No. 1. Advantages and disadvantages

An electric heating boiler works extremely simply. In it, electrical energy is converted into thermal energy. When the boiler is turned on, the heating elements heat the coolant. The latter enters the living space through a system of pipes and radiators and heats the air in it. In the simplest and most common version, the usual heating element is used as a heating element, but there are also induction and electrode boilers in which heating is carried out somewhat differently. The only thing that remains unchanged is the power source – electricity. Many boiler models are equipped with a monitoring and control mechanism.

Despite the fact that electric boilers can hardly be called an economical source of heat, they are very popular, and there are many reasons for this. The advantages of electric heating boilers include:

- versatility. The unit can be installed wherever there is electricity ; no permits from technical supervision authorities are needed. Today, electric boilers are used both in private homes and apartments, as well as in commercial and industrial premises;

- low cost compared to gas and solid fuel boilers;

- high efficiency , which reaches 95-99%;

- ease of installation. Electric boilers are small in size , and when connecting them there is no need to build a chimney;

- ease of operation and temperature adjustment. Most models are equipped with convenient control systems and thermostats, so the user just has to press a few buttons or turn a lever - he won’t have to constantly run to the boiler, control its operation, or, worse, add fuel. Since the boiler perfectly controls its operation, its efficiency increases;

- safety . There is no open fire in electric boilers, and no flammable fuel is used. Plus, well-thought-out automation is used, so the likelihood of emergency situations compared to other types of boilers is sharply reduced, if, of course, the installation was carried out correctly;

- compactness, so installation of such a unit is possible even in the smallest rooms;

- environmental friendliness, because no harmful emissions are generated during boiler operation;

- noiselessness;

- no need for constant monitoring of operation (you can leave the boiler unattended) and frequent maintenance. Solid fuel boilers, for example, require constant care and cleaning;

- a wide range of. There are models on the market with different power (from 2 to 60 kW or more) and functionality (single-circuit and double-circuit).

disadvantages :

- high cost of operation. Despite advanced automation and energy saving systems, electric boilers are still quite expensive to operate. In most cases, it is not profitable to use them for heating large rooms. Often such boilers are used as a backup heat source ;

- dependence on the availability of electricity. If the region experiences frequent power outages, then this heating option is not suitable;

- the need for special three-phase wiring if a boiler with a power of more than 12 kW is used. Some experts recommend using a line with three phases even when connecting a boiler from 6-7 kW.

Despite the existing disadvantages, electric boilers find their buyers. Moreover, if you carefully analyze the conditions at the site where you want to create a heating system and choose the right electric boiler, you will be able to enjoy the positive qualities of these devices to the maximum.

What types of boilers are recommended for water floors, basic requirements

There are no boilers designed specifically for heated floors with circulating liquid inside, and not all existing models can be used. The equipment passport specifies the possibility of installing them with heating systems.

The main requirement for a boiler with an electric motor for heating with circulating liquid is to operate in low-temperature mode, that is, not to heat the coolant above 55 degrees. Then, it will warm the surface up to 30 degrees, and this is a comfortable level of heating.

Professionals advise installing warm water floors in the house from electric low-temperature boilers. To maintain the required water temperature, they must have a regulator; induction types and most heating elements have one. But electrode types are not low-temperature; they have a minimum heating temperature of 60 degrees, so without a mixing unit they are not suitable for heated floors.

It is possible to use condenser gas boilers that operate efficiently when heating a small amount of water. Simple gas ones, for installation in a structure with water floors, are suitable only if a mixing manifold is additionally installed.

Solid fuel boilers are also not the best model for hydrofloors. To ensure proper operation, it is necessary to install a number of additional components (mixing and distribution unit, thermostat, pump, etc.), but even so, it is difficult to achieve the desired level of water heating.

How to choose an electric boiler? Advantages and differences of Protherm and Stout boilers

No. 2. Types of electric boilers by type of heating element

Depending on how the water is heated, all boilers are divided into heating elements, electrode and induction.

Heating elements new boilers

This is the most popular version , and so popular that when talking about electric boilers, as a rule, they mean designs with heating elements. This unit works on the principle of a boiler. Electricity is supplied to a tubular electric heater (TEH), it heats up and transfers heat to water, which is used as a coolant. The heating element consists of a nichrome spiral and a durable shell made of steel, aluminum or titanium. The space between the spiral and the shell is filled with quartz sand or other dielectric filler.

The rated power in such boilers is achieved abruptly, approximately 10-15 minutes after switching on. Heating element boilers operate in flow mode and can be single-circuit or double-circuit. As a rule, several heating elements are placed in the boiler tank.

Since there is no direct contact of the heating coil with water (the dielectric plays the role of a separator), there is no need to be afraid of a short circuit. The main problem of such boilers is different. scale appears on it relatively quickly , which can gradually damage the boiler. To slow down this process or even avoid it completely, it is better to use distilled water in the system. Special liquids are also sometimes used. The boilers are protected from overheating of the coolant by a thermal regulator, but if a leak occurs, the unit risks overheating and failure.

Electrode (ion) boilers

The design of this boiler involves the presence of two electrodes immersed in a heat exchanger. Electrical energy is supplied to them, due to which a potential difference is created. Due to the presence of salts in the coolant, it turns into a current conductor. Electricity passing through the high resistance electrolyte causes it to heat up. Just a couple of minutes is enough for the boiler to reach its rated power. Specially prepared water or ethylene glycol-based liquid is used as an electrolyte (coolant)

Boilers of this type are quite economical , and to provide the same thermal power as a heating element boiler, they consume almost half as much electricity. Such units, as a rule, have reliable, well-thought-out automation and rarely fail, since, in fact, there is nothing to break here. If a leak occurs in the system, overheating will not occur - there is no electrolyte. Electrode boilers also perform well under unstable voltage conditions. If it drops down to 180 V, the unit will continue to operate and produce heat.

The only downsides are the cost of the equipment and the need to use specially prepared coolant. Its composition will determine how much energy the boiler will spend on heating. Another nuance is the need for reliable grounding. The electrodes will have to be changed periodically.

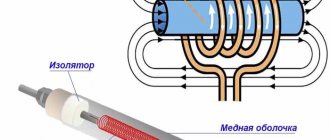

Induction boiler

Boilers of this type began to be used back in the 80s of the last century, but at first they were installed only in production. The production of household models began only towards the end of the 90s. Their operating principle is quite complex and resembles a transformer. The heart of the unit is an induction coil, which converts electrical energy into a magnetic field, directing it to the core. The latter is a system of steel pipes with coolant inside.

The system performed well. Induction boilers are economical and very compact , durable (service life 30 years or more) and fireproof, and the problem of scale is not a problem with them. There are no strict requirements for the coolant, as in the two previous types of boilers - even purified petroleum products can be filled.

The main disadvantage is the high price . In addition, induction boilers weigh decently, despite their miniature dimensions. You won’t be able to find a model lighter than 20 kg.

Which boiler is better to choose depends on your budget and your requirements - all three types can be found on sale.

Heating options

If it is possible to connect to the gas mains, we recommend choosing a gas boiler without hesitation, even despite the complex process of its registration. Otherwise, from an economic point of view, electric heating boilers are not always justified.

Electric boilers are compact in size, require a minimum of wiring and have a modern design, which allows them to be installed anywhere.

The most financially profitable option is to temporarily use an electric boiler. For example, at a dacha or in a second country house, where the owners come only from time to time, but do not live permanently. In such cases, the 1.5-3 times lower initial cost of the boiler, its installation and connection will cover the cost of electricity during operation for a long time.

Since all electric boilers (with the exception of induction) are designed to use exclusively water as a coolant, which freezes at subzero temperatures, it would be desirable in such a situation for the boiler to have the ability to connect external control. For example, using a GSM module or Wi-Fi module. Firstly, this will allow you to control the electric boiler remotely and set the desired temperature before arriving at the house. Secondly, remote control will give you confidence that in the absence of the owners the boiler maintains a positive temperature and the system is not damaged (otherwise you will immediately receive a notification).

Another great option is to use an electric boiler as an additional or backup heating equipment. For example, in a scheme using a buffer tank in case of problems with the operation of the main boiler and heating at a night tariff, or for a heated floor circuit. For such purposes, an inexpensive 3-6 kW electric boiler costing 11-15 thousand rubles, operating from a single-phase power supply, is quite sufficient. It will be able to maintain temperatures above +18°C in a house of about 100 square meters. m. for 2-2.5 days or completely ensure the normal temperature of the heated floor on an ongoing basis.

A simple and compact low-power model EVAN EPO.

Water-heating electric boilers can be used as the main heating equipment only if you have a free budget. The only exceptions are small and insulated houses with an area of up to 90-100 m2. To heat such an area, taking into account medium or dense insulation, an inexpensive electric boiler with a capacity of 6-9 kW will be sufficient. The low cost of the boiler unit and its installation, as well as the absence of the need for its coordination with Energonadzor services, will pay off the high operating costs for another 1-3 heating seasons.

No. 3. Connection type

Before purchasing a boiler of a certain power, you need to find out the features of the electrical wiring in the house. Among boilers with a power of up to 10-12 kW, you can find models that can be connected to both single-phase (220 V) and three-phase networks (380 V). It will not be possible to use more powerful boilers with a single-phase network - you will need to connect the house to a three-phase network.

To connect the boiler to the panel, it is better to use a stranded copper wire, which, with higher conductivity, will heat up less.

Rating of the TOP 20 best electric boilers

| Place | Name | Price |

| TOP 3 best electric boilers by price, quality and reliability | ||

| 1 | Protherm Skat RAY 12 KE /14 12 kW | Find out the price |

| 2 | STOUT SEB-0001-000009 9 kW | Find out the price |

| 3 | Protherm Skat RAY 14 KE /14 14 kW | Find out the price |

| TOP 3 best electric boilers for 220 V (single-phase) | ||

| 1 | EVAN Warmos-IV-3.75 3.75 kW | Find out the price |

| 2 | EVAN EXPERT 7.5 | Find out the price |

| 3 | Protherm Skat RAY 9 KE /14 9 kW | Find out the price |

| TOP 3 best electric boilers for 380 V (three-phase) | ||

| 1 | Protherm Skat RAY 18 KE /14 18 kW | Find out the price |

| 2 | EVAN EXPERT 9 | Find out the price |

| 3 | EVAN Warmos-IV-12 12 kW | Find out the price |

| TOP 3 best electric boilers per 100 square meters | ||

| 1 | EVAN S2 12 12 kW | Find out the price |

| 2 | STOUT SEB-0001-000012 12 kW | Find out the price |

| 3 | Navien EQB 12HW 12 kW | Find out the price |

| TOP 3 best electric boilers for 150 square meters | ||

| 1 | Reko 15P 15 kW | Find out the price |

| 2 | STOUT SEB-0001-000014 14 kW | Find out the price |

| 3 | EVAN EPO 18 18 kW | Find out the price |

| TOP 3 best electric boilers for 50 square meters | ||

| 1 | EVAN EPO 6 6 kW | Find out the price |

| 2 | EVAN Warmos-IV-5 5.1 kW | Find out the price |

| 3 | Reco 7P 7 kW | Find out the price |

| TOP 2 best double-circuit electric boilers | ||

| 1 | ACV E-Tech S 160 Mono 14.4 kW | Find out the price |

| 2 | Savitr Premium Plus 21 21 kW | Find out the price |

No. 4. Number of circuits

Among electric boilers, single-circuit models . They are only responsible for the heating system. To provide yourself with hot water supply, you need to retrofit the system with a water heater or take a double-circuit boiler . The latter has two independent circuits for heating water. Double-circuit electric boilers consume a lot of electricity, so they are used quite rarely.

Rating of floor-standing gas boilers

If you need to heat a room with an area of no more than 900 square meters, install a floor heat source. The TOP of the best included the most reliable and energy-consuming models. Before purchasing, you need to study the characteristics of floor-standing gas boilers. It is important to pay attention to the following parameters:

- Functionality. If a double-circuit boiler provides heating and water heating, then a single-circuit boiler can only provide heating.

- Control method. The electronic model works autonomously and does not require settings, while the mechanical one is easily repaired.

- Efficiency. Modern condensing boilers have high efficiency, while convection boilers lose a lot of heat.

- Power. Ability to heat the declared area of houses.

- Ignition type. The electronic type ignites the fuel system automatically, and the piezoelectric element with the help of a person.

- Type of burner. The modulated element saves fuel, while the single-stage element is durable and silent.

- Material. The heat exchanger is made of copper, cast iron and stainless steel. The weight and power of the model depends on this.

- The combustion chamber. Compared to an open chamber, a closed chamber requires the installation of a coaxial chimney for air intake.

- Method of release of processed products. To remove substances, a natural way or forced draft is used.

Good boilers are sold in specialized stores, on the Internet, and in markets. But you shouldn’t buy cheap equipment; it’s better to buy a model with full functions. This option will be convenient for use at home.

The best economical boilers

No. 5. Electric boiler power calculation

The power of electric boilers ranges from 2 to 60 kW (for industrial and commercial premises there are even 400 kW models) and is selected depending on the size of the room to be heated and whether there is a need to heat water for hot water supply. Ideally, to determine power, it is necessary to carry out a full thermal calculation, taking into account not only the area of the room, but also the height of the ceilings, the level of thermal insulation, the number of windows, doors and other factors. To do this, it is better to turn to professionals, but calculate the approximate power yourself.

The easiest way is to use the proportion according to which it is necessary to provide 1 kW of boiler power for every 10 m2 of area, provided there is sufficient thermal insulation and with a ceiling height of no more than 3 m. It is better to add a little more reserve (10-15%), and if you use a double-circuit boiler, then add another 25% to the resulting value. This calculation is quite conditional, and to obtain more accurate results you can use another, slightly more complex, formula.

The power of an electric boiler can be calculated as follows:

- W = (40*S*h+Qo +Qd )*k , where

- 40 – average required boiler power per 1 m3, 40 W/m3;

- S – area of the house/apartment;

- h – ceiling height;

- Qо – heat loss through windows, 100 W for each;

- Qd – heat loss through doors, 200 W for each;

- k is a coefficient that depends on the region; for the southern regions of the country it can be taken as 0.7-0.9, for the central and European parts - 1.2-1.4, for the north and far east - 1.8-2.0.

If the calculation is carried out for a private house , the result obtained is multiplied by another 1.5.

Let's say there is a house with an area of 85 m2, a ceiling height of 2.8 m, with 6 windows and 2 doors, it is located in the southern part of the country. The required power will be equal to W=(40*85*2.8+600+400)*0.8*1.5=12.6 kW.

How to choose for your home?

The choice of an electric boiler depends on a large number of factors, but it is necessary to take into account not only the estimated heated area, but also the technical characteristics of the models.

When choosing a heating unit, you should consider the following points::

- Power . For simplicity, you can take 1 kW per 10 sq.m. area, but for more accurate calculations you can use tables and formulas that include heat losses, room volume, and climatic features of the region.

- Energy efficiency . Often, more expensive models can save energy consumption due to a more optimized device. Modern models are created according to certain standards, which include energy saving.

- Equipment . An important point if additional connections in the form of a boiler are planned in the future. Also, some units do not have the necessary components for installation, which entails extra costs.

- Mains voltage . There are models operating on a single-phase network (220, 230 V), three-phase (380, 400 V) and on both networks. When choosing a model, this factor can be decisive, since three-phase units will not work on a single-phase network.

No. 6. Power regulation and boiler control system

In electric boilers, it is enough to simply regulate the power and temperature of the coolant. Actually, these two parameters are interrelated, so it is impossible to consider them separately from each other.

The boiler power is adjusted in one of the following ways:

- stepwise - a common option in heating element boilers. In this case, the design provides one heating element, which provides half the power, and two, which provide 25% heating each. It turns out that the boiler can operate at 25, 50, 75 and 100% of the maximum power; more precise adjustment can be made in each room thanks to the valves on the radiators;

- Smooth adjustment is achieved through the use of a rheostat. This is a privilege of more expensive models. In simple low-power boilers there may be no adjustment at all.

The user sets the boiler the required coolant temperature to maintain comfortable conditions in the house, and the boiler turns on the heating and turns it off when the coolant is sufficiently hot. Automation can work using mechanical and electronic thermostats. Both options allow you to save energy and maintain a comfortable temperature without constantly monitoring the boiler.

A mechanical thermostat cuts off the coolant flow or opens the electrical network when the user-specified coolant temperature is reached. When the temperature drops, the boiler turns on again. This is a simple and cheap method, but not the most accurate - the coolant temperature at the boiler outlet may differ by 2-30C from the set one. Electronic thermostats are more accurate; they consist of a remote sensor and a control unit. The sensor is attached to the heating element and transmits information about its temperature to the unit remotely or using wires. Naturally, such boilers are more expensive.

The best double-circuit electric boilers

ACV E-Tech S 160 Mono 14.4 kW

Double-circuit floor-standing electric boiler with stainless steel heat exchangers.

A built-in 12-liter expansion tank, a built-in 99-liter boiler, overheating protection, and a safety valve are just some of the advantages of this model.

It is possible to connect an external control unit.

Electronic control is carried out using a monochrome display; in general, it is not difficult even for those who have never encountered such units before.

The device is economical, energy consumption is 15-20% lower compared to similar models, but in itself it is very expensive.

Specifications:

- Heating element: heating element;

- Circuits: dual circuit;

- Efficiency: 99%;

- Placement: floor;

- Built-in circulation pump/expansion tank: no/yes;

- Heat exchanger: stainless steel.

pros

- built-in boiler;

- power;

- reliability;

- efficiency;

- high-quality assembly.

Minuses

- very high price.

Savitr Premium Plus 21 21 kW

One of the most powerful electric boilers with a rich set of equipment and a large operating area of up to 220 sq.m..

Works only from a three-phase network. Safety is ensured by overheating protection, safety valves and an air vent.

The intelligent control system remembers the specified settings even when the device is turned off, and the outdoor temperature sensor allows you to timely adjust the specified settings to suit weather conditions without operator intervention.

Energy efficiency is due to automatic rotation of heating elements and programming of operating modes.

Specifications:

- Heating element: heating element;

- Circuits: dual circuit;

- Efficiency: 99%;

- Placement: floor;

- Built-in circulation pump/expansion tank: yes/yes;

- Heat exchanger: stainless steel.

pros

- high-quality assembly;

- integration with the “warm floor” system;

- intelligent control system;

- long service life.

Minuses

- price.

No. 7. type of instalation

Electric boilers can be:

- wall-mounted;

- floor-mounted

It is clear that wall-mounted ones take up less space and are suitable in cases where space is very limited. Western manufacturers prefer this installation format. In floor-standing versions, as a rule, more powerful boilers are produced, which need to heat a large volume of coolant.

Instructions for connecting the boiler to a heated floor

Step 1. According to the rules for installing a heated floor system, the rough covering is covered with a layer of thermal insulation, waterproofing, reinforcing mesh, to which the coolant pipes are screwed according to the diagram.

Installation of heated floors

Step 2. An electric boiler is installed in its designated place.

Installed electric boiler

Step 3. All pipes for the coolant are supplied to the boiler.

Pipes are connected to the boiler

Step 4. The distribution manifold is installed and all pipes for the coolant and the boiler are connected to it.

Pipes connected to distribution manifold

After this, the tightness of the system is checked by pouring the coolant, and then the heated floors are filled with a cement mixture (the coolant must be inside the pipes). After the screed has dried, the heating system can be used.

Heated floor pipe circuit length calculator

Go to calculations

Video - Connecting a solid fuel unit

No. 8. The best manufacturers of electric boilers

There are dozens of manufacturers, both foreign and domestic, on the electric boiler market. European boilers usually have smooth adjustment and are assembled from more expensive components. Our boilers mainly have step adjustment, which is why they are cheaper. Probably, each of us understands well that it is better not to save on the heating system, so you should not trust little-known companies. The largest , proven and reliable manufacturers of electric boilers in the world and Russia:

- Protherm is a Czech manufacturer that started with the production of electric boilers. Today, other types of heating boilers are produced, as well as boilers, thermostats, etc. The company's electric boilers are wall-mounted, power from 6 to 28 kW, efficiency 99.5%, and are available in a single-circuit version. In 2001, the company became part of the German Vaillant group of companies;

- Vaillant produces slightly more expensive boilers than Protherm, power up to 28 kW, all models are easy to use and reliable;

- Buderus is a large German company that produces electric boilers for private homes and commercial properties, the power of wall-mounted single-circuit models is 30-60 kW;

- Kospel are reliable Polish electric boilers, available in a wide range. Power from 4 to 36 kW, models up to 8 kW are presented in two versions, for working with a network of 220 V and 380 V;

- Bosch also produces electric boilers, power from 4 to 24 kW, wall-mounted, with one circuit, but it is possible to connect an indirect heating boiler. You can buy either a simple boiler or a boiler complete with an expansion tank and pump;

- Ferroli are high-quality Italian electric boilers with a power from 6 to 28 kW with very well-thought-out automation and a wide range of additional functions. The boilers have connectors for connecting room and street temperature sensors, a large display, the ability to daily program the operation of the boiler and even control the boiler using the remote control;

- ZOTA are domestic boilers that are distinguished by the most affordable price and fairly high-quality performance. Power from 3 to 400 kW, boilers are presented in several lines, heating elements are used as heaters;

- RusNIT - good budget boilers from a Ryazan company, power from 3 to 99 kW;

- Evan is a large domestic manufacturer, part of the NIBE concern, producing boilers in different price segments. Power from 2.5 to 480 kW.

It is also worth noting the products of the companies Dakon, ACV and RECO, Intois, Alvin, Resurs.

Features of underfloor heating without radiators, boilers for underfloor heating

People often think about underfloor heating specifically in the winter, when you really want to move around the premises barefoot, but the flooring is so cold that this is not possible. An option to make it more pleasant and tactilely comfortable is to install a heated floor system.

Pipes for water heated floors

There are different floor heating systems - water, electric, infrared. And often owners of apartments and houses make a choice in favor of the first option. The system will consist of main pipes through which the coolant - hot water - circulates, as well as a boiler that heats this water.

Water heated floor

On a note! In new buildings, floor heating can often be connected to the central heating system - it will have special outlets for connecting the heating system pipes. But in private houses, as well as older apartments, connecting to heating is impossible, so there are two options - using other heating systems or installing a water heating boiler.

Connecting underfloor heating to central heating

The boiler is often used to heat premises for various purposes - apartments and garages, houses and offices. This reliable device has acceptable dimensions and is not dangerous for use in a residential area. It also has a very convenient temperature control system, which will allow you to control the microclimate in the room. This will make it possible to leave the unit turned on unattended for a long period of time.

Electric boiler

On a note! The boiler belongs to an autonomous heating system; it will save a lot of money that would be spent on regular additional heating of the room.

The temperature of the heated floor is much lower than that of heating radiators

Expert opinion

Afanasyev E.V.

Chief editor of the pol-exp.com project Engineer.

It is not recommended to use only a heated floor system without heating radiators to heat a room. The fact is that in order to warm the house to a comfortable temperature, you will have to heat the floors to at least +30 degrees, and this can negatively affect the floor covering, and it will also be unpleasant for a person to move on such hot floors. Also, thanks to radiators, the air in the room can be warmed up much faster than with a heated floor system. The latter even take longer to warm up due to the fact that they are covered with a screed, which also needs to be warmed up.

Conventional heating and underfloor heating

On a note! Only electric boilers can operate efficiently and economically at low power. Everyone else will burn too much fuel to keep the temperature low, which is not profitable.

An electric boiler brings comfort to your home

That is why the underfloor heating system should heat only the surface of the floor, the rest of the room should be heated by radiators. And, nevertheless, for the correct and economical operation of the equipment, it is worth purchasing a heating boiler.