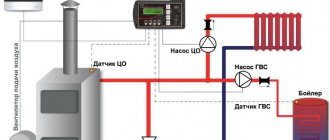

A fan, also known as a smoke exhauster, is installed in gas heating equipment for the purpose of forcibly removing smoke from the combustion chamber. A gas boiler equipped with such a system is called turbocharged. The operation of the exhaust device is controlled by a smoke pressure sensor (pressostat). It is connected to the impeller chamber via a Venturi tube. A breakdown of the gas boiler fan leads to a stop of the heating device and its further operation until the fault of the smoke exhauster is eliminated is impossible.

Repairing a gas boiler fan is not difficult if you have identified the cause of the breakdown, found the components and know how to work with the tool.

The principle of operation of the gas boiler smoke exhauster

The fan consists of components:

- The motor that rotates the impeller.

- A turbine that creates a vacuum in the combustion chamber.

- Blades for mixing supply air.

- Venturi tube, which creates a pressure difference for the effective operation of the pressure switch.

Gas boiler fan device.

The smoke exhaust turbine is housed in a housing made of galvanized sheet or aluminum. The motor is attached to the housing with mounting bolts through vibration pads.

When 220 volts appears on the stator inductance coil, the armature begins to rotate the turbine and blades. Mixing of supply air and removal of flue gases through a coaxial pipe or separate air duct and chimney is created.

The electric power of the fan depends on the thermal power of the boiler, for household models, 35 - 80 Watt.

Snail design

A standard volute (umbrella) consists of an impeller and a power unit. Your fan, depending on its assigned functions, may have protective properties against corrosion or be characterized by increased heat resistance.

The structure of the snail is selected directly for the room in which an additional cleaning system should be installed. When choosing a device, it is recommended to take into account the strength of the air flow, namely:

- low pressure flows;

- average pressure;

- high pressure flows.

When choosing a “Snail” fan, you should take into account the strength of the air flow

Professionals warn that the more powerful the ventilation unit, the more effort should be put into installing it. A homemade box or base will facilitate quick connection and correct operation of the entire device for a long time.

Causes of failure

The smoke exhauster may be faulty for the following reasons:

- The inductor is damaged. Under the influence of high temperatures resulting from the removal of hot gases or motor overload, the insulation of the wire melts, which leads to an interturn short circuit or a break in the coil winding.

- The turbine is unbalanced. During the process of removing smoke, the fan blades become covered with soot, dust, etc., which leads to a change in the center of gravity of the wheel.

- Bearings are worn out. The armature shaft is equipped with plain or rotation bearings. If the turbine is unbalanced or there is insufficient lubrication, the service life of these components is reduced.

- There is no power to the smoke exhauster. The impeller will not rotate if the control board module responsible for supplying power to the fan is faulty.

- Low mains voltage. When the electrical voltage supplied to the boiler is less than 195 volts, the pressure switch can turn off the fan, since due to the reduction in power, sufficient vacuum is not created. An underestimated gas boiler supply voltage does not lead to fan failure but creates the effect of a malfunction.

Deflectors for hoods

This is a fairly common option for forced ventilation. A deflector is an aerodynamic device that is installed above the chimney. It increases draft in the chimney due to changes in air flow. The essence of its work is the pressure drop when air flows around an obstacle, as well as the principle of changing air flows. It turns out that its shape allows you to increase draft in the chimney. Made of stainless steel, they are not afraid of corrosion, resistant to acids and high temperatures.

It cannot be called a full-fledged fan, since the deflector has a simple shape, without working mechanisms. But, there are types of smoke deflectors designed specifically for chimneys.

- Wolpert deflector.

- Grigorovich deflector.

- Round or spherical deflector.

It is the round deflector that can create rotational movements under the influence of wind and remove smoke from the room. But, again, the disadvantage of the product is that it is ineffective in the absence of wind. The operating principle of this draft amplifier for ventilation pipes and chimneys is demonstrated in the video*

In addition, weather vanes, umbrellas and similar structures are often installed on chimney pipes. But they can't do everything that a high-temperature chimney fan can do. Let's look at how they work and what makes them special.

Boiler fan diagnostics

Before carrying out diagnostics, it is imperative to turn off the power to the device being repaired and remove the front cover for a detailed inspection of the fan. If one of the above symptoms of malfunction occurs on a turbocharged boiler, you can proceed as follows:

- Check the mains voltage value. Connect the voltmeter to the power outlet. If its readings are less than 195 volts, it means that the pressure switch turns off the fan due to a decrease in its performance. Since the electrical components are powered by an unstable voltage, it is advisable to connect the boiler to the electrical network through a voltage stabilizer.

- Examine the inductor for an open circuit. A serviceable stator winding has a resistance of 50 - 80 Ohms.

Checking the motor coil of a gas boiler smoke exhauster.

- Determine the voltage supply from the control board. With the equipment de-energized, disconnect the power terminals from the smoke exhauster, connect a 250-volt voltmeter to them and start the boiler. After turning on the circulation pump, electrical power from the control board will go to the fan, and in this case to the measuring device, which should record about 220 Volts. No reading indicates a faulty fan control board module. The relay may be damaged. In such situations, the control module is restored or replaced with a similar one.

Inlet valve for increased draft

Without air entering the room or directly into the stove, the chimney will not work. Vents or cracks in old windows are not the best method for air flow.

The disadvantages are obvious:

- Cold air enters the room through the cracks even when the stove or fireplace is not working.

- In winter, air from the street constantly changes the indoor environment. At the same time, the relative humidity of the air drops sharply, which has a harmful effect on health. A person's mucous membranes dry out, creating conditions for colds.

- The window must be opened and closed manually.

It is much more effective to provide air flow using a valve. It closes automatically when furnace equipment or gas heaters are not operating.

This is what a wall supply valve looks like, which is installed in rooms with stove heating or gas equipment to improve air flow

Heaters require a boiler room valve to operate. The device has different characteristics than similar operating principles for room ventilation.

The supply valve is placed diagonally or above the heated surface so that the cold air rises to the ceiling. But it is best if oxygen is supplied directly to the firebox. At the same time, the humidity and temperature conditions in the room are not disturbed.

Fan for solid fuel boiler

According to parameters and functional characteristics, fans for solid fuel boilers are divided into the following types:

- devices with electrically commutated motors (EC);

- fans equipped with synchronous motors;

- blowers with asynchronous motor.

Each type has its own advantages and disadvantages:

- Electrically commutated motor. This device is capable of independently changing the speed, having previously received the corresponding signal from the control unit, and also has a wide range of adjustment of the fan operation. However, the device also has a number of disadvantages - it is not compatible with most temperature controllers produced by domestic manufacturers, and besides, this equipment has a high price.

- Fan with synchronous motor. The device is easy to manufacture and has a low price. But this type of fan also has a number of disadvantages. For example, a small adjustment range and minimal torque during start-up.

- An asynchronous electric motor has many advantages. First of all, it is simple and easy to use. Secondly, it has a reliable design. However, there is also a drawback - high inrush currents.

Device

Any blower fan, regardless of what country it is manufactured in, consists of a metal casing, and inside it there is an electric motor. Another important part of the blower fan are the blades, which are protected by a safety grille. The structure of the device is not complicated, but at the same time reliable.

This is ensured by its robust housing, high operating temperature and reliable electric motor manufacturer. Vulnerable elements and parts are protected by a grille. The blower fan is lightweight, so installation problems do not arise.

Fan for solid fuel boiler

On the Russian market you can find fans for solid fuel boilers from the following manufacturers:

- Injection centrifugal fan (turbine) WPA of various modifications. Manufacturer: Polish company MplusM. This company specializes in the production of turbines for solid fuel boilers. The model is in stable demand on the Russian market, as it is characterized by high quality and good reliability.

- NWS fan of various modifications. Manufactured by Nowosolar (Poland). Its purpose is to pump air into the combustion chamber. This increases the efficiency of fuel combustion in the combustion chamber.

How to choose the right one

The performance of a solid fuel boiler is largely determined by a properly selected fan. What does this mean?

Let's consider several situations:

- If a fan is installed that supplies less of the required air, the fuel will not burn completely. As a result, the boiler power decreases and the rated temperature is not reached.

- If a fan is installed that supplies a larger volume of the required air, then the solid fuel boiler will quickly gain temperature, and the fan will constantly turn on and off. As a result, fan failure is inevitable, the chimney will be constantly hot, and heat will escape through it.

There is only one way out - choose the right blower fan.

The table shows options for installed fans on solid fuel boilers of various capacities.

| Fan model | Volume of supplied air, m³ | Dry wood boiler power, kW | Boiler power Anthracite coal, kW |

| WPA X2 | 285 | 62 | 32 |

| WPA 07 | 160 | 35 | 18 |

| WPA 06 | 255 | 55 | 28 |

| WPA 117 | 180 | 39 | 20 |

| WPA 120 | 285 | 62 | 32 |

| WPA 140 | 395 | 86 | 44 |

| WPA 145 | 505 | 110 | 56 |

| WPA 160 | 600 | 130 | 67 |

| NWS 75 | 205 | 45 | 23 |

| NWS 79 | 205 | 45 | 23 |

| NWS 100 | 240 | 52 | 27 |

Purpose and device

Blower fans are installed at the end points of chimneys and facilitate the removal of combustion products by creating a strong vacuum that draws smoke and other gases from the firebox system and chimney. The operating conditions of the smoke exhauster are characterized by high temperature loads; contact with combustion products contributes to rapid wear and metal fatigue. The design of the smoke exhauster must correspond to the load level and ensure efficient operation throughout its service life.

The structure includes:

- heat-resistant fan (made of stainless, alloy or, less commonly, carbon steel)

- a guide device installed on the suction side and organizing the correct flow direction

- suction funnel connecting the guide vane to the fan inlet

- electric motor

The body of the smoke exhauster, regardless of the material of manufacture, is covered with a protective polymer coating. It increases the service life of parts and helps reduce thermal corrosion of materials. The direction of inclination of the impeller blades is used both forward and reverse. The first option is most often used on small boilers with relatively mild operating conditions, the second option is used on powerful installations with high temperatures of exhaust gases.

For use as smoke exhausters, not only radial, but also axial devices can be used. There are flow-through structures that are located at the outlet of the boiler. They are not completely located in the channel, but only a part of the impeller that increases thrust. Such designs are not full-fledged smoke exhausters, but they are quite effective as draft amplifiers. The best option is to install a specialized centrifugal type device that gives maximum effect.

Atos

- Manufacturer: Poland;

- Power supply: 220V/50Hz;

- Connected pump power: up to 130W;

- Fan power: up to 130 W;

- Coolant temperature setting range: 35-80°C;

- Temperature measurement accuracy: 1°C

- Room temperature setting range: 25-50°C;

- Alarm when the set temperature range is exceeded;

- Relay output for additional alarm;

- Manual target temperature setting and circulation pump control.

- Estimated cost: 6750 rub.

How to make an exhaust unit

The main difficulty in assembling a smoke exhauster with your own hands is making a balanced impeller; the remaining parts are not difficult for a home craftsman who knows how to weld. If the impeller blades vary in weight, normal fan noise will turn into rumble due to vibration.

In addition to the blades, you will need the following elements:

- electric motor with a power of up to 150 W, maximum shaft speed – 1400 rpm;

- snail or homemade box shown in the drawing;

- a shaft with ventilation holes or an additional cooling impeller;

- studs with M8 nuts and other fasteners;

- power cable.

Sources

- https://ProUteplenie.com/otoplenie/dymosos-dlya-kotla-bytovoy-ustanovka-ventilyatora-svoimi-rukami

- https://kotle.ru/tverdotoplivnye/ventilyator-dlya-kotla

- https://otivent.com/dymosos-dlja-tverdotoplivnogo-kotla

- https://oventilyacii.ru/otoplenie/kak-vybrat-ventilyator-dlya-kotla-na-tverdom-toplive.html

- https://www.tproekt.com/kak-soorudit-samodelnyj-dymosos-dla-kotla/

- https://www.teplodar.ru/help/articles/detail/konstruktsiya-i-osobennosti-pelletnogo-kotla-s-avtomaticheskoy-podachey-topliva/

- https://ZnatokTepla.ru/kotly/tverdotoplivnie/vidy-i-funktsii-ventilyatorov-dlya-tverdotoplivnyh-kotlov.html

[collapse]

Air

- Manufacturer: Ukraine;

- Power supply: 220V/50Hz;

- Connected pump power: up to 450W;

- Fan power: up to 220 W;

- Coolant temperature setting range: 40-85oC;

- Temperature measurement accuracy: 0.1°C

- Room temperature setting range: 20-45oC;

- Estimated cost: 3000-3500 rubles.

Compact automatic control unit for solid fuel boilers. Allows installation and control of a powerful circulation pump and fan with a corresponding load current of 2 and 1 ampere; the modification allows load currents of up to 5A.

- Manufacturer: Poland;

- Power supply: 220V/50Hz;

- Connected pump power: up to 200W;

- Fan power: up to 200 W;

- Coolant temperature setting range: 30-80°C;

- Temperature measurement accuracy: 1°C;

- Room temperature setting range: 20-45oC;

- Manual target temperature setting and circulation pump control.

- Estimated cost: 6500-7250 rubles.

Functional control unit with practical overheat-protected housing. User-friendly interface. The presence of an LCD display and an expanded set of control keys makes it easier to configure the automation and control the operation of the boiler.

Some tips

To make or buy a smoke exhauster correctly, you need to follow some recommendations. For example, if the house has a special technical room for a boiler room, then the hood is installed in it, since in this case it will be more convenient to service it.

If you need to install a powerful smoke exhauster for a large ventilation system, then it is better to install it outside. The fact is that such devices are very noisy, and this noise will not be heard from outside.

The electric motor is usually equipped with a separate circuit breaker. It will be convenient when the control of the smoke exhauster is transferred to the general control panel of the heating system.

If the smoke exhauster is mounted not near the boiler, but outside or in any other place, then it is necessary to provide free access for cleaning it.

Thus, protection from rain and snow must be installed at the end of the chimney pipe. The fan and all moving parts must be lubricated regularly, and the hopper must be cleared of accumulated particles.

Weather factors should also be taken into account. Excessive humidity and temperature changes lead to severe corrosion of some elements of the smoke exhauster.