Procedure for crimping

- Before starting tests, it is recommended to check the condition and functionality of the shut-off valves; visually assess the quality of existing connections; isolate the heat supply from the water supply system using plugs.

- Then you need to turn off the boiler and expansion tank and pre-flush the pipelines, radiators, etc. from dust, small debris (in the new circuit), from various deposits (in operating systems).

- During hydraulic testing, the system is filled with water (air pressure testing does not require this operation), a compressor is connected to it, usually to a drain valve. After this, the pressure is increased to the required value and its indicators are monitored using a pressure gauge. The absence of any changes indicates the tightness and possibility of operating the system. A decrease in pressure above the permissible value indicates the presence of any defects. In a heating circuit filled with water, it is not difficult to determine the location of leaks. To be able to detect damage during air testing, it is recommended to treat all joints and connections with a soap solution before starting work.

- After troubleshooting, the procedure is repeated. This step is carried out until the system becomes airtight.

- 5. Upon completion of all procedures, a pressure testing report is drawn up.

Figure 2 – Sample certificate of pressure testing of the heating system

What is crimping

There is a misconception among people that if the heating is assembled correctly, then it will work well and for a long time. This is partly a correct thought, but do not forget that for the system to function flawlessly, it must be tested before launching.

The heating unit is checked using pressure testing. Pressure testing is a set of works that helps to check the heating for leaks.

There are two types of crimping:

- Using compressed air. Using a compressor, compressed air is supplied to the heating device to a certain pressure value. After this, radiators, pipes and stopcocks are monitored for depressurization.

- With the help of water. This method differs from the first in that instead of air, water is supplied into the pipes from a hydraulic pump. Water is also supplied to a certain pressure value. This is also followed by checking the tightness of the device components.

It should be noted that both methods are effective and allow you to fully test all heating units for leaks. During the inspection period, using pressure testing, you can quickly identify flaws in the heating device and eliminate them, which allows you to avoid unpleasant incidents during the heating season.

Hydropneumatic flushing

As mentioned earlier, hydropneumatic flushing of the pipeline heating system is carried out using a special pulp. This method of descaling pipes involves using a large amount of water. Houses connected to central heating or water supply use hot water circulating in pipes. If the heating system is located in a private house, then purification is carried out using cold water supply.

Hydropneumatic cleaning

When flushing the heating with hydropneumatic pressure cleaning, perform the following algorithm of actions:

- the water is forced to circulate in the opposite direction to the heating, then it is started again;

- together with the incoming liquid, compressed air is blown in using a compressor;

The resulting flow copes well with sludge, but does not sufficiently wash away salt deposits and rust formed on the walls of the pipeline and radiators. When risers are used in heating, during the process they are blocked in groups and washed. The fewer risers are included in the group, the better the radiators will be cleaned.

When cleaning the heating yourself, it is very important to carry it out until the waste liquid is as clean as possible and no longer contains rust particles or sediment.

Useful technical details

Chemical

Chemical flushing involves filling the heating circuit with reagents (alkali or acid solution with inhibitors that prevent further corrosion of pipelines) and long-term circulation of the reagent in the circuit.

Used reagents are generally disposed of by the contractor. You cannot pour them into the sewer: such aggressive substances can sharply shorten its service life, and wastewater treatment plants are not designed for the disposal of acids and alkalis.

If it is necessary to use the sewer system for disposal, the reagents are first neutralized. Acidic - alkali solutions and vice versa.

Hydropneumatic

This type of flushing is the most common, cheapest and most versatile. However, it is associated with the consumption of a significant amount of water. If the house is connected to a heating main, the coolant coming from it is usually used; Autonomous heating systems are washed with cold water.

The actual washing is done like this:

- The heating system starts to reset - first from the supply to the return, then in the opposite direction.

- A stream of compressed air from the compressor is mixed through the valve into the flow of water coming from the route. The resulting pulp effectively washes away silt and, partly, deposits on the pipe walls.

- With a standing heating system, groups of risers are blocked in turn so that the entire flow of pulp goes through no more than 10 risers. Less is better.

Washing of each group of risers in each direction is carried out until the moment when the pulp going for discharge becomes transparent.

The hydropneumatic flushing pump is a simple and relatively inexpensive device.

In what cases is the act filled out?

The document is required at the time of acceptance of gas, heat and water supply. We are talking about both a newly opened system and one that has undergone repairs or scheduled maintenance. The most common type of pressure testing is hydraulic testing of the water supply system. The entire set of tests is designed in such a way as to check the operation of the system under various conditions.

After filling out the form, you should check it

The operator evaluates how the degree of tightness of the entire pipeline changes. During hydrotesting, not only the tightness is tested, but also the quality of the existing joints. In most cases, they are the cause of failure of a separate section. In addition to the pipeline, terminal equipment is subject to control. The heating system installed at the consumer's place, taps and gas stoves - all this needs to be checked.

Each stage of control is regulated by a separate SNiP:

- 41-01-2003;

- 3.05.01-85;

- Rules for technical operation of thermal power plants.

The regulations for conducting hydrostatic testing are prescribed in several regulations. They regulate the order and timing of tests. Consumers of utility services should remember that compliance with these deadlines is in their interests. Preventive examinations allow you to detect problems at an early stage.

Fire test reports

During testing for the performance and safe operation of fire equipment, several reports are drawn up:

- checking fire hydrants;

- diagnostics of internal water supply;

- checking for the safety of use and compliance with labor protection rules of fire escapes.

Fire hydrants

Testing the performance of hydrants for water loss is carried out twice a year and is often combined with checking the fire-fighting water supply system. Based on the results of the inspection, an act is drawn up and signed by the commission. Mandatory members: a representative of the fire inspection and a representative from the organization in which the inspection is taking place. Also, the commission may consist entirely of company employees.

The act states:

- general organizational information (information about the company, date and place of compilation);

- the main part describes the members of the commission and the progress of the test. Information about hydrants is presented in tabular form. The location address, diameter, pressure, water yield and affiliation of the hydrant are indicated;

- in the final part, compliance (or non-compliance) with the requirements of the hydrant condition is established.

At the end, the act is signed by authorized members of the commission.

Internal fire water supply

The act establishes the presence or absence of defects and malfunctions in the fire water supply system. The inspection is carried out by responsible employees of the enterprise. Frequency – at least twice a year; for flammable industries, inspections may be scheduled more often.

Internal fire water supply (IFP) is a complex system of pipes, sensors, and switches. Therefore, it is often checked by a labor protection or fire safety specialist, as well as by persons who are trained in fire safety.

The act is drawn up on letterhead or plain paper indicating the details. Be sure to register:

- information about the organization and participants of the inspection;

- information about the object being checked;

- inspection results;

- recommendations for eliminating defects and malfunctions, if any are found;

- signatures of responsible persons.

If additional documents are attached to the act, their list and name are indicated.

Fire escapes

Testing of firefighting equipment, including ladders and stepladders, is regulated by a special GOST. Inspections can be carried out by organizations that have received permission from the Ministry of Emergency Situations and have special equipment for this.

The test results are recorded in the test report. The documentation provides standard information about the organization and its details, information about the members of the commission. The main part provides information about the inspected objects (number of ladders and stepladders, their inventory numbers and affiliation with the structural unit), information about the results of inspections (absence or presence of defects). An instruction is given to eliminate the identified faults.

At the end, the act is signed by the members of the commission.

The meaning and types of crimping

At the moment, heat supply is very often carried out by a “hydraulic circuit” system. At the same time, the heated water moves through the works, imparting its own heat energy to the premises. Leaks are not allowed; the pipe wire must be absolutely sealed for proper operation. Pressure testing specifically makes the volume in the pipe larger than normal.

When this is done using air, it is called pneumatic pressing.

When using water, then by hydropressing. The final method is safer and therefore more widespread. Due to this, an example of hydropressing is given as a form.

When testing, it is recommended not to exceed the pressure in the middle of the pipe more than 15 MPa. If we are talking about raising pressure with water, then there are restrictions. The maximum possible pressure should not be greater than 30% in most cases.

In high-rise buildings they resort to pneumatic pressure testing if the pipes are very old and there is a risk of flooding. But then a risk parameter appears and all residents are required to be notified of the tests being carried out.

The workflow is simple, but multi-step. The method looks like this:

- The required materials and equipment are being prepared.

- Draining the liquid that was previously in the heating system.

- Uploading a new one.

- Create maximum potential test pressure.

- Taking control measurements after 10 minutes.

- Flushing, adjusting the heating system to normal pressure levels in the middle.

- Documentation of work performed, development of reports and acts.

But this is how the list of procedures looks only if there are no “thin spots” in the heating system and, based on this, the tightness in it is not compromised. If the pressure drops quickly and cannot be maintained, it means that the system needs repair work. In such a situation, the master performs the necessary actions (replacing the pipe, sealing connections, cleaning, etc.), and then begins crimping initially. Only a heating system that has passed the testing is allowed into the heating period.

An important invisible moment! Pressure testing should be performed after cleaning and flushing the pipes. Otherwise, salt and other deposits in the middle can veil supposed external damage and breakthroughs.

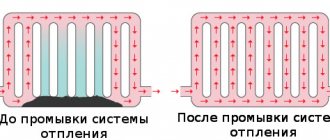

If there are deposits of about 1 cm on the inside surface, then this reduces the overall heat transfer and efficiency by 15 percent or more of the overall indicators. To document the cleaning, a specialized report is also drawn up.

In what cases is it compiled?

The act is required when:

- Commissioning of new equipment. The certificate will confirm that each element is in its place, the installation was carried out responsibly, and the system is working.

- The heating season is approaching. After a summer break in work, the pipes could fail. After checking their capacity, a report is drawn up.

- Already carried out repair work.

- The occurrence of contained emergency situations on the pipeline. In this way, specialists identify the amount of work required and the weak points of the existing heating network.

For the uninterrupted operation of the heating system, preventative control checks and reliable information about the quality functioning of the system upon startup are necessary.

How is joint work with a contractor organized?

In addition to the final act, indicating high-quality work performed, you will need to draw up and sign a number of other documents together with the contractor. All papers drawn up in accordance with the law will give you the opportunity to make claims to the contractor in the event of poor-quality washing or in the event of material damage in the form of damage to system elements. This will also allow you to defend your rights in court. Let’s imagine the sequence of actions of the contractor, in which you will also take part: initial visual inspection by representatives of the organization;

- choosing a washing method and agreeing it with you;

- submit for review and signing an estimate that reflects the types of work and materials used, as well as the contract price;

- enter into a contract;

- then the heating system of the residential building itself is flushed;

- acts are drawn up for hidden work (if any);

- testing (pressure testing) of the pipeline network is carried out, which is confirmed by the relevant document;

- a report of the washing performed is drawn up, which you must endorse if there are no complaints against the contractor.

Note.

The official document indicating hidden work must be accompanied by photographic evidence of the fact that these operations were performed.

last name, first name, patronymic, passport details,

The essence and types of crimping

Nowadays heating is most often carried out by a “water circuit” system. At the same time, heated water circulates through the works, imparting its thermal energy to the premises. Leaks are unacceptable; the pipeline must be completely sealed for normal operation. Pressure testing specifically creates a larger volume in the pipe than normal.

When this is done using air, it is called pneumatic pressing.

When using water, then hydropressing. The latter method is considered safer and therefore more popular. For this reason, an example of hydropressing is provided as a form.

When testing, it is recommended not to exceed the pressure inside the pipe more than 15 MPa. If we are talking about raising pressure with water, then there are limitations. The maximum possible pressure should not exceed the normal operating pressure by more than 30%.

In multi-storey buildings they resort to pneumatic pressure testing if the pipes are very old and there is a risk of flooding. But then there is a level of risk and all residents must be notified of the tests being carried out.

The work process is simple, but multi-stage. The algorithm looks like this:

- The necessary materials and equipment are being prepared.

- Draining the liquid that was previously in the heating system.

- Uploading a new one.

- Create the highest possible test pressure.

- Taking control measurements after 10 minutes.

- Flushing, adjusting the heating system to normal pressure levels inside.

- Documentation of work performed, generation of reports and acts.

But this is how the list of procedures looks only if there are no “thin spots” in the heating system and, accordingly, the tightness in it is not broken. If the pressure drops quickly and does not hold, then the system needs repair work. In such a situation, the specialist performs the necessary actions (replacing the pipe, sealing connections, cleaning, etc.), and then begins crimping from the very beginning. Only a heating system that has passed the test is allowed into the heating season.

Important nuance! Pressure testing should be carried out after cleaning and flushing the pipes. Otherwise, salt and other deposits inside them can mask possible external damage and breakthroughs.

If there are deposits of about 1 cm on the inner surface, then this reduces the overall heat transfer and efficiency by 15 percent or more of the overall indicators. To document the cleaning, a special report is also drawn up.

Methods for cleaning radiators

Chemical cleaning method for heating systems

During the chemical cleaning of parts of heating systems, their internal cavity is filled with special solutions. These include substances made from acid or alkali. They contain inhibitors. They are able to prevent metal corrosion, help preserve its internal part, and extend its service life.

heating systems. During work, old alkali and acid solutions should be drained. Such solutions are quickly neutralized. Acid components of an alkaline solution are added to them. This cleaning method is used when washing steel pipes. The composition of the reagents cleans the inside of the battery from rust and salt deposits.

Cleaning heating systems using hydraulic pneumatics

This method of cleaning the heating system is recognized as the most universal, inexpensive and most popular. This cleaning method requires using a lot of water. In autonomous heating systems, all internal parts are washed only with cold water.

Flushing sequence

using hydraulics:

- start the heating system in reset mode;

- a stream of air is directed to the coolant of the system, which will quickly clean the internal structures of the battery from scale and formations;

- if there are risers in the heating system, then they are washed; if the heating system is cleaned by the tenant himself, then the risers should be washed individually. This is done in order to flush the radiator itself.

According to the drawn up agreement, and this is necessary to check the quality of flushing, it is necessary to carry out control coolant intakes

. Such work is carried out in the thermal unit, in other parts of the system. This is done for the equipment acceptance committee, which will sign the equipment acceptance certificate. She can always make sure the water is clean and free of impurities.

The topic of this article is documentation of flushing the heating system. We are interested in drawing up an estimate, concluding a contract and drawing up a report.

In addition, the criteria by which the work performed is assessed are also interesting.

Components of the heating system pressure test report

At the top left is information about the organization that carried out the inspection. Ideally, there should be a signature for approval by the chief power engineer of the heating supply organization.

The top right should contain subscriber information. That is, about who is the client and consumer of heating services. This could be a partnership of residents of a particular house, any organization that occupies the building, the owner of a private house, etc.

It is important to provide names and other information accurately and in detail. In this case the address is required

The main part of the act states:

- City.

- The date of signing the act (and the pressure test itself).

- Heat supply organization: its form of ownership, name, full name of the representative.

- Which of the subscriber's representatives accepted the heating system after the test: full name, position.

- To what indicators the pressure in the system was raised is indicated in kgf/cm2.

- To what indicators did it drop after 10 minutes following the shutdown (the units of measurement here are also kgf/cm2, it is also permissible to measure it in mPa if accurate data on this matter is available).

- Whether the system passed or failed the test (the person completing the form needs to highlight the correct option).

The final part consists of the signatures and seals (if any) of the representatives:

- Subscriber.

- Heat supply organization.

- Service organization.

In general, the act of pressure testing the heating system is a convenient primary document, for filling out which the heat supply organization is responsible.

What is this procedure

So, what is pressure testing of a heating system? This procedure is carried out using special equipment - a hydraulic or pneumatic pump. Equipment is selected depending on whether tests are carried out with air or water.

A leak test is performed by pumping water or air under high pressure into the system. For private houses it is usually about 2 at. (in the event that the operating pressure during operation does not exceed 1.9 at.). In multi-unit buildings, tests are carried out under much higher pressure. Its indicator also depends on the worker and exceeds it by 20-30%. After completing all pressure testing of the heating system.

If the system is leaking, the injected air or water will leak out during the test. In this way, it is possible to identify the “weak” points of the equipment and eliminate them in a timely manner. There are specially established rules for pressure testing the heating system, according to which it must be carried out at least once a year.

Regulatory Standards

To properly carry out pressure testing of networks, you need to know the regulatory framework. This knowledge is also important when carrying out design and installation work.

The main recommendations for conducting hydraulic tests are listed in SNiP number 41-01-2003:

- when carrying out test work in the structure, the temperature must be maintained at least zero degrees;

- when determining the crimping pressure, adhere to the data on the maximum permissible pressure that the materials and equipment used can withstand (the crimping pressure should not exceed the limit values);

- the pressure in the system during testing must exceed the performance indicators of the equipment and materials used by 50% (however, this value cannot be less than 0.6 MPa).

Another regulatory document (SNiP number 3.05.01-85) contains the following information:

- All large-unit elements can only be tested at the assembly site.

- If during testing the pressure in the system drops, then you need to inspect the entire line and instruments to identify the location of the leak. After this, repair work must be carried out to eliminate the leak. Then activities to check the tightness of the networks continue.

- If wedge valves and valves are installed on the main line, then pressure testing can be carried out by turning the control handle twice.

- If non-factory assembled devices are used in the circuit, they are crimped on site.

- If hidden piping is used in the house, then these areas are pressurized before finishing work is carried out.

- Pipelines that must be insulated are checked for leaks before installing thermal insulation material.

- During testing, membrane tanks and hot water boilers must be turned off.

- The heating system is considered working if the pressure test does not decrease within half an hour, and if it is not possible to visually detect leaks.

- Additionally, the heating circuit is checked for uniformity and correct heating. To do this, the network supplies coolant with a temperature of at least 60°C for 7 hours.

Standards

Before pressure testing, a special program is drawn up, which is approved by the engineer of the heat supply organization. It should define:

- Sequence of work.

- Personnel procedures.

In addition, it is indicated which team will perform the work and which teams are working in adjacent areas. Pressure testing of heating equipment is carried out under the supervision of the shift supervisor. In this case, all other work aimed at repairing or maintaining the pipeline must be stopped. Do not remain in the immediate vicinity of the equipment under test when the pressure rises to the maximum value. Inspection of pipes and other heating equipment should be carried out only at average values. If work is carried out in areas adjacent to the test subject, they must be fenced off and disconnected from the test equipment. If the inspection was carried out in compliance with all the above standards, an act is signed, which will be discussed below.

Heat supply flushing methods

It is not recommended to start flushing the heating system without preliminary preparation. It is necessary to determine the chemical composition of scale and select a specific type of equipment for cleaning.

A technological map that prescribes all stages of the procedure will help you correctly complete the necessary steps. The latest regulation ends with the treatment of the internal area of the pipes with a chemical composition to prevent the appearance of corrosion, lime deposits, and scale.

The main washing methods are the following:

- chemical method;

- hydrodynamic;

- hydropneumatic.

Chemical flushing of coolant

This method does not involve the intervention of mechanical devices and the dismantling of radiators. Cleaning is carried out with chemicals or solutions.

However, using the method can damage the inner plane of aluminum radiators, which can lead to their destruction.

If the heating network is not very clogged, you can use the following reagents:

- sodium hydroxide;

- vinegar essence;

- ordinary phosphoric or condensed acid;

- whey.

However, it is better to use compounds that allow you to thoroughly clean the pipes. The instructions for the preparations specify the material and the nature of the layers.

Chemical treatment can be carried out using additional equipment - a booster, consisting of a centrifugal pump and a large container. The first one is connected at the break in the centralized supply system with the heating boiler. A valve must be installed at the outlet of the circuit to discharge the spent chemical.

For high-quality corrosion of lime deposits, experts recommend leaving the reagent in the network for several days, depending on its slagging level. However, to avoid exposure of the pipes to the chemical, the circuit must be rinsed with industrial or tap water after cleaning.

A more gentle metal structure is the dispersed cleaning mode. The method differs from the chemical method in that the reagent destroys the mechanical bonds of the deposits themselves, without interacting with the material of the heating communications.

Hydrodynamic cleaning

The described operation is carried out using specialized equipment. One of them is a powerful centrifugal pump with a hose having a small diameter end nozzle. Strong water pressure cleans scale and deposits from the walls of heating mains and removes them through the return line.

Mechanical flushing method

Method for cleaning radiators and small pipes. The shut-off valves, expansion tank and centrifugal pump must be cleaned separately. Before the procedure, it is necessary to carry out a minimal drain of the house system, and then close the inlet and drain valves. Only after this they begin to reset the rest of the media.

The discharge occurs through a drain valve installed in the basement, which communicates with the sewer through a hose. This will prevent the technical subfloor from flooding with water. Radiators are cleaned by unscrewing the plug and dumping the media. However, removing the battery and processing will improve the thermal performance of the radiator.

After dismantling the radiators and areas of heating distribution to the yard, the equipment is cleaned with a cable with a brush-shaped tip. The tool is inserted into the batteries in the reverse position to the supply of thermal resources to improve the removal of scale flakes and deposits. Cleaning is carried out until the rinsing water becomes clear.

Hydropneumatic

Belongs to an effective and equipment-friendly method for cleaning heating circuits. Contains a high pressure air jet. The compressor creates high-power turbulent flows inside the communications, leading to the breakdown of build-ups and washing out accumulated dirt.

The operation is performed with a pneumatic gun that delivers short-term impulses. Lime deposits are discharged through open radiator plugs. The initial purge procedure is performed against the flow of the coolant, and the repeat procedure is performed clockwise. Removing batteries and cleaning them outside will improve air operations.

Electrohydropulse cleaning option

The method is based on the formation of an electric discharge, the shock wave of which breaks up lime deposits on the internal walls of the system, without causing harm to the latter. To carry out cleaning, you will need a voltage generator and a coaxial cable to supply high-frequency signals.

The efficiency of the method is high, so the dismantling of radiators and the entire heating circuit is not provided. After the scale is destroyed, the coolant is washed and the water goes down the drain.

How and how to flush radiators and heating systems

The process of cleaning the heating system of a house is not complicated; any owner can handle it.

There are several ways to clean the heating network in a private home with your own hands.

:

- mechanical flushing;

- dry cleaning;

- hydropneumatic flushing;

- pneumohydraulic hammer method;

- biological washing.

Mechanical flushing

This method of flushing heating systems requires complete disassembly of all communications - before cleaning the elements, you will have to remove every part of the system. The complexity of the method lies in cleaning the internal surfaces of pipes and batteries from scale and rust manually using metal brushes. Nowadays, it is practically not used, as it requires a significant investment of time and effort.

Chemical washing method

To clean the system, you need to connect a pump with a container filled with chemicals. The detergent dissolves and loosens contaminants stuck to the pipe walls.

For chemical cleaning, two types of liquids are used - acid or alkaline based, used depending on the material from which the pipes and batteries are made, as well as the type of deposits. It is recommended to flush the heating system with chemicals also in cases where it is too difficult to remove the system elements.

Alkali- or acid-based cleaning fluid cannot be used when working with aluminum batteries due to the fact that the metal reacts with chemical compounds. It is also prohibited to clean depressurized systems, since the chemical cleaning agent is toxic and can cause harm to health.

. For the same reason, used liquids should not be poured down the drain, and work should be performed with rubber gloves and a respirator.

After chemical cleaning, all contaminants will be completely removed, extending the life of the system.

Hydropneumatic flushing

This method involves treating the internal surfaces of batteries and pipes with a flow of a mixture of air and water supplied under high pressure. Flushing the heating system in this way is highly effective, but its use requires special equipment.

Hydropneumatic cleaning has proven itself excellent when working with cast iron radiators of the old type, still made in the Soviet Union. Cleaning with water and air does not impose any strict requirements on the elements of the heating system, like a chemical method, that is, it is equally suitable for all types of materials and pipes. Despite the high cost compared to the chemical method, it is completely safe and more effective.

Before cleaning, it is recommended to treat batteries using a special composition that softens the crust of contaminants.

Pneumohydraulic hammer method

This method is the fastest (takes no more than an hour), convenient, since you do not have to dismantle the elements of the system, but requires the use of special equipment.

At the end of the heating communications, special equipment is attached - a pneumatic gun, with the help of which a pneumohydraulic pulse is supplied to the pipeline, peeling off pollutants adhering to the walls of pipes and batteries.

Despite the serious and frighteningly complex name, flushing pipes in this way is absolutely safe, since a force of no more than 2% of the pulse power is applied to the walls, and the main impact falls on the dirt.

Biological washing

At its core, this method is very similar to the chemical one, only instead of dangerous reagents, high-tech solvents and proppant biological products are used. Under their influence, the crystalline bonds of pollutants are destroyed and corrosive and organic deposits are cleaned off.

The flushing biomaterial is produced on a water basis, and their use allows you to completely clean the heating network in an apartment building and in an individual home.

Why is this necessary?

In the vast majority of old houses, the filling, risers and heating connections are installed with steel pipes. Black steel has an unpleasant feature: the rough walls of pipes tend to collect dirt, gradually becoming overgrown with scale. The build-up is formed mainly from rust and calcium salts.

Rust is a product of corrosion of pipe walls. The source of calcium is sedimentary rocks, which are eroded by water on the way to the water intake.

Not only that: over time, spills, hoses and radiators become clogged with silt - suspended matter that settles in them, which enters the heating devices along with the coolant and settles in areas with a minimum speed of its movement.

Typical condition of the heating radiator supply after five years of operation without flushing.

The consequences of decreased pipe flow and the appearance of sludge deposits in radiators are very predictable:

- Reduced circulation rate. It leads to a drop in the temperature of the return pipeline and, accordingly, to a decrease in the temperature in residential premises;

- Cooling of the last sections of sectional batteries. It is there that the water speed is minimal, so silt begins to accumulate in the lower collector of the outer sections and over time completely blocks the circulation in them;

If the outer sections have cooled down, the battery needs to be flushed.

In the most advanced cases, defrosting of the heating system or its individual sections. If the coolant circulation stops in cold weather, the water in the pipes and radiators will freeze very quickly. Since when the state of aggregation changes to solid, it increases in volume, pipelines and heating devices will be torn.

No flushing

Flushing the heating system in a private home is not necessary if three conditions are met:

- The system is autonomous (i.e. it is not connected to the heating main, but has its own heat source);

- It refers to closed heat supply systems (without extracting hot water from the heating circuit and, accordingly, without renewing the coolant);

- It is equipped with a membrane expansion tank. An open tank means water evaporates and is periodically topped up.

Closed autonomous system with a membrane tank and without hot water connections.

If all conditions are met, the coolant, in the absence of leaks, circulates in a closed circuit indefinitely. After the precipitation of a small amount of salts and suspended matter contained in the water, the contamination of pipes and radiators will completely stop.

Hydraulic testing report for the heating and water supply pipeline system

Checks of heating and plumbing systems are carried out:

- when introducing new engineering communications;

when reconstructing an existing one;

during a routine check of the functioning of the system.

The step-by-step inspection and its results are recorded in the test report. The system is tested for tightness and strength in two ways, one of which is the hydraulic method: testing by using water with increased load. This method is suitable for indoor and outdoor systems (at temperatures not lower than +5C). The second method is pneumatic.

Both methods of acceptance testing are called pipe testing.

The results of the inspections are recorded in a report, the form of which is established by the Code of Rules for building codes and regulations. The template is presented in Appendix 1 to SANPin “External networks and structures of water supply and sewerage.” The presented form of the act is mandatory.

Procedure for drawing up the act:

1. Indication of general organizational information: city of compilation and date.

2. Representation of the members of the commission that carried out the pressure testing and acceptance of the pressure pipeline. Three parties become members:

The company that installed the pipeline

Technical supervision representative from the customer

Operating company representative

3. Below is information about the inspected object and a description of the pipeline (length, diameter, material of pipes and joints), information specified in the working documentation is given, and information about the pressure gauge used is given.

4. The section about the test and its results is completed.

5. In the section “Decision of the commission” there is a statement that the system is considered strong and airtight and this is signed by the members of the commission.

You can download the form for free at the end of the article.

Sample sewer cleaning report. Heating system flushing certificate

Flushing of heating systems is carried out by specialized organizations after the preliminary conclusion of an appropriate agreement. Upon completion of flushing heating systems. The sample and appearance of this document depend on the complex of activities carried out by specialists.

Mandatory procedure

Heating systems are a set of equipment (pumps, boilers, pipelines and radiators) designed to heat rooms.

Due to the fact that heated water is usually used as a coolant, all parts from the inside are covered with a dense layer of contaminants. Sometimes in pipes such deposits reach more than fifty percent of the cross-section.

This reduces heat transfer and lowers the temperature inside the room itself. There are two ways to combat this phenomenon:

- replacing individual parts of the heating circuit;

- flushing the system.

The second option is considered more preferable, since it does not require serious constructive interventions. After carrying out the necessary set of measures, a heating system flushing report must be drawn up, a sample of which specialists have in the form of prepared forms.

They do not have to be ordered from a printing house. To do this, you can use any printing device. How to fill out the heating system flushing report? The sample is usually a standard text in which individual fields that are required to be filled out are deliberately omitted.

It is usually compiled by a representative of the organization involved in the cleanup. What does the act of flushing heating systems look like? A sample form begins with its name and date of preparation. The following information is presented sequentially:

- Address of the object.

- Information about the three obligatory participants in whose presence this procedure takes place (customer, representative of the service company, specialist from the cleaning organization).

- Date of work.

- From four options, you select the method by which the system was cleaned.

- water before and after work. The amount used and temperature are indicated separately.

- The quality of the work performed.

All data specified in the act ends with the signatures of three parties.

Additional work

After other equipment, it is advisable to do pressure testing. This additional procedure will allow you to check the tightness of the entire system and identify places where air or water may escape. Such actions are not mandatory, but highly desirable.

They correspond to the interests of both the customer and the contractor. Upon completion, both will be able to verify the quality of the previous stage.

The execution of work records the act of washing and its sample will look like a table that contains a list of all activities carried out during such a procedure.

Against each of the points, the specialist must make a note of completion. At the end, as usual, the customer and the contractor put their signatures, confirming the fact of the work.

Experts sometimes call this procedure because most often such a test is carried out using water. It is believed that the air may be more dangerous when serious faults are detected.

Therefore, many people prefer to take the easier path.

Features of registration of the washing certificate

To control the quality of work, water is taken from different parts of the heating system.

Sample documents.

The simplest way to check is this: in the entrances or apartments, unscrew the blind radiator plugs and evaluate the quality of the work. There may be water or sludge on the radiator cap, but there should be no solids.

Then a washing report is drawn up, which should contain the following information:

- heating system cleaning method;

- water consumption, if there are metering devices;

- water temperature (if washing was performed with hot water);

- service quality assessment: satisfactory or unsatisfactory;

- signatures of persons responsible for the work;

- date of service.

If the act has a unified form, then a special form is drawn up. For a sample washing report, various organizations use documents that may differ in detail, but the contents of the document must comply with the state quality standard.

An approximate sample of the act is attached.

Heating systems that are cleared of dirt work better. The heating of heating radiators is improved. Cleaning is carried out depending on the performance of the equipment. It is better to use purified water as a coolant, which will contribute to less contamination of pipelines.

Flushing is an effective measure to increase the productivity and quality of the system, which can be combined well with preventative maintenance.

If carried out in a timely manner, you can avoid additional costs and save money.

Novel