Women often do not understand the full value of a garage for men, for whom it is their second home (and for some, their first). They are ready to spend days and nights there. But to do this, you need to create comfortable conditions in the garage. And first of all, you should take care of the temperature. You can do this with your own hands quite simply - using a potbelly stove in the garage. Naturally, you can buy it in any store where this category of goods is available. But it will be much more pleasant for any man to make it with his own hands. There are a lot of ways to make a potbelly stove for your garage. The most popular and inexpensive ones are presented below.

Advantages and disadvantages of potbelly stoves for heating

A homemade potbelly stove fits perfectly into the garage. Small sizes, affordable materials, ease of manufacture.

A homemade potbelly stove is ideal for the garage

There are several options for making a potbelly stove from scrap materials:

- Made from an old barrel. Advantages: few materials are made quickly. Disadvantages: thin walls (low heat capacity, will burn out quickly).

- Made from an old milk flask. Advantages: there is even less work here - weld the legs, weld the pipe, install the grate and drill holes in the door for air access. Disadvantages: the thickness of the walls of the flask is the same as that of a barrel.

- Made from an old gas cylinder. Advantages: the walls of the gas cylinder are quite thick and made of high-quality steel. It's easy to find the old one. There are options for manufacturing vertically and horizontally. Disadvantages: you need to be very careful during the opening process. Even after standing open for a week in the air, the cylinder can cause an explosion when cut. It is recommended to first fill the bottle with water.

- Made from metal sheet. Advantages: you can choose any sizes and materials, make a screen and make technical additions to increase the heat capacity (for example, pour sand between the walls or cover it with bricks). Disadvantages: Weight gain will require building a normal foundation.

Potbelly stove with water circuit

By upgrading an ordinary potbelly stove, you can get an original, effective source of heat in case of emergency, which will not interfere with any home.

This can be done in two ways:

- Place the water jacket on the burner pipe

- Loop several copper pipes around the outer body of the potbelly stove, thus forming a coil.

The turns of the coil tubes should be located at a distance of 5 cm from the perforated stove body and connected to the main heating system. Place a screen outside the coil to reflect the heat. It is made of tin, aluminum, galvanized steel.

Water jacket - a tank located on the top of the furnace, the body of which contains fittings (2 - water is supplied/discharged). The result is a structure similar to a samovar.

It is also advisable to install a thermometer.

Calculation of basic parameters (with drawings and dimensions)

Despite its simplicity, for high-quality operation of a potbelly stove, you need to make some calculations. All structural elements are calculated.

Pipe

The main thing is to calculate the diameter of the pipe. If this diameter is too large, then all the heat will escape into the atmosphere. If it is small, there will be no draft, the stove will smoke. The diameter (in mm) should be 2.7 times the volume of the potbelly stove in liters. The capacity is determined without the volume of space below the grate (the height is equal to the distance from the top to the grate).

Example: height from the top wall to the grate is 25 cm, width is 40 cm, length is 50 cm, then the total volume in liters is 50 liters. The diameter of the pipe will be 50 x 2.7 = 135 mm.

There are several options for making potbelly stoves for the garage

Screen

The main task of the screen is to reflect heat inward to increase the combustion temperature. Then the gases will not cool down, but will completely burn out. The fuel must be burned by partial pyrolysis. The screen is installed at a distance of 50-70 mm from the walls on three sides. It is good to make a screen from red brick. It heats up and then gives off heat for a long time and gradually.

You can also make a water heating system throughout the garage using a potbelly stove.

Litter

Due to the fact that part of the heat is radiated downwards, the floor under the stove heats up. If it is wooden, then a fire is possible. Embers may fall out when opening the door. A bedding made of iron or other non-combustible material (for example, sheet asbestos) is required. The litter should overlap the contour of the stove at a distance of 350-600 mm.

Useful tips

A potbelly stove will be easy to use if you listen to the recommendations of experts:

- To check the quality of welded joints, the first ignition is carried out outdoors.

- To ensure tightness, the chimney running inside the garage is made from an all-welded pipe without horizontal sections.

- There should be a box of sand and a fire extinguisher next to the stove.

- The places where the chimney pipe passes through the wall or ceiling are insulated with fireproof material.

- A brick screen lined on 3 sides of the stove will protect against accidental burns and retain heat after the fuel burns out. The distance from it to the walls of the potbelly stove should be 5 - 7 cm.

Despite its simple design, a potbelly stove is considered the most reliable and cheapest way to heat a garage. Even garbage can be burned in such a stove. When choosing, it should be taken into account that horizontal structures last longer than vertical ones.

Required tools and materials

To make a potbelly stove you need the following tools:

- welding machine;

- hammer;

- chisel;

- rags;

- Bulgarian;

- sandpaper.

Of the materials, first of all, you need to have the basics - a barrel, or a milk flask, or a gas cylinder, or sheets of metal from which the stove will actually be made.

In addition to them you will need:

- sheet material;

- steel pipes;

- door hinges;

- grate bars or reinforcement bars;

- pipe with weather vane;

- fire brick.

This list may not be complete and some may be replaced.

Option #1 - reliable and efficient brick

Brick ovens are not often found in garages, since this option is quite labor-intensive. Such a device occupies a small area, approximately 2x2.5 bricks. For masonry, refractory bricks are taken, and a solution of sand, refractory clay and fireclay powder is mixed.

When making a brick oven for a garage, a special fireclay brick is used, and when mixing the solution, it is recommended to add fireclay powder

For the combustion chamber, fireclay bricks are used at the level of the second, third and fourth rows of brickwork. The height of such a brick kiln is usually nine bricks. To remove furnace gases, a brick chimney is installed into which a stainless steel sleeve is inserted. The chimney is usually brought out through the roof.

Beginning builders who decide to build a brick stove in the garage should discuss the nuances of the project with an experienced stove maker - after all, this is a whole science worthy of its own profession. If significant flaws are made during the work, the masonry will have to be destroyed and completely redone.

Fuel selection

A potbelly stove is a stove that can be heated with a variety of fuels. This is firewood, peat briquettes, etc. Waste fuel such as waste oil is often used. This type of fuel requires some modification of the stove, but is available and cheap, especially in large cities, where it is not always easy to obtain firewood. And if this is a garage where they change the oil, then there is no problem with working out. Fuel in the form of oil gives more heat and burns completely. No ash.

Firewood for a potbelly stove

Firewood for a potbelly stove can be of any kind, but there are still certain preferences.

Softwood firewood burns quickly, produces less heat and produces a lot of soot, which clogs the chimney. There is a risk of fire.

It is better to use hardwood firewood:

- birch;

- acacia;

- aspen:

- oak;

- fruit trees;

- alder.

This wood burns long and hot.

Water heating in a garage from a potbelly stove has a special advantage - you can use any available fuel to heat the stove: wood, coal, vegetable waste.

Garage stoves and their varieties

Before we tell you how to make a stove for a city with your own hands, let’s try to look at the main types of stoves and the types of fuel available to us. To heat garages we can use:

- Diesel fuel;

- The most common firewood;

- Coal;

- Petrol;

- Workout.

A store-bought diesel stove operates without a chimney and takes up little space.

A purchased diesel heater for a garage is an excellent and aesthetic solution. It will allow you to completely warm up the garage using simple diesel fuel. Such a stove ignites quickly and reaches operating mode and does not require a chimney. But you need to remember that you will forever be haunted by the smell of diesel fuel, which is simply impossible to get rid of. In addition, you will need to buy diesel fuel somewhere, spending large sums on heating.

There is practically no high-quality diesel fuel that will produce a minimum of unpleasant odor on sale.

With the help of a gasoline stove for the garage, the design of which we will describe in our review, you can quickly warm up your work space. The main thing is to get cheap gasoline from somewhere. A garage stove made from a barrel, powered by gasoline, will delight you with its ease of manufacture. And such a unit can be used to heat any other premises, for example, country houses.

The main feature of our stove will be the absence of a strong unpleasant odor during its operation.

If you have a solid fuel stove, you will have to find a place to store firewood.

Solid fuel stoves using wood and coal are pleasing with their simplicity and affordability. Their fuel is cheap and in some cases free. A wood-burning stove for a garage has a simple design, does not emit an unpleasant smell of petroleum products, and can operate on various types of solid fuel. Only the garage owner will have to constantly remove the ash from it, but it can be used as fertilizer in your garden plot or vegetable garden.

An oil stove (also known as a working stove) will delight you with the simplicity of its manufacture. A self-made device installed in a garage will provide people with warmth. And if your activity involves frequent oil changes, then you will have an inexhaustible and free source of fuel at your disposal. Let's see how to make a stove for a garage and what you need for it.

Preparatory work before assembly

Before assembly and installation, you need to choose the right location. For safety reasons, the stove must be installed in a place away from the car at a distance of no closer than 1.5 meters. Optimally in a corner away from the entrance. The walls of the garage in this place are best protected with sheet asbestos.

Assembling a potbelly stove in the garage

How to improve oven performance

This stove has one significant drawback - it cools down very quickly. However, this is very easy to fix with the help of a brick screen, which is installed on three sides of the structure. This will allow you to accumulate heat and release it to the room even after the stove stops burning.

It should be placed at a distance of 5–7 cm from the walls of the stove, and in no case end-to-end. In this case, you need to take care of the presence of ventilation holes.

The screen should not be close to the walls of the stove

A structure with a brick screen will weigh much more than a conventional metal stove, so it is recommended to first build an individual foundation.

In some cases, it may be necessary to install a custom foundation. It's very easy to do:

- Dig a hole about 50 cm deep. All other dimensions depend on the size of the stove itself and the screen.

- Fill the bottom of the hole with sand (usually this takes about 3-4 buckets), after which it needs to be compacted. Cover the sand with a 10–15 cm layer of crushed stone and compact it as well.

- Level the backfill and fill it with prepared cement mortar. Leave it for a day (you can do it for several days, the foundation will only benefit from this).

- Cover the base with several layers of roofing felt.

- Now you can start laying out the screen in the brick floor. In this case, the first two rows should be laid out in continuous masonry directly on the roofing material. In rows 3–4 it is necessary to make ventilation gaps. Continue solid masonry.

- It is recommended to make the screen without a top covering.

How to make a potbelly stove in the garage with your own hands

If you have the skills to perform welding work, then installing a potbelly stove in the garage will be no problem. To do this you need:

- draw a preliminary design for yourself;

- choose a place;

- conduct an audit of available materials;

- select the required amount of materials;

- find or buy what is missing;

- mark and cut according to the sketch;

- cook the stove;

- install it in place and take the pipe out.

Do-it-yourself potbelly stove for the garage is ready!

Features of operation

Expert opinion

Pavel Kruglov

Stove maker with 25 years of experience

The operation of such a stove is similar to a conventional brick stove. Although it does not retain heat so well. Therefore, a brick potbelly stove made with your own hands will have to be heated again 4-6 hours after the last coals have burned out.

This indicates the unprofitability of using such a design for constant heating. However, for heating a garage, cottage, etc. periodically, it may well be used.

This stove runs only on solid fuel. This is another drawback.

At the same time, the design is simple to manufacture and operate. This is what determines its popularity.

Classic stove - potbelly stove

To make a classic potbelly stove with your own hands for the garage, you need to take 10 steps:

- Make 5 blanks from sheet material: a bottom, two sides, two to form a smoke circulation.

- Mark the places for attaching the grate and smoke circulation sheets on the side blanks. Weld a reinforcement bar or angle in these places for subsequent fastening of the grate and smoke circulation sheets in these places. You can buy a standard cast iron grate or weld a grate from strips 25 - 30 mm wide of thick metal (you can use reinforcement bars, tractor fingers or pieces of pipes with a diameter of 20 -30 mm).

Classic stove - potbelly stove - Weld the side walls to the bottom. Use a builder's square to weld vertically.

- Sequentially weld the lower and upper workpieces so that a smoke channel is formed.

- Weld the lid with the welded sleeve. Install a damper in the sleeve so that the chimney can be closed. Cut and weld the jumpers.

- Make a door. Equip it with hinges and a latch. Make the door large to make it easier to remove the ash later. Secure at the front.

- Weld legs from pieces of metal pipe 8-10 cm long. Nuts can be secured inside the pipe. By screwing the bolts into the nuts, you can level the position of the stove.

- Make a chimney from a pipe. Select the pipe diameter to be no less than the calculated one.

- Secure the chimney by insulating the transition in the wall.

- Place the stove in place and adjust the height. Secure the chimney in the sleeve.

Step-by-step instructions for making a stove

Step 1. In our example, we use a simple 250-liter barrel with thick walls - ideal for making a stove. Cut off the top of the barrel, but do not throw it away.

Step 2. Make a kind of lid from the top - a “pancake” for oxygen supply. Adjust it to the size of the barrel - as a result, when installed, there should be 2 mm between it and the walls around the entire circumference. Weld the neck of the lid. In its center, make a hole to install a pipe through which air will be supplied. Also weld 4 channels, as in the photo below.

Step 3. Stepping back a little from the top edge, cut another hole in the barrel wall for installing a chimney. In our example, the chimney will be a pipe with a diameter of 140 mm.

Step 4. Start making the lid. Make it from sheet metal 4 mm thick, and weld a sealing ring at the bottom corresponding to the diameter of the barrel. In the center of the lid, make a hole for the pipe that was welded to the “pancake”.

Step 5. Make simple legs at the bottom of the barrel to make the structure stable. The legs must be metal, as well as all other elements.

Step 6. Install the stove in the desired location and begin creating the chimney. In our example, it is of a prefabricated type. First of all, make a clamp with which the chimney will be attached to the body.

Step 7. Make guides in the chimney, thanks to which it can be easily fixed to the body.

Step 8. Join the barrel with the pipe, making sure to lay all the joints with asbestos fabric. Place a clamp over the fabric and tighten it.

Step 9. That's it, the structure is assembled, you can check its functionality. Load sawdust or firewood inside.

Step 10: Add used oil to the fuel, then install the cap. As for the “pancake”, don’t use it yet. After the fuel ignites, remove the lid and place the “pancake”. To fully warm up such a structure, it takes about 10 minutes; in the future, the firewood will burn for a long time. Although exactly how long the combustion will last largely depends on the quality of the fuel.

Calculator for calculating solid fuel consumption for a furnace

Go to calculations

Video - Making a bubafoni stove

Video - Homemade potbelly stove for the garage

If you wish, you can modify the design described above, although it will already cope with its functions perfectly. For example, to increase efficiency, you can increase the surface area and thereby improve heat transfer. For this purpose, weld metal plates on the sides of the body.

In addition, you can make a grate with an ash pan: cut a circle from a sheet of metal along the inner diameter of the body, drill holes with a diameter of 60-80 cm and install from below. After this, the ash will be poured down through the holes - to where the ash pan is equipped. It is believed that this will cause the fuel to burn faster, remember this point and make sure that the ash pan is sealed as much as possible.

Milk flask stove

Before you put such a potbelly stove in the garage, you need to know that the scale of welding work here is smaller. In fact, here the legs and the chimney pipe are welded to the body. The door remains standard. Holes are drilled in it for air flow. The grate is made from a metal rod. It is mounted horizontally at the bottom of the flask.

It is installed in the desired place and the chimney is attached to the sleeve.

Such a stove is more suitable for burning garbage than for heating.

Design and operating principle

For heating, you do not need to build a separate foundation or build a chimney. It is for these reasons that many owners of private houses choose a potbelly stove for heating the garage and various buildings. The stove does not require gas or electricity to operate.

This is a metal box that is equipped with a door and a pipe. It is taken outside the room to remove the smoke. The pipe can be used as heating if you first take care to change its design. Hot air will be trapped inside in small quantities.

The pipe should run at a slight angle

From a gas cylinder

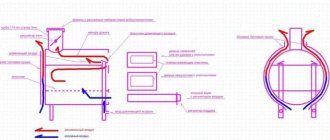

How to make a potbelly stove for the garage with your own hands from a cylinder? A gas cylinder stove is made in various designs - horizontally and vertically.

When installed horizontally, the container itself is the combustion chamber. Instead of a grate, rows of holes are drilled in the wall and in this place I weld an ash pan box with a drawer. You can cut out a window and install a standard grate. A cutout for the door is made in the end part. The door can be made from this segment by hanging it on hinges and attaching a handle with a latch, or by welding a standard one. The chimney liner is welded on the opposite side.

The legs are attached at the bottom.

When installed vertically, the internal space of the cylinder is divided into two parts. At the bottom there is a round grate and an ash drawer.

A window for the door is cut out in the upper part and the chimney liner is welded. The upper semicircular part can be cut off and a metal sheet welded to form a hob.

What is the difference between a long-burning stove and a wood-burning stove?

Fundamentally, the difference between a long-burning stove and a conventional potbelly stove is how the combustion process occurs. A conventional cast iron or steel stove with a grate and a straight chimney is characterized by rapid combustion of fuel. In fact, the name “potbelly stove” itself comes from the exorbitant appetites of the stove. The combustion process in the firebox occurs on a grate, with a large air flow, which, on the one hand, makes it possible to increase draft, and on the other hand, when burning wood, I burn with a large amount of soot and smoke. This state of affairs cannot indicate fuel economy; they simply have to be constantly added to maintain the temperature.

In a long-burning furnace, the process occurs differently. Depending on the design of the firebox and additional equipment, combustion can take the form of slow combustion (smoldering) or pyrolysis - combustion of gases emitted by the fuel.

When smoldering, it is possible to make the combustion process controlled by reducing or increasing the air flow into the firebox. The result is slow combustion of fuel and the combustion process increases in time. It is difficult to judge how economical such heating is, but it is a fact that the combustion time increases significantly.

During pyrolysis, solid fuel decomposes into simple substances under the influence of high temperature. As a result, it turns out that it is not wood that is burned in the firebox, but the gas emitted by the wood. Such long-burning stoves are much more economical and their installation quickly pays for itself.

But, in fairness, it is worth mentioning intermediate designs that combine the advantages of controlled smoldering furnaces and pyrolysis furnaces. These hybrids are basically the most commonly used DIY projects.

Step-by-step assembly of a potbelly stove

Work on assembling the structure is carried out strictly in accordance with a pre-prepared plan. Instructions on how to make your own potbelly stove:

- Five parts are cut out of sheet iron: the bottom, three walls and the roof. The supporting legs are prepared separately.

- Weld the walls to the bottom, periodically monitoring the progress of work using a building level.

- Further actions are related to the division of the internal space into the chambers of the ash pit, firebox and vestibule of the chimney. Separation is carried out using a grid.

- To fix the grille, retaining sides (metal corners) are first welded to the inner walls of the housing.

Installation and connection

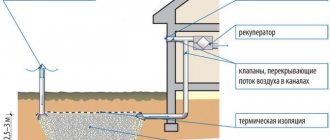

When installing the stove, you must strictly follow the fire safety rules:

- The distance to walls and surrounding objects must be at least 800 mm. The walls can also be covered with ceramic tiles.

- All parts of the chimney must be tightly connected.

- The room must be equipped with a supply and exhaust ventilation system.

The chimney is installed like this:

- We fix the first piece of pipe above the chimney opening.

- We increase the pipe bends to the ceiling level.

- We make holes in the ceiling with a diameter of 170 mm. We remove a layer of thermal insulation around the hole to prevent fire.

- First, we mount the pass-through glass, then insert the pipe into it.

- Next, we connect the pipes to the external chimney.

- We apply bitumen to the pipe and insulate it.

If you need to heat a large area, you can connect the stove to a heating panel. This will increase the heat flow and allow it to be retained longer.

Pros and cons of such a stove

Before deciding on the advisability of making a potbelly stove for the garage, you need to weigh the pros and cons of such an action.

Advantages of a potbelly stove for heating a garage:

- High efficiency. The output from such a stove will be much higher than most modern heating devices. The efficiency of a well-assembled potbelly stove will be in the range of 85 - 95%, which is simply a record without the use of additional devices (convectors, for example).

- Universal purpose. Almost all combustible materials can be used as fuel: sawdust, paint waste and waste oil.

- Budget cost. Unlike most heating devices, this is a simple and cheap option. Even if we don’t talk about a full-fledged heating system, a potbelly stove is much cheaper and more economical to use.

- Quick kindling and warming up the room. After just a few minutes, the garage will become noticeably warm, and heating occurs more or less evenly, unlike the same fireplaces and convectors.

- The possibility of self-assembly will provide an additional advantage with certain “male” skills in working with the tool. At the same time, you can consider that even buying a new unit is much more economical than other devices with a similar purpose.

Despite the obvious advantages of this option, you should not consider it the only possible and ideal one. A potbelly stove for a garage also has its drawbacks, which will be discussed further.

Negative aspects of use:

- Mandatory installation of a chimney. In addition to the obvious reason - the removal of combustion products, there is another important nuance: the height of the chimney must be at least four meters, otherwise the stove will not have the necessary draft. This design feature is not always convenient for placement, and also entails additional material costs.

- Regular cleaning of the chimney. Soot and soot quickly clog the outlet and can lead to fire hazards. Therefore, a small diameter pipe must be cleaned every week, and a larger diameter – monthly.

- The oven body cools down quickly. Heat is released directly during combustion. As soon as the firebox burns out, the oven immediately begins to cool down. This problem is partially solved by using brickwork placed around the body. Bricks do not cool down as quickly, releasing heat into the surrounding air.

Whether it is worth getting involved with such a heating source is up to you to decide, but for those who are interested, our article will present diagrams and features of self-production.

Among all the variety, such a device is in excellent demand. Many factory-assembled products are made in the shape of a rectangular box. This potbelly stove does not take up much space and has reasonable dimensions.

Main manufacturing nuances:

- The dimensions of the potbelly stove are determined by the drawings provided. Usually they are adjusted to the existing workpiece size.

- The metal used must be at least 4 - 5 mm, otherwise the service life will be short.

- The chimney is located at the rear of the stove. New models of potbelly stoves offer front placement, so check out both options. The chimney joint needs to be further strengthened; this is the first place to burn out.

- There is no grate in a traditional potbelly stove, but you can find options for its use. It is also better to weld an additional partition to increase the recoil coefficient.

- It is also advisable to make an ash pan - a special hole for cleaning waste slag. This will make the operation process easier.

- To maximize the impact, you can use strip steel. Thus, the exchange surface is increased due to additional ribs.

The body can be made in a vertical plane or horizontally directed. This will not affect performance; a vertical stove just takes up less space. On the other hand, you will have to add fuel more often, which is not always a suitable option. An appropriate protective screen must be made around the entire perimeter to ensure the necessary fire safety

This is very important, especially for do-it-yourself equipment.