Electric boilers are the most environmentally friendly, practical, easy to operate and install. From a comfort point of view, this is an ideal heating equipment. Their well-known disadvantage is the high cost of electricity, which makes it absolutely unjustified from an economic point of view to use them in heating systems for large private houses.

The situation is different when using an electric boiler to heat a house with an area of 60 square meters. Even when used as the main heating equipment, electricity costs will be in the range of 6-10 thousand rubles, which is more expensive than when using natural gas or solid fuel, but still an adequate amount. You can further reduce costs by choosing a model with programmable automation, and also by installing an electric meter that differentiates consumption by zone of the day (peak, half-peak, night).

To heat a small house with an area of 60 square meters. m. low-power electric boilers operating from a single-phase network (220 V) are used; their installation does not require coordination with the Energonadzor services (<10 kW).

Minimum required power of an electric boiler for heating a house with an area of 60 m2

Electric heating element Protherm. Compact size, minimum communications and nice design.

For standard average houses in the climatic zone of the Moscow region with 2 bricks and a ceiling height of up to 2.7 m, the minimum required power is calculated quite simply: 1 kW for every 10 m2. It is also recommended to reserve a reserve of 15-20% in case of the coldest decades of the heating season and about 10% in connection with a decrease in efficiency due to the possible formation of scale on heating elements (if you choose the most common heating elements models). Total about 30% power reserve.

For example, for a private house with an area of 60 square meters, the minimum required electric boiler power is 6 kW * 1.3 = 7.8 kW, rounded up to a larger whole - 8 kW.

Simple calculations are sufficient in more than 95% of cases. For non-standard houses or climatic conditions, for example, extreme southern or northern climate zones, high ceilings, large glazing areas, etc. correction factors are taken into account. You can calculate the result taking them into account using the calculator below.

Rules for the location of batteries in the house

In order for the system to work properly, installation rules must be strictly followed. Although the installation technology is not complicated, it has its own nuances, so the work must be carried out by specialists.

Important! If radiators are installed incorrectly, they are not covered by the warranty.

In order to avoid heat loss and uneven heating of the room, when installing devices it is necessary to observe indentations and choose the correct location:

In the middle of the content

If you need to order high-quality installation of engineering systems (heating, water supply), please contact DESIGN PRESTIGE by phone +7 , and we will install the system at a professional level in accordance with high quality standards.

- The most suitable option for the battery is considered to be a place under the window, i.e. where the heat loss is the most significant. The radiator width must be at least 70% of the window width. Mounted clearly in the middle.

- Leave at least 10 cm from the battery to the windowsill, as well as to the floor. The optimal distance between the floor and the radiator is 12 cm. It is not recommended to leave more than 15 cm.

- The battery is fixed at a distance of 5 cm from the wall.

- You can stick heat-reflecting material behind the radiator - then some of the heat will not go into the wall, but will return to the room.

- If the radiator is planned to be placed not under the window sill, but on the wall, then the distance between them should be at least 20 mm.

Calculation of the number of sections

It is not necessary to look for the most expensive heating devices to make the room comfortable. The main thing is to correctly calculate the number of sections. If the rooms are standard, then this greatly simplifies the calculations.

Often they resort to calculations based on the volume of space because they are simple, but at the same time give fairly accurate results.

- 1 m³ requires 41 W of power. If good double-glazed windows are installed and heat loss is minimal, then the indicator drops to 34 W.

- Room volume (m³) = area (m²) × height (m).

- Required heating power for the entire room (W) = room volume (m³) × 41 W (or 34 W).

- In the technical data sheets of devices, manufacturers indicate the heat transfer of one section.

- The total power (the value calculated in point 3) must be divided by the heat transfer of one section. The resulting number is the number of sections.

For example, the required thermal power is 2890 W, and the heat output of one section is 170 W. Then for this room you need to purchase 17 sections.

If the room is non-standard, the calculations become more complicated. To calculate the total power, the features of double-glazed windows (double or triple), thermal insulation parameters of the walls, the ratio of the sizes of windows and floors, ceiling heights and other parameters are taken into account. Designers calculate all this using specialized software.

Advantages and disadvantages of electric boilers

The main advantages of electric heating boilers are the following factors:

- relative cheapness and easy access to an energy source;

- a minimum of mechanical parts, due to which maintenance of such a boiler is easier than a gas or any other;

- the possibility of automatic operation, which allows you to turn on the heating at any time convenient for you according to a given program;

- no noise during operation. An important feature for a residential building, as well as compactness and light weight, which allows electric boilers to be installed almost anywhere;

- no harmful emissions into the atmosphere and no need for additional installation of the chimney.

Among the disadvantages of electric heating boilers is their low power. For heating rooms larger than 300 square meters. m such equipment is not enough. Another disadvantage is low efficiency, due to which they consume quite a lot of electricity.

What parameters should you pay attention to when selecting a boiler?

A household heating boiler is a complex technical device that contains not only a heating element. When purchasing, you need to pay attention to auxiliary components and additional options on which the reliability of the entire unit, safety and ease of use depend.

Expansion tank

An expansion tank for closed heating systems is a small container with an internal membrane dividing it into two halves filled with water and air. It allows you to compensate for the thermal expansion of the liquid during temperature changes. Without it, a sharp increase in pressure is possible with the danger of pipe rupture. If it is not included in the boiler kit, you will have to buy it in addition.

Expansion tank for heating system.

Possibility of working with a multi-tariff meter

When installing a multi-tariff meter, it becomes possible to pay more economically for the energy consumed. The heating system has a certain inertia. If it is heated intensively at night, when minimum tariffs apply, during the day it will be able to gradually release heat. Regulation of the boiler operation according to a schedule in automatic mode is carried out in the presence of a programmer.

Pump

A circulation pump is necessary to pump coolant throughout the entire circuit. It provides optimal conditions for the heat exchange processes occurring in the boiler and external heating devices. It is economically feasible for it to be able to change the flow rate of the pumped liquid. If this is not provided by the boiler manufacturer, it is better to purchase an additional regulator.

Weather-compensated regulation

Most well-known manufacturers of electric boilers provide the ability to operate the equipment depending on the readings of temperature sensors, which can be installed in a heated room or outdoors. This function improves the quality of maintaining a comfortable microclimate in the house and makes it possible to significantly save energy consumption.

Diagram of a heating system with weather-compensated control.

Three way valve control

When operating a single-circuit boiler, an additional indirect heating boiler is installed to provide hot water supply to the building. To do this, the manufacturer must provide the ability of the control system to give commands to the three-way valve, which is responsible for the timely supply of hot water to the storage tank. Without this option, high-quality operation of the DHW system will be impossible.

Possibility of connection to load shedding relay

When several powerful electricity consumers operate simultaneously, the home network may experience overload. This threatens to trigger emergency protection and cut off power to the building.

The priority consumer selection function implemented on the boiler allows you to automatically turn off the boiler when an alternative device that is more important from the point of view of the given logic is turned on. The unit will return to its previous mode as soon as such an opportunity arises.

Classes of heating radiators and their types and features

The principle of operation of a radiator is to transfer heat to the surrounding space from the coolant fluid circulating in this heating device.

The autonomous heating system (AHS) consists of:

- boiler;

- pipelines;

- thermal elements.

The table shows the main types of thermal appliances:

| Device | Operating principle | Example |

| Radiator | Heat is radiated | ceiling radiant panels, sectional cast iron, tubular radiators |

| Battery | Heat is radiated and also transferred by convection | sectional aluminum, sectional steel, bimetallic, tubular |

| Convector | Heat is mainly transferred by convection | plate, tubular convectors, finned tubes |

Heating a house with radiators

In addition, heating devices are divided into the following classes, let's consider a unique rating of heating radiators from this side:

Sectional

They consist of heating sections that are connected to each other. The more sections, the more heat they will transfer to the surrounding space. To prevent the room from overheating, special thermostats are installed on the radiators to regulate the temperature.

Standard cast iron radiators are also sectional: heat from them is transferred in the form of infrared radiation, evenly distributed throughout the room - top, bottom and middle. Such batteries have large dimensions and thick walls, which accumulate enough heat so that it is emitted in the infrared spectrum. It is this method of heating that is considered optimal for human health, although it must be borne in mind that part of the heating also occurs through convection.

Thanks to the thick walls, such batteries have high thermal inertia - therefore, after turning off the AOS, the radiators remain hot for a long time. Cast iron is not very susceptible to corrosion and is not afraid of harmful impurities in the coolant - the service life of such devices reaches 50 years. One of the disadvantages is the heavy weight.

Aluminum radiators have good heat transfer (1/2 radiation + 1/2 convection) and quickly warm up the room. Compared to cast iron, they are more lightweight, and in general, the ability to transfer heat into the room is several times higher than that of cast iron and steel.

An additional advantage of modern models is the ability to regulate the temperature using a valve with a thermal head. The metal surface is coated with a protective coating, which increases its service life. The cost of aluminum radiators is low, and therefore the prices are more affordable.

Aluminum radiators cannot withstand high overloads, so they are not used in central heating systems (CHS). They break due to pressure surges, the presence of rust or sand particles in the coolant. Chemical additives are not allowed in liquids.

Bimetallic heating radiators consist of external aluminum plates and steel pipes located inside the sections. They are valued for their reliability and durability, but are not cheap. Equally well suited for centralized and autonomous heating systems.

Radiators are also produced that have only steel-reinforced vertical pipes. These are no longer completely bimetallic devices; they are less corrosion resistant. Among their advantages, it is worth noting their high thermal conductivity, which is higher than that of real bimetallic radiators.

Tubular

Steel tubular heating devices give off heat well, are economical in terms of energy consumption, and heat up quickly. Their disadvantage is that they are sensitive to oxidative processes. If the coolant fluid does not fill the steel radiator reservoirs, it will begin to corrode. Another weakness of a steel radiator is its hypersensitivity to water quality. Even if the water is considered good by usual standards and can be drunk, it is recommended to install filters to minimize the formation of scale.

The sizes of steel tubular radiators are from 30 cm to 3 m. The number of rows of tubes is 1–9. They are considered very reliable - the permissible operating pressure for devices from a number of Russian manufacturers reaches 15 atm. Radiator reservoirs are designed to hold a large volume of liquid, so they quickly reach the required temperature levels when it is necessary to increase or decrease power. The method of heat transfer is radiation and convection.

Steel radiators are also used as heated towel rails, which, in addition to drying clothes, provide additional heating in bathrooms

Floor radiators-benches with support legs are steel tubular heating devices with a seat in the form of a wooden board on top. They are connected to the heating system in the same way as conventional radiators. They can also serve as the main heating device in rooms such as the kitchen, bathroom, hallway.

Panel

These steel radiators are a rectangular panel that acts as a heating device. The panel consists of 2 ribbed sheets welded to each other; plates with a U-shaped relief are placed inside.

Operating pressure is 6–8 atm, high sensitivity to pressure changes, therefore they are used only in autonomous heating systems for residential and commercial premises. Such radiators can consist of 1, 2, 3 heating plates. React quickly to temperature changes. The main method of heat transfer is convection. The choice of sizes of such devices is wide enough so that they can be selected for a room of any size.

Ceiling thermal panels consist of steel plates to which pipes intended for coolant are welded. Their use is advisable in rooms with high ceilings from 3 to 20 m. Heat transfer is carried out by radiation.

Lamellar

Plate heating devices consist of horizontally arranged pipes to which metal plates are welded, thereby increasing the surface area for heat transfer. Heat transferrs can additionally be covered with protective covers. The advantage of such radiators is their reliability - they can be used for centralized and autonomous heating. The main method of heat transfer is convective, so the space is heated unevenly: it is much warmer on top. They are mainly used for offices, corridors, garages and utility rooms, but there are also models for residential premises.

Complete set of heating units

We have already listed the elements of any electric boiler in the basic, cheapest configuration. This is a heating unit, thermostat, automation with an actuator, controls and a temperature sensor.

An important nuance. In budget versions of boilers, the executive element is a magnetic starter. It clicks loudly when the heating is turned on, the sound is clearly audible in the rooms adjacent to the boiler room.

In an extended configuration, manufacturers supply electric boilers with the following equipment:

- low-noise modular contactor instead of a magnetic starter;

- circulation pump;

- membrane expansion tank for a closed heating system;

- overheating and coolant pressure sensors;

- safety group – automatic air vent, safety valve;

- circulation sensor – for induction heat generators;

- weather automatics;

- LCD display, programmer, GSM remote control module from a smartphone.

Video description

In our video we’ll talk about heating in a private country house.

Our guest is the author and presenter of the Teplo-Voda channel Vladimir Sukhorukov: The heating system is not only a stove and radiators. It includes:

- Boiler;

- Pumping station;

- Pipes;

- Radiators;

- Control devices;

- Sometimes an expansion tank is needed.

This is roughly what the diagram of a house heating system looks like Source lucheeotoplenie.ru

Which electric boiler to choose - recommendations

In 90% of cases, we recommend choosing an electric boiler with heating elements. These are reliable devices that are equally suitable for different heating systems - radiators, heated floors, floor or baseboard convectors. Select the level of staffing based on the conditions of installation, operation and the allocated budget.

A few more tips:

- For your apartment, definitely take a wall-mounted electric mini-boiler room, equipped with heating elements, its own pump and tank.

- If the electric boiler must work in tandem with a solid fuel or gas unit, it is better to choose a model without a built-in pump and expansion tank. The specified equipment is connected separately - the tank works for the entire system, the pump is controlled by a room thermostat, as shown in the diagram.

It is more convenient to operate the circulation pump when it is located separately from the boiler - Install a remote thermostat. Then the boiler will focus on the temperature of the air, and not the coolant.

- Choose an electrode heat generator in 3 cases: limited budget, too little space in the boiler room, or connection to a gravity heating circuit without a pump.

- Electrode units create the least problems in open systems - the resulting gases safely escape through the atmospheric expansion tank.

- Choose an induction boiler according to your desire and availability of funds. But keep in mind: operating experience has shown that the specified device is no better than a heating element. No special technical problems were noted with induction heaters, only financial ones.

Comment. An electrode-type boiler for a gravity system must have pipes of the appropriate diameter (minimum Ø32 mm), the supply pipe is directed upward.

For a water heated floor, only an electric heating element boiler is suitable. It is difficult for induction and electrode units without stepwise heating to maintain a low water temperature in floor circuits - 35...45 °C.

TOP 8 electric boilers for 60 square meters

Each electric boiler is the product of painstaking work of professional engineers and craftsmen. The following are popular models from global manufacturers. They were able to prove their effectiveness in a work environment.

EVAN Warmos-IV-9.45 9.45 kW

Wall-mounted model in a compact case. The boiler is designed for operation in residential premises and industrial areas.

Equipped with wear-resistant heating elements with three-stage power adjustment.

Peculiarities:

- maintaining optimal temperature;

- single-circuit design;

- possibility of functioning in tandem with non-freezing liquids;

- quiet operation;

- presence of a self-diagnosis system.

Characteristics:

- belongs to the single-circuit type;

- Max. power - 9.45 kW;

- Max. area - 94.5 sq. m;

- Efficiency - 99%;

- equipped with electronic control, display, auto-diagnosis, protection against freezing and overheating, connection of a heated floor, power-on indication, thermometer;

- mains voltage is three-phase with a rated current of the circuit breaker of 25 A;

- temperature of heating elements - 5-85°C;

- service life - 10 years;

- manufacturer's warranty - 2 years;

- dimensions - 380x640x245 mm;

- weight - 27 kg.

Advantages:

- the boiler independently selects the number of power stages to maintain the set temperature. It is also possible to adjust the power manually;

- maintaining operability if a sharp decrease or increase in voltage is observed;

- if the unit overheats too much, the auto-shutdown system is triggered;

- the ability to connect the unit to remote control via Wi-Fi or GSM channel;

- heat loss is minimized;

- durability, strength and attractive design;

- cost - from 18,000 rubles.

Flaws:

- The boiler requires the installation of an additional water heater to produce hot water.

EVAN Next 7 7 kW

It looks like a monoblock, the design of which consists of a boiler and a control panel . Wall model with

Three-stage power adjustment is designed for installation in any type of premises.

It can be used as a stand-alone unit or acts as an addition to heat-solid equipment.

Characteristics:

- belongs to the single-circuit type;

- power - 2.33-7 kW;

- heated max. area - 70 sq. m;

- Efficiency - 99%;

- control - mechanical;

- mains voltage - single-phase or three-phase;

- coolant temperature - 30-85°C;

- presence of an overheating protection system;

- service life - 10 years;

- warranty - 2 years;

- dimensions - 205x600x105 mm;

- weight - 8 kg.

Advantages:

- compact dimensions;

- high build quality;

- The heating elements are made of stainless steel, which affects their durability;

- ease of installation and maintenance. A 1″ pipe is required for connection;

- quick heating of rooms with long-term maintenance of the set temperature;

- attractive price - from 8,000 rubles.

How to choose?

When choosing, you should take into account the power and type of unit . So a house with an area of 60 sq. m are capable of heating devices with a power of 4 to 18 kW. The more powerful they are, the faster the rooms warm up, and the higher their cost.

Today, manufacturers offer 3 types of electric heating boilers.

They differ from each other in design, advantages, additional features:

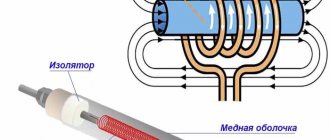

- Heating element boilers . The heating element in the form of plates or tubes acts as a heating element. It is housed in a heat exchanger. One device can be equipped with 8 2 kW elements. Adjustment occurs automatically or manually. Such models are presented on the market in the form of single-circuit and double-circuit products. They operate on water, antifreeze or oil. Double-circuit ones additionally heat a container of water for its subsequent use in domestic needs. But heating element boilers have low efficiency due to the stepped water heating system - 80-93%.

- Electrode boilers . Heating elements - electrodes. Water acts as an excellent electrolyte with a given resistance. When it passes through a salty environment, heating occurs. They are characterized by simple, high efficiency - 94-95%, simplicity and safety. Disadvantage - they require frequent replacement of electrodes due to their rapid dissolution in a salty environment.

- Induction boilers . Complex systems involve induction coils in the form of wire wound around a dielectric. Electric current passes through the coil, forming electromagnetic induction. After its influence on the potential difference, the core is heated. The efficiency is 99%, energy savings are observed, and a comfortable temperature in the room is maintained for a long time.

The buyer decides which type of boiler to choose. The main thing is to pay attention to power consumption and output .

Advantages and disadvantages

The advantages of electric boilers include:

- practically do not make any sound during operation;

- easy to install, and operation does not require special knowledge (just read the manufacturer’s instructions);

- no chimney or ventilation required.

Since the devices do not emit harmful combustion products, they are considered environmentally friendly equipment and are installed even in rooms that have special requirements (for example, in laboratories).

The only drawback of such equipment is that a constant supply of electricity is required. If in the city failures with the latter rarely occur, then in the periphery such a problem is typical.

What requirements must you meet?

If we compare an electric boiler with a gas or solid fuel one, it does not require a separate boiler room.

The device meets all safety requirements thanks to the following nuances:

- the coolant heats up without releasing hazardous combustion products;

- there is no need to install a ventilation system;

- Each design element is carefully thought out, so a person is maximally protected from accidental injuries.

This boiler is environmentally friendly . It operates from the electrical network, does not emit dangerous poisons into the atmosphere, but only provides warmth to all household members.

Installation Rules

When installing equipment, the following aspects are observed:

- the device body must be grounded;

- connection of units with heating elements is carried out through an RCD, with electrodes and induction coils - using separate automatic devices and a power supply panel;

- the cable material and cross-section are checked, since the manufacturer indicates this data on the equipment.

It must be remembered that the connection of units is carried out exclusively by a specialist. According to SNiP, liability in the event of an emergency lies with the person who performed the installation. However, you are allowed to carry out other work yourself - fastening pipes, radiators, etc.

Types of electric boilers

Manufacturers supply the following devices, similar in operating principle:

- Equipped with heating elements. A tungsten spiral is located in a special housing filled with quartz. When current is passed through the wire, the wire becomes heated. The resulting heat increases the temperature of the circulating fluid inside the tank. Next, the water enters the system (pipes, radiators) and returns to the tank.

- Electrode. The zero phase is connected to the cylindrical body. There is an electrode inside. The undistilled liquid that circulates through the tank has resistance. And when the current passes through the water, the coolant heats up.

- Induction. The tank contains a coil wrapped with a cable, inside of which there is a metal rod. When the current moves, vortex flows arise and the water heats up.

DIY electrode boiler drawings

Before you begin manufacturing, you should take into account that the lion's share of the price of the electrode installation falls not on the heater itself, but on the electronic control system, the pump that circulates the coolant and other components, which are unlikely to be made at home. Well, for those who still decided to try their hand, below are step-by-step instructions.

- A coupling is screwed onto one end of the pipe, which will act as an outlet pipe.

- A tee is screwed on from the other end to provide coolant supply.

- A plug is made from durable textolite or other dielectric to ensure the electrode is fixed in the center. To make the electrode itself, you can use a steel rod with a diameter of 10-12 mm. After installing the rod, the plug together with the electrode is screwed into the tee.

- Two M8 bolts are welded to the pipe, which will serve as the neutral wire and grounding terminals.

- The device is connected to the heating circuit through the coupling and the free end of the tee.

Particular attention should be paid to sealing threaded connections and grounding arrangements.

Modern electrode heating boilers are distinguished by their simplicity of design, reliability and long service life and can easily compete with solid fuel and gas boilers. Using electricity allows you to avoid both the tedious preparation of firewood or coal and the construction of chimneys.

Choosing a boiler: assessing the main parameters

When purchasing a heating unit for installing an electric heating system, it is worth taking into account the area of the home, the heat-saving characteristics of the materials from which the house is built, as well as the climatic characteristics of the region.

Basic selection options:

- power;

- connection type;

- equipment;

- performance adjustment method;

- control option.

Power. The main characteristic showing the heating intensity. To determine it, use special calculators, rely on the recommendations of boiler manufacturers, or calculate it yourself.

The calculation norm is for 1 cubic meter. m of room should account for about 40 W of device power. The value must be adjusted taking into account probable heat losses

To the resulting value add 100 W per window and 200 W per entrance door.

The climate zone should also be taken into account. Table coefficients by which you need to multiply the calculated figure:

- northern regions – 1.8-2;

- central zone – 1.2-1.4;

- southern area - 0.7-0.9.

When choosing an electric boiler for a cottage or private house, the final value should be multiplied by 1.5. A reserve of 50% is needed to cover heat costs through the ceiling and walls.

Connection type. Electric heaters are divided into single-phase, operating from 220 V, and three-phase - requiring a recharge of 380 V

This parameter depends on the boiler power. For devices up to 9 kW it is possible to connect to a single-phase network. High-power units require a 380 V network supply. A separate three-phase network will require permission.

Equipment. There are two options:

- basic equipment - purchase of one boiler, the remaining necessary components will have to be purchased separately;

- mini-boiler - a complete boiler.

The second option is preferable. Purchasing and installing all components separately will cost more than purchasing and commissioning a complete boiler.

Power control method. The ease of use of the device depends on this parameter. Stepwise and smooth adjustment is possible. The first option is used in boilers with several heating elements.

The downside of the technology is the limited choice of capacities. To more accurately regulate the temperature in the room, use valves and thermostats on radiators

Smooth power selection is preferable. Its advantages: obtaining a more comfortable microclimate, energy efficiency. In budget versions of low-power boilers, there may be no performance adjustment at all.

Control methods:

- Mechanical. Such boilers are affordable, but the accuracy of temperature control is insufficient. In addition, mechanical systems are loud - clicking sounds are heard when shifting. This option is suitable for boilers operated in non-residential premises.

- Electronic. The control system is more convenient and economical. The use of electronic thermostats and thermostats allows you to save up to 20% of electricity. The downside is the high cost.

It is worth paying attention to the features of the case. It is better to choose a closed type boiler so that children do not have access to electrical parts.

We also recommend reading the article about arranging a boiler room in a private house. For more details, follow the link.

Finally, about energy consumption

The natural desire of a homeowner is to know how much electricity an electric boiler will consume when heating a private home. Unfortunately, actual consumption cannot be predicted. The indicator is too individual and depends on a number of factors - the degree of insulation, the temperature maintained inside, the weather.

Monthly consumption can be calculated approximately: take 50% of the estimated heat loss of the house, multiply by 24 hours and 30 days. Example: losses are 6 kW, half - 3 kW, per day 3 x 24 = 72 kW, per month - 72 x 30 = 2160 kW. Why we take ½ power: during the season the weather is not always cold, the warmer it is outside, the more often the electric boiler turns off.

An example from personal experience. A house of 100 m² is heated at night with a 9 kW electrode boiler for 8 hours, the region is southern. Over 6 months of the heating season, the electric boiler consumed 9104 kW. Average monthly energy consumption is 1517 kW, average daily energy consumption is 1517 / 30 = 50.6 kW.

Connecting an electric boiler to the heating system

Connection diagram for a single-phase low-power boiler

Installation is permitted anywhere, but the device must be protected from moisture and access to it must be limited. Therefore, it is not advisable to install a boiler in the bathroom. Heating element heaters can be installed in the kitchen and hallway - they are not afraid of moisture, but then the heating line will have to be laid into this room. In fact, the boiler almost always ends up in a separate technical room.

An electric boiler is installed to heat a private house of 100 square meters. m. according to the instructions. Follow some general recommendations:

- Most models are wall mounted. If the wall is lined with wood, it is recommended to insulate this area.

- The boiler must be freely accessible.

- A free area is left near the induction boiler, since a pump and expansion tank need to be secured next to it.

- The cables are placed above heating and sewer pipes so that in the event of a leak, the wires will not flood.

- The housing is connected to the grounding bus. If it is not there, construct a ground loop and lay it in the boiler room.

- The supply and return pipelines are secured into the corresponding nozzles and fixed.

The connection diagrams are different, depending on the type of device. If the boiler is not equipped with its own tank or pump, these devices are installed in the return line.

Tips and tricks

Before choosing a boiler for heating a private home, you need to decide for what purpose the equipment is being purchased. If additional hot water supply is required, it is recommended to purchase a dual-circuit unit.

They also take into account where the device will be placed - on a horizontal or vertical surface. In the latter case, the boiler must be securely mounted on the wall (a plasterboard partition, for example, will not work).

They also look at the presence of automatic functions, whether there is a circulation pump, a remote control, pay attention to electricity consumption, etc. Often the boiler is selected to fit into the overall interior.