Defrosting the heating system is one of the few problems that private home owners are actually afraid to face. In essence, defrosting is a process when the coolant in heating pipes or appliances simply freezes. Such a situation can become a real disaster - after all, if this happens, the house is left without heating for a long time - and the system requires major repairs. What to do to avoid getting into such a situation? And how to defrost the heating system?

Defrosting a heating pipe

About preventing freezing

A very important aspect is the choice of pipes for the heating system of the building. The weakest point of all pipes is corrosion processes. The most durable material is cast iron; according to manufacturers of cast iron batteries, they can last up to 100 years. The least resistant is aluminum, whose service life is about 10 years. Steel batteries will last you 25 years. Plastic pipes are not subject to corrosion, scale is not deposited in them, and they will last 50 years.

In addition, such pipes will not burst if the heating system needs to be defrosted - only a slight swelling will be visible in that place.

The owner of the house must be personally present at the moment when the heating system of a private house is launched. First of all, you need to pay attention to the welded joints, as well as how the pipes are laid in the trenches. Before filling them, you need to make sure that the thermal insulation of the pipes is in the gravel “backfill”.

Otherwise, deformation or even rupture may occur. It is also necessary to check how reliably the threaded connections of heating systems are sealed in areas where welding is not required.

How to prevent freezing

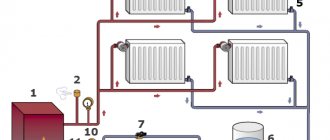

To prevent freezing, first of all, it is necessary to correctly approach the layout and design of the heating system. It is advisable to purchase an auxiliary power supply. This is especially worth considering for those who experience frequent power outages. Using these simple tips, you can prevent system downtime. And, consequently, freezing of the heating system.

When constructing a heating system, it is necessary to use only high-quality materials. For example, it is not recommended to use aluminum pipes as they have a short service life. Usually it does not exceed 10 years. The highest quality are cast iron pipes and radiators. They have a service life of more than 50 years. Copper and steel pipes are less reliable. Their service life usually does not exceed 20 years. When using low-quality water, the service life of pipes is significantly reduced. Metal pipes are more susceptible to corrosion than others.

Plastic pipes are considered the most profitable. They do not corrode and have a service life of more than 35 years. Once pipes are defrosted, metal pipes often collapse. And plastic pipes can only swell a little. This is another advantage of such pipes.

The main means of protecting heating system pipes from freezing is high-quality thermal insulation. When installing pipes, the following rules must be observed: pipes must be laid on a bed of crushed stone and must be covered with thermal insulation. Pipe joints are more susceptible to freezing.

Equipment for quick defrosting of the heating system

With the help of one of these devices, you will have the most modern and fastest defrosting method - within a few minutes, ice plugs in the pipes will be removed. With the use of such devices, an electric current is passed through the defrosted pipes at low voltage; the current strength should be equal to 400 Amperes.

The power depends on the length of the pipe - it can be adjusted from 1.7 to 4 kW.

If defrosting is necessary in pipes of large diameters, then they resort to using several devices simultaneously. The duration of this process is half an hour. The main thing is that the sealing of threaded connections of heating systems is not broken during defrosting.

Preventing the situation

When a situation has already happened, you need to think about how to get out of the situation. However, before this happens, all preventive measures should be taken.

Initially, freezing of heating pipes depends on the correct installation of the heating system, proper calculation, and diagram.

An option for an alternative power source is provided (relevant for areas with constant interruptions in electricity and gas supply). Even during installation, you need to rationally choose the material of the pipes; plastic has the advantage here; if it freezes, it will swell a little, when steel, cast iron, or aluminum simply breaks.

High-quality thermal insulation is the second protective measure. Place special material on the pipes that will prevent freezing (especially important underground, when the pipe connects the summer kitchen and the house). You can read more about pipe insulation here. Insulated heating pipes are recommended for use, an important effective energy-saving solution used during reconstruction and installation. To protect short lengths, resistive, self-regulating cable should be used. In closed systems, antifreeze is added for the winter.

Anti-icing and network heating systems

There is one more unfavorable nuance: pipes burst, which subsequently washes away the house structure with water, and the foundation is eroded. Next, you will need to carry out serious repairs, which will entail impressive amounts of costs. To avoid such an unpleasant moment, you can use a system of anti-icing and network heating of pipes.

To ensure continuous external defrosting of the heating system, a heating device such as a resistive series cable is used.

This system is good to use for pipes of considerable length. If compact heating is required, a self-regulating cable can be used.

To ensure anti-icing in drinking water pipes, a cable of this type is laid directly inside the pipes.

Determining the location of freezing

Determining the location of the freeze is the first and easiest step in defrosting the pipeline. To do this you will need a tape measure and a steel plumbing cable.

First of all, a visual inspection of the pipeline is carried out. If the outer part is frozen, then the plug can be detected by simple inspection, but if nothing can be detected visually, then a cable is passed through the open tap. The passage of the rope must be continued until it stops in the ice plug.

After this, the cable is removed, measured and compared with the approximate length of the pipeline. This way you can determine the approximate location of the plug, but the exact value is not required to defrost the pipe. To make sure that the location is determined correctly, you need to make a verification pass with a steel cable on the other side of the plug. To do this, the cable is inserted in the same way into the tap closest to the place of freezing.

Methods for defrosting pipes

Each stage of defrosting pipes must comply with rules that must be followed. For example, how to check the tightness of the heating system during defrosting. If you decide to defrost yourself, you need to adhere to the following:

- Before defrosting, fully open the tap, which is located directly near the place where the water freezes in the pipes.

- Defrosting should be done slowly, gradually moving from the unscrewed tap to distant areas of the frozen pipe.

- The temperature does not need to be very high, it should be approximately such that a person can touch the pipe with his hand.

- When a pipe overheats, steam is formed; if the pressure created in the pipe is excessive, it can rupture, similar in nature to an explosion.

The simplest defrosting option is to turn on the autonomous heating system. When the house begins to warm up, the pipes themselves will go through the defrosting stage.

A fairly effective way to defrost in wooden floors or walls is to install electric lamps with a reflector that reflects heat energy. Electrical wiring is designed for power exceeding that used for an electric lamp.

Each of the listed defrosting methods is allowed to be used for metal-plastic pipes.

The temperature of such pipes during defrosting should not exceed 120 degrees.

More on this topic on our website:

- Collector heating system for a two-story house Heating affects comfortable and cozy living in the house. Therefore, the choice of heating your home must be approached with all seriousness. If your home has...

- The Leningrad heating system, the scheme of which is widely used in multi-storey and private buildings, is one of the most common schemes for organizing heating in buildings. Heating by…

- Gas heating is characterized by its low cost of energy, but is inferior to electric heating in terms of accessibility to the general population, ease of installation and ease of operation. Therefore, for many citizens of our country, electric...

- A country house can be a building equipped with various communications and high-quality furniture, but all luxury will become meaningless if the housing is not heated or the heating system is not...

How to prevent pipes from freezing

A preventive solution to this problem is to initially prevent the formation of ice plugs along the entire length of water pipelines. To do this, during the laying and installation of utilities, I advise you not to ignore the requirements of the Building Codes and Rules, and to follow the basic tips and recommendations set out in the regulatory and technical documents and suggested by experienced builders.

- The minimum depth for laying a water or sewer pipeline must be located below the greatest depth of soil freezing for your region , in accordance with the requirements of SNiP II-G.3-62 “Water supply. Design standards";

Water communications must be laid below the freezing depth of the soil.

- When laying external or underground communications, you need to use water pipes with a diameter of 48 mm and above , because thinner pipes are susceptible to rapid freezing throughout their entire thickness;

- If possible, I advise using pipes and fittings made of polymeric materials (polyethylene, polypropylene) for these purposes, since they are more elastic, which allows them to stretch slightly in case of deformation, and in addition, these materials have lower thermal conductivity;

- I also do not recommend laying the pipeline in the ground, close to building structures made of brick and monolithic concrete, since their thermal conductivity is much higher than the thermal conductivity of dry soil;

Thermal insulating segment linings made of extruded polystyrene foam.

- To protect external and underground pipelines from the cold, it is necessary to use heat-insulating sleeves or segmental linings made of polypropylene foam, polyurethane foam or pressed mineral wool , and in those places where the pipe passes through a concrete foundation or brick wall, a double layer of heat-insulating material must be applied to it;

- In unheated private houses for seasonal residence, water cannot be left inside pipelines and other communications for the winter, therefore, with the onset of the first cold weather, it must be completely drained.

If these measures were not enough, or they were taken untimely, and the water in the pipes still froze, in order to minimize the likelihood of unpleasant consequences in the form of burst pipes, shut-off valves or fittings, then the reader will be offered simple instructions in which I offer several simple ways to remove ice blockages in water pipes.

Insulated pipeline with heating cable.

To ensure guaranteed protection against freezing, in regions with cold climates, I advise using an electric heating cable, which must be laid along the entire length along the pipe and shut-off valves, under the thermal insulation lining.

How to defrost an open pipeline

If the frozen section of the water pipeline is located in an open place, within direct reach, solving the problem of thawing the ice plug is significantly simplified, since external heating of the pipe can be used for this.

As a heat source for external heating of metal-plastic, polyethylene or polypropylene pipes, it is allowed to use only electric heating devices, for example, a construction or household hair dryer, an electric heating pad or a heating cable. To heat bare metal pipes without external heat and waterproofing, in addition to the presented devices, you can also use an open flame from a gas burner, a blowtorch, or a homemade improvised torch.

- First of all, you need to determine the location of the icy section of the water supply, and open the tap of the nearest plumbing part halfway to ensure the free drainage of thawed water;

Portable gas burner with replaceable cylinders.

- Before defrosting the heating pipes, you need to turn off the heating boiler, make sure there is no water pressure in the system, start the circulation pump and slightly open the coolant drain valve from the heating circuit;

- Connect a heating device to the network, or light the flame of a gas burner, and from a safe distance begin to warm up the frozen section of the pipe, gradually moving the tool from the drain valve towards the supply riser;

Instead of an open flame, it is more convenient and safer to use a hair dryer.

- When using an electric heating pad or heating cable, you need to wrap it evenly around the frozen section of the pipe and plug it into the network. To enhance the effect, I recommend wrapping a thick cloth or an old blanket over it;

- After some time, as the temperature increases, a thin stream of water will appear from the slightly open tap, which indicates the gradual thawing of the ice, and after the pressure increases sharply, you can turn off the heating devices.

The heating cable must be wrapped not only around the pipe, but also around the shut-off valves.

If the icy area is located in an apartment, you can use hot water to warm it up by pouring a kettle onto a pipe or radiator, after wrapping it with a thick cloth and placing a wide bowl or basin under it. Also in the house, instead of a hairdryer, you can use a medical lamp with a deflector, or a household electric heater.

How to remove an ice blockage in a drain

In private permanent residences, freezing of sewer pipes is a fairly rare phenomenon, since with continuous use of the sewer system, a positive temperature is naturally maintained in the drainage system due to the wastewater’s own heat.

However, if for some reason this did happen, then I will talk about how to defrost a sewer pipe in a private house using simple and affordable, but at the same time effective methods.

A frozen inspection well or septic tank can be warmed up using hot water or steam.

- In cases where the drainage collector lies at a shallow depth, if the conditions on the plot allow, a fire must be lit above the supposed place where the soil freezes and the fire must be maintained until this area of the ground is completely warmed up;

- If the ice plug is located near the sink or toilet drain, I recommend pouring a saturated hot solution of table salt (1 kg of salt per 10 liters of water) into the drain. The resulting brine has a fairly low melting point (below -22°C), so ice reacts upon contact with it and begins to actively melt;

Flexible silicone hose with plumbing cable.

- If the plug is located far away, you can take a plumbing cable and attach a flexible rubber hose to it with electrical tape in several places. After this, insert the free end of the cable with the hose into the sewer pipe until it hits the ice jam, and then use a wide funnel to pour hot salt water into the hose;

- If the septic tank is significantly removed from the house, an ice plug may form at the end of the drain collector. In this case, you need to open the inspection hatch of the septic tank's receiving chamber, insert a flexible rubber hose into the sewer pipe all the way, and supply water from the hot water supply system until the ice completely melts.

A homemade device made from a heating cable and wire with a plug.

If there is a piece of electric heating cable of sufficient length left in the house, it should, as far as possible, be inserted into the drain hole of the sink or toilet and connected to the electrical network (the drain system should be filled with water).

Thawing hidden plastic pipes

Currently, pipes made of polymer materials (polyethylene, polypropylene, PVC, metal-plastic) are widely used to supply cold water to the house from a well or a centralized water supply, as well as to perform intra-house wiring. Freezing of internal communications is rare, however, if a water pipe is laid underground, laid inside a wall, or passes through an uninsulated underground space, it may freeze during prolonged severe frosts.

Rupture of a metal-plastic pipe due to frost.

The methods described above will not work in this case, so next I will tell you how to defrost polypropylene pipes if they are not in plain sight and there is no direct access to them.

- First of all, you need to purchase a coil of two-core electrical cable of sufficient length, with solid copper conductors. At one time I used for these purposes a power installation cable NYM 2x1.5 mm², costing 20-35 rubles/m.p., but you can take its domestic analogue VVG 2x1.5 mm², the price of which is 16-25 rubles per linear meter;

Scheme for thawing a plastic pipe using an electric cable.

- One of the free ends of the cable must be cut as shown in the figure below. On a section 80-100 mm long, you need to completely remove the top insulation, then completely strip one copper core. Strip the second core halfway, bend it back, and make several turns of the bare wire around the cable;

- Also turn the completely stripped core back, and, trying not to damage the insulation, wind it in several turns onto the very end of the cable;

The photo shows a diagram of cutting the end of the cable.

- Place the prepared end of the cable into a plastic pipe and push it forward until it hits the ice plug. After this, connect the free end of the cable to the electrical network;

- When an electric current passes between the two copper windings at the end of the cable through the water in the pipe, it will begin to heat up and gradually melt the ice;

- The shut-off valve at the entrance to the house must be kept half open, and a bucket or bowl should be placed under the free end of the pipe, because after a while thawed water will begin to flow out of it.

The cable must have solid copper cores.

Once again, I would like to remind you that this method can only be used on plastic pipelines with plastic shut-off valves, since even if a steel pipe or metal fitting is installed in some section, this can lead to a short circuit.

Defrosting a hidden metal pipeline

Despite the widespread use of polymer materials in modern construction, metal pipes are currently no less popular. Since the technology described in the previous section cannot be used to defrost metal pipes, I invite the reader to become familiar with two more similar methods that can be used to thaw metal utility lines hidden underground or in a wall.

- The first of these methods resembles the previous one, however, instead of an electric cable, in this case a thin flexible hose is used, into which hot water or saline solution is supplied directly to the place where the ice plug forms;

Scheme of heating the pipeline using hot water.

- To ensure that the hose does not break, get stuck or bend as it moves inside the pipe, it must be wound with electrical tape to a thin but rigid steel wire in several places, approximately every 600-800 mm, and so that the wire does not catch on bends and turns , it needs to be bent with a small hook inside the hose;

- After one end of the hose reaches the ice plug, you need to attach any suitable container to the other end, preferably with a tap, into which you need to gradually pour brine or clean hot water;

- As a container for water, I recommend using Esmarch’s medical mug, or, more simply, a regular enema. All other steps must be performed similarly to the previous method using an electrical cable;

Esmarch's medical mug can be purchased at any pharmacy.

The second method, in my opinion, is much simpler, since it does not require partial disassembly of the pipeline and dismantling of shut-off valves with your own hands, moreover, it can be performed without further human intervention, however, it is quite energy-intensive, and a welding machine is also required for operation.

- The first step is to roughly determine the section of the pipe where the ice jam has formed, then remove a small part of the thermal insulation from both sides of this section and clean the metal of the pipe until it shines;

Connection diagram for a welding machine for thawing a steel pipe.

- Connect electrical cables connected to the secondary winding of the welding transformer to the cleaned areas; it is important to ensure a high-quality electrical connection;

- Set the welding machine to the minimum value of the working current and connect it to the electrical network. When low voltage with high current passes through metal pipes, they will begin to heat up along the entire length of the connected section, which will lead to a gradual thawing of the ice;

- Heating can take up to several hours, and during this time it is important that the water tap of the nearest plumbing fixture in the house is open.

Electric apparatus for heating metal pipes.

When working with a welding machine, it should be borne in mind that connecting and disconnecting the electrical cables of the secondary winding to the pipe is allowed only when the transformer power is turned off, otherwise, at the moment the circuit breaks, an electric arc is formed, which can cause burns to the hands and eyes, and even lead to burning through the walls of a steel pipe.

Esmarch's irrigator

But so far we have considered easy cases - defrosting on straight and short sections. But what should you do if the pipe froze several tens of meters from your home, and the route is still complex - with turns and bends horizontally or vertically?

Such complex problems are solved by using an Esmarch mug complete with a construction hydraulic level and a coil of rigid steel wire. You can buy all these components without any problems, their cost is low, and the effect of use is one hundred percent.

Prevention measures

It is better to prevent any trouble in advance. As for measures to counter freezing of pipes, they can be divided into two groups: installing the system again and correcting the existing situation.

In order to properly remount the system you need to:

- Choose pipes with a diameter of at least 40 mm.

- It is advisable to use plastic pipes, since metal ones tear more easily under the influence of ice.

- Do not lay pipes near brick walls and foundations, and use a double layer of insulation in places where they pass through the fence.

- The pipes must be laid below the freezing level of the soil.

- All external pipes must be insulated.

In order to correct the existing situation, there is only one option: installing a heating cable. Moreover, it is the internal heating cable, since in order to lay the cable on the pipe, you will have to open the layer of earth above the communications, and in this case you can install the system again.

As you can see, there is nothing difficult about defrosting pipes yourself. The main thing is to do everything quickly and in compliance with all safety measures.

Who is to blame and what needs to be done?

The reasons for freezing of water mains are commonplace. These are errors in the installation of water supply, sudden temperature changes, lack of fluid movement, and the presence of a leak. For sewerage, the cause may be blockages and overflow of drains.

At the stage of building a house, preventive work is important:

- Determining the maximum depth of soil freezing. Accordingly, the laying of the pipeline is below this point.

- If it is impossible to fulfill the first condition, it is necessary to insulate the line with heat-insulating materials, for example polyester, on one side of which there is a layer of heat-reflecting foil.

Pipe insulation

Pipe heating

- Ensuring a constant flow of water. In severe frosts, it is necessary to open the taps at night. If the system is not used for a long time, it is necessary to completely remove water from it.

- When installing a water supply system, it is necessary to wrap the lines with an electric heating cable.

Particular attention should be paid to the places where the pipe comes out of the ground and enters the structure.

Simple ways to solve the problem

The localization of the ice plug has been established; it remains to resolve the question of how to warm up plastic pipes without making much effort.

When heating ice, it should be taken into account that it obeys the same laws of physics as any other solid body. When water becomes ice, its volume increases. Ice, when heated, expands before melting. If you heat it up sharply, the plastic line may not withstand it and burst. Therefore, it is better to spend a little more time to preserve the pipeline than to try to speed up the process of rendering the plastic plumbing unusable.

For highways located indoors, one of the options would be to heat it with electric heaters. If this method cannot be applied, we use external defrosting methods:

- The most popular method is boiling water. It is used to water the area where the plastic line is damaged. To reduce heat loss, the area is wrapped in several layers of rags. To make the process go faster, you need to open the nearest tap; as soon as the ice melts, the resulting flow of water will prevent it from forming again.

- Ice can be melted with a regular or construction hairdryer. In the latter case, care must be taken; the outlet temperature is 250°. If you overdo it, the pipe may melt. A canopy made from scrap material will help reduce the consumption of warm air.

- A financially expensive, but pipe-friendly method, is the use of metal-plastic systems for heated floors. They are wrapped around the frozen area, then connected to the power supply.

The ice has broken

The problem has been resolved, what to do next? You will say that you can go relax and enjoy the fruits of victory. But this is the time to think about how to prevent a similar problem from occurring in the future. It is necessary to analyze why the plastic lines froze.

- If the pipe laying depth was chosen correctly, then a leak may have appeared at the joints or the waterproofing may have been damaged. It is important to schedule inspections of all plumbing during the summer.

- If an ice jam occurs between the facade of the building and the ground, then it is necessary to enlarge the hole where the plastic pipes are connected and provide additional thermal insulation from the concrete.

- It may be necessary to equip areas located in open space with electrical heating, with automatic adjustment. So that the system turns on when the set temperatures are reached.

- Or violate all safety standards and regulations and constantly keep at least one of the water taps open. And the first morning flush into the sewer should be done with boiling water.

- If the soil is frozen, then after some time, after the accident is eliminated, the problem will arise again. You need to be prepared for such a scenario.

It is possible to warm up frozen plastic pipes without resorting to the help of specialists with your own hands. The main thing is to prepare in advance for the winter season. Although plastic pipes are flexible and can withstand significant expansion, it is best not to test their strength.

Far from home underground

Warming up a plastic pipe in the ground is much more difficult. To use external defrosting methods, you need to dig a line. In thirty-degree frost - the pleasure is below average, there is a chance of missing and damaging the pipeline. The only option is defrosting from the inside.

Folk craftsmen have come up with many means:

- The operation is carried out using the same boiling water. A pipe made of metal-plastic is taken with a cross-section less than half the size of the main water supply. Pushes towards the frozen area. Boiling water is poured into a thin pipe, which will wash away the ice, and melt water will escape between the walls. The supply of hot water can begin when the thin tube rests against the plug. As the cork breaks down, the metal rubber is moved forward. The tap must be kept open to reduce the pressure in the system.

- A more advanced option allows you to eliminate ice at a great distance from the building. Instead of a metal-plastic tube, a hydraulic level is taken, it is connected on one side to a steel wire, and the opposite end is connected to a bucket with a hole at the bottom. Boiling water is poured into it. The wire allows you to supply hot water to ice located at a great distance from the beginning of the line and overcome its possible bends.

- For small distances from a building, an original method based on a “boiler” was invented. Water contains a certain amount of salts, being an electrolyte, and accordingly conducts electricity. You need to take a two-core wire, strip the wires, wrap them around the insulation so that they do not intersect, and you will get a simple boiler. It is pushed towards the ice plug and power is supplied to the other end.

- There are high-tech products for removing ice clogs. Steam or water are used, which are supplied under high pressure. A special hydrodynamic installation can supply water with a pressure of 10 atmospheres and a temperature of 100°. The device combines thermal and mechanical methods of ice destruction. The disadvantages include the need for access to running water, and high temperature and pressure can lead to damage to the walls of the plastic line.

- Steam generator, a more gentle option. It can be used for pipes made of any materials. Steam under pressure, one of the most effective methods, ice melts before our eyes, but it is necessary to follow safety rules, since while the hose with the fitting is removed from the system, a fountain of steam mixed with water will erupt from it. A hydrodynamic machine and a steam generator are expensive devices; it is much cheaper to make high-quality water supply than to purchase them.