connecting units are installed in the circuit, which allow you to drain excess liquid into a storage tank, turn off the floor heating as needed, and switch the heating to a radiator system.

Warm floor "Valtek" has its advantages over electric floor heating. You can lay any cladding on the floor and install interior items without restrictions. “Locking” of the system will not occur, the line will not overheat.

Water heated floor VALTEC

The VALTEC brand was one of those who had a serious influence on the popularization and development of built-in heating systems in Russia and other neighboring countries. In our range you will find everything you need to create the most comfortable and reliable underfloor or combined heating system.

- Thoughtful, practice-tested technical solutions.

- Quickly complete the project with products of one brand.

- Optimal cost.

- The choice of equipment depends on the customer’s requests and budget.

- Easy installation and operation.

- Comprehensive technical support.

Advantages of VALTEC underfloor heating:

Modules as a principle

The use of ready-made VALTEC units and modules, designed specifically for underfloor heating systems, allows you to quickly solve the problems that arise when creating a water-heated floor.

The use of VALTEC pumping and mixing units and manifold blocks in water heated floor systems saves money and time, and allows you to minimize the likelihood of design and installation errors. The equipment is compact, reliable, easy to use, and its installation does not place excessively high demands on the qualifications of the installer.

At the same time, we offer modules of various functionality, price categories and do not exclude other solutions (in particular, based on mixing valves and thermostatic kits) - where they are more appropriate.

Advantages of the Valtek system

- Exceptionally reliable. High-quality materials and fasteners, the system is equipped with blocks and modules manufactured by the manufacturer itself virtually eliminate the likelihood of errors when performing calculations and design, which already indicates guaranteed stability and efficiency of operation without the risk of leaks.

- The company's product line includes everything that is necessary for installing a heating system, including accompanying materials, for combining it with the future finishing coating, and organizing hydro- and thermal insulation. In other words, everything that will ensure maximum energy efficiency of the heated floor used.

- The manufacturer uses uniform standards in production that ensure full compatibility of all possible structural components, as well as materials.

The choice is for the client

Unlike many other manufacturers of underfloor heating systems, our company provides customers with a flexible approach when choosing equipment and materials. This applies to all groups of products offered.

The ability to maneuver in the configuration of a VALTEC water heated floor allows the customer to provide the level of comfort they require without overpaying for the system, and also to select materials depending on the priority installation technique.

In particular, taking the use of VALTEC PEX-AL-PEX metal-polymer pipes as the base option, we have included in our assortment other types of pipes for built-in heating systems (pipes for water heated floors).

PEX-EVOH pipes

In most cases, the company's specialists recommend using pipes made of cross-linked high-density polyethylene. Currently, the range includes 2 models with diameters of 16 and 20 mm. A system of fittings made of brass alloy is used as connecting elements.

Since cross-linked polyethylene is capable of transmitting oxygen molecules, the surface of the pipelines is covered with a protective layer of polyvinylethylene. If you install simple garden hoses, which look very similar to PEX-EVOH, then saturation of oxygen in the water will lead to rapid rusting of the steel components.

Modern technologies

VALTEC water heated floor is an opportunity to get a system equipped with all modern functions, such as weather-dependent regulation or heating control according to a given time program and/or according to a given room temperature. The level of automation of the system is determined by the wishes of the customer (see section “Automation for controlling water heated floors”).

Installation of Valtek underfloor heating

It’s worth saying right away that all work on installing such a water floor must be carried out by qualified craftsmen. Only in this case is there a guarantee of high-quality and correct assembly and, as a result, successful completion of installation.

Installation instructions for Valtek heated water floors:

- First, the manifold cabinet is installed.

- A pumping and mixing unit and a manifold block are installed in it.

- Level the floor surface in the room.

- Lay out the damper tape along the edges of the room.

- They do vapor and waterproofing.

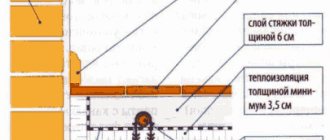

- Lay insulation.

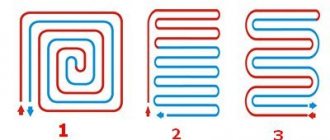

- Lay pipes using any of the options.

- Connect the pipes to the collector. Conduct hydraulic tests.

- All automation is connected.

- After all, the floor is filled with concrete screed.

It must be said that Valtec water heated floor is universal, i.e. You can lay both finishing tiles and parquet on it. The only important condition is the top layer of screed, at least 2 cm thick, which ensures uniform thermal distribution over the floor surface.

From tool to fitting

One of the main principles of VALTEC is to offer not individual components of engineering systems, but a range of products for their creation. In relation to water heated floors, this means the presence in our assortment of both basic equipment and building materials, connecting parts and fasteners, and installation tools (“Components for water heated floors”, “Building materials for heated floors”, “Tools for installing pipes” ). In addition to our own brand products, we sell underfloor heating products from our partners; they are presented in the “VALTEC Recommends” section of the catalogue. Getting everything you need from “one source” is beneficial in all respects.

Operating principle of underfloor heating

The Valtec heating system consists of two sections. The first looks like pipes laid in a special way on the floor, produced using a unique technology. These pipes are heated by the second section, which consists of a pumping and mixing unit.

In the figure you can see a diagram of the universal connection of a Valtek water heated floor through a boiler.

Connection diagram for Valtek heated floor through a boiler

The pipes offered by the manufacturer are represented by basic models:

- Metal-plastic pipe. It is designed specifically for organizing drinking water, ceiling and radiator heating. The diameter of the pipe is 16-40 mm. It can be easily bent, and the top layer of protection will not be damaged. Fastening is done using clamps.

- Red pipe made of cross-linked polyethylene. Produced for organizing underfloor heating and heating the room. The surface is smooth from the inside, which eliminates the risk of dirt plugs forming. Pipes are not afraid of temperature changes, they are not subject to corrosion, mechanical stress, and cannot be crushed or flattened. The outer shell provides excellent protection against cement exposure. It will serve properly for more than half a century.

To connect the pipes, press fittings are used - also a unique development by Valtec. Pipes are laid either in a spiral or in a circle. The pumping and mixing unit includes a pumping and manifold block, control and shut-off valves, as well as special wall mounts and sockets for installing auxiliary equipment. The coolant is prepared from water and glycol antifreeze.

How to choose a boiler for a warm water floor?

Technical support

VALTEC specialists provide customers with technical support at all stages of the creation and operation of water heated floor systems.

- At your disposal:

- free program VALTEC.PRG and training video course on calculating water heated floors;

- a huge amount of reference and educational materials (articles, technical manuals, etc.);

- free training in the format of seminars and webinars;

- video materials on the VALTEC YouTube channel.

You can obtain comprehensive information on VALTEC products, their selection, installation and configuration by contacting VALTEC specialists by phone or using the feedback form on the website.