Hydroflushing process

This method of cleaning pipelines and radiators is based on the simultaneous supply of water and air under a certain pressure. The resulting mixture is capable of cleaning the heating structure due to numerous pulses produced by the compressor to flush the heating system. You can see what this installation looks like in the photo.

The resulting small bubbles, moving through the elements of the system, gradually destroy the deposits accumulated on their walls. But in order for the cleaning process to be successful, it is necessary to first calculate the speed and flow of water, as well as air pressure in accordance with the diameter of the pipes and the length of the pipeline.

Flushing should be carried out in separate areas (in groups of risers).

Set of rules for flushing heating systems

When carrying out work, it is important to consider a number of factors.

- When the coolant is ordinary water, it is advisable to carry out flushing annually. If the water is filtered, then cleaning is allowed once every few years.

- Each heating circuit is washed separately, and in high-rise buildings - floor by floor.

- Before the next chemical flush or the start of the heating season, it is necessary to pass a neutralizer through the system to eliminate the effect of the introduced reagents.

- Chemical flushing is carried out by one-way movement of liquid in pipes. Other methods require forward and reverse.

- The washing procedure is followed by pressure testing.

Methods for hydroflushing a heating system

There are two washing options:

- The first of them is called flow-through, it is used for the prevention of hot water supply and heat supply systems: - pipelines (return and supply) are filled with water, while opening the valve on the air collector; - when the pipes are filled, the valve is closed, and then compressed air is supplied; — air and water mixtures should be supplied to the pipelines simultaneously; - complete the flushing after clean water begins to flow out of the pipe, which is then poured into the drain.

- The second method is filling. To implement it, a certain sequence of actions is followed: - the pipelines are filled with water, after which the valve is closed; — compressed air is supplied to the second pipe for 20-25 minutes; - after the air supply is completed, shut off the shut-off valves and drain the water, passing through the drain pipe. After the process is completed, the system is washed several times using clean water (read: “Hydro-pneumatic flushing and hydroflushing of heating systems”).

How to choose a reagent

Consider the material of the equipment

To choose a chemical solution, you need to know what substances it will come into contact with in the equipment being cleaned. Gasketed heat exchangers usually consist only of stainless steel; brazed ones additionally contain copper or nickel soldering. Boilers may contain cast iron; heating or hot water supply systems often contain stainless steel, cast iron, and polypropylene.

View composition

Equipment is professionally cleaned using a multi-stage principle: washing, neutralization of acids, passivation (special protective treatment). High-quality washing liquids help to comply with this principle - in addition to the main acid, they contain inhibitors and other surfactants that manufacturers do not disclose.

The inhibitor passes between contaminants and metal, creates a protective film and further prevents the formation of corrosion. Inhibition is regulated by boiler services that use industrial heat exchangers (shell and tube, plate).

In the case of washing with pure orthophosphoric acid, phosphating of the surface may occur - the formation of a protective film. But over time, the coolant will wash away this film, and the metal will not be protected from corrosion. If devices are regularly cleaned with uninhibited acids, pinpoint leaks will eventually occur.

Flushing chemicals

Chemical compounds are used to remove scale, which forms mainly on the internal surfaces of steel and copper pipes. These solutions prevent foaming of the coolant, which provides protection against corrosion processes and thereby increases the life of the circulation pump.

The chemical used changes color. The active composition is colored red, and the spent one has a yellow-orange tint. To prepare a water-based solution, you will need to use 10-30% of the chemical. It is prohibited to drain the waste into the sewer; the composition must first be neutralized. Read also: “Do-it-yourself device for washing heat exchangers.”

Signs of a poorly maintained heating system

For the normal functionality of the heating system, nothing should interfere with the movement of the coolant through the channels constructed for it.

There are several symptoms that a large amount of debris has accumulated inside the heating circuit, and scale has settled on the walls of the pipes. There are no obvious visual signs of clogging of the heating system.

It can be diagnosed by carefully monitoring the operation of the entire system and the appearance of a number of indirect signs:

- warming up of the system takes longer than before (for autonomous heating systems);

- the operation of the boiler is accompanied by uncharacteristic sounds;

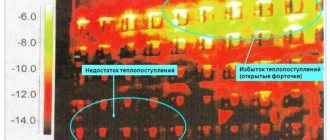

- increased gas or electricity consumption; the temperature in different parts of the radiators varies significantly;

- radiators are noticeably cooler than supply pipes.

However, weak or uneven heating of batteries is not always a sign of clogging. Perhaps they were aired out. In such a situation, it is enough to reset the air lock through the Mayevsky tap.

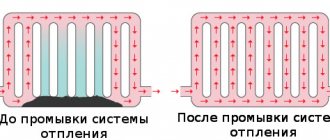

Without regular flushing of heating systems, pipes become overgrown, their flow area decreases, resulting in an increase in hydraulic resistance

In houses with a central heating system, its flushing should be carried out by employees of the heat supply company. In a private home, this procedure is carried out by the owners or invited specialists.

It is difficult to unequivocally recommend the frequency of flushing the system. There are too many factors influencing this.

Image gallery

Photo from

During long-term operation, the system requires mandatory flushing.

Slowing down the temperature rise in the room

Boiler signal about the need for flushing

Uneven heating of heating devices

For example, in centralized heating systems, the coolant must undergo a water treatment cycle, which reduces the degree of contamination. True, this rule is not always followed. And the system itself is often in its third or fourth decade of operation, and the amount of waste circulating inside increases every year.

But for both centralized networks and autonomous systems, it is recommended to flush annually. Which, by the way, is confirmed by the requirements of building codes. This period is considered critical for the accumulation of debris inside the circuit, which significantly reduces operating efficiency.

If the system is not flushed before the start of the heating season, the pipeline becomes clogged and appliances and heating equipment fail prematurely.

Heating system flushing equipment

Romantic 20

. This installation for flushing heating systems allows you to get rid of scale. It is equipped with automatic control of the flow interval and is used when significant deposits and scale form in devices whose volume does not exceed 300 liters. Its price is quite affordable.

Ropuls

. A combined installation for flushing the heating system, equipped with a microprocessor control, is also used for flushing drinking water pipes in full compliance with current requirements. This device is used for the prevention of floor heating systems, solar heating collectors, hot water pipelines and cold water supply pipes.

Rockal

. It is a hand pump designed to remove deposits and scale in installations whose volume does not exceed 300 liters. It operates with a flow rate of 40 liters per minute and a pressure of just over a bar. The pump excels at eliminating scale in steel or copper pipelines.

How to choose equipment

When choosing, you need to consider:

- The power and productivity of the installation affect the flushing speed. The larger the dimensions of the equipment being cleaned, the higher the power and performance of the device should be. Also, high power allows you to remove stubborn deposits and better wash the structure.

- The washing tank should be selected the same volume or larger in relation to the volume of the equipment being cleaned. You can also find out whether the pump has dry-running protection.

- Connection diameter. Must match the connection diameter of the equipment being cleaned. You can also connect hoses to the water supply and heat exchanger ports using special adapters.

A pump is considered more efficient if it can do reverse - change the direction of flow. This allows you to completely remove scale and wash away reagents. For automatic reverse, the device must have a flow change button. Manual reverse is carried out using a valve or manually reconnecting the hoses.

There are also models of installations with a tubular electric heater for heating the liquid to the desired temperature (for most - 40 ̊C).

Selecting a compressor for flushing

Today, the retail market offers a huge number of equipment models for various types of washing. It is almost impossible to formulate specific requirements for a compressor, since it is selected based on future operating conditions. This includes pumping volume, the ability to work in a specific mode, the ability to lift water to a height, and much more. However, there are brands that have earned a good reputation and offer devices with an attractive price and technical and functional performance.

Ropuls

Compressors of this brand are characterized by fairly high versatility, suitable for servicing pipes, individual radiators, and heat exchangers. The models have a disinfection circuit for the pumped liquid, which allows them to be used to clean drinking water pipelines. Ropuls compressors show good performance in maintenance procedures for underfloor heating systems and even solar collectors.

Rockal

Compressors of this brand provide gentle cleaning. The devices are of the manual type, light in weight, compact, and in operating mode create a pressure of 1 atm. Their low productivity (on average 40 liters per minute) allows procedures to be carried out with minimal consumption of the active composition.

Advice! Compressors of this brand are an ideal option for cleaning heating systems in a private home with a coolant volume of up to 300 liters.

Cillit-Boy

Compressors of this brand are capable of solving almost any task. They are suitable for servicing systems made of steel and plastic pipes and show good results when cleaning heated floors. The functionality of the compressors includes disinfection, which allows them to be used for flushing the drinking water network.

The advantages of compressors include the ability to carry out hydropneumatic cleaning with a very uniform supply of air-water mixture for maximum efficiency. In addition, the devices are capable of operating in water hammer mode.

The compressor control is electronic, with convenient mechanics for setting and monitoring operating parameters.

Flushing methods using a compressor

To do everything quickly and efficiently, it is recommended to use a compressor when flushing heating radiators and piping systems to restore the heat exchanger of a gas or other heating boiler. For some procedures you will need specialized equipment, for others a regular household (for example, car) compressor is sufficient.

Hydraulic and hydrochemical flushing

Hydraulic flushing is considered a classic of the genre. To carry it out, a water source is connected to the inlet pipe of the heating circuit after disconnecting the corresponding pipe from the boiler or inserting the outlet. This could be a public water supply.

A hose is connected to the drain pipe of the heating system or a specially made insert to drain dirty liquid into the sewer. In the simplest case, no equipment is required to carry out the procedure. Water is supplied to the pipeline.

Important! The minimum pumping volume to clean the system should be no less than five times the amount of coolant.

The procedure can be carried out with the addition of chemicals, in the simplest case - soda ash. In this embodiment, it is called hydrochemical. Cleaning can be carried out either manually, with preliminary preparation of a large volume of working composition and pouring it into the system, or using a compressor. The most complex option in terms of the equipment used looks like this.

- A special flushing compressor creates pressure of the working solution and ensures its movement in the pipeline system. A circulation pump can be used instead.

- A filter is installed at the outlet of the drain pipe to trap contaminants.

- The working solution is circulated for at least an hour.

Advice! To ensure that the cleaning is nearing completion, it is recommended to install a transparent hose on the drain pipe of the heating network. In this case, washing continues until the working solution comes out almost clean.

The procedure can also be done using a regular car compressor. In this case, a container is mounted, a 19 liter polyethylene tank is quite suitable, into which purified water is poured. A removable sealing block with a tube equipped with a check valve is installed on its neck. A chemical solution will be supplied through it. An inlet for the compressor is mounted in the bottom or wall of the tank. This is a fairly simple device that you can assemble yourself.

The chemical solution is poured into the tank. A tee is used to enter it into the system. A water supply or other source of liquid, the outlet pipe of the tank, is connected to it. The outlet from the tee will be connected to the inlet pipe of the heating system. The procedure looks like this:

- water turns on;

- after some time, after preliminary washing, the compressor turns on;

- As the pressure increases, the chemical solution enters the system.

By adjusting the compressor performance or performing short-term start-stop, it is easy to achieve a fairly uniform supply of the active substance. The best results are achieved when using a compressor with low capacity. The completion of hydrochemical cleaning should be flushing the pipe network with clean water to remove chemical residues.

Advice! To achieve truly high-quality flushing using a hydraulic or hydrochemical method, it is recommended that after treating the system as a whole, remove the radiators and carry out the cleaning procedure for each of them separately.

Hydrodynamic cleaning

The hydrodynamic cleaning procedure allows you to remove almost all contaminants from the heating system:

- scale residues;

- soot;

- sediment of solids;

- corrosion products;

- fats of organic origin;

- mineral deposits;

- waste products of bacteria.

The procedure is carried out using specialized compressors equipped with nozzles that emit water in high-energy pulses. The jet has a high speed and operating pressure of up to 200 atm.

However, it is difficult to operate inside pipelines using such nozzles. Therefore, hydrodynamic cleaning is used mainly for heating radiators. Services are provided by specialized companies, since for a private individual the idea of buying equipment of this class is simply irrational; its price is very high.

Bubbler or hydropneumatic flushing

Hydropneumatic flushing is the most common way to restore the parameters of a heating system. It is the process of feeding an air-water mixture into pipes under significant pressure. Its effect literally removes plaque, breaks up sediments and perfectly cleans both pipelines and heating radiators.

There are two ways to carry out this procedure.

- The system is filled with water and left for up to 1 hour. After this, an air compressor is connected to the inlet pipe and a pressure is injected that the pipes and radiators can withstand. The system settles down again within half an hour. Finally, the drain pipe opens and dirty water is discharged. If necessary, repeat the procedure. You can use any compressor, including a car one.

- An active air-water mixture is supplied to the system. When carrying out this version of the procedure, you need to use a special compressor. The device immediately supplies the finished mixture, allowing you to carry out the washing procedure as quickly as possible.

Hydropneumatic flushing is often called blowdown. The procedure is carried out simply, quickly, without adding chemicals to the water, which can be immediately drained from the outlet pipe into the sewer.

Advice! Hydropneumatic cleaning is recommended before putting the heating system into operation.

Water hammer cleaning

Water supplied by a powerful pulse at a speed of up to 1200 m per second perfectly breaks down any deposits and dirt inside the heating system pipelines. This method has some danger for modern plastic pipes, unwelded joints, household heating boilers and boilers, and thin heating radiators. However, water hammer is the most effective way to clean extremely clogged, old systems built on metal pipes and cast iron radiators.

To carry out the procedure you will need:

- pneumatic gun, pressure accumulator with pressure gauge and valve opened by pressing the handle;

- a compressor that creates operating pressure to generate a pulse;

- source of liquid, water supply can be used.

The mechanics of operation are quite simple. Water is supplied to the heating system in a constant flow. The worker, monitoring the pressure indicator, launches the air gun.

Air pressure creates a hydraulic wave, which pulses and destroys deposits in the pipes. The time it takes to flush the system of a private home is an hour or a little more. To carry out cleaning as quickly as possible, you can use a specialized compressor, which is adjusted to certain water hammer parameters and the volume of liquid pumped.

Such an installation can be equipped with containers with chemicals for automatic addition to the cleaning liquid, has a wide variety of protections, and is capable of combining hydraulic shock with hydropneumatic mechanics, creating an air-water mixture.

Chemical cleaning

Cleaning with a concentrated active solution is a method that must be used carefully. Aluminum and silumin parts can suffer significant damage when exposed to even relatively safe citric acid. However, for steel pipes, radiators, heat exchangers of gas and other boilers, this is the most convenient cleaning method.

The procedure looks like this:

- the volume to be cleaned is filled with a concentrated solution;

- after a period of time during which the maximum effect of the drug is achieved, it is removed from the system;

- the procedure is repeated for maximum thorough cleaning;

- the system is washed with clean water to remove chemical residues.

In domestic conditions, a method with the movement of the active composition is used. To do this, the liquid is pumped. It is most convenient to use a special compressor.

However, it is not necessary to look for this type of equipment. You can get by with a regular car compressor.

- To do this, a container is made with two outlets at the top and bottom. The ideal option is a plastic canister with a tightly screwed lid with a capacity of at least 5 liters.

- The compressor is connected to the upper outlet, and one of the heat exchanger pipes is connected to the lower outlet.

- A drain pipe is connected to the second pipe of the heat exchanger, the end of which is placed in an open container.

The procedure looks quite simple. The canister is filled with 2/3 of the active solution. Turn on the compressor and start feeding. The chemical mixture passes through a heat exchanger and is discharged into a container. The liquid is pumped in portions for maximum impact.

After the canister is empty, the compressor is turned on in reverse. This provides a vacuum, and the active composition reverses. The chemical mixture flows back into the canister. During the entire procedure, you need to ensure that the end of the drain tube is in the liquid. Complete the cleaning process by thoroughly washing the heat exchanger.

The following types of active chemistry produce good results:

- alkalis;

- organic and inorganic acids;

- solvents.

Advice! If the pipes are slightly dirty, you can use citric acid and even a regular toilet cleaner.

In order to flush not an individual radiator, but the system as a whole, specialized products are used. Their solution is pumped into pipelines and left for a period of 6 to 10 hours to completely dissolve the contaminants.