Today we have to consider in detail the issue of arranging a heating system in a garage. Of course, maintaining the desired temperature level there is very important. Then you can work effectively. Some garage workers even organize real professional workshops. Of course, for their uninterrupted operation, regardless of the weather and time of year, you will need to install a boiler in the garage.

Let's find out what heating systems are available, what types of fuel are more economical to use, and what kind of boiler is best to install in the garage. Let's find out what car enthusiasts think about this, who have already assessed the pros and cons of different options personally.

Basic requirements for the heating system

First of all, you need to identify all the key requirements for heating in a garage. Let's list the main factors.

- It is important to make the heating system reliable, to ensure its resistance to sudden temperature fluctuations. Of course, most garages are not constantly heated. Consequently, the system will first heat up and then cool down greatly. These are significant additional loads.

- Please note that there is a high probability of frequent power outages. Here we are dealing not with a living space, but with a garage. And the electric heating system must be adapted to more difficult conditions.

- The optimal solution is to orient the heating system to operate in automatic mode. The automatic locking system must be activated in any emergency situation.

- Safety, especially in a garage, plays a huge role. In this room, fuels and lubricants, wheels and all kinds of spare parts and tire sets are stored. Of course, it is especially important to carefully follow fire safety rules.

- It is advisable to consider the efficiency of the heating system. Here you should try to maintain a balance of performance and cost so that heating is feasible from an economic point of view.

The heating boiler in the garage should work as efficiently as possible. To do this, it is imperative to minimize heat loss in the room. This is the only way to achieve better results. The building is well insulated and a sophisticated ventilation system is installed. It is also worth considering the optimal temperature for warming up the garage. In this room there is no need to achieve 18-20 degrees, as in a residential building. It is enough if the thermometer rises to 5-10 degrees Celsius.

Solid and liquid fuels and gas are used as fuel for boilers. You can install a water or electric heating system.

Convector

Models of electric convectors for use in garages and other technical premises

A reliable and efficient device, the operating principle of which is based on air convection initiated by heating elements - cold air enters the device from below and, heating up upon contact with the heating element, rises warm to the top.

Convectors are available in floor-mounted, wall-mounted or universal versions - on support legs, with brackets for mounting to the wall, or equipped with both mounting options. The latter version is especially convenient, as it allows you to compactly place the heater on the wall with the possibility of quick dismantling and installation next to the car - at the place of repair.

Advantages of an electric convector:

- quick heating to working condition;

- heating in automatic mode - a certain temperature value is manually set, upon reaching which the device turns off and resumes heating the room only when the air cools by 1 degree;

- safety of operation and ease of routine maintenance;

- durability;

- Possibility of use in rooms with high humidity and pollution, since the operating elements of the device are covered with a protective housing.

- higher cost compared to some other types of electric heaters (quartz);

- the effect of operating a convector in a garage is achieved after at least half an hour;

- increased electricity consumption.

Types of boilers

When organizing garage heating, it is possible to use the following types of heating boilers:

- A gas boiler. If it is possible to divert the pipe from the gas main, installing a boiler running on natural gas solves all problems. Gas as a fuel is considered one of the cheapest. Water heated by a boiler can be used as a coolant. Heating can be provided by convection using fans. When installing for heating gas installations, the following advantages can be highlighted: cheap energy resources, accessibility of highways, autonomous operation, increased energy efficiency, high reliability and durability. Modern gas boilers can operate from a gas central line or from liquefied gas cylinders. The disadvantages include the need for complex coordination and increased requirements for fire safety and the ventilation system.

- Electric boiler. The easiest way is to install a boiler in the garage, in which the coolant is heated by electricity. The operating principle of this equipment is based on heating water into heat exchangers using electric heating elements. Installations of this type are small in size and easy to operate. The main advantages are complete silent operation, automatic adjustment, and the absence of combustion products. The main disadvantage is the significant increase in the cost of electricity compared to natural gas. In addition, the heating system becomes completely dependent on uninterrupted power supply, which causes certain problems, for example, in rural areas.

Choosing the right gas boiler

You can purchase a suitable gas boiler yourself

It is worth paying special attention to each component of the equipment. In particular, this applies to the body material itself, the chimney (if there is one), as well as the ignition system

In addition, you need to find out which gas connection option is available.

The most popular devices are boilers made of cast iron and steel. If you choose between the two, preference should be given to the latter, since cast iron is considered a rather heavy metal. A convenient boiler is one that has an electric igniter installed.

Particular attention should be paid to the chimney. Since combustion products are aggressive, this part must be made of durable material

Alloy steel is considered the ideal option. However, there is equipment where there is no chimney as such (the device is equipped with fans).

Fuel boilers

The options discussed above involve connecting the equipment to centralized gas or electrical networks. What to do in the absence of highways and unreliable power supply? A mini-boiler room in a garage can be based on boilers running on liquid or solid fuel, which do not depend on the supply of centralized energy. The following settings are distinguished:

- Solid fuel boilers. A modern boiler of this type can be safely installed even in a room such as a garage. The installations are distinguished by their versatility, i.e. they are able to work on coal, peat, firewood, even construction waste and straw. It is considered optimal to use special combustible briquettes based on compressed coal dust and other components. Fuel consumption occurs in a minimum amount, which is ensured by its complete combustion. The boilers operate on the pyrolysis principle, which gives a fairly high efficiency.

- Liquid fuel boilers. They lay down an important principle of economy. They can be operated on used engine oil. This makes it possible to obtain cheap fuel and at the same time solve the issue of waste disposal.

The main advantage of fuel boilers is the absence of the need to obtain permits and the availability of fuel. An important disadvantage is the presence of a significant amount of combustion products. To remove them, you need a reliable chimney, the pipe of which should go to the roof.

Heat gun

A compact and easy-to-use device that provides quick and effective heating of the garage. It differs from a fan heater in the significantly higher power of heating elements. The device is based on electric heaters and a high-performance fan, which provides intensive air flow to the heating elements, causing rapid distribution of heat in the room.

Connecting high-power heat guns requires a three-phase power supply with a voltage of 380 V; less powerful units are designed for 220 V.

In small garages, the use of heat guns creates dust in the air, so they can be used effectively only if the room is constantly kept clean, including through high-quality finishing of the enclosing structures.

Installation stages

To ensure safe operation of the boiler room in the garage, it is important to install a high-quality ventilation system that can remove all harmful gases from the room. To do this, you need to correctly assess the required fan performance. Its power can be calculated using the following formula: M = (SxHx12) + 30%, where M is the hood power; S is the area of the room; H is the height of the garage. In this case, the formula takes into account that complete renewal of the air volume must be ensured in 12 hours, and the minimum power reserve of the installation is estimated at 30%.

The design of the heating boiler can be single-circuit or double-circuit. In the first case, the coolant heated in the boiler is intended only for heating the room, and therefore circulates through a closed system with radiators. In the double-circuit version, an additional network is provided for obtaining hot water or removing coolant for heating another room, a house.

If the owner wishes, the boiler room in the garage can easily be installed with his own hands, but using standard equipment. When installing a gas boiler, the project must be agreed upon with the relevant authorities. The arrangement of the system must be carried out taking into account technical and fire safety requirements. After completing all these stages, you can use the installed equipment for many years and enjoy the unconditional comfort that it will give.

Step-by-step instructions for making a stove

Step 1. In our example, we use a simple 250-liter barrel with thick walls - ideal for making a stove. Cut off the top of the barrel, but do not throw it away.

The top of the barrel has been cut off

Step 2. Make a kind of lid from the top - a “pancake” for oxygen supply. Adjust it to the size of the barrel - as a result, when installed, there should be 2 mm between it and the walls around the entire circumference. Weld the neck of the lid. In its center, make a hole to install a pipe through which air will be supplied. Also weld 4 channels, as in the photo below.

“Pancake” for air supply

Another photo of the item

Step 3. Stepping back a little from the top edge, cut another hole in the barrel wall for installing a chimney. In our example, the chimney will be a pipe with a diameter of 140 mm.

Hole for chimney installation

Step 4. Start making the lid. Make it from sheet metal 4 mm thick, and weld a sealing ring at the bottom corresponding to the diameter of the barrel. In the center of the lid, make a hole for the pipe that was welded to the “pancake”.

Oven cover

In the middle of the lid there is a hole for the air duct from the “pancake”

Step 5. Make simple legs at the bottom of the barrel to make the structure stable. The legs must be metal, as well as all other elements.

Making legs for the stove

Legs must be metal

Step 6. Install the stove in the desired location and begin creating the chimney. In our example, it is of a prefabricated type. First of all, make a clamp with which the chimney will be attached to the body.

A clamp that will allow you to attach the chimney to the stove

Step 7. Make guides in the chimney, thanks to which it can be easily fixed to the body.

Guides in the chimney

Step 8. Join the barrel with the pipe, making sure to lay all the joints with asbestos fabric. Place a clamp over the fabric and tighten it.

Asbestos fabric

Tightening the clamp over the fabric

Finished joint between pipe and barrel

Step 9. That's it, the structure is assembled, you can check its functionality. Load sawdust or firewood inside.

The stove is loaded with fuel

Step 10: Add used oil to the fuel, then install the cap. As for the “pancake”, don’t use it yet. After the fuel ignites, remove the lid and place the “pancake”. To fully warm up such a structure, it takes about 10 minutes; in the future, the firewood will burn for a long time. Although exactly how long the combustion will last largely depends on the quality of the fuel.

Photo of the finished stove for the garage

Calculator for calculating solid fuel consumption for a furnace

Go to calculations

Video - Making a bubafoni stove

Video - Homemade potbelly stove for the garage

If you wish, you can modify the design described above, although it will already cope with its functions perfectly. For example, to increase efficiency, you can increase the surface area and thereby improve heat transfer. For this purpose, weld metal plates on the sides of the body.

In addition, you can make a grate with an ash pan: cut a circle from a sheet of metal along the inner diameter of the body, drill holes with a diameter of 60-80 cm and install from below. After this, the ash will be poured down through the holes - to where the ash pan is equipped. It is believed that this will cause the fuel to burn faster, remember this point and make sure that the ash pan is sealed as much as possible.

The better to heat or the choice of energy carrier

In 99% of cases, garage buildings are not connected to centralized heating networks or main gas, so owners have to choose autonomous heating methods. To heat a garage, you can use 4 groups of energy carriers:

- various types of solid fuel - firewood, coal, briquettes, agricultural and other combustible waste;

- diesel fuel, waste oil;

- electricity;

- liquefied gas in cylinders.

Advice. When you start choosing an option for heating your garage in winter, keep in mind an important rule: the more expensive the energy source, the easier and cheaper it is to organize heating that is convenient to use. Conversely, cheap or free fuel in the form of waste and garbage will bring a lot of trouble - labor costs and initial financial investments.

Solid fuel combustion

Wood and various waste are the cheapest fuel for heating, and in some cases it is available completely free of charge. In the southern regions, which are not rich in forests, another type of fuel is widely used - small agro-industrial waste.

For reference. Agricultural waste consists of small particles sifted from grain crops. These are pieces of stems, weeds chopped by a combine, straw and other waste. The energy price is very attractive and starts from 20 USD. e. for 1 ton.

After cleaning the grain, waste remains that is used for heating.

We recommend: Insulating a well for the winter with your own hands: methods, soil freezing depth, video and photos

If you decide to heat your garage with solid fuel in the winter, get ready to deal with the following issues:

- purchase or manufacture of a furnace (ideally a boiler);

- chimney installation;

- storage of firewood, coal or waste;

- labor costs for preparation, combustion and soot removal.

Storing firewood in the garage is not a very convenient solution

The gain is in money and excellent heating of a room of any size, the losing points are listed above. Add here the time for kindling and warming up (0.5-1 hour). Hence the conclusion: cheap heating with solid fuel is suitable for owners of garages and boxes who stay there for 4-6 hours or more every day.

Potbelly stove for heating a garage

Potbelly stoves are the most primitive stoves that began to be actively used at the beginning of the last century. Then their popularity sharply decreased due to the spread of centralized heating. However, potbelly stoves are still used, because they are practically the cheapest way to heat a garage.

The potbelly stove is made of metal. The largest part is occupied by the chamber into which the fuel is thrown. The room warms up due to the contact of the stove walls with the surrounding air. Not the least important role is played by the pipe, which also accumulates heat. To prevent heated combustion products from immediately flying out into the street, a pipe of a clearly defined diameter is used, due to which the warm gases make several revolutions in the vertical plane. This allows you to make maximum use of the heat of combustion of the fuel (efficiency reaches 60-80%) and effectively suck in the air necessary for the fuel to burn completely. The diameter of the pipe in mm should be 2.7 times greater than the volume of the stove in liters.

It is important that the chimney has a complex shape: first there is a vertical insulated part, then a horizontal or inclined part, the so-called. hog, which provides up to a quarter of the heat received, because the flue gases burn out here. Potbelly stoves are sold ready-made: there are both the simplest and most primitive options, as well as sophisticated designer ones. If you have the skills, you can assemble a potbelly stove yourself from a barrel or sheet metal.

Advantages:

- a potbelly stove can be heated with any solid fuel, but wood is usually used;

- low price and low cost of operation;

- relatively high efficiency;

- allows you to quickly warm up the room and dry the air in it;

- There are models that can also be used as a stove. They will come in handy for those who spend even too much time in the garage.

Minuses:

- the need for constant monitoring of work;

- high fire danger;

- Suitable for small spaces only;

- the air cools quickly;

- it will be impossible to get rid of the specific smell;

- the need for regular chimney cleaning.

Solid fuel boiler

This is a more expensive, but at the same time, safer and more effective solution. The principle of operation is simple: fuel is burned in the firebox, a container with coolant is heated, which is supplied through pipes and radiators. improved types of boilers are increasingly used

- a pyrolysis boiler has two combustion chambers, in the first the firewood smolderes at a high temperature due to the fact that the amount of air is insufficient. The combustion product is pyrolysis gas, which is burned in the second chamber, releasing much more heat than just wood. The boiler efficiency increases to 90%, and one portion of firewood lasts for 10-13 hours;

- Pellet boilers are fired using pellets obtained from wood waste. They are placed in a bunker, from where they are fed into the firebox in doses. The boiler efficiency reaches 95%; fuel can be loaded once every few days.

The body of solid fuel boilers is made of cast iron or steel. Pyrolysis and pellet boilers are, of course, very convenient, but they are expensive. If funds allow, you can afford such a purchase - it will soon pay off

.

Brick oven

Building a brick oven in a garage is a long, expensive and painstaking task. The fuel for such a stove is usually wood, but coal can also be used. The principle of obtaining heat is still the same. The fuel burns, heats the walls of the stove, and they heat the air. A good option for small spaces. Brick takes longer to warm up than metal, but it also cools more slowly.

Stove Buleryan

The Buleryan stove is often confused with a potbelly stove and a regular wood-burning stove. She actually absorbed a little bit of both. The operating principle is based on convection. The design assumes the presence of pipes at the base of the furnace and in the upper part. Cold air enters through the bottom of the stove, receives heat from the chamber where the fuel is burned, and exits, already heated, through the top. The pipes are 2/3 soldered into the furnace body to ensure maximum heat transfer. The special design of the firebox and chimney allows you to extract maximum heat from fuel combustion. The presence of a chamber for pyrolysis combustion of fuel plays a significant role here. Combustion products are removed through the chimney.

Advantages:

- rapid heating of the room due to convection and heat transfer from the surface of the stove;

- compactness;

- there is no need to frequently add firewood;

- higher safety compared to a potbelly stove.

Minuses:

- price;

- complexity of chimney installation;

- the need for frequent cleaning of soot.

Use of mining and diesel fuel

Heating a box or garage with diesel fuel purchased at a gas station is expensive and extremely unprofitable. An exceptional option is to heat a small area of the room where work is being done using a portable heater, whose characteristics are described in a separate material.

Waste oil is a more financially economical energy carrier, although not the cheapest. This option can be seriously considered when used oils can be obtained at a reduced price. What are the features and pitfalls here:

- Homemade potbelly stoves are used to burn liquid fuel in various types of mines. The safest is a drip stove, which you can order from craftsmen or do it yourself.

- A chimney installation is required.

Drip-type exhaust boiler with forced air supply - Oil containers take up less space than firewood. They are usually placed in the basement.

- The workings need to be settled and filtered.

- The inevitable companions of liquid fuel heating are smell and dirt, although this is not critical for a garage.

- Homemade waste oil stoves are considered a fire hazard.

Note. Due to their cheapness and simplicity, the oil miracle stoves shown in the photo have become especially popular. They tend to shoot flames when the fuel contains a small amount of water or antifreeze, causing a fire.

The advantages of using mining are high heat transfer, quick ignition and warming up of the garage box, ease of use (it’s easier to add oil than to chop and carry wood). The conclusion is this: if fuel is inexpensive, or you spend a little time in the garage, then liquid fuel is a suitable option. The initial investment is comparable to wood heating.

When using diesel fuel, it is worth considering the option of a factory-made diesel air heater of the “Planar” type, shown in the photo. With a fuel consumption of 250 ml in 1 hour, the unit develops heat transfer of up to 2 kW. There are also more powerful heaters - 3 and 4 kW with diesel consumption of 0.37 and 0.5 l/h, respectively. Price – within 330 USD. e.

Autonomous diesel-powered air heaters designed for cars

Electrical heating

Heating with electricity is the most comfortable and cheapest option in terms of initial investment. But during operation you will have to pay the full tariff - it makes no sense to install a two-zone meter, you are not going to work in the garage at night.

Let's list all the advantages of electric heating:

- Heating with electricity is convenient and safe. There is no dust, dirt or odors, no need to carry firewood or barrels of fuel.

- There is a wide selection of different air-type electric heaters on sale: convectors, oil radiators, infrared panels and heat guns.

- You can make a water heating system with an electric boiler (if the power limit allows).

- Heating of the garage begins immediately after turning on the heater; a comfortable temperature for work is reached in just half an hour (again, when there is enough power).

An inexpensive portable fan heater can heat only part of the room where work is being done

There are only two disadvantages, but they are critical: the price of electricity and the limitation of the power consumption limit, which does not allow installing an effective heat source. For example, if the contract with the management company specifies a figure of 3 kW, then a convector with only 2 kW is installed, which is not capable of properly heating the garage in the winter.

For reference. Sometimes car enthusiasts use homemade “goats” and fan heaters in the pits, despite the restrictions. Why you can’t do this: there is a danger of the wiring catching fire, the neighbors’ voltage drops, and if employees check the electrical networks, you will face a large fine or shutdown.

Electric heating is an option for short stays in the garage. They came, turned on the heater, completed the intended work in 1-2 hours, turned off the heating and left. If you turned the room into a workshop where you spend your working hours, you will have to pay significant amounts for energy consumption.

A standard wall convector heats the air in the room much slower than a fan heater

Gas heating

This method of heating a vehicle storage space is acceptable for residents of the Russian Federation, where the retail price of liquefied gas is quite low. It will be too expensive for Ukrainians to heat their garages with propane.

Autonomous heating from gas cylinders is as safe and comfortable as electric heating. Moreover, in the Russian Federation the cost of energy is lower. But there are a number of pitfalls here:

- you need to place the propane tank somewhere so it doesn’t interfere with your work;

- you will have to periodically take the tank to refuel;

During operation, the tank freezes over, causing the gas supply to deteriorate. - To burn propane, you need factory-made equipment; making gas burners yourself is strictly not recommended;

- you will need a chimney pipe to the street.

If you add up the financial costs, the problems of organizing such heating and refueling cylinders, then the negative aspects will cover up some of the positive aspects of ease of use.

Watch this video on YouTube

A comparison of the cost of 1 kW of heat obtained from various energy sources in Russia and Ukraine is published on this page.

Infrared heater

The operation of the device is based on the emission of infrared rays, which, upon reaching the surface of objects along the propagation path, heat them, and they, in turn, give off heat to the room. Such devices are sometimes called UFO heaters, but UFO, the common Cyrillic abbreviation of the same name in everyday life, has nothing to do with ultraviolet irradiation.

UFO heaters are available in various sizes and power; they can be on a leg or designed to be attached to a vertical or horizontal base (wall, ceiling). Provided the housing is waterproof or placed under a canopy, infrared heaters can also be used in front of the garage on the street.

- economical electricity consumption;

- ease of operation and installation;

- reliability, safety and environmental friendliness.

The disadvantage of infrared heaters when used in a confined garage space is the effect of infrared rays on a small area, which causes less heat transfer from objects into the air. But when focusing radiation in the direction of the actual zone, these heaters are quite effective.

Electric heating in garage

Quite often in garages you can find electric air heating. Here, electric convectors are used to generate thermal energy. This type of heating functions well autonomously. It is possible to constantly maintain a certain temperature in the garage. But still, there is a big disadvantage: the inertia is low, which is why the room instantly cools down if the heating stops.

Electric boiler for garage

Among a wide range of modern electric boilers, you can choose a model with optimal power, taking into account the area of the garage. The range is impressive: there are models for heating a garage with an area of 30 square meters, and boilers designed for 600 square meters are also presented. At the same time, the price of a ready-made branded boiler is quite affordable: it starts from only 6 thousand rubles.

Let us dwell on the key advantages of electric heating boilers.

- Compactness. Such a unit can be easily placed even in a small garage.

- Reliability. The equipment works without failures.

- Automation of work. Since power outages often occur in garages, this factor plays a huge role. Even if there is a short-term power outage, the heating system will start working again automatically when the electricity is connected.

- Versatility. There is no need to install a chimney.

- High level of security. It is also extremely important to provide everything in a garage from a safety point of view. This is especially important since flammable materials are stored here. The boiler has a special security system. It turns on when the coolant overheats.

An electric boiler, despite the fairly high cost of energy, still allows you to spend money efficiently. Only the garage room must be well insulated. In addition, only with an electric boiler was it possible to ensure safety at such a decent level. There is no need for the constant presence of a person in the garage or personal control.

Modern technologies have even made it possible to control the operation of a garage's electric heating system from a distance. You can install an electric boiler with a GSM module in the garage, and control its operation using a regular mobile phone.

Water heating: adjustable power

First of all, when carrying out water heating, it is necessary to make the system reliable. At the same time, experts note that it is advisable to install the heating boiler closer to the garage. A good solution is to purchase a powerful pump in advance, and also take care of insulating the coolants, that is, the pipeline. Power is calculated as follows. If the garage has an area of 15-20 square meters, a boiler with a power of 1.5-2 kW will be sufficient. At the same time, it is worth remembering about frequent disconnections from the network and the high price of electricity.

Fan heater

Operating principle: a heat exchanger (heating elements or coil) is heated by electricity, air from the room is pumped into the heater by a fan, passed between the heating elements and returned hot to the garage.

- environmental friendliness - the absence of any emissions into the surrounding space during operation;

- ease of adjusting the heating intensity - there are switches for heating modes (turning off some heating elements) and fan rotation speeds;

- small dimensions and mobility - can be installed anywhere in the garage;

- the possibility of focused heating of zones or objects;

- quick heating of the room;

- equipped with automatic shutdown devices in case of overheating or overturning;

- the possibility of additional independent configuration with an electromechanical thermostat to automatically maintain the set temperature in the room;

- low cost of electrical appliances of low and medium power;

- ease of operation and maintenance.

Like any unit, the fan heater also has disadvantages that must be taken into account:

- accompanying heating, a decrease in air humidity in the room;

- the presence of dust accumulation on heating elements, fraught with fire or, at least, an unpleasant odor in the garage;

- noise caused by the operation of the fan;

- increased electricity consumption.

Despite these disadvantages, the use of a fan heater is the most popular heating option for a garage.

Water heating system

You need to understand that installing water heating makes sense when you are in the garage all the time. Otherwise, the costs will not justify themselves, because in addition to a source of heat and fuel, you will need to buy:

- cast iron or steel batteries (as an option, weld registers from pipes);

- circulation pump;

- expansion tank;

- pipes on the main line;

- non-freezing coolant - antifreeze.

For reference. The garage space is heated periodically, so the system cannot be filled with plain water.

Knowing the need for the amount of heat to heat the room (calculated in the previous section), select the power of the radiators or determine the length of the pipes of the homemade register using the table:

In the table, t1 means the coolant temperature, t2 means the air in the room

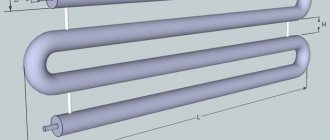

The calculation method is as follows. We take a steel pipe DN 80 (Ø89 mm) and find out from the table that 1 m of length is enough to heat an area of 1.37 m². We take the square footage of the garage, for example, 20 m² and divide by this figure: 20 / 1.37 = 14.6 m - the total length of the heating part. We distribute it among 2-3 heating devices and cook the registers according to the drawing.

Use the circulation pump with the lowest pressure (4 m of water column), and the expansion tank with the minimum volume. Pipes - polypropylene, steel or metal-plastic size DN 15. Then install radiators on 2 opposite walls and assemble a simple two-pipe closed-type heating system connected to a heat source according to the following diagram:

Instead of a wood-burning stove with a water circuit, an electric boiler or other heat source is installed in the circuit

The following can be used as a water heating installation:

- a wood-burning or exhaust stove with a water circuit, shown in the diagram above;

- heat exchanger – samovar-type economizer installed on the chimney;

- an electric heating element mounted in a vertical steel pipe, as shown in the diagram;

- a full-fledged electric boiler or solid fuel unit.

The simplest electric boiler with a water register

Advice. Do not forget to add a filter to the circuit - a mud trap and ball valves to cut off the heat source and drain water from the system. At the top point, install an automatic air vent, and on the batteries - Mayevsky valves for bleeding air.

Why don’t we recommend making an open-type system in the garage, as it is simpler and cheaper? The reason is antifreeze, which will evaporate from an open tank, which is unsafe for health (ethylene glycol is poisonous), not to mention the price of the coolant.

About some important points

Typically, long-burning stoves are made of metal. The optimal metal thickness is 4 mm (more is possible). It is better to make the chimney consisting of several parts to make it easier to clean in the future. The chimney also needs a fairly thick metal - this will extend the service life of the element.

On a note! If you work in the garage often and for a long time, then do not skimp on materials!

Making a stove with your own hands will not be very difficult for a person who has the necessary skills.

For the body, you can use a piece of a large pipe, a gas cylinder or an old 200-liter barrel; or, alternatively, it can be welded from pieces of metal. You need to make a hole on top of the body to install the chimney (its diameter should be about 15 cm); another hole (10 cm in diameter) will be required for air flow, without which the wood will not burn.

You will also need a load - it will put pressure on the fuel. This should be a heavy iron circle with a diameter slightly smaller (several millimeters) than the diameter of the body. The circle should have a small air duct through which oxygen will flow.

Western European experience

If you type the phrase “garage heating” in the search and look at pictures on English-language sites, you will not find any wood-burning or oil-fired stoves in Western European garages. How do local motorists warm themselves:

- electric portable heaters;

- infrared hanging heaters;

- air heating units (heaters).

The suspended air heating unit does not take up useful space in the garage

We have already discussed the first 2 options above. The third method is also far from new: water heated in the boiler passes through a radiator, blown by a powerful axial fan. Ideally, the unit is suspended from the ceiling and distributes hot air throughout the room.

The advantages of this option are compactness, heating speed and the possibility of air conditioning in the summer (cooled water is sent to the radiator instead of heated water).

Heater made from a car radiator

There is one downside - increased costs for equipment, because the coolant must be heated in the boiler and supplied through pipes to the heater. But if the garage is attached to a private house, then the problem is easily solved by connecting the radiator to the building’s water heating system.

Reference. Many garage craftsmen already use such heating, installing a homemade analogue of a heater made from a car radiator and any suitable fan. How this is implemented, look at the video:

Watch this video on YouTube

Location of a gas boiler room in a private house, distances

The main condition is to maintain the thickness of the wall connecting the garage and the boiler room, everything else is optional

It is also important to maintain a time period, not immediately after the foundation, start building walls, but wait a year until the foundation settles. This is necessary so that there are no cracks in the walls

Today, construction projects are often rushed, but in vain! - fraught with consequences

Since gas heating is one of the cheapest, the best option for heating a garage is to install just such a system.

Before installing a gas heating system, the following points must be considered:

Since the gas has explosive and flammable properties, it must be handled with great care. This means choosing high-quality gas appliances and having them installed by professionals; Gas heating is best used if the garage is attached to the house, has a gas pipeline nearby, or if it is necessary to provide heat to several garages at once.

Cheap and fast garage heating: do it yourself

Obviously, it is not at all necessary to order a heating system for your garage from professionals. Here you can do it yourself, provided you fully comply with all safety measures. It is not difficult to purchase and install one of the devices listed in our top list. All of them have detailed installation instructions, and the store salesperson will certainly advise you on any questions you may have.

All that remains is to consider how to make heating in the garage with your own hands in the simplest and cheapest way.

Do-it-yourself air heating of the garage in winter

One of the cheapest and fastest ways to organize heating in a car box is air. Heat is supplied through pipes only to the place where a person works. This way you can save money by not using fuel to heat the entire garage.

In this device, heated air circulates through metal pipes and is supplied through grilles. The efficiency of such a system is more than 90 percent, and the design itself is extremely simple and easy to install. Warming up the room takes just a few minutes. The only negative is the drying out of the atmosphere, but you can get rid of this disadvantage just by ventilating the garage.

Video material on air heating:

Installation of a contour heating system

If your choice fell on a system with a water or antifreeze circuit, you will need to purchase the appropriate boiler and heating radiators. It is best to use metal batteries. Recommendations for this type of heating are in the following video:

Popularity record: heating a garage with a potbelly stove with a water circuit

As we have already said, potbelly stoves are by far the most popular heating device for car boxes. Among such systems, devices with a built-in water circuit occupy a special place. It’s easy to weld the potbelly stove yourself from thick steel, and make the water counter from a small-diameter metal pipe.

For your information! When starting to make your own stove, consider the type of fuel. To store firewood you need a large hole.

In order for water to circulate well in the system, a pump is required. But in principle, you can do without it if you arrange the pipes so that the liquid circulates in them by gravity.

An example of such a system in the video:

How to reduce heat loss and not go broke?

No heating system will be profitable and efficient if care is not taken to reduce heat loss. Heaters will waste a huge amount of energy resources. This is expensive and impractical, so you will have to insulate the gates, walls, floor and roof.

You can use expanded clay, polystyrene concrete, foil insulation, but the cheapest and most versatile option is polystyrene foam. It is suitable for insulating all structural elements.

It can also be used for thermal insulation of the floor, provided that a floating screed is made: polystyrene foam does not tolerate mechanical stress well, so it is filled with cement.

Foam is ideal for lining garage doors. The insulation is attached to a special sheathing, and the top is covered with external cladding - MDF boards, chipboard or plywood.

The ceiling, walls and garage doors are covered with polystyrene foam. There are two options - external or external wall decoration. Both are equally effective and allow for excellent thermal insulation of the building. The choice should be based on the convenience of the garage owner himself.

How to choose the most economical way to heat your garage

Once you have decided on the type of fuel, you need to consider the type of heating device required. The heating device should also participate in fuel saving. If you opt for gas heating, it is best to choose a condensing device with automatic control. It can operate in low pressure conditions and consumes gas almost 20 percent more economically than other models.

Wall-mounted boilers are convenient because they take up little space and can be adjusted according to your wishes

Among solid fuel systems, it is better to give preference to pyrolysis ones. They decompose fuel into dry residue and pyrolysis gas. Of all solid fuel systems, these are the most profitable.

The only thing you need to take into account is that such devices do not work on coal.

Electrical devices with thyristor control are the best in their segment. Their power can be adjusted, and thus reduce energy costs.

Video: different heating options from experienced garage workers

It’s worth watching additional video materials to evaluate the advantages and disadvantages of different methods and to visualize everything clearly.

This video discusses the option of organizing a heating system in a garage on your own, with minimal investment.

The following video tells about the operation of the fireplace stove.

Of particular interest is a furnace that operates on waste oil. It is quite possible to make it with your own hands, and it works on already used oil. There are, of course, some nuances here. But in general, this method is quite rational and safe if it is possible to organize timely cleaning of the waste in a special installation. The arrangement and manufacture of a boiler for heating during mining is described in the following video.

A boiler in a garage will be an excellent solution for organizing a heating system. This will allow you to create comfortable conditions in the garage at any time of the year, work there with high efficiency, and carry out vehicle inspections and repairs.

Spent fuel

Used engine oil can also be an excellent fuel for a special boiler. This method is attractive for its efficiency, since fuel costs are extremely reduced. Just a liter of fuel takes an hour. One important point to remember is that the oil must be cleaned before use. There are special fuel installations where it is purified. The installation with the boiler is assembled independently.

Look at the diagram: it’s not at all that difficult to understand the structure of such a system and make it yourself. If it’s difficult to visualize everything clearly, you can additionally watch an informative video.

The best heating boilers

When the issue of choosing an energy carrier has been resolved, it is necessary to decide on the type of heating boiler. It must be economical, easy to use, and have high efficiency. Depending on the heat source, you can choose:

- Gas. The ideal option is a condensing boiler equipped with automatic control. In addition to the cost of fuel itself, you can also save money due to the boiler’s ability to operate at low pressure. In the heat exchanger of the unit, water transitions from steam to liquid, which leads to the release of heat. Thanks to this principle of operation, the boiler is 15% more economical than gas models of other types. You can also install a wall-mounted gas boiler, which provides power modulation.

- Solid fuel. It is best to buy pyrolysis. The operating principle of the unit is based on the effect of high temperatures on wood, as a result of which it decomposes into pyrolysis gas and dry residue. Gas is burned. For the boiler to operate, a buffer tank is needed; it accumulates heat. Of all the solid fuel models, pyrolysis ones are the most economical, but there is a caveat: in the absence of wood, coal cannot be used for heating.

- Electrical. If you need to efficiently heat a room and prevent overloads in the electrical network, it is better to choose a boiler with six heaters and thyristor control. Thanks to the features of the device, you can limit power and save money; an additional plus is silent operation. There is only one minus, but it is significant: heating with electricity is always expensive, because... electricity is the most expensive source of heat.

The cheapest heating for a garage is a gas condensing boiler; other types of units may be more affordable and convenient, but they are all more expensive to operate

What to look for when choosing

The decisive factors when choosing a gas boiler are:

- the material from which its body is made;

- ignition system;

- the presence or absence of the need to install a chimney;

- features of indoor installation;

- method of connection to gas and water supply.

Material

The most common models on the gas equipment market are cast iron and steel models. Cast iron is a high-strength and durable material, but its disadvantage is its heavy weight. Therefore, it is preferable to use steel heaters.

Manual or electric igniter?

Boilers with an electric ignition are much more convenient to use. When installing them, the following conditions must be met:

- uninterrupted power supply;

- separate connection to the power supply network;

- grounding

The solution to the first problem is to install an electrical stabilizer that suppresses voltage surges.

Types of boiler equipment

The chimney stove has an inlet temperature of about 120°C. The gas combustion process produces substances such as carbon monoxide, hot steam, sulfur dioxide, etc. All of them are removed from the garage using a chimney. At low ambient temperatures, vapors condense on the walls of the chimney and flow down.

Combustion products are quite caustic substances, so increased demands are placed on the chimney material. For the construction of a chimney, it is recommended to use alloy steel pipes, as well as carefully insulate them.

The garage can also be heated by boilers that do not require a chimney. They have built-in fans. Condensing boilers with a pulsed gas combustion mechanism are also becoming very popular.