Procedure for registration and work

The instructions for a flushing organization look something like this:

- The equipment is pre-inspected

. Its technical condition is assessed and initial pressure testing is carried out with a pressure exceeding the working one by 1.25 times, but not less than 2 atmospheres. What is it for? So that leaks that appear during the work do not become a reason for conflict with the customer. Identified malfunctions are eliminated before flushing begins. - An act is drawn up for hidden operations during the execution of work

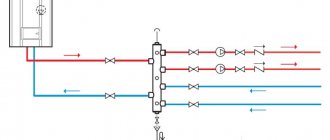

. Let's say on ; for disconnecting flanges for connecting a chemical flushing pump, etc. - The technology for cleaning the heating system is selected

. In the vast majority of cases, hydropneumatic flushing is used using a slurry of water and compressed air; less often - chemical cleaning. - An estimate is drawn up for flushing the heating system

. The total cost includes the cost of depreciation of equipment, fuel consumption, reagents and payment for the actual work, including hidden ones. - Based on the estimate, a contract for flushing the heating system is drawn up

.It stipulates:- Cost of work and procedure for calculating cost.

- Obligations of the parties, including deadlines for completing work.

- After signing, the actual work is carried out

. - After washing, a secondary wash is carried out

. The system is checked for functionality. - Upon completion of all work, a heating system flushing certificate form is filled out

. The customer evaluates the quality of the work and accepts it or declares non-fulfillment of the terms of the contract.

Controversial issues are resolved in the prescribed manner through the courts.

Procedure for crimping

- Before starting tests, it is recommended to check the condition and functionality of the shut-off valves; visually assess the quality of existing connections; isolate the heat supply from the water supply system using plugs.

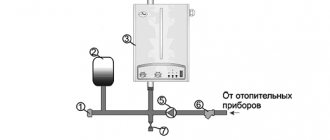

- Then you need to turn off the boiler and expansion tank and pre-flush the pipelines, radiators, etc. from dust, small debris (in the new circuit), from various deposits (in operating systems).

- During hydraulic testing, the system is filled with water (air pressure testing does not require this operation), a compressor is connected to it, usually to a drain valve. After this, the pressure is increased to the required value and its indicators are monitored using a pressure gauge. The absence of any changes indicates the tightness and possibility of operating the system. A decrease in pressure above the permissible value indicates the presence of any defects. In a heating circuit filled with water, it is not difficult to determine the location of leaks. To be able to detect damage during air testing, it is recommended to treat all joints and connections with a soap solution before starting work.

The minimum test time for hydraulic testing is 1 hour, for air testing - 20 hours.

- After troubleshooting, the procedure is repeated. This step is carried out until the system becomes airtight.

- 5. Upon completion of all procedures, a pressure testing report is drawn up.

Figure 2 – Sample certificate of pressure testing of the heating system

It should be remembered that it is not recommended to carry out crimp testing yourself, because... this process requires special skills and knowledge (including regulatory requirements and documents), as well as compliance with safety measures during testing.

When the system should be cleaned

The system will require an initial flush after installation to remove any remaining flux or pipe joining material, as well as any metal particles such as swarf left over from recent installation or changes to the piping.

If the system is properly maintained, well designed, and regularly treated with a corrosion inhibitor, unscheduled flushing is unlikely to be required unless significant changes are made to the system.

However, not all of these requirements are common and sludge can build up in the system very quickly. Here are a few clues that indicate that sludge has already begun to accumulate in the heating system:

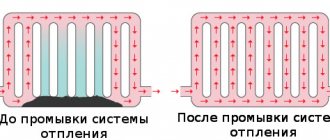

- cold “spots” on the bottom of radiators;

- parts of the heating circuit that do not heat up correctly;

- Excessive noise (bumps, clicks, pops) made by the boiler when it heats up.

The heating circuit should also be thoroughly flushed before installing a new high-efficiency condensing boiler, as the heat exchangers in such boilers are particularly susceptible to damage from contaminants in the heating system.

General information

Before cleaning, you should check the system to determine its configuration. You also need to determine the “age” and general condition of the components in order to select the required system flushing mode. For example, the procedure may remove corrosive debris blocking openings in radiators, which can lead to coolant leaks. If there is any doubt as to whether the system will withstand any cleaning methodology, replacement or repair of the relevant components will be required before proceeding.

Cleaning procedure

There are several ways to clean a system and there are a number of cleaning products on the market designed to help flush heating systems. Many products are designed to be added to the circulating water some time before flushing and help mobilize contaminants prior to flushing. Here you need to follow the instructions from the manufacturer of these products.

Basic flushing procedures:

- Powerflushing.

- Overpressure flushing.

- Flushing with a circulation pump

Positive pressure flushing is probably the most effective procedure (although it is important to check the boiler manufacturer's instructions to determine whether flushing the system using the boiler in the heating circuit is acceptable). Powerflushing is also an effective method for cleaning heating systems, especially those containing high levels of black magnetite sludge.

Powerflushing is also an effective method for cleaning heating systems, especially those containing high levels of black magnetite sludge.

Please note that with all methods, changing the direction of coolant flow will help remove debris that could otherwise remain in the system and cause it to fail.

Preparation

Before flushing with any method, there are several general preparation steps. Typically these involve adding a suitable detergent to a running heating system and letting it sit for some time before actually flushing. The cleaner is usually flushed (while hot) from the system and the system is primed to begin the final flushing process.

Before flushing, you may also need:

- Turn off all electrical controls and electrically isolate the system.

- Avoid supplying cold water to the central heating system.

- Manually close all heating circuit vents.

- For systems with open ventilation, close or temporarily connect the open ventilation and cold water supply to the supply and expansion tanks.

- When draining a vented system, the collection tank may have quite a large portion of floating sludge. It must be removed to prevent it from being drawn into the pipeline.

- Mark the operating position of any shut-off valves or other control valves, and then open all valves fully.

- Remove all thermostatic radiator valve (TRV) heads to ensure maximum flow through the valves.

- Set any diverter or zone valves to their manual open position.

- Where check valves are present, they must be closed, bypassed or temporarily removed, otherwise this will prevent flow reversal.

Features of registration of the washing certificate

To control the quality of work, water is taken from different parts of the heating system.

Sample documents.

The simplest way to check is this: in the entrances or apartments, unscrew the blind radiator plugs and evaluate the quality of the work. There may be water or sludge on the radiator cap, but there should be no solids.

Then a washing report is drawn up, which should contain the following information:

- heating system cleaning method;

- water consumption, if there are metering devices;

- water temperature (if washing was performed with hot water);

- service quality assessment: satisfactory or unsatisfactory;

- signatures of persons responsible for the work;

- date of service.

If the act has a unified form, then a special form is drawn up. For a sample washing report, various organizations use documents that may differ in detail, but the contents of the document must comply with the state quality standard.

(Document)

- Letchford A.N., Shinkevich V.A. As-built documentation in construction (Document)

- Cheat sheets – Organization of construction production (Crib sheet)

- Abstract Restoration of buildings and structures (Abstract)

- Komkov V.A. Technical operation of buildings and structures (Document)

- RSN 8.01.102-2007 Collection of resource estimates for the construction of temporary buildings and structures (Document)

- RSN 8.03.105-2007 Collection 5. Pile work. Drawer wells. Consolidation of soils (Document)

- Litvinova O. O, Belyakova Yu.I. Construction technology (Document)

- Moiseev I.S., Shaitanov V.Ya. Inventory production enterprises in hydropower construction (Document)

- Yudina A.F. Reconstruction and technical restoration of buildings and structures (Document)

- Safety rules for the construction of underground structures (Standard)

- Technical regulations on fire safety requirements. Federal Law of the Russian Federation of July 22, 2008 N 123-FZ (Standard)

Features of dismountable flushing of the heat exchanger

If the heat exchanger is very dirty or completely out of order, dismountable flushing can help. The rules and technology for dismountable washing are quite simple. It is necessary to disassemble the heat exchanger, remove all the plates, soak them in a special solution, wash each plate manually, and insert the package of plates into the heat exchanger. After this, the heat exchanger is assembled and pressure tested.

By following the rules of this work, you will receive many benefits:

- dismountable heating flushing guarantees the highest quality;

- any contamination is eliminated;

- everything happens clearly, and you can see the entire work process.

However, there are also disadvantages that cannot be avoided, even if you follow all the rules of work. So, if your heat exchanger has been worn out, under critical conditions, or the service life of the rubber seals has expired, then you may have to change the heat exchanger seals, which will increase the cost and duration of the work.

- in the case of dismountable washing, it is sometimes possible to remove contaminants using a jet of water from a special high-pressure apparatus;

- If there are more serious deposits, you must first clean the heat exchanger plates from the top layer of deposits using a high-pressure apparatus, then soak them in an acid solution, and then clean them again using a high-pressure apparatus.

Options for flushing heating systems

The choice of cleaning method depends on the total length of the circuits, the degree of contamination and other factors. Methods include:

- Mechanical method.

- Hydrochemical cleaning.

- Hydrodynamic flushing.

- Electrohydropulse method.

- Hydropneumatic option.

Washing Process

Some methods require equipment. Hydropneumatic guns can be rented, but you will need some skill to operate them.

There are a number of general rules for flushing the heating system of a private or apartment building. If you deviate from their implementation, efficiency will be low.

Mechanical cleaning

The method is suitable for cleaning batteries. All other elements will have to be cleaned separately. First you need to drain the coolant from the system. You must first close all valves that limit the flow of coolant into the radiator. In high-rise buildings, valves are usually located in the basement, in private houses - on parts of the circuit before and after the heating element.

Mechanical cleaning

To drain the liquid, you need to open the drain valve located on the circuit. If it is missing, it is enough to unscrew the plugs on the last battery located below the others.

It is convenient to discharge the coolant through a hose that is connected to the tap and discharged into the sewer. The mechanical cleaning method is effective when the heating elements are first removed and the pipes and radiators are cleaned separately.

The dismantling method depends on the connection options and other parameters. It is necessary to protect the floor from flooding by placing a container. Take the radiator outside or into the bathroom (the enamel parts must be protected with a rag). To prevent clogging of the sewer, it is necessary to block the drain in the sink with a network.

After mechanical cleaning, it is necessary to rinse the pipes with plain water. Through a water tap or hose, supply water under pressure into the radiator. Rinsing is carried out until the water becomes clear.

Hydrodynamic cleaning

The method involves supplying water to the circuit from a pump under high pressure. Can be connected to an open circuit to use as many radiators as possible before the water is discharged. However, special hoses are used for this.

Hydrodynamic flushing principle

For small deposits, pressurized water effectively counteracts salts and dirt. You will have to rinse several times. After cleaning, the operation of the heating system will improve significantly.

Chemical washing method

The principle of the method is based on the introduction into the cavity of the radiator of substances that dissolve or promote the peeling of scale. They use both ready-made substances and solutions prepared with their own hands. It may not be necessary to remove radiators from brackets.

However, it is prohibited to wash aluminum radiators. Caustic solutions are formed that cannot be poured down the drain.

To clean lightly dirty circuits, it is enough to:

- Soda;

- Vinegar;

- Acid.

It is better to use special compounds. After finishing work with chemicals, it is necessary to flush the pipes.

Dry cleaning

Hydropneumatic flushing

This cleaning method involves treating internal surfaces with an emulsion under high pressure. Emulsion is a mixture of water and oxygen. The effectiveness of the method is high, however, sophisticated equipment is required.

Suitable for cast iron radiators with large collector capacity. There are no strict requirements for the type or material of elements. The method is quite expensive, but is compensated by its effectiveness and safety. To reduce the impact on batteries, pre-treatment with chemicals is necessary.

Hydropneumatic

Electrohydropulse technique

The principle of operation of the method is to use an electrical pulse that destroys insoluble substances that transmit current.

To create an impulse of this level you need a special apparatus. A coaxial cord is connected to it, on which a charge is formed; the shock wave destroys scale on the surface of pipes or radiators. After cleaning, you need to rinse the system with clean water.

Electrohydropulse washing, results

This method is effective and does not require complete disassembly of the system. However, equipment is required. Slag waste can be washed down the drain.

Sample act of flushing the water supply system. Certificate of flushing the heating system - sample contract form

31.03.2019

Flushing of heating systems is carried out by specialized organizations after the preliminary conclusion of an appropriate agreement. Upon completion of flushing heating systems. The sample and appearance of this document depend on the complex of activities carried out by specialists.

Goals

Let's immediately separate the flies from the cutlets, so to speak.

- Testing and flushing of the yard water supply network is carried out as part of the transfer of the facility from the construction to the operating organization. , checked for leaks, cleaned of debris, foreign objects and disinfected.

Important: cold water supply is positioned as drinking water, which implies strict requirements for the composition of the water.

- If the throughput of the water supply system is significantly lower than the norm for a pipe of a given diameter, it needs mechanical cleaning or chemical washing with reagents that dissolve lime deposits and rust. The use of hydropneumatic flushing in this case, as a rule, does not bring any results.

Tests

The procedure for hydraulic tests is comprehensively set out in SNiP 3.05.04-85, which regulates, in particular, the construction of external water supply networks.

According to SNiP, the test must be carried out hydraulically or, if it is impossible to fill the water supply before it is put into operation, by air. The pressure during testing should be:

Disinfection and washing

Guidelines for disinfecting water supply can be found in the same SNiP.

According to the document, you can use:

Bleach is the most common disinfectant.

- Sodium hypochlorite solution.

- Liquid chlorine.

Flushing (cleaning) of the pipeline can be performed:

- Elastic piston. As a rule, this role is played by a foam rubber cylinder with a diameter 1.3 times larger than the internal diameter of the water supply and a length of 1.5 - 2 times the diameter.

The photo shows foam pistons for cleaning water supply pipes.

- Water distilled through a section of a water pipeline for discharge.

- Pulp (water-air mixture). Hydropneumatic flushing is organized by supplying air with a compressor; The optimal ratio of water and air in the pulp is 1:1.

The foam piston can be used in areas with smooth turns at an angle of no more than 15 degrees with the valves fully open and in the absence of structures protruding inward.

The speed of movement of the piston at a pressure in the pipeline of 1 kgf/cm2 should be in the range of 0.3 - 1 m/s.

In this case, the diameter of the discharge through which contaminants leave the water supply system can be only one step smaller than the diameter of the pipe being flushed.

When hydropneumatic flushing, air should be supplied into the pipeline under pressure 0.5-1.5 atmospheres higher than water pressure. The speed of pulp movement should be within 2 - 3 m/s.

Disinfection of pipelines is carried out in sections no longer than 1-2 km at a time. In this case, temporary control valves are installed every 500 meters to take samples for chlorine concentration.

Based on the results of the work, a certificate of flushing the internal water supply systems and its disinfection is drawn up.

Its text should indicate:

- Composition of the commission (SES, construction and installation organization and operators).

- Description of the object (type, length, diameter, volume).

- Type of reagent and concentration of active chlorine.

- Duration of processing.

- Results of biological and physicochemical analyzes of water after treatment.

Removing blockages

Dealing with cold water supply is very different from flushing a heating system or cleaning a sewer. The key difference is that the blockage cannot be destroyed by a stream of water or weak mechanical action: the pipes are overgrown with durable lime deposits and rust.

However: sometimes the initial cause of a blockage is sand or a piece of scale. If it is not removed immediately, after some time the blockage becomes cemented and can be destroyed with great difficulty.

Is it possible to do something with your own hands if the water pressure in a house with an old steel water supply has dropped catastrophically?

- Try plugging the faucet with your finger and simultaneously fully open the cold and hot water taps. DHW pressure is noticeably higher most of the year; the counterflow can destroy a fresh blockage, after which its fragments will be carried out by water into the sewer.

- If this does not help, repeat the operation by resetting the cold water riser. The pressure difference between the hot water supply and the empty riser will be significantly greater.

- Is the water still not flowing at normal pressure? Open the valve (with the riser down, of course). Debris deposits under the valve seat are a common problem with cast iron and, to a lesser extent, brass screw valves.

- Finally, if all else fails, try disassembling all available threaded connections and cleaning the pipe with a steel wire from the curtain rod, bending a hook the size of a pinhead at the end. On the second side of the string a handle is formed, resembling a well gate. The string is fed into the pipe with continuous rotation; after it passes the blockage, its remains are washed with water.

Advice: lime deposits dissolve well with acid solutions. Just plug the pipe near the valve and fill it with the reagent for a couple of hours.

As an active substance, you can use imported Cillit or, which is much better, a solution of dry oxalic acid: its price is several times lower with much greater chemical activity.

Conclusion

We hope that we were able to satisfy the reader’s curiosity, and at the same time help him in solving some everyday problems. The video in this article will provide additional useful information to his attention. Good luck!

When providing services for flushing the heating system by specialized companies, documentation of the work performed is required. First of all, an estimate is drawn up and a contract is concluded.

Then the heating system flushing certificate is filled out and signed. Pipelines, radiators and connections to them require preventive work.

The technical side of flushing, as well as its documentary component, have their own peculiarities.

Causes of clogged heating pipes

The water contains many additional components. The most predominant are iron, calcium and magnesium. When exposed to relatively high temperatures, they are released in the form of small fractions that settle on the inner surface of pipes and radiators.

Therefore, before washing aluminum radiators, you need to find out the nature of the contamination. In addition to calcium and magnesium deposits, oxide deposits can form due to natural rusting of metal heating components. Depending on the nature of the contamination, the optimal cleaning technology is selected.

Usually the plaque includes the following elements:

- Iron oxides. In a system with steel pipelines and radiators, they can occupy up to 25% of the total plaque volume;

- Calcium and magnesium deposits occupy up to 60%;

- Oxides of copper, sulfur and zinc – up to 15%.

Since the heating radiator in an apartment should be flushed only after a preliminary analysis of the nature of the contamination, it is recommended to first take a plaque sample. To do this, you can dismantle part of the pipeline. In practice, this is not always done, especially for heating systems installed relatively recently.

Form of act on carrying out (purging) of pipelines (SNiP 3.05.03-85, Appendix 3)

ACT ON WASHING (BLOWING) OF PIPELINES

Commission consisting of:

| representative of a construction and installation organization | ||||

| representative of the customer's technical supervision | ||||

| (last name, first name, patronymic, position) | ||||

| representative of the operating organization | ||||

| (last name, first name, patronymic, position) | ||||

| inspected the work performed | ||||

| (name of construction and installation organization) | ||||

and drew up this act as follows:

1. Flushing (purging) of pipelines in the area from chamber (picket, shaft) No. _________ to chamber (pickets, shafts) No. ____route is submitted for inspection and acceptance

| length | m. | |||

| (name of pipeline) | ||||

| Washing (purging) completed | ||||

| (name of medium, pressure, flow) | ||||

Commission decision:

The work was carried out in accordance with design and estimate documentation, standards, building codes and regulations and meets the requirements for their acceptance.

Appendix 125

Stages of preparation and carrying out crimping

Before starting preventive manipulations, the master determines the features of the system. The calculation is needed to supply the standard pressure, since exceeding the indicator will damage the heating equipment.

Indicators taken into account:

- type of wiring;

- characteristics of the pipeline - material, wall thickness, degree of wear;

- number of storeys of the building;

- features of shut-off valves.

Upon completion of the calculations, the specialist will pressurize the network.

Stages of work:

- Preparation of equipment for injection of water or air.

- Disconnecting the network from the coolant supply. This is required during the heating season if equipment was repaired after a pipe or battery burst.

- Draining coolant from the main.

- Injection of test substance under pressure. Maintaining the design high pressure for a certain period of time.

- Draining the test coolant, flushing the system, filling with standard substance.

After the test, a crimping certificate is issued. Defects identified during prevention should be eliminated. The absence of leaks means the line is ready for continuous operation.

Why do you need to flush your heating system?

The water that flows through the heating pipes is far from distilled. What it doesn't have:

- mechanical impurities: rust, sand, scale and other dirt;

- chemical impurities: metal salts, especially calcium and magnesium;

- microbubbles of dissolved air and other gases.

Coupled with temperatures up to 100°C and high pressure, all this forms a “hellish” mixture. Chemical reactions take place around the clock, the main result of which is the formation of scale, corrosion of heat exchangers and communications.

The water entering the system must not only be filtered from mechanical impurities, but also brought to the required chemical and physical characteristics, that is, meet the standards for water treatment in thermal systems.

If measures are not taken in a timely manner:

- the heat transfer of the system is noticeably reduced;

- energy consumption increases;

- The walls of the pipes and boiler become thinner and destroyed, and leaks form in various elements of the pipeline.

There are several ways to remove harmful deposits. Of these, hydropneumatic flushing of the heating system is the most radical and effective. It is used both in private and multi-storey buildings.

Why is system pressure testing used?

The heating system has natural or forced circulation of coolant. In forced systems, the liquid moves through pipes using a pump; in natural systems, it is supported by a certain pressure in the circuit. Pressure testing - checking the tightness of all connections. It is performed immediately after installation of the system before commissioning, as well as after a period of downtime in the off-season, repair, redevelopment and modernization of system elements.

Pressurized water or compressed air is supplied to the heating system circuit. This procedure allows you to identify weak points in the circuit, poor-quality connections, and leakage points. Damaged elements and places with poor-quality connections leak. Thus, it is possible to quickly and efficiently eliminate malfunctions before starting the system. Checking for leaks prevents circuit breakage and leakage during sudden pressure changes in the heating system.

Types of tests during pressure testing of heat supply systems

Pressure testing is, first of all, testing heating systems with increased pressure created using air or water. In accordance with this, they distinguish:

- pneumatic testing - its main purpose is to check the tightness of all connections and the system as a whole; To carry it out, electric or manual pneumatic pumps are used, filling pipelines, radiators and other elements with compressed air;

It should be borne in mind that pneumatic testing is a dangerous process, because... If there is any damage in the system, air is not only quickly released, but can also cause significant damage. In this regard, it is not recommended to increase the pressure more than 0.15 MPa.

- hydropressure testing - such tests allow you to check the strength of the system, and to create excess pressure in it, various types of hydraulic pumps are used.

As a rule, the pressure created during hydropressure should exceed the standard working pressure by 20-30%, and with air - by 40-50%.

Is it possible to wash a separate battery?

Now you know how to flush the heating system. However, sometimes it becomes necessary to clean a separate battery. There is a solution for this situation too.

Buy a flushing faucet from a plumbing store. Additionally, you need to purchase a rubber hose and a fitting with a thread that matches the diameter of the purchased flushing valve. Install the fitting onto the hose.

Direct washing is carried out in the following sequence.

First step. We connect the flushing tap to the heating radiator.

Second step. We connect a fitting with a hose to the flushing tap.

Third step. We direct the second end of the rubber hose into the toilet.

Fourth step. Open the flush tap and leave for 20-30 minutes. While waiting, hold the hose so that it does not jump out of the toilet.

Additional work

After washing pipes and other equipment, it is advisable to perform pressure testing. This additional procedure will allow you to check the tightness of the entire system and identify places where air or water may escape. Such actions are not mandatory, but highly desirable. They correspond to the interests of both the customer and the contractor. Upon completion, both will be able to verify the quality of the previous stage. The completion of the work is recorded by the act of flushing and pressure testing the heating system. A sample of it will look like a table that contains a list of all activities carried out during such a procedure.

Against each of the points, the specialist must make a note of completion. At the end, as usual, the customer and the contractor put their signatures, confirming the fact of the work. Experts sometimes call this procedure a hydraulic test, since most often such a test is carried out using water. It is believed that the air may be more dangerous when serious faults are detected. Therefore, many people prefer to take the easier path.

Components of the heating system pressure test report

At the top left is information about the organization that carried out the inspection. Ideally, there should be a signature for approval by the chief power engineer of the heating supply organization.

The top right should contain subscriber information. That is, about who is the client and consumer of heating services. This could be a partnership of residents of a particular house, any organization that occupies the building, the owner of a private house, etc.

It is important to provide names and other information accurately and in detail. In this case, an address is required.

The main part of the act states:

- City.

- The date of signing the act (and the pressure test itself).

- Heat supply organization: its form of ownership, name, full name of the representative.

- Which of the subscriber's representatives accepted the heating system after the test: full name, position.

- To what indicators the pressure in the system was raised is indicated in kgf/cm2.

- To what indicators did it drop after 10 minutes following the shutdown (the units of measurement here are also kgf/cm2, it is also permissible to measure it in mPa if accurate data on this matter is available).

- Whether the system passed or failed the test (the person completing the form needs to highlight the correct option).

The final part consists of the signatures and seals (if any) of the representatives:

- Subscriber.

- Heat supply organization.

- Service organization.

In general, the act of pressure testing the heating system is a convenient primary document, for filling out which the heat supply organization is responsible.

chemical flushing of the boiler _______, inventory number _______,

____ year of manufacture, located in the boiler room _____________________

We, the undersigned: 1 Repairman____________________, 2. Chemical engineer _________________________, have drawn up this ACT stating that during the period from _______ to _______ in the boiler room _________ a chemical flush of the boiler ________________________________ was carried out in the following volume. 1. Installation and hydropressure testing of the flushing circuit, testing the performance of the flushing equipment on water. Duration __ hours. 2. Acid flushing of the boiler. Sulfuric acid concentration __%. The concentration of methenamine inhibitor is __%. The temperature of the washing solution is __ OS. Air stirring - every __ hours. Washing duration is __ hours. 3. Water flushing of the boiler. Filling the boiler and emptying it – __ times. Duration __ hours. 4. Alkaline-phosphate boiler flushing, acid neutralization, passivation of steel surfaces. Alkali concentration __%. Phosphate concentration __%. The temperature of the washing solution is __ OS. Air stirring - every __ hours. Duration __ hours. 5. Water flushing of the boiler. __multiple water exchange has been carried out. Duration __ hours. 6. Chemical control of washing water at the end of washing: — transparency – __; — pH – __; — sludge (visually) –__; - hardness - __.

Procedure for cleaning pipes yourself

To clean the heating system pipes with your own hands using chemicals, you need to know how to flush the heating system and follow a certain sequence of actions:

- The system must first be thoroughly examined to determine which solution to use for cleaning.

- Next, carefully study the instructions for the selected chemical. The solution must be prepared in strict accordance with the specified recommendations, since each preparation has a certain consistency.

- Fill the pump reservoir with the prepared solution and connect the device to the system.

- It is necessary to ensure that the chemical is moving through the system.

- Wait a certain period of time, which depends on the degree of contamination and its composition.

- At the end of flushing, remove the chemical solution from the system, rinse it thoroughly and fill it with clean water.

Heating system pressure test certificate

The act of crimping is a document that has legal force. It confirms that:

- all work and tests were carried out in full and in accordance with the approved program (it is drawn up by an engineer of the heat supply organization);

- heating equipment is in working condition and ready for use;

- in case of emergency situations, responsibility lies with one of the specified parties (or both), which must compensate for the damage caused.

The act contains several points that must be filled out as completely and accurately as possible. Among them are:

- name of the object (house, plot);

- date and time of crimping;

- instruments used for testing;

- system diagnostic parameters (load amount, duration);

- test results;

- information about the repair activities carried out;

- signatures of responsible persons.

Persons responsible for the conduct and results of crimp testing

Pressure testing of heating systems should be carried out:

- a representative of the heat supply organization (inspector, foreman, engineer, technician), who has the necessary certified equipment and certificate forms;

- representatives of the facility where testing is performed; in apartment buildings - employees of the management company; in administrative and social facilities - managers and persons from the supervisory organization; in individual buildings - the owners.

- If pressure testing is carried out in a building being put into operation, representatives of the customer and contractor organizations must be included in the commission.

Replacing piping is an expensive option for improving your heating system. High-quality flushing of the system allows you to eliminate various contaminations of pipes, which lead to a significant reduction in the heating temperature of heating equipment.

Pipes before and after flushing.

High fuel consumption and low heating temperature of the heating system are the most important indicators of the need to clean the system.

Peculiarities

Flushing the heating system cannot be done “blindly”, because you need to know what you will encounter. Typically, batteries do not heat up well when the fluid circulation in them is weak due to debris clogging the internal walls. It is found in the water itself in the form of suspensions of alkali salts, heavy metals and rust. Utilities are required to flush the system annually to prevent a decrease in water flow. But often this task has to be performed by the residents themselves, inviting specialists to clean the radiators from the dirt compacted inside.

This problem is especially typical for cast iron batteries, where sometimes there is a channel for water circulation no more than 1 cm in diameter due to infrequent washing. The cause of clogging of steel radiators is stagnation of rust, due to which they are subject to not only clogging, but also destruction. Not every type of flushing is suitable for such batteries, since after some methods leaks may appear in them. Plastic radiators also become clogged, but cleaning them differs from cleaning their metal counterparts.

This process cannot be called universal, because it is selected specifically for each case. An example of a bad choice is the flushing of the heating system by housing and communal services workers, when they apply powerful pressure by abruptly opening the riser valve located in the basement of an apartment building. This leads to knockout of locking elements and leaks at the junctions of spans. But not every family owner can disassemble the battery into separate bends for the purpose of mechanical cleaning in order to solve the problem of a clogged heating system.

When flushing radiators in an apartment on the lower floors, one cannot always expect the efficiency of the coolant, since for high-quality cleaning it is necessary that the neighbors of all floors of the same branch do the flushing. Otherwise, after cleaning one apartment and washing the batteries by utility workers with high pressure, some of the garbage may fall behind the walls, and mud masses will fall into the newly cleaned batteries. However, it is unlikely that all neighbors will agree when it comes to flushing, but the insufficient internal cross-section creates high hydraulic resistance.

Every mm in thickness of deposits increases fuel consumption by 20-25%. In central heating systems, the water must be pre-treated to reduce clogging. But this is not always done, although residents pay decent amounts every month for house maintenance. In addition, radiators last for decades without replacement. According to the established regulations, flushing of centralized and autonomous systems must be carried out annually. This period is critical. If the pipes are not flushed before the start of the heating season, the pipeline becomes clogged, causing the heating equipment to break down.

If you ignore the blockage, the consequences can be disastrous:

- the heating system may freeze;

- you will have to buy new batteries;

- You will need an electric heater, which will increase the price of electricity.

Concentrates

DIXIS LUX

The drug is diluted with water (preferably soft or rain) in a ratio of 1 to 9. The product is suitable for heat transfer surfaces made of ferrous metal, stainless steel, and copper alloys.

Price: from 1530 rub./10 l.

DIXIS LUX

pros

- low price;

- neutralizing solution included;

- You can drain the used product into the sewer;

- quick rinse (2.5 hours);

- Contains only organic acids, acid corrosion inhibitor.

Minuses

the required temperature of the working environment is 60...70 °C.

DIXIS LUX

ARGUS SUPER POWER

Before use, the concentrate should be diluted with 10-15 liters of water, depending on the degree of contamination. Contains a corrosion inhibitor. Operating temperature for effective cleaning is 20...40 °C.

Price: from 1200 rub./4 l.

ARGUS SUPER POWER

pros

- low cost;

- color indicators;

- corrosion inhibitors;

- low operating temperature.

Minuses

- has a characteristic odor;

- there is no information about the possibility of draining liquid into the sewer.

ARGUS SUPER POWER

Heat Guardex Cleaner 824R

The product is intended for cleaning the circuit in a heating system running on antifreeze. The product is diluted in a ratio of 1 to 30.

Price: 6400 rub./l.

Heat Guardex Cleaner 824R

pros

- highly concentrated substance;

- Effectively removes sludge and glycol residues.

Minuses

high price.

Heat Guardex Cleaner 824R

TELAKKA HEAT

1 liter of concentrate is diluted in 3–5 liters of water. The product is suitable for flushing systems with plastic and rubber tubes. The product is safe for sealants. The working temperature of the solution is 20...35 °C.

Price: from 1600 rub./5 l.

TELAKKA HEAT

pros

- operates at relatively low temperatures;

- contains anti-corrosion components;

- safe for rubber seals;

- without smell;

- does not contain mercury, chlorine, heavy metals and other harmful components;

- When combined with waste water, it does not form toxic or explosive compounds.

Minuses

- not suitable for products made of aluminum, non-ferrous metals and stainless steel;

- quite high cost.

Telakka HEAT heating system cleaner

SYNTILOR Watesup

This professional product is suitable for washing pipes made of plastic, metal alloys, and rubber. Requires prior testing when used in stainless steel equipment. Requires dilution in 5–15 liters of water. The solution does not destroy seals.

Price: from 450 rub./l.

SYNTILOR Watesup

pros

- operates at low temperatures 20...35 °C;

- does not destroy rubber, plastic;

- does not affect the structure of metals;

- provide protection of metals from oxidation;

- has no pungent odor;

- without mercury, heavy metals, chlorine.

Minuses

- not suitable for cleaning aluminum and aluminum-based alloys;

- relatively high cost.

SYNTILOR Watesup

SYNTILOR Watesup All

The product is intended for flushing heating systems made of aluminum. The product does not destroy seals. Before use, it is recommended to dilute in 5–15 parts of water.

Price: from 480 rub./l.

SYNTILOR Watesup All

pros

- the preparation can also be used for different types of steels, including stainless steel (after a preliminary test);

- the solution is compatible with plastic and rubber pipes;

- does not contain mercury, heavy metals, or other harmful impurities;

- without smell;

- effective at temperatures 20...35 °C.

Minuses

not noticed.

SYNTILOR Watesup All

Flushing heating pipes

Cleaning of the pipeline is recommended before testing. The process is needed to eliminate deposits inside tunnels and radiators in order to prevent inaccuracies in the results of crimping.

Why do flushing before crimping? This procedure will help identify sections of the pipe with thin walls. If a layer of slag has grown on the inside of the tunnel, the line will withstand the pressure testing, but will burst at any moment during the heating season. To prevent such an outcome, it is recommended to first flush the pipes, then perform pressure testing.

Flushing should be done with an electric or manual compressor, with or without dismantling the radiators. The recommended frequency of the procedure is once every 4-6 years.

Methods for cleaning the heating network

To eliminate blockages and accumulations inside tunnels and heating devices, various means and equipment are used.

Let's look at some of them:

- Hydrochemical washing. The process uses special chemicals to dissolve salt and lime deposits. The procedure is not the main one, it is auxiliary, since it does not remove bottom accumulations of silt.

- Pneumatic shock. Removes all deposits inside the tunnels. After exposure to the wave shock, the network is washed with water pressure.

- Sparging or pneumohydraulic cleaning. It is organized by simultaneous supply of air and water under pressure. Efficiency reaches 89%, so bubbling is used most often to remove blockages.

Experts recommend a comprehensive flush that includes all of the options listed. The process is relevant for significantly contaminated pipes or lines with a small cross-section.

Hydropneumatic flushing

This flushing technique has been used by the domestic housing office for more than a decade, therefore, it is quite effective. Of course, if everything is done correctly.

Video guide

Video air gun Typhoon

Carrying out this procedure is quite simple: water is discharged from the system first on the return line, then vice versa. In this case, the water flow must be “adjusted” with a powerful pneumatic pump. Strong pressure will remove deposits and scale and carry them out of the system.

Regarding the mentioned housing office, the flushing of the heating system, which is carried out by its employees, looks something like this:

- the return valve is closed;

- a pneumatic pump is connected to the valve, which is located after the valve;

- the “return” is reset;

- after the pressure in the pump exceeds 6 kilograms per square centimeter, the valve to which it was previously connected opens;

- all risers are blocked in turn, but so that no more than ten are blocked at the same time; Only if all these conditions are met will the washing be carried out extremely effectively.

The time that the procedure will take can be easily determined by eye, taking into account the degree of contamination of the heating system. New risers begin to be cleaned only after the water from the previous ones comes out completely purified

After flushing all the risers, the system is switched to discharge in the opposite direction.

- the discharge closes, as does the valve to which the air pump was connected;

- the open valve is also closed, after which a similar one on the “return” is opened;

- the system is reset - the device is connected to the valve in the reverse direction, the valve opens, and the device turns on.

The next steps of the procedure are the same as in the previous version, only the water will move in the other direction.

Heating system flushing report: documents, form, sample, snip, hydropneumatic flushing

: 5 569

In this article you can learn about the features of registration and preparation of documents accompanying flushing of the heating system. Accompanying documents for flushing include an estimate, contract, forms and a certificate of flushing the heating system. You need to know certain nuances

Algorithm for completing documents and the procedure for drawing up an act

Organizations involved in the repair and maintenance of heating systems have an algorithm for drawing up documents and a procedure for drawing up reports that determine the procedure for flushing.

Such instructions are usually composed as follows:

- Inspection of heating equipment for cracks, chips and places where the walls of the pipeline have become thin. The pipeline is checked using increased pressure, the value of which increases by 1.25 times. Moreover, its value should not be less than 2 atmospheres. Such a check is carried out to ensure that the detected malfunction (if any) does not become a cause of disagreement between the customer and the contractor;

- After inspection, repair work is carried out to eliminate cracks, leaks, etc.

- The next step is to draw up an act containing information about the previous stage. That is, records are made about unforeseen repairs;

- After documenting the repair, a method for flushing the heating system in your home is selected. Most often, hydropneumatic washing is chosen, which is carried out using a pulp containing water and compressed air;

- The penultimate step is drawing up an estimate of the work done, the cost of which includes the cost of depreciation of equipment, fuel costs, chemicals, and also takes into account the labor of workers.

Based on all of the above, a contract for flushing the heating system is drawn up. This document, the act, stipulates the cost of services provided and the sequence of their implementation.

In particular, the contract and form spell out the responsibilities and obligations of the customer and contractor and the timing of flushing the heating system.

It is very important to include in the contract fines and sanctions for failure to complete it on time or for poor performance.

Sample contract

These points will help avoid conflicts and push the contractor to perform higher quality and more conscientious work.

This clause is called “liability of the parties”. It is also necessary to indicate in the act for flushing the heating system in what cases, in what situation and for what reasons this contract can be terminated

At this stage, the work is just beginning, since before flushing the heating it is necessary to carefully check everything and document both the test results and organizational issues. The drawn up agreement is signed by the parties.

It must be remembered that all controversial issues that arise and are not resolved at the level of management of the organization carrying out the work are resolved in court.

To do this, it is extremely important to keep all documents confirming the work carried out by company representatives in your home.

The final stage is the actual work of flushing the heating system; then a secondary check of the pipeline and radiators should be carried out for leaks and cracks. Then a final performance check is carried out and, after the customer evaluates the work, the heating in the house is started.

Important nuances and technical points

What does flushing the heating system mean and what important nuances and technical points should be taken into account during the work? The liquid contains chemicals that facilitate the peeling off of limescale and other metal deposits that have formed during use. The reagent in this case is an alkali or acid solution, which will prevent the formation of rust in the pipeline. The reagent, circulating for a long time in the pipeline and heating radiators, washes away sediments that reduce heating performance.

Chemical cleaning

The customer should be aware that the chemicals used in flushing heating systems are very toxic and aggressive. Disposal of such waste into regular sewerage is not possible.

Therefore, to dispose of them, a special container is required. The contractor is responsible for disposal.

The alkali is first neutralized with an acid or vice versa, depending on what was used in the process.

Unfortunately, the reagents are not able to cope with the sludge that settles on the walls of the pipeline and batteries. Therefore, there is a second way to flush the heating system of a house or apartment.

Hydropneumatic flushing

As mentioned earlier, hydropneumatic flushing of the pipeline heating system is carried out using a special pulp.

This method of descaling pipes involves using a large amount of water. Houses connected to central heating or water supply use hot water circulating in pipes.

If the heating system is located in a private house, then purification is carried out using cold water supply.

Hydropneumatic cleaning

When flushing the heating with hydropneumatic pressure cleaning, perform the following algorithm of actions:

- the water is forced to circulate in the opposite direction to the heating, then it is started again;

- together with the incoming liquid, compressed air is blown in using a compressor;

The resulting flow copes well with sludge, but does not sufficiently wash away salt deposits and rust formed on the walls of the pipeline and radiators. When risers are used in heating, during the process they are blocked in groups and washed. The fewer risers are included in the group, the better the radiators will be cleaned.

When cleaning the heating yourself, it is very important to carry it out until the waste liquid is as clean as possible and no longer contains rust particles or sediment.

Acceptance of finished work

In order to accept the finished work, you should take a control water intake in different places of the heating systems. Evaluate the quality of the circulating water by eye.

It should be as transparent as possible and free of particles.

The works of housing and communal services employees are accepted as follows: they open some sections of the pipeline in apartments and entrances and visually assess the internal condition of the battery.

Heating flushing act

The act of flushing the heating system, in addition to the cost of the services provided and the method of flushing, must contain the parameters of the liquid used for cleaning. The amount of water consumed and its temperature.

Didn't get an answer to your question? Ask our expert: Ask

Source: https://SdelatOtoplenie.ru/dokumenty-dlya-promyvki-otopleniya.html

Conclusions and useful video on the topic

You can see how to flush a heating system that consists entirely of heated floors in this video. The chemical washing method was not chosen by chance, because other options are almost impossible to implement with so many tubes, connections and bends:

Cleaning a separate radiator using the hydropneumatic method is shown and described here:

When choosing a flushing method for your heating system, try to find a balance of convenience, cost and safety for both the pipes and the environment. Remember that it is up to you to live with this system and repair it in the coming years.

How often do you flush your heating system? Do you use the services of professionals or do it yourself? Which washing method do you prefer? Join the discussion on the topic in the block below the article.