Solid fuel boilers have been proving their effectiveness in practice for many years. They act as a reasonable alternative to traditional stoves for heating a private home in those regions where there is no centralized supply of gas as the main source of energy.

Now it is possible to purchase a unit that runs on various types of fuel (coal, wood) with the possibility of equipping it with a gas or pellet burner. As for domestic manufacturers, this is, for example, //www.teplodar.ru/catalog/tverdotoplivnye-kotly/, where you can buy solid fuel boilers that are universal regarding the fuel used.

However, like any other boiler, a solid fuel unit does not cost that little, and therefore many owners of houses and apartments decide on the issue of autonomous heating of their homes on their own, that is, they make solid fuel heating boilers with their own hands.

Recommendations for organizing solid fuel heating boilers with your own hands

If you are going to burn with wood, it is better to make a larger firebox.

Experts recommend that anyone who intends to build a solid fuel heating boiler with their own hands should take into account several rules. Firstly, the device must be absolutely safe. To do this, before carrying out work, you need to familiarize yourself with a number of government regulations and standards. Secondly, you need to take care of the efficiency of the equipment. The boiler must produce as much heat as is required to maintain the normal temperature in the house plus heat losses. Thirdly, any heating device requires a separate room, that is, a boiler room.

There are also requirements for the firebox. It should maintain a fairly high temperature. In some cases this is 500°C, which is necessary for complete combustion of fuel and waste gases. If this condition is not met, then substances containing hidden energy (nitrogen oxides, carbon monoxide) will escape into the pipe, and the efficiency of the equipment will decrease. It is for this reason that home-made solid fuel heating boilers, their internal parts, are made of materials with low thermal conductivity, which makes it possible to achieve the desired temperature in the firebox.

The outer part of the boiler, on the contrary, is made of materials with low heat capacity, which increases the safety of the unit itself. The heat accumulated by the housing must quickly escape into the atmosphere. In this case, the possibility of burns is eliminated. On the other hand, a housing with low thermal capacity will not take heat from the firebox, which will have a good effect on the efficiency of the heating element. However, before you start organizing the heating element, you need to correctly calculate the power of the solid fuel heating boiler. In principle, it is similar to calculating the power of an electric boiler.

The question of which propylene pipes are better for heating worries many. There are several types of these products, each of which has its own characteristics.

How does the horizontal distribution of heating pipes differ from the vertical? The answer is here.

How is fuel calculated for the season?

There is a method according to which the amount of firewood to produce 1 kW of heat is calculated, after which the total fuel consumption is calculated. But this is a difficult path; to determine the wood consumption of a solid fuel boiler or stove, we suggest using a simpler formula:

In this formula:

- V – the required consumption of firewood in cubes for 1 month;

- Q – the amount of heat required to heat the house, kW/h;

- q – calorific value of 1 cubic meter of a particular type of wood depending on humidity, kW/m³;

- Efficiency is the efficiency of a wood-burning heat generator, indicated as a percentage.

The result of the calculation will be the volume of pure wood, but not chopped firewood or cylindrical logs. It is clear that the density of a storage cubic meter (storage meter) differs from the pure density of the substance, so the resulting volume should be divided by the conversion factor. This is the so-called full wood coefficient, whose values for different types of chopped firewood are presented in the table:

Knowing the consumption of firewood for 1 month, it is easy to calculate its consumption and financial costs for heating for the entire season, multiplying the result by the number of months in the heating period.

How to quickly calculate the performance of a heater?

To increase the temperature in the firebox, the lid must be well insulated.

Professionals, when calculating the power of a solid fuel heating boiler, are guided by building codes on building climatology from 1999, which contain all the necessary quantities and formulas. For people who do not have a specialized education, a simplified version of calculating boiler power is offered. It is carried out according to the formula:

W = q * S, where

W is the desired value, that is, the performance of the heating element;

q is the specific power factor; it is different for each region of the country. Its value can be found in the above regulatory document;

S is the area of the room that needs heating.

Today, experts have slightly adjusted the form and for those who want to get efficient solid fuel heating boilers with their own hands, the value obtained as a result of calculations should be increased by 15, or better yet, 20 percent. In the case of using a double-circuit heating device, an adjustment is also made to the power for preparing hot water.

Calculation methods

To maintain a comfortable temperature in residential premises, when installing a heating system yourself, you need to take into account heat loss through the floor, walls, ceiling, door and window structures. There must be a reserve of power in case of severe frosts.

By volume of heated area

Formula for calculating heat:

Q = V × ΔT × K / 850, where

- Q – amount of thermal energy, kW/h;

- V – room volume, m³;

- ΔT – temperature difference between the external and internal air environment;

- K – thermal energy loss coefficient;

- 850 is a constant number for converting to kW/h.

The volume of heat can be calculated based on the volume of the heated area.

Thermal coefficient values for different objects:

- improved building structures (brick walls, thick floors, double-glazed windows in window openings, 2 layers of insulation) – K = 0.6-0.9;

- standard residential buildings - K = 1-1.9;

- simplified house designs with one layer of thermal insulation and standard windows - K = 2-2.9;

- wooden buildings - K = 3-4.

When calculating the required amount of heat for all living rooms of the house, it is necessary to take into account the heating of water for the consumer needs of the family.

By room area

When calculating the amount of heat required for a room, many nuances are taken into account, so this method is more accurate.

Formula: Q = 0.1 × S × k1 × k2 × k3 ….. k7, where

- thermal energy norm – 0.1 kW/m²;

- S – area of the territory;

- k1 – indicator of losses through window structures (single glass unit – 1.27, double glass – 1, triple glass – 0.85);

- k2 – heat consumption by window area (Sw) relative to the floor area Sf (with Sw/Sf = 0.1, k2 = 0.8; respectively, 0.2 to 0.9; 0.3 to 1.0; 0 .4 to 1.1 and 0.5 to 1.2);

- k3 – energy leakage through the walls of the room (when using low-quality insulation material – 1.27; using 15 cm thick material or double brickwork – 1.0; for high-quality insulation – 0.854);

- k4 – heat loss due to external temperature (at T=-10°С, k4=0.7, respectively, -15°С to 0.9; -20°С to 1.1; -25°С to 1 ,3; -30°С to 1.5);

- k5 – energy consumption due to 1 external wall – 1.1; 2 – 1.2; 3 – 1.3; 4 – 1.4;

- k6 – additional amount of heat depending on the height of the ceiling of the room: H=2.5 m, K=1, respectively, 3 m to 1.05; 3.5 m to 1.1; 4 m to 1.15; 4.5 m to 1.2;

- k7 – energy losses depending on the structure located above the heated room (cold attic – K=1, insulated – 0.9, heated room – 0.8).

When performing the calculation, many nuances are taken into account.

For example, the building has 4 external walls, the window openings are equipped with triple-glazed windows, the parameters of which are 30% in comparison with the area of the floor base. Between the ceiling and the roof structure there is a cold attic.

Calculation formula: Q = 0.1 × 200 × 0.85 × 1 × 0.854 × 1.3 × 1.4 × 1.05 × 1 = 27.74 kW/h.

The resulting indicator is increased by the amount of thermal energy that will be needed for hot water supply (if this system is connected to a solid fuel apparatus).

Calculation for a hot water boiler

This indicator is obtained using the following formula:

Qв = с × m × Δt, where

- Qв – energy required for a hot water boiler;

- c – specific heat capacity of the liquid (constant value equal to 4200 J/kg*K);

- m – mass of water;

- Δt – temperature difference between cold and heated liquid.

Incorrectly selected boiler power will lead to increased energy consumption.

For example, a family of 4 people consumes 150 l/day of hot water. The boiler is equipped with a coolant capable of heating the liquid coming from the general communication system from T = 10°C to T = 80°C. In this case, the temperature difference Δt = 80 – 10 = 70°C.

We substitute all the values into the formula and get:

Qв = 4200 J/kg*K × 150 kg × 70 °С = 44,100,000 J (translated as 12.25 kW/h).

For example, you need to heat 150 liters of water for washing at once. Accordingly, the indirect heat exchanger has a capacity of 150 liters. Therefore, to 28.58 kW/h (energy consumption per room), an additional 12.25 kW/h (water heating) must be added. In this case, the value of Qzag is below 40.83 kW/h, i.e. the air temperature in the rooms will be less than the calculated 20°C.

When batch heating the liquid (capacity of the indirect heat exchanger = 50 l), the costs will be 12.25 kW/3 = 4.08 kW/h. Accordingly, Qzag = 28.58 + 4.08 = 32.66 kW/h. This is the required power of heating equipment to maintain room temperature above 20°C and heat a container of water for domestic use.

About the boiler heat exchanger

After the solid fuel heating boiler has been calculated, you need to decide on the type of heat exchanger, its construction material and capacity.

The heat exchanger can be made from:

- become;

- cast iron

A cast iron heat exchanger is cheaper compared to the cost of a steel one. However, cast iron has a high heat capacity, which is a disadvantage, since it will be difficult to raise the temperature in the firebox to the required 500°C (for complete combustion of fuel and gases). The low thermal conductivity of cast iron will reduce the efficiency of the equipment, because the heat from the combustion reaction will not be transferred to the coolant in full, but will be discharged along with the combustion products into the pipe.

Experts recommend that when constructing a solid fuel heating boiler with your own hands, use heat-resistant or heat-resistant steel for the structural material of the heat exchanger. But processing it requires production conditions, and therefore ordinary structural steel is most often used, as it is easier to work with. Just remember that the temperature of the return flow entering the heater should not fall below +65°C. Otherwise, acidic condensate from the exhaust gases in the furnace falls on the steel heat exchanger, which leads to rust damage to the steel.

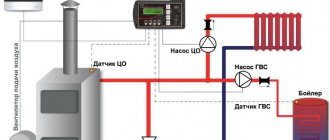

A properly designed forced circulation boiler should switch to thermosyphon mode in the event of a power outage. This means that it operates at low power, but contributes to the gravitational movement of the coolant.

To prevent the formation of condensation on the heat exchanger, homemade solid fuel heating boilers should be equipped with either a bypass valve for mixing hot water from the supply pipe into the cold return (this option is suitable for units with a power of up to 12 kW), or an elevator unit (for high-performance equipment operating under pressure).

A do-it-yourself solid fuel heating boiler can be equipped with the following types of heat exchanger:

- with vertical or horizontal registers;

- with flow or counterflow movement of the coolant.

Register-heat exchanger with horizontal coolant circulation.

A horizontal register is simpler in design, however, there is a possibility of incorrect (reverse) movement of the coolant, and therefore it is recommended to construct a heat exchanger with vertical registers.

Register with vertical coolant circulation.

From an efficiency point of view, it is most advantageous to use a register with countercurrent coolant movement. Do-it-yourself heating of a private house with a solid fuel boiler will be the most effective. In this case, the hot gas and coolant move along the same axis, but in the opposite direction to each other, which ensures good heat transfer. The result is high efficiency of the heating element.

Selecting the type of solid fuel heating element

The most economical solid fuel heating boiler is a pyrolysis type or top-burning device. For self-production, the first option is difficult. An upper combustion device is somewhat easier to design, but here the drawings and calculations must be carried out by a specialist, which costs a lot of money. That is why people who want inexpensive solid fuel heating boilers should pay attention to traditional designs.

Before starting design, you also need to consider what type of energy carrier in the region is considered the most accessible. If it is firewood, then the combustion chamber must be large. After all, only a large volume of wood can ensure normal temperature conditions in the house. In the case of a small firebox, energy will need to be constantly supplied, which is not very convenient.

If it is planned to use coal as the main fuel, then the firebox can be made small, thus saving on structural materials. Coal is energy efficient and a large amount of it in the firebox can increase the temperature of the coolant to a critical level, which can lead to an accident.

The standard installation of heating pipes in a private house is done using the open method, but there are other options.

Read about which installation method makes it easier to replace heating pipes in an apartment here.

Buy the most powerful one?

Some buyers decide not to think about how to calculate a solid fuel boiler, but simply take the most powerful installation. Yes, you can do this, but you will pay more than you could. Productive equipment is expensive to purchase and operate, contributes to increased loads on hydraulic systems, causes malfunctions in their operation, and constant breakdowns.

The above problems are partially eliminated by the modulation burner, which is responsible for adjusting the combustion strength. But if the difference between the optimal and actual power is large, the burner may not always fire, it may not work correctly, and the boiler will start working impulsively. There is no point in overpaying for a super-efficient installation, especially since the basic calculations are simple.

Making a boiler with your own hands

Since the most economical solid fuel heating boilers are pyrolysis units, we will consider the diagram and implementation options for this type of equipment.

Detailed manufacturing diagram of the TT heater.

According to the resulting diagram, you will get the boiler shown below:

Note the electronic display at the top. Its presence means that the unit is volatile.

To successfully complete the job you will need the following tools:

- sheets of heat-resistant steel 6 mm thick;

- pipes of the same material of different diameters;

- fan;

- temperature control device;

- Bulgarian;

- grinding wheel;

- cutting wheel;

- DC welding machine;

- electrodes.

Cheap solid fuel heating boilers are made according to the instructions in the video:

When carrying out work, you must remember that a homemade boiler must be equipped with a limiter, with which you can control the flow of air into the fuel combustion chamber. It is made from a pipe with a diameter of 70 mm. Its length is equal to the length of the heating element body, plus 5 cm on each side. At the bottom of the limiter there should be a steel disk with a diameter of 40 mm, thus creating a hole between it and the walls of the pipe. The other end of the limiter is attached to the boiler body. To do this, a hole of the required diameter is made in the wall.

The loading chamber is made of a rectangular shape. It should be closed by a door, with additional reinforcement made of a steel plate. This will extend the life of the product and ensure a tight fit of the door. The heat exchanger is made in a curved shape. This will increase the level of heat exchange between hot gas and coolant in the heating system. After all, economical solid fuel heating boilers must have high efficiency.

What is boiler power and how to find it out

The thermal power of a boiler is the maximum amount of thermal energy transferred to the coolant during fuel combustion (measured in kilowatts/hour or simply kW). This means that a boiler with a power of 20 kW, when continuously operating at maximum power, will generate and transfer 20 kW of thermal energy to the coolant in an hour.

The boiler power can be determined in several ways:

- look for a list of technical characteristics on the boiler body;

- find the value in the model data sheet. If the documentation has not been preserved, you can look for an electronic version or study the offers of online stores, which must indicate its rated power in the description of the model;

Location of technical specifications on the boiler body - if we are talking about a gas boiler, you can find out the approximate heating output by gas consumption, for which you need to check and record how many cubic meters the boiler consumes during continuous operation at maximum power. The specific heat of combustion of gas is a constant value and is equal to 9.3 kW. It is also important to take into account the efficiency of the boiler (it can also be found in the list of technical characteristics), for old Soviet models these values are in the region of 70-85%, for new models the efficiency is in the range of 86-94%. Total, maximum power = 9.3 kW (specific heat of combustion of natural gas) * 0.8 (if efficiency is 80%) * 2.5 cubic meters. m/hour (resulting gas consumption per hour) = 18.6 kW. In a similar way, you can calculate approximate values for a solid fuel, liquid fuel or electric boiler.

It is impossible to increase the heating output of a domestic boiler without serious unsafe changes to its design, therefore the choice of the minimum required power must be approached responsibly. If it is not enough, you will have to install an additional boiler unit or insulate the walls, floor and ceiling, replace windows and doors in order to reduce heat loss.

Do-it-yourself solid fuel boiler is a reality

Anyone who knows how to operate a welding machine and an angle grinder can make a solid fuel boiler with their own hands. Before starting work, you need to choose the optimal type of heating element, perform the correct calculation of the power of a solid fuel heating boiler, select the required construction material, and decide on the type of heat exchanger.

During the work, it is imperative that you follow state standards regarding the safety and efficiency of heating equipment. The boiler must be built according to a pre-created drawing, for the creation of which you can hire a specialist.