The microclimate in the house depends on heating. During operation of the system, deposits in the form of scale, silt or rust form on the walls of the pipeline and heating devices.

Examples of scale formation

The system needs regular cleaning and flushing. In order to remove dirt, you need to prepare so as not to damage the heating and clean the radiators.

Purpose of flushing the heating system

The main task is to wash out accumulated deposits in the system. Water circulates through the system, transferring heat from the boiler to the radiators. The liquid is in a closed cycle, sometimes not changing for years. The metal salts included in its composition begin to settle on the walls of the radiators.

There is a constant layering, and it only grows from year to year. The process of dirt formation is long, so the sooner you start acting, the easier it will be to deal with this problem.

With gradual clogging, the passages in the pipes narrow. Thermal conductivity deteriorates, and more fuel is required to heat the room.

If you do not ensure regular cleaning, the following problems will appear:

- Pipes become less durable, cracks and leaks appear.

- Heat transfer decreases.

- Heating costs increase because the resulting dirt narrows the passages of the pipeline and fuel consumption increases.

- Thermal resistance increases, which reduces the overall heating temperature.

- The coolant flow rate decreases.

- A decrease in strength causes unexpected ruptures and flooding of an apartment or house with dirty boiling water.

Why is regular maintenance essential?

In addition to the occurrence of emergency situations, the accumulation of scale in a pipeline heating system also sharply reduces its efficiency. Thus, just a millimeter of scale on the inner surface of a heating radiator reduces its heat transfer by 15 percent. Accordingly, in order to achieve a normal temperature in the house, you will have to increase the power of the boiler, and therefore increase fuel costs. In order not to incur extra costs, you need to clean the system.

The accumulated scale on the internal surfaces of the system has a much lower thermal conductivity than conventional metal used to make pipes. Scale is essentially a heat insulator - its thermal conductivity is 40 times less than that of metal. Even a thin layer of scale reduces the efficiency of the heating system to minimum values. Moreover, scale actively interacts with the metal of the pipes, which leads to increased corrosion and even the formation of fistulas.

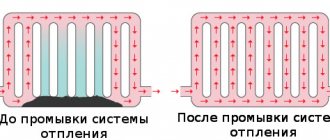

Before and after washing

In order to improve the quality of operation of the heating system, it is not necessary to wait for emergency situations. Such work must be carried out regularly, usually at least once a year.

When is system flushing required?

Signs indicating the need to remove dirt and plaque:

- The temperature on the surface of the devices decreases significantly.

- The interval between turning on the heating system and completely warming up the radiators to the required levels increases.

- The batteries warm up unevenly, you can feel it to the touch: warm bottom, cold top.

- When radiator heating is completely absent, only the pipes remain hot.

- The monthly heating bill is increasing.

Methods

Cleaning the system

Methods:

- Water-pulsating mixture. The method is based on the use of pulsating flows of liquid and compressed air bubbles. Deposits, rust, silt, sand are removed. Costs for energy resources are reduced and the service life of heating devices is increased. Performed with special equipment.

- With the help of biological products. The product penetrates deep into the accumulated layers and begins to act from the inside. The biological product acts on scale, oil and mud, hard crystalline, corrosive and organic deposits.

- Pneumohydraulic hammer. Requires special equipment. There is no need to disassemble the heating equipment. Operating principle: using technology, a pneumohydraulic shock is performed that destroys deposits. The layers crumble and dissolve in the coolant. The method does not cause ruptures or cracks.

- Chemicals. The mixtures are based on acids of organic and inorganic origin. The products begin their action by completely destroying the formation of scale and rust.

Hydrodynamic type of flushing

The heating flushing scheme in this way involves active action of water on scale and deposits. This happens thanks to a stream of water, which is directed under extreme pressure to the desired area.

Water is supplied through special nozzles of the required size and diameter. This type of washing is more expensive than chemical washing, but the result is much more satisfactory.

Scheme of using the hydrodynamic method of cleaning the heating system. Click to enlarge.

This type of flushing is best suited for batteries made of cast iron. Removing scale from cast iron using chemicals is very problematic due to the properties of the material itself, and sometimes even impossible.

However, the hydrodynamic system does an excellent job in such cases.

Another undoubted advantage is the environmental friendliness of such washing, since no acids or solvents are used. But only water.

To achieve the desired effect, specialists must have a special mechanism that will create a pressure of two hundred or more atmospheres.

Naturally, all scale is removed solely by exposure to water. No additional liquids or reagents are needed.

But here, too, everything is not as simple as it seems. Before flushing using this method, you must take the radiator to a service center. There it will have to be treated with a special liquid so that the layer that needs to be removed becomes softer and more pliable.

Only after this can the walls be treated with a jet of water operating under pressure. Using this method, you can remove almost everything: grease, scale, rust, dyes, carbon deposits, etc.

Facilities and equipment

Scale and rust reduce thermal conductivity. To maintain temperature conditions, it is necessary to increase fuel consumption and budgetary funds. Equipment such as a compressor is used for washing.

Cleaning the system with special equipment

Attention! Within 10 years of operation, the pipeline without cleaning can become clogged by 50%. One millimeter of layering on the inner walls increases fuel consumption by 25%. If you do at least one cleaning, the heating efficiency increases and budget costs are reduced.

Selecting equipment for flushing heating

Electronically controlled devices are considered the best equipment.

When using them, there is not a simple supply of chemical solutions or streams of compressed air, but a complete analysis of the intensity and nature of vibrations in the circuit. The operator is only concerned with timely regulation of the frequency and power of the pulses.

The devices are equipped with special sensors that monitor pressure and fluid flow and protection in case of unexpected activation.

Washing technology

First, it is necessary to check and assess the condition of the system. Afterwards, the cleaning method and equipment mode are determined. There are 2 ways:

- Filling method. The pipeline is filled with pure liquid or with chemical impurities. After 30 minutes the compressor turns on and compressed air is supplied. The supply valve is closed and the drain valve opens. Dirt is thrown out through it. The procedure is repeated until the water becomes clear.

- Flow washing method. This is a continuous supply of liquid with compressed air into the heating system. The growths on the walls peel off and are instantly removed.

Not every compressor unit is designed for two cleaning methods and can only supply water or compressed air. Ask the seller about technical specifications.

Is it possible to wash a separate battery?

Now you know how to flush the heating system. However, sometimes it becomes necessary to clean a separate battery. There is a solution for this situation too.

Buy a flushing faucet from a plumbing store. Additionally, you need to purchase a rubber hose and a fitting with a thread that matches the diameter of the purchased flushing valve. Install the fitting onto the hose.

Direct washing is carried out in the following sequence.

First step. We connect the flushing tap to the heating radiator.

Second step. We connect a fitting with a hose to the flushing tap.

Third step. We direct the second end of the rubber hose into the toilet.

Fourth step. Open the flush tap and leave for 20-30 minutes. While waiting, hold the hose so that it does not jump out of the toilet.

Cleaning methods

Several methods allow you to quickly and inexpensively clean your heating system of dirt and deposits.

Chemical washing

The method does not require removing batteries. Store-bought mixtures are used for cleaning. Make them at home by mixing a few essential ingredients.

If the circuit is slightly clogged, the following means are used:

- caustic soda;

- vinegar 9%;

- some acids;

- milk serum.

Ready-made mixtures are the best option; the packaging contains complete information about in what cases to use it and what dosages to use.

When using reagents, you must maintain the recommended time specified in the instructions. Remember to start the pump to ensure even distribution of the mixture throughout the circuit.

The idea is to supply chemical reagents together with a corrosion inhibitor. The preparations accelerate the dissolution of deposits, and the inhibitor covers the inside of the pipes with a protective layer that prevents the development of rust.

After flushing, the service life is extended by 10 years, the heating functions better, and the cost of heating the premises is reduced.

Sparging: pneumohydraulic cleaning

The method is harmless, as it does not contain any impurities. To create high pressure, a compressor is needed to supply a water-air mixture that removes deposits accumulated inside from the walls.

Flows are created inside the circuit, passing in the form of short pulses created by a pneumatic gun. It is better to connect the compressor to a check valve. This is necessary to prevent liquid from entering the device.

If the radiators are not removable, then at the very end you need to open the cap, a hose is connected through it to discharge dirt, which is lowered into the toilet.

Compressor unit

When starting for the first time, it is necessary to supply air in the direction opposite to the movement of the coolant. Then the direction changes. To do this, it is necessary to change the discharge and supply hoses.

After cleaning, the hoses are removed and a plug is installed. Only after this the heating is operated.

Ram: hydropneumatic shock cleaning

The method is based on the formation of a shock wave, which is capable of passing along the contour at a speed of 105 km/sec. It is recommended to use with a total pipeline length of no more than 60 m. As a result, the layers begin to peel off and fall off, being washed away with the liquid.

Flushing agents

Various reagents are used. Before purchasing, find out what layers the drug is designed for.

Using acidic preparations, they clean the pipeline, but alkaline mixtures are safer for metal pipes.

By carefully studying the instructions on the label or packaging, you can understand which metals the drug should not come into contact with. Some destroy the materials from which the pipes are made.

Features of the heating system and hot water supply

According to SNiP and GOST standards, such technology should guarantee a stable temperature range of 20-22 degrees and humidity parameters of 30-45% in apartments.

The principle of operation of the system is as follows: water flows from the thermal power plant to the house, its indicators are 131-151 degrees. It follows a pressure of 6-10 atm. This ensures its appearance at all levels without loss. Getting through the return pipeline, the water can have a temperature of 60-75 degrees.

Water with a reading of 130 degrees is not suitable for everyday use. And the reduction in parameters is ensured using an elevator unit. This device ends the heating supply and passes to the return circuit.

Through this channel, water is sent for recycling into the network. As a result, the coolant reaches the required temperature to heat the apartments on each floor.

Equipment for flushing heating systems from dirt

The degree of clogging depends on the regularity of cleaning, as well as on what salts and trace elements are contained in the coolant circulating through the pipes.

For flushing, special equipment is used to wash away dirt from the heating system.

Pipe cleaning devices

Different methods require their own equipment. Such equipment is expensive, but if you compare it with the amount of damage that can occur when pipes burst, you can turn a blind eye to the price.

Hydrodynamic installations

Water jetting machines deliver liquid under pressure. Connection to pipes with a diameter of at least 20 mm is available. The device comes with various attachments.

Hydrodynamic installation

Removal of deposits using a hydrodynamic apparatus is carried out in a gentle manner. The pressure created within communication is low. Cleaning is safe for all heating equipment.

Device Features:

- Jet thrust, under the action of the liquid, moves through the pipeline.

- The choice of nozzle depends on the nature of the contamination.

- Use of punching attachments: chain carousel and rotary tip are recommended for difficult clogs.

Fact! After washing with a hydrodynamic device, all elements return to the state in which they were installed.

Pneumohydraulic units

The compressor is the main element in the device. Its main function is to compress air followed by a sharp release into the system.

A kinetic impulse is created, forming powerful vortices in the liquid. Thanks to this, the layers are separated from the inner surface.

There are two options for compressed air accumulation in a pneumohydraulic device:

- container for accumulating air masses;

- a pump designed to flush the circuit.

The pump is equipped with a piston built inside, which pumps air. In the first option, the compressor handles everything.

The device has two outlets, one contacts air, and the second contacts water. Stages:

- First, the device is connected to the switch and hoses.

- The coolant is pumped in, part of it reaches the cylinder of the pneumohydraulic installation, placing the piston at the ready.

- The balloon is charged with air and pressure is created inside it.

- When everything is ready, a shock pulse is applied, which has a destructive effect on the deposits.

Mechanical impact devices

For mechanical cleaning, a flexible shaft is used with a handle placed at one end to tighten the mechanism, and a metal brush at the other. A drill is used to rotate the shaft.

Mechanical cleaning device

Brief instructions on how to operate:

- Preparation for cleaning. To do this, you need to drain all the liquid. The fitting is twisted at the required points.

- Assembly of a mechanism that removes deposits from the inside of pipes. To assemble it, you need to attach a metal brush to one end and insert the other into a drill.

- The shaft is carefully placed inside the pipeline. Rotational movements are performed, the walls are cleaned of scale.

Flexible shafts can be of different sizes. To store them, do not twist them too much.

Electrohydraulic devices

Operating principle of the device:

- The cable coming from the device passes into the coolant.

- The device sets the required power indicators for a certain type of pollution.

- After switching on, the device begins to create pulsed current discharges, as a result of which the accumulated layers are destroyed.

All models are used for cleaning pipes with a diameter from 10 to 100 mm. The kit may include additional devices.

Compressor for washing: means and equipment, reagent

When choosing equipment, familiarize yourself with the characteristics and features of the heating circuit. Pay attention to the size of the heating system and how many heating devices are installed in it.

There are other parameters that affect the compressor installation.

Often, specially prepared coolant is poured. In this case, the pipeline will remain in normal condition for a long time. But this happens rarely, and usually ordinary running water is poured in, containing salts of microelements, which gradually settle on the walls. A simple example is a kettle with scale that has formed.

In addition, silt and dirt accumulate inside, and rust forms. A number of problems arise:

- Reduced heating quality. Since salt layers have low efficiency, they become an obstacle to the transfer of thermal energy to radiators.

- Due to the reduction in the internal diameter of the pipes, the passage of coolant becomes less intense.

- Any type of pollution helps reduce the operating period of heating.

After such problems occur, coolant circulation deteriorates. This is reflected in a decrease in air temperature in the heated room.

Any type of pollution causes unexpected leaks, which are the result of unplanned spending of budget funds on equipment repairs.

The best preventive measure to combat this problem is regular cleaning of the circuit. Cleaning methods:

- Using chemical reagents that can dissolve dirt and scale.

- Jets of liquid supplied under high pressure wash away the plaque on the inside.

- Using the hydropneumatic pulse method.

Compressor for hydropneumatic flushing of the heating system

The compressor is connected using hoses. First, a thorough analysis of the structure is needed to identify areas that are severely affected by layers.

Then the compressor operating mode and cleaning method are selected.

Hydropneumatic flushing is performed in the following ways:

- Filling the circuit and supplying compressed air under pressure. After the procedure is completed, the drain valve opens.

- Flow-through method: water is supplied continuously.

In order to protect the receiver from liquid entering it, a check valve is used.

The device is turned off and dismantled. The results are checked: a small section of the pipe is cut off, with a clean inner coating.

Models are top sellers

Popular brands of washing equipment:

- Ropuls. The compressor cleans heating appliances, water pipes, heated floors and solar collectors. Among the advantages is the disinfection of drinking water.

- Rockal. Small heating cleaner (no more than 300 l).

- Cillit-Boy. Universal equipment: with its help, heating circuits, hot water supply and hot water supply pipes, drinking water pipelines and the “Warm Floor” system are freed from dirt. Controlled by an electronic module.

The supply of compressed air with liquid is under pressure. This loosens all the accumulated layers.

How to choose the optimal flushing pump?

Modern washing equipment is represented by units with a variety of functionality. The main manufacturers that have earned the approval of the international market are German factories (Rems, Rothenberger), Italian concerns (Manta Ecologica) and American (RIDGID). But, despite the high quality of each device, it is short-sighted to buy a flushing pump without assessing its operational capabilities. When choosing the optimal model, experts advise studying the specification of the unit.

- For the private sector, preventing and eliminating deposits in the system is a big problem. Utility workers stand guard over the apartment building. In a cottage, the costs fall on the homeowner. The Ridgid DP-24 or DP-13 descaling flushing pump will help the owner deal with the annual problem on his own.

- Inexpensive pumps from Rothenberger compete with compact “Americans”. Rocal and Romatic washing devices do an excellent job of removing scale in installations with a capacity of 300 liters. At the same time, the technical characteristics of Rothenberger and Ridgid units allow the equipment to be used for commercial purposes.

- In the Pump Eliminate , professionals will find devices for removing scale from heat exchangers. Any flushing pump from Manta Ecologica is distinguished by high productivity and good throughput. A wide price range and variety of functionality mean you can purchase a unit that meets different tasks.

- Ropuls compressors from Rothenberger are devices on a different scale. They allow you to buy a flushing pump in conjunction with many additional options. In addition to their direct specialty, the units sanitize water pipes, are suitable for testing pressure in the system, and even for connecting pneumatic tools.

- A separate category is pressure testing devices with hydropneumatic pumps. REMS units open up wide scope for the work of specialized enterprises.

The presented models are ready for use immediately after purchase. Chemicals for flushing heating systems can be purchased in the online store catalog of the same name. Euroinstrument.rf offers a convenient order form, affordable prices, delivery of goods to the client in all regions of presence or to the TK terminal to buyers from other regions of Russia.

Bucha: washing equipment

The installation for cleaning the Bucha heating system is a compact and portable compressor with a pulse pneumatic generator. All layers can be easily removed without the use of chemicals.

Bucha-K

It is enough to flush the system once to carry out high-quality cleaning of heating equipment. The device is compact, designed to remove deposits and prevent clogging.

The Bucha-K compressor is used for flushing Russian-assembled heating appliances, which is better than all foreign analogues in terms of price and quality.

Average score of ratings is more than 0

Share link

Comments There are no comments yet, but you could be the first...