An electric boiler is an advantageous alternative to solid fuel or gas appliances. It has increased efficiency, does not make noise during operation, and does not require a separate room or special permission for installation. Electric boilers for heating a private house at 380 V belong to the category of powerful three-phase devices and are divided into several types. Before purchasing and installing such a boiler, it is useful to study its pros and cons, operating and installation rules, as well as available connection options.

Types of three-phase heating boilers

Manufacturers produce many modifications of devices designed for heating domestic premises.

These devices differ in connection schemes and are classified according to:

- Configurations

- Characteristics of the thermal modes used in operation.

- Structural solutions.

- Types of heating.

Electric boilers may differ in the type of coolant. Some devices provide for the use of antifreeze for this purpose.

If you need to install an electric boiler for heating a private house with increased power, the productivity of which is more than 12 kW, then a separate three-phase line is laid. To do this you need to obtain permission.

Types of electric boilers

Electric boilers are available on the market in a wide variety of products. The differences between them are as follows:

- Number of circuits. Like other types of heaters, an electric boiler can be single- or double-circuit. A single-circuit boiler has a slightly higher output power, since it does not provide for operation with domestic hot water.

- Type of heating element. This can be a heating element, an electrode or an induction coil (inverter).

- Coolant type. Some single-circuit heater models use antifreeze.

- Type of electrical network used (220 or 380 volts) and connection method (single-phase or three-phase).

- Heating method. The boiler is of flow-through or storage type.

To create increased power, greater electrical system performance is required. It is recommended to connect an electric heating boiler with a power of over 12 kW to a 380 V network. To do this, you need to obtain permission and draw a separate line.

If there is insufficient water pressure, it can boil!

Design and operating principle

Typical heating units operating from a household electrical network already contain all the components.

These functional units include:

- network pump;

- heat exchanger;

- expansion tank;

- temperature controller;

- safety system;

- one or more thermoelements.

The latter are used to heat the coolant. The pump circulates water in the heating circuit.

The expansion tank is a buffer tank that receives part of the liquid from the line that expands as the temperature rises.

The safety system includes a safety valve to relieve pressure in the boiler when it reaches critical values. Reliable operation of the device is ensured by an electronic automatic control unit.

Choosing a brand of electric boiler

Today, buying a three-phase boiler for heating does not seem problematic. There are a great many manufacturers and versions.

The choice is not easy to make. Be sure to pay attention to available features and warranties. Customer trust was formed under the influence of subjective and objective factors. The most popular brands today are produced in Germany, the Czech Republic, Spain and Switzerland.

German samples Bosch Wespe Heizung and Swiss STS are distinguished by high performance, but also by the same high price.

Wall-mounted units of the Bosch Tronic 5000 H series are used in various heating systems, including in conjunction with battery tanks. These are heating element type boilers. There are three of them installed.

Bosch Tronic 5000H

The heaters are single-circuit, suitable for supplying hot water using an indirect heating tank. The efficiency declared by the manufacturer is 99%. They provide water heating up to +90 degrees, four-stage power and temperature adjustment using a room regulator.

Slovakian Protherm boilers are distinguished by no less functionality and performance at an adequate cost. The same equipment is supplied by the Czech company Dakon - the Protherm 18K model, like the German ones described above, is equipped with a steel heat exchanger and automation, providing even greater capabilities with the same efficiency. The boiler has the function of remote control of power supply from the tariff meter.

Russia produces products that are not inferior in quality, but are more affordable. Since 2010, the SAVITR company (part of NPK VETROSTAR) has been producing double-circuit boilers of the Ultra series with weather-dependent automation and remote control with a GSM module. According to reviews, the quality and reliability are the highest.

Russian manufacturers have extensive service networks, which is important.

Main types of heaters

The operating principle of a house boiler is based on an increase in the temperature of thermoelements when exposed to electric current and subsequent heat transfer.

There are 3 types of designs for household electrical units:

- Models with heating elements.

- Induction.

- Electrode.

Boilers in which elements in the form of a tube are installed are called heating elements. Such installations are the safest to operate. Special anode rods are used to purify water.

Boilers of this type can be double or single circuit. The heating element is heated by applying voltage to the thermoelement.

These models are quiet in operation and have high efficiency. Heat exchangers used in structures can have different shapes and are made of copper.

Features of three-phase models are:

- high degree of housing protection;

- fast heating of the coolant;

- ease of operation;

- good power with relatively low energy consumption.

Electrode boiler

The difference between modifications and brands of devices lies in the external design and features of the control system. An electrode heating boiler can operate in both single- and three-phase networks. The unit has design differences consisting in a different number of thermoelements.

The device body has terminal blocks for connecting the zero or ground wire. Electrodes are located inside; depending on the number of current phases, they can be from 1 to 3. These elements are a replaceable part of the boiler; in a three-phase unit they are located on a dielectric block in the form of an equilateral triangle. To prevent injury, the body of the heating apparatus is coated with an insulating polyamide compound.

Additional features of the electrode unit:

- the need to use pressure reduction protection;

- wide operating temperature range;

- the presence of a surface insulating layer;

- application in the valve body system.

Electrode devices are suitable for installation on heating mains of small houses. Such units are characterized by a soft start and ease of connection.

Induction boiler

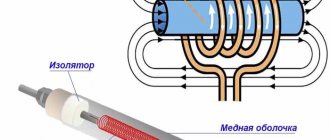

This type of electrical unit produces heat and heats the room due to changes in the magnetic field. The design of the device uses an inductive coil with a core that heats the coolant.

Such boilers are always built into a closed circuit. The system includes a membrane tank, the function of which is to receive excess water resulting from thermal expansion.

Induction units are designed to operate in circuits that provide for forced circulation of liquid. For this purpose, a transfer pump is built in. The need to install additional equipment is due to the small size of the heat exchangers, the water in which can boil due to rapid heating, which leads to the formation of deposits in the pipes.

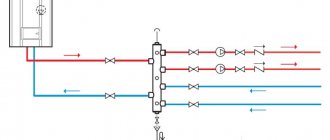

Transfer pumps are installed in each circuit. When using heated floors in a house, the scheme involves installing a distribution manifold and additional pumping equipment.

The electric boiler control system consists of:

- temperature sensors;

- thermostat;

- safety group, the function of which is to prevent overheating and pressure increase above the permissible level.

The elements of the latter are a pressure gauge, air vents and safety valves. Protection against power surges in the network is carried out automatically. Treating some components of the electrical part of the boiler with a compound increases their safety.

Household induction heating equipment can be used when connecting 1 or 3 wires under alternating current voltage (at a frequency of 50 Hz). The power of a single-phase unit is small, so it is used for heating small rooms. The water in the device is heated by cyclic startup and shutdown using temperature sensors that are part of the control system.

The following types of induction boilers are produced:

- casing;

- with volumetric heat exchanger;

- with a tubular coil;

- with inverters.

Electric heating devices with converters use direct current from batteries, which is transformed into high-frequency alternating voltage and only then supplied to the inductor. This equipment power supply system allows the heater to function during periods of no voltage in the network.

The induction heating boiler is supplied complete with a remote control unit, which is designed to automate the operation of the equipment.

Advantages of an electric boiler

The electric three-phase boiler is constantly being improved by developers. Wall and floor models are available.

The best representatives of this class receive additional systems and devices that provide multi-stage adjustment, automation of air exhaust and temperature control processes.

An electric three-phase heating boiler can work in conjunction with other types of heaters. Compactness and design are considered an indisputable advantage.

Although an electric heater is not as economically profitable as, say, a gas heater, it still has certain advantages:

- An electric boiler takes up less space compared to a solid fuel boiler. It can be installed in any place where there is an electrical network;

- No chimney or additional ventilation is required - this is a direct saving of money and time on maintenance;

- It is not a source of unpleasant odors and carbon monoxide. The boiler is environmentally friendly.

- Makes almost no noise during operation;

- The absence of open flames makes it easier to comply with fire safety measures.

Electrode boiler

Electric boilers have a high efficiency of at least 96%.

The disadvantage of a three-phase boiler is the need to convert the current to 380 V and the presence of good electrical wiring in the house. Electricity is more expensive than gas, and frequent power surges affect the quality of boiler operation. This also applies to the disadvantages.

Features of operation

After all the connections in the lines have been made and the device is connected to the power supply, start it up.

To fill the system, the return valve is opened slightly. When the pressure reaches 1.5-2 bar, the valve is unscrewed to bleed air. Next, to start the system, turn on the gas station. By pressing the corresponding buttons on the control panel, the required coolant temperature is set.

During operation of the unit, it is prohibited:

- touch the elements of the grounding system;

- cause mechanical damage to equipment.

It is necessary to periodically call a technician for maintenance and repairs. Before starting the device, you need to check the serviceability of the electrical network.

Safety regulations

Installation of an electric boiler must be carried out in compliance with safety rules:

- Before starting work, make sure that the electrical supply is turned off.

- It is prohibited to install an electric heating boiler in close proximity to a water supply or water source.

- The recommended distances between the unit body and building structures should be observed.

- Make sure that the electrical wiring parameters correspond to the power of the boiler (connecting a powerful unit to a 220 V household network can cause overload and short circuit).

- The boiler must be connected to a grounding circuit.

- Installation of an electric boiler is permitted on a wall made of non-combustible material. If the wall structures are made of wood or other material prone to fire, non-combustible sheathing made of basalt cardboard and sheet metal is mounted on the wall.

- Power cables must not be laid under heating circuit or water supply pipes. If this cannot be avoided, use special sealed housings made of metal or plastic to protect the cable from possible moisture ingress.

- When installing a heating boiler with your own hands, the heating circuit pipelines that are connected to it should be securely attached to the wall so that they do not add load to the body of the unit.

Installation of a residual current device

Installation and connection diagram

The presence of circuit breakers that provide network protection allows you to deactivate the unit in the event of a short circuit and sudden voltage surges. To eliminate fluctuations in the power supply, it is recommended to integrate an uninterruptible power supply into the device connection circuit.

When installing three-phase equipment for space heating, correct grounding is mandatory. All work is carried out in accordance with the instructions developed by the boiler manufacturer.

The most important part of the connection is connecting the wires. The procedure for carrying out this procedure is indicated in the operating instructions.

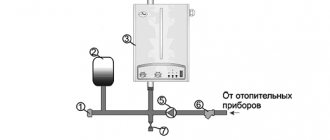

Correct piping is a guarantee of normal functioning of the boiler. Water must be supplied to the device through the return line. This is done so that it is possible to add liquid during operation of the equipment without provoking the development of cavitation.

A tap is installed in the supply line, and a filter is installed in the discharge line. The valves also cut into the pipes of the heating system of the living space.

The boiler must be installed at the lowest point of the heating main. The double-circuit unit must be connected in such a way that the water in the small circuit is heated to the required temperature and supplied to the large circuit.

Device

The single-phase (three-phase) electric heating boiler consists of the following main parts:

- A tank with heating elements built into it (they are also called heating elements), which acts as a heat exchanger (details about: Heating boilers);

- Unit for adjusting and controlling the boiler.

The kit may also include:

- Pump for regulating the circulation of heated liquid;

- Expansion tank with a valve as a fuse;

- Filter.

Electrical installation in a single-phase network

As we have already said, you can connect the water heater to a single-phase network through a plug or a separately powered cable. There is no point in even stopping at the first option, because... Anyone can insert a plug into a socket.

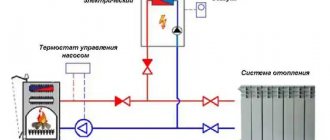

As for the second option, first you need to calculate the current cross-section of the cable (if the required diameter of the cores is not indicated in the product data sheet), and then bring the conductor to the installation site of the boiler. Then everything is simple - we connect the phase, neutral and grounding to the corresponding terminals in the unit (they are marked on them). For your attention, a schematic diagram of connecting an electric boiler with a thermostat to the heating system:

Theory

What is a heating element in an electric boiler? From the point of view of electrical engineering, this is an active resistance that generates heat when an electric current passes through it.

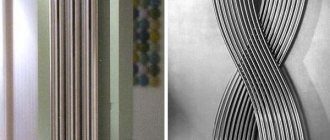

In appearance, a single heating element looks like a bent or curled tube. Spirals can be of very different shapes, but the connection principle is the same; a single heating element has two contacts for connection.

When connecting a single heating element to the supply voltage, we simply need to connect its terminals to the power supply. If the heating element is designed for 220 Volts, then we connect it to the phase and working zero. If the heating element is 380 Volt, then connect the heating element to two phases.

But this is a single heating element, which we can see in an electric kettle, but not in an electric boiler. The heating element of a heating boiler is three single heating elements mounted on a single platform (flange) with contacts located on it.

The most common boiler heating element consists of three single heating elements mounted on a common flange. On the flange there are 6 (six) contacts of the electric heating element of the boiler for connection. There are boilers with a large number of single heating elements, for example, like this: