A device such as a room thermostat for a gas boiler is an important element in the heating system. Its main task is to compare user-specified data incoming from the temperature sensor. This allows you to turn the heating on and off in a timely manner, which minimizes energy consumption while obtaining the optimal temperature in the house.

A thermostat will be required to minimize energy consumption

Briefly about the principle of operation

To better understand the principle of operation of room thermostats, we first explain the operating algorithm of a water heating boiler in the basic configuration:

- The user ignites the heater and uses buttons or control handles to set the desired coolant temperature.

- Each device is equipped with a submersible or surface-mounted sensor that informs the control unit about the degree of water heating. When the coolant temperature reaches a predetermined threshold, the gas valve is activated and shuts off the fuel supply to the main burner. The circulation pump continues to “drive” water through the system.

- After the coolant has cooled to the lower temperature limit, the gas supply is resumed, the burner is re-ignited and heats the water.

Reference. In turbocharged wood boilers, the automatic system turns off the blower fan. The flow of air and the combustion process in the furnace are suspended, and the unit goes into standby mode.

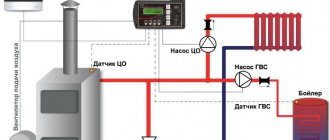

Scheme of operation of a heating boiler with a remote thermostat - the automatic system stops and starts the burner depending on the temperature of the air, not the coolant.

Without an external temperature sensor, the heater “does not see” the air temperature in the rooms and stupidly heats the water to the specified limit. Result: during the transitional autumn-spring period, the so-called clocking is observed - frequent start/stop of the burner (once every 2-3 minutes), reducing the life of the unit as a whole.

Now about the main thing. A remote thermostat extends the intervals between turning on/off a gas boiler, since it focuses on the temperature of the air, which cools more slowly. The device is connected to the power supply circuit of the gas valve (turbines on TT boilers) and the built-in pump.

Installing an automatic thermostat allows you to kill three birds with one stone:

- reduce energy consumption;

- make boiler control more convenient;

- extend the life of the heat source.

Important note. The listed points apply not only to gas heaters. Any heat generator equipped with an electronic or electrical control unit is connected to the thermostat: solid fuel, diesel, electric boiler, and so on.

The automation unit of the wood-burning boiler has a connector for connecting the thermostat.

When the room warms up to the specified temperature, the thermostat breaks the circuit, the burner and the built-in heat generator pump stop. The unit starts up after the air has cooled by 1-2 degrees, which increases the duration of the interval between shutdown and ignition to 15-20 minutes.

Let us note 2 significant nuances:

- When using a room regulator, the standard start/stop function based on the water temperature in the boiler jacket continues to operate. When the coolant in the boiler heats up to the set limit, the gas burner device will turn off.

- If the burner is extinguished at the command of the internal temperature sensor, the standard circulation pump continues to operate. When the remote thermostat is triggered, both devices – the burner and the pumping unit – stop.

This is why it is important to correctly configure the boiler-external thermostat combination.

What is it needed for?

Even modern gas boilers of domestic and foreign production, as a rule, have the simplest system for regulating the level of heating of the coolant. The user sets the temperature parameters using a mechanical or electronic regulator.

The sensor monitors the heating of the liquid in the heating system and sends signals to turn off or turn on the gas supply. The main feature of such a device is its lack of efficiency, which is explained by the lack of taking into account the air temperature inside the heated room.

Installation work on installing a remote-type room thermostat for a gas boiler will become relevant if it is necessary to ensure the most accurate temperature control. Installing a special sensor indoors can reduce fuel costs by about 16-20%.

Types of room regulators

To automatically adjust the boiler combustion according to the room air temperature, 2 types of thermostats are used:

- Mechanical. The electrical circuit is broken and closed by a bimetallic plate that bends when heated. To change the desired temperature, the user rotates the knob, which increases or decreases the gap between the plate and the second contact.

- Electronic (digital). Here, the role of a heat-sensitive element is played by a thermistor, which changes resistance depending on temperature. The circuit, which includes the specified part, closes the relay contacts, guided by changes in resistance and user settings.

Reference. Mechanical and electronic temperature sensors are used not only for the boiler. Thermostats are successfully used in other areas of the heating system, for example, to turn off the circulation pump of a separate radiator branch or for zonal control of heated floors.

The device of the simplest mechanical temperature controller

The mechanical device is connected to the heat generator via a cable. Most electronic models provide wireless connection. According to reviews, radio-controlled thermostats are gaining wide popularity due to their ease of installation and operation. How a wireless boiler thermostat works:

- The device consists of two blocks equipped with radio modules.

- The first block, including the executive relay, is placed directly next to the heater and connected to the desired connector. Power supply - from the house electrical network 220 volts.

- The second unit with a display and control buttons is powered by batteries and is installed in a convenient place in the home.

- The temperature sensor located inside the remote control reacts to the air temperature. At the right moment, the radio module sends signals to the first block to turn on/stop the boiler. It opens the relay contacts, heating and circulation of the coolant is stopped or resumed.

Wireless thermostats consist of 2 blocks that exchange radio signals.

Typically, electronic models are equipped with programmers that allow you to set the boiler operating schedule for a week. The temperature in the rooms can be changed several times during the day. Individual instances are programmed for 90 days and controlled via mobile communications, for example, via SMS or a smartphone Internet application.

What are they for?

Temperature is the main physical quantity, moreover, sufficient to monitor the operation and control of the boiler and the entire heating system in the house. It is enough to know how much the coolant is heated in order to automate the operation of the boiler to a minimum extent.

If you add a thermometer installed in the room, you can already talk about energy-efficient boiler control and greater comfort for residents.

The most important thing for the user is to choose the best option for a room thermostat so that it is convenient to regulate the temperature in the room. You have to choose from mechanical or electronic devices.

Electronic thermostats provide greater accuracy and convenience, but mechanical devices still find applications, mainly due to their low cost, simplicity and, most importantly, energy independence.

Which thermostat is better to choose?

To make the right choice of a room regulator, we suggest considering the pros and cons of two types of household appliances. Disadvantages of mechanical models:

- low accuracy of maintained temperature;

- wired connection - the cable will have to be pulled from the boiler room to the desired room;

- lack of various convenient functions available in programmers.

Note. Judging by the reviews of real owners on the forums, the accuracy of temperature maintenance is not a critical problem and does not worry users too much. Another thing is the wires that need to be hidden under the baseboards, in the grooves of the walls, and so on.

There are also three obvious advantages of bimetallic thermostats:

- low price and availability;

- reliability in operation - in the simplest models there is nothing to break;

- ease of control of the boiler using one handle, which is important for older homeowners.

The negative aspects of electronic regulators are a higher price, a not always clear interface and the need to timely replace batteries. Cheap Chinese models encounter an additional problem - a breakdown in communication with the relay unit when installing the control panel behind 1-2 partitions.

An absolute plus of digital thermostats is comfortable operation. It is enough to set the weekly and daily operating program for the heat generator once; no further actions are required.

Wireless programmers need to change batteries on time.

We list a typical set of functions using the Baxi Magic Plus thermostat as an example:

- temperature control range – 5…35 °C;

- protection against freezing of the heating system, by default starts the boiler when the home cools down to +3 degrees;

- LCD display with backlight, control – push-button;

- shift of temperature sensor readings ±5 °C (read the explanation in the next section of the publication);

- 2 operating modes – economical and comfortable;

- hourly/daily/weekly programmer.

Reference. Manufacturers often call such devices digital chronothermostats. The weak point of the devices is their low maintainability in the event of a breakdown, especially Chinese products for which it is not easy to find spare parts.

Knowing the features of electronic and mechanical regulators, it is not difficult to choose the appropriate model. Focusing on your budget, first of all consider reliable products from European, Japanese and Korean brands, there are also decent brands, but on average the quality of the products leaves much to be desired.

Installation and connection of the device

Installation of a household regulator consists of two stages - mounting in a convenient place and connecting to a gas (solid fuel) boiler. In order for the thermostat to record the temperature without deviations, position the control element according to the recommendations:

- minimum height from the floor – 1.5 m, maximum – 1.7 m;

- within 1 m from the device there should not be heating radiators, heaters or other household appliances that distort the thermal image (including air conditioners);

The temperature regulator should be placed away from various sources of heat or cold. - exclude exposure to drafts and running ventilation;

- It is not advisable to install the sensor away from heated rooms.

Advice. For a private home with heated floors, it is worth buying a thermostat model equipped with an additional temperature sensor. The latter is placed above the floor surface and measures the temperature in the lower zone of the room.

After mounting the device on the wall, according to the manufacturer’s instructions, lay the wire to the heat source in a hidden or open way (if there is a wired connection). How to connect the regulator to the boiler:

- Connect one end of the control cable to the contacts marked COM (common) and NO (normally open) of the thermostat. On the wireless version, these terminals are located in the relay block.

- In the operating instructions for the heat generator, find the connection diagram for the remote thermostat, markings and location of the contacts.

- Remove or fold down the front panel of the gas heater, which provides access to the control board and connectors.

- Remove the jumper inserted between the terminals indicated in the passport. Do not throw away the part; you may need it later.

- Connect the wires coming from the regulator contacts to the free terminals. There is no need to observe polarity.

- When installing a wireless thermostat, connect a three-wire 220 V power cable with a grounding wire to the relay unit.

Advice. If the contacts of your device have numbers or strange letters instead of the indicated markings, find the 2 required terminals using a tester (the circuit between them must be open). There are three contacts in total, the pair COM and NC are initially closed, as shown in the diagram above.

Details of installing a wireless thermostat are shown in the video:

Non-volatile floor-standing boilers equipped with gas automatics 630 SIT, 710 MiniSIT, SABC, Orion and the like are incompatible with remote controllers. The reason is the completely mechanical design of the gas valve and the absence of electrical circuits where the breaker relay can be connected.

Connection diagram of the regulator to the SIT 820 NOVA valve

The exception is gas heat generators equipped with Kare automatics and the latest generation of Italian valves EuroSIT - 820 NOVA. These blocks provide solenoid valves and special contacts for connecting two types of external thermostats - mechanical and digital.

The “Kare” automation uses an electromagnetic valve, where the thermostat is connected

Setting procedure

To configure the system and select a comfortable temperature, follow these steps:

- Set the maximum temperature using the remote controller.

- Start the boiler and bring it to the optimal operating mode, in which the unit achieves the greatest efficiency.

- When all rooms are at a comfortable temperature, take an electronic thermometer and measure the temperature near your regulator.

- Select the measured value on the thermostat as the heater shutdown threshold. Enter the required settings into the programmer.

Important clarification. The gas boiler operates with maximum efficiency at a temperature range of 80/60 °C (supply/return).

Let us explain the purpose of these manipulations. Due to different areas and heat losses, the temperature in the rooms may differ by 1-3 degrees, so it is better to navigate by the degree of heating of the air near the sensor itself.

If the temperature at the point where the regulator is installed is very different from other rooms, when setting, you need to make an adjustment for the magnitude of this difference. Some models, for example, Baxi Magic Plus, provide a function for such adjustment (called temperature shift). Then all that remains is to enter the desired value into the device’s memory, ranging from 1 to 5 degrees.

Tips for choosing

- If you are short on funds, then purchase a simple, wired, electronic thermostat. Such devices are more technologically advanced, have a better response, and the quality of their operation does not depend on contacts oxidizing in air, as in mechanical analogues.

- If you are concerned about saving energy resources, and at the same time your own funds, purchase a weekly programmer. This device will significantly reduce the temperature in the room, and, accordingly, the frequency of turning on the boiler installation during hours when all household members are at work.

- If you have already made repairs, and there is no desire to ditch the walls for laying cables, then purchase wireless air thermostats.

In principle, any room thermostat is suitable for any wall-mounted gas boiler. However, boiler manufacturers strongly recommend connecting air thermostats of only one brand. For example, according to the manufacturer, the room thermostat for the baxi gas boiler should only be of this brand. This is a marketing ploy to attract more customers!

When does the thermostat not save gas?

There are quite a few reviews like this on the Internet: “I fell for the sellers’ assurances about saving 30%, bought and installed a temperature regulator, now the boiler consumes more gas. Why is it needed at all? Let's figure out how this device saves energy (not only gas, but also solid fuel, diesel fuel and electricity):

- The interval between starts of the heat generator increases. The reason is that the cooling and heating of the air occurs more slowly than the water in the batteries.

- Together with the burner, the circulation pump is turned off, consuming up to 100 W of electricity. In TT boilers the fan (turbocharger or smoke exhauster) stops.

- The premises are fully heated at the right time when residents are at home. During other hours, a reasonable permissible temperature is maintained. It is recommended to reduce the heating at night - for a comfortable sleep, it is enough to heat the rooms at 18-19 °C.

Explanation. Reasonably acceptable means the temperature at which the boiler will quickly warm up the rooms to a comfortable level without much energy consumption. It is determined empirically and lies within 15-18 degrees.

Now let’s look at situations where, instead of saving, there is increased consumption or deterioration in heating:

- The boiler is set to the minimum coolant temperature (40-45 °C), because the underfloor heating circuits are connected directly. The heater operates with low efficiency, gas consumption does not decrease.

- When the home is heated exclusively with warm floors, and the thermostat does not measure in the lower zone of the room. The screed and air warm up slowly, and at the moment the sensor is triggered, the floors become too hot. When cooling, the opposite picture is observed.

- The heat loss of the building is too great. No thermostats will help here; insulation is required.

- The temperature sensor-boiler connection is incorrectly configured, the hysteresis (temperature difference between starting and stopping the heat generator) is incorrectly selected.

Each thermostat provides a temperature difference between turning off and turning on the boiler. The value can be changed within 0.5-2 degrees. If maximum hysteresis is selected and the house is heated with underfloor heating, the air temperature difference will increase greatly, staying in the room will become uncomfortable, and the heat generator will consume more fuel for heating.

The master installer will tell you about the intricacies of setting the thermostat in the video: