Stoves called potbelly stoves are as popular today as they were many years ago. They are used in homes, dachas, garages, bathhouses, potbelly stoves are also used to heat greenhouses, and even the Ministry of Emergency Situations uses stoves of this type in emergency situations. You can make a potbelly stove yourself or buy a ready-made factory model. We advise you to read our articles on making a potbelly stove for your garage yourself, as well as about making a potbelly stove for a bathhouse.

There are a huge number of furnace modifications: they are supplemented with water tanks, connected to heating systems (both air and water), and adapted to work on waste oil or sawdust.

Determining the volume of fuel fill

For the potbelly stove to operate efficiently, it is important to load the optimal amount of fuel into it, and for each type of fuel it is necessary to find its own indicator.

If you overload the furnace, there will be too many combustion products and they will block circulation; if you underload, there will be few of them, which also makes circulation impossible. The bookmark volume is selected as follows:

- fuel is collected in a bucket;

- they take a handful from the bucket and, placing it in the firebox, set it on fire;

- add fuel in small portions until the initial section of the hog is cherry red hot. Now they estimate how much fuel is taken from the bucket - this is the minimum volume of the stowage;

- continue to add fuel (the portions must be increased) until the dimensions of the hot section reach 80%-85% of the length of the “hog”. At this moment, the volume of fuel taken from the bucket will correspond to the maximum fuel load.

The test is carried out in moderate lighting: if during the day, then in cloudy weather (winter); If it’s clear outside, it’s closer to evening. When loading high-calorie fuel (pellets, anthracite), the hot area sometimes takes the form of a ring with different widths, occupying different positions along the length of the hog.

Then the volume of the bookmark is determined as follows:

- maximum: the section of the hog farthest from the furnace is hot for 1/3 of its length;

- minimal: the hot zone is located in the middle and is 3-4 palms long.

Propane stove

The ideal stove is a self-made gas stove. It does not need a chimney because no smoke is released when the gas is burned. Its analogue is a room gas stove with an oven.

It’s not difficult to make - take... a ready-made potbelly stove, insert a steel pipeline into it with a nozzle from an old gas stove. Connect it to a standard gas hose with a reducer from a household gas cylinder.

There is no exact cost for a potbelly stove; you can use a 4-burner stove as a guide. The capacity of a cylinder (50 liters) with 21 kg of propane-butane is enough for 34 hours of operation of such a stove.

If anything is unclear from our recommendations, watch the video of making a potbelly stove with your own hands.

General requirements

In the case of installing a heating system with your own hands, the property owner can personally choose the timing and need to turn it on.

Most often, the heating is turned on during repair work, and turned off while the car is being stored.

Safety

One of the main requirements for garage heating is its safety. The room contains a large amount of fuels and lubricants, as well as highly flammable items.

In cooperatives where structures are located end to end, a fire in a separate area can lead to the burning out of a significant area. For this reason, all heating systems must be capable of emergency shutdown in the event of an emergency.

Feasibility

For property owners, the economic feasibility of the methods used is important. If the installed heating system requires significant operating costs, you should think about choosing a different method.

Proper garage heating should be reliable and resistant to temperature changes outside the room. This also applies to energy supply interruptions.

Insulation

The garage heating scheme involves preliminary thermal insulation of the room. Heating unprotected buildings is pointless - the heated air will escape through the cracks of the enclosing structures.

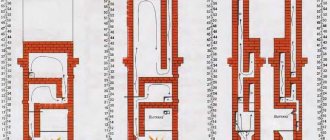

We increase the efficiency of the furnace

door to the firebox and ash pan; it is advisable to provide a damper; side metal screens

Potbelly stove in casing

Round furnace with afterburner and casing with heat gun

A stove with elbows for a chimney,

the throughput of the chimney, blowing the chimney with a fan firewood in the stove with slots and a valve, strips of metal buckets or a metal box with sand, sand backfill or a heat accumulator made of stones

Scheme of a potbelly stove with sand backfill, the stove is made of a pipe with a diameter of 500 mm, its length is 650 mm,

lined with 1-2 layers of brick.

Brick screen,

the area of its walls is bricks or a metal sheet. Video on the topic: Do-it-yourself potbelly stove stove

Selection of shape and components

A potbelly stove is usually made of steel sheets in the form of a rectangular box.

You can use a gas cylinder, but not a narrow industrial one, but a wide household one. The cylinder should be placed vertically, since the potbelly stove is designed for flat roofs and under. With a horizontal orientation, the rounded surfaces will collect flue gases into a bundle, for afterburning of which the length of the “hog” (see below) will have to be increased to 12 m.

In addition, to ensure normal operation of the potbelly stove, you will need a chimney and a screen.

Chimney

The throughput capacity is slightly less than the furnace productivity in terms of combustion products. Thanks to this, gases are retained, circulating in the firebox.

Double effect:

- combustion products give off more heat;

- Due to their circulation, air is sucked in and this ensures complete combustion of the fuel.

To meet this condition, the pipe diameter is calculated using the formula D = (2.5...3) V, where:

- D—pipe diameter in mm;

- V is the volume of the firebox in liters.

Ideal ratio: D = 2.7 V.

In designs with a grate and horizontal partitions in the upper part (smoke channels), the height of the firebox is taken as the distance from the beginning of the grate to the bottom partition.

Screen

To increase the efficiency of a potbelly stove, it is necessary to ensure:

- partial pyrolysis (decomposition of solid fuel into gaseous substances);

- combustion of flue and pyrolysis gases circulating in the furnace.

These processes take place at high temperatures, for which purpose the potbelly stove is surrounded at the back and sides with a screen. It returns the infrared (IR) rays emitted by the housing, preventing the gases from cooling quickly. At the same time, it solves safety issues: it makes the oven less traumatic and reduces the risk of fire (the temperature of the screen is lower compared to the body).

The screen should cover 50% of the oven surface (a very important indicator). The width of the gap between it and the body is 50-70 mm. Additionally, the screen increases the efficiency of the stove during lighting: air moves in the gap along the entire body, taking away maximum heat. In this embodiment, the role of the screen is played by a container for heating water.

Air heat exchanger

In the case where the primary heat exchanger is a firebox (steel stoves, long-burning stoves - PDG, waste oil stoves - POM), the following measures can be taken to increase the efficiency of “dry” heat transfer.

Through vertical and horizontal straight channels (pipes)

Steel pipes are welded directly onto the firebox. It is better to install them vertically - this will improve air flow. Suitable if you have available material - pipe scraps (the cross-sectional shape does not matter). Diameter 50–200 mm. The original solution for the firebox would be to weld the walls from equal sections of pipe.

Curved and rounded channels

The ideal option is to “wrap” the entire firebox in 1-2 turns. This will require skill and time, but the effect will be much higher than from simple direct channels. The greater the difference between the levels of air intake and outlet, the better the channel will work. If you take the fence outside, the effect will be maximum, because when the firebox is heated, due to the temperature difference, a draft will arise, which will ensure a constant flow in “automatic” mode.

Labyrinths with bulkheads in containers

To implement such a heat exchanger, you need to install an additional steel box on the top wall with a height of about 100 mm and thick walls. In this box, steel 5–8 mm bulkheads should be placed in such a way as to create a “labyrinth”. At the beginning and end of it there should be inlet openings for the cross-section of the air duct. The top of the “labyrinth” is also covered with a lid. In this embodiment, the heat exchanger is the space between the firebox wall and the walls of the box. Such heat exchangers can also be installed on the side walls of a steel reactor.

Through channels in the reactor, integrated into the furnace

Such channels are included in the design when creating the furnace, then welded into the walls. They can be located side by side at the top of the firebox. Diameter from 50 mm.

In any type of VT, the phenomenon of convection* is used, but in most cases, due to the high temperature in the reactor, the natural movement of air is not enough and it is forced in by fans. This method is also called injection.

* Convection is a method of transferring heat by flows or jets.

Injection can be done in any available way - by building an air pump into the channel or simply directing it to the heat exchanger. “Dry” heat exchangers are the simplest and most affordable heating devices.

Advantages of air heat exchangers:

- Tightness of connections is not required.

- Can work without injectors.

- Ease of installation and availability of available materials.

Disadvantages of air heat exchangers (HE):

- A significant (from 100 mm) diameter of the air duct is required.

- Low heat capacity of the medium (air).

- Short range of temperature transfer.

Design advantages

Despite the emergence of more and more economical wood-burning stoves and boilers, the old potbelly stove remains quite in demand, this is explained by its advantages:

- simple device. There are no high-tech components in the oven, so anyone can make it themselves;

- low cost. This "plus" stems from the previous advantage;

- ease of use. Heating a potbelly stove is extremely simple; you don’t need to know any subtleties. All you need to do is select the correct volume of the bookmark;

- omnivorous. The heater operates on any fuel, including used engine oil;

- multifunctionality. A potbelly stove can be equipped with a hob and a water circuit, which significantly increases its value for a living space;

- multi-mode. In addition to the usual functionality with direct combustion, a properly designed stove is capable of operating in smoldering mode (the duration of heating on one tab increases);

- efficiency. With all these advantages, there is also a good efficiency of 60% if the assembly is carried out in compliance with the rules set out below.

Do-it-yourself potbelly stove with a water circuit

A potbelly stove with a water circuit is made with your own hands in a few steps.

Furnace formation

First, a sketch is worked out, which indicates all the main dimensions of the future structure. To work you will need:

- hammer;

- Bulgarian;

- welding machine;

- pliers;

- workwear.

When drawing up a project, it is very important to take into account how thick the parts of the future product will be. After cutting the metal, the bottom is connected to the walls, excluding the front side

Welding parts must be performed at 90 degrees

After cutting the metal, the bottom is connected to the walls, excluding the front side. Welding parts must be performed at 90 degrees.

The bottom of the stove should be installed 25–30 centimeters from the floor surface. After installing the legs, the floor covering will not heat up much.

In the free space formed between the firebox and the ash pit, a partition with holes is installed to remove ash.

The blower hole is made 3 centimeters smaller than the blower itself.

Openings are made on the front wall where the doors will be installed. The front part is equipped with canopies on which doors are installed.

The chimney pipe is welded to the top of the stove.

When the work is completed, the welds are checked. Defects are not allowed. If everything is in order, add a water circuit.

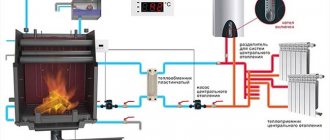

The main part of such a stove is the heat exchanger. It can be made from sheet steel or use hollow metal pipes. In addition, this “potbelly stove” includes:

- frame;

- radiators;

- pipes;

- steel sheets.

System installation

To create free circulation of water, two holes are made on the upper surface of the stove. Through one the water is supplied, through the other it returns back.

You can use any leftover material to create a water tank. The tank usually takes up the most space. Before installing it behind the firebox, holes are made in it where the pipes will be connected. A metal sheet is installed between the firebox and the tank.

Then the piping is created. It can have several types:

- two-pipe;

- collector

A two-pipe design is considered more preferable. It makes it possible to change the temperature value using special taps. The room is heated evenly.

It is very difficult to create collector wiring with your own hands.

After installing the wiring, all pipes are connected to the radiators installed in the house.

It is advisable to install batteries under a windowsill. This will help increase the thermal conductivity of the stove.

The created water circuit is thoroughly checked. There should be no leaks anywhere.

f11c6cd147659b13152568a02d83062b.jpe

The supply line is equipped with an expansion tank. It will prevent cold water from entering the system. The dimensions of the tank are calculated according to the volume of water in the system. The tank capacity should exceed this value by 20%. If everything is installed correctly, the water in the heat exchanger will be evenly heated. The liquid will begin to move and enter the radiator. After cooling, it will return to the heat exchanger.

The created stove can be painted and, if desired, covered with brick. It all depends on the imagination of its owner.

What is so attractive about a potbelly stove?

Although in this case half of the thermal energy evaporates through the direct-flow pipe. But no one writes off even a heating source that has rusted over time as scrap.

Such a temporary stove can be easily made in a day or two. But first, make your own drawings of the potbelly stove. Much of what is stored in the closets of rural houses and dachas is used. These are milk and water metal (not duralumin) cans, barrels for diesel fuel, vegetable oils, pipes, boxes, corners.

Nothing expensive, including tools - in villages every owner has them at hand. High-quality assembly using gas or electric welding.

But neighbors who have units will help with this. Welding machines provide greater reliability and rigidity of the assembly. Below are step-by-step instructions on how to make a potbelly stove with your own hands.

Conditions for optimal fuel combustion

How to properly install a potbelly stove in your home to get maximum heat transfer from fuel combustion?

In order for the draft in the stove to be sufficient, the height of the chimney (counting from the stove grate) must exceed 5 mm. If the installation of a potbelly stove is carried out in a one-story house, the roof ridge is located at the highest height. In this case, it is possible to save the maximum amount of heat by placing most of the chimney inside the house. At the same time, the attic (or attic) space is also heated, contributing to the overall heating of the house. The absence of a temperature difference along the length of the chimney will also help stabilize the draft in the stove, which depends, among other things, on the heating level of the chimney.

Making a potbelly stove with a water circuit with your own hands

When installing this type of heating system, you can either build a water boiler into a potbelly stove or create the stove itself from scratch. Therefore, the process can be divided into two stages.

We also recommend that you study the article: Water heating from a stove on our website!

Formation of a potbelly stove

Before starting work, drawings are drawn up that include all dimensions of the furnace, and the basic materials for working with metal are prepared: a welding machine, a hammer, an angle grinder, as well as pliers and special clothing.

When drawing up a diagram of a potbelly stove with a water jacket with your own hands, it is important to take into account the thickness of the elements of the future unit. After the metal has been cut, you can proceed to further steps:

After the metal has been cut, you can proceed to further steps:

Connect the bottom to the walls, excluding the front. All elements should be welded at right angles.

00f39f8c5e29ae86bb91a48939ae3381.jpe

The blower opening should be up to 3 cm smaller in comparison with the blower itself.

- Openings for doors are made on the front wall. After this, it can be installed to the main structure;

- Canopies are added to the sides of the front part and doors are installed;

It is better to equip all doors with deadbolts

A chimney pipe is welded to the top of the stove. Upon completion of work, all parts must be checked for defects in the seams. If none are found, you can proceed to the next step - adding a water circuit.

Adding a water circuit to a potbelly stove

The basis of this type of furnace is a heat exchanger, which can be constructed from different materials, for example, hollow steel pipes or steel sheets. In addition to the heat exchanger, to create a potbelly stove with a water circuit you will need:

- Finished furnace body.

- Radiators.

- Pipes.

- Metal sheets.

We advise you to read about water heating from a stove on our website.

The system is installed as follows:

Two holes are made in the upper part of the potbelly stove base for the supply and return of water.

Drawing up a drawing of a future potbelly stove with a water circuit, created independently, will help to simplify the work.

- The water tank is formed from metal or other suitable unused materials, and the largest space should be allocated for it in comparison with the firebox and ash pit. Holes are made in the tank for the pipes, then it is installed behind the firebox. The space is separated by a metal sheet.

- Next, the pipework is installed. It can be one-pipe, two-pipe or manifold.

It is recommended to install radiators under windows. This will increase the thermal conductivity of the stove. The design of a potbelly stove with a water circuit is checked for the absence of holes where water can leak through the circuit.

An expansion tank is installed to the supply line, which will prevent the supply of cold water. Its size is selected based on the volume of water that will be in the entire system - the tank should be made 20% larger.

Example of a potbelly stove with an expansion tank

If constructed correctly, the water will heat up in the heat exchanger, pass through the pipes to the radiators, cool and return to the heat exchanger.

We advise you to read more about the types of heat exchangers in addition to this material.

The finished structure can be painted or covered with brick, depending on what appearance the owner prefers.

Video: project of a potbelly stove with a water circuit

With the help of a self-designed potbelly stove with a water jacket, you can significantly save on heating a country house. Such a structure can provide the necessary amount of heat to any room.

Buy or make it yourself

If you want to increase the heat transfer from an expensive purchased boiler, it is better to buy ready-made high-quality devices - the industry produces them in a sufficient range. But if you want to modernize a potbelly stove in a bathhouse or garage, or increase the efficiency of a fireplace with a steel pipe in the country, you can save a lot of money by making and installing a heat exchanger on the chimney yourself. Installing a heat exchanger by a hired specialist will cost the same as the structure itself.

The simplest option - a coil - can easily be made by a home hobbyist even without much experience, but a home craftsman with at least some welding skills can handle more complex designs.

approximate price

The cost of industrially manufactured chimney heat exchangers varies depending on the design and manufacturer.

Operating principle and operation of a potbelly stove

The operating principle of a solid fuel stove is to burn fuel and maximize the use of thermal energy released as a result of combustion. To increase efficiency, you need to force warm flows to linger in the firebox as much as possible. To do this, the diameter of the chimney is determined according to a certain formula. Thanks to correct calculation, warm smoke does not immediately fly out into the chimney, but makes several turns in the firebox, giving off all the heat.

How to properly heat a potbelly stove with wood? First, a bookmark is made and set on fire. At first, until the flame flares up sufficiently and engulfs most of the wood, the ashpit opens to the maximum. Then the air supply is almost completely shut off so that the fuel begins to smolder.

There is no need to rely on afterburning of gases released as a result of pyrolysis, since the design of a wood-burning potbelly stove does not provide for a second afterburning chamber. In this case, the time between bookmarks will increase significantly and the oven will operate in temperature maintenance mode. If we are talking about a potbelly stove using waste oil, then everything is the other way around. The main amount of heat is released due to the combustion of gases released from the oil.

Operating principle of the device

Fuel combustion in a potbelly stove during processing occurs in two main stages. Initially, the poured oil burns in the tank, after which the gases are mixed with air, enter the second chamber, where they are burned and ensure the maximum possible efficiency of heating the room. At the same time, fuel consumption is significantly reduced, and the need to constantly refuel the unit disappears.

A properly assembled oil stove will consist of two separate compartments. The first chamber is a small tank into which used oil is poured. Fuel combustion occurs at a relatively low temperature. There is an afterburning chamber on top, where the resulting gas mixes with air and burns at a temperature of about 800 degrees. The metal walls of the potbelly stove become hot, and the thick metal effectively retains heat, quickly heating a small room.

In this video you will learn useful information in making a potbelly stove:

Exploitation

The potbelly stove is used taking into account some features:

- The smoke exhaust duct must be led outside - through the ceiling or wall. It is prohibited to connect the pipe to ventilation. Intersection areas must be reliably insulated using non-combustible materials.

- Modern designs of metal stoves, when properly assembled, can efficiently heat one room with an area of up to 30 square meters. But the garage must be well insulated.

- If the heating area is more than 30 m2, the organization of a circuit is mandatory.

- When there is a potbelly stove with a circuit in the room, you should always have a box of sand and a container of water ready.

- It is necessary to arrange a separate place for storing firewood for the stove, since their consumption will be rather large.

- Compliance with all operating and fire safety regulations will keep the property safe and sound.

Rules of care

The stove will serve for a long time, provided that the owners follow the rules for caring for the equipment. These include:

Opening the condensate container daily to drain the water

It is placed on the chimney. Before starting the heating season, the chimney is thoroughly cleaned of soot that has settled and stagnated in it using special tools. During operation, the stove body and pipe are regularly inspected to prevent exhaust smoke from entering the garage. It is important to constantly monitor the condition of the hood and supply ventilation. Recommendations for caring for the structure

Recommendations for caring for the structure

Self-construction of a metal wood-burning stove is not only effective. With the right approach, such a stove becomes a real decoration of the room. But the main thing is to follow all the rules of construction, care and operation.

Power calculations

It is almost impossible to independently calculate the power of a recuperator in the absence of initial data (furnace power, temperature and amount of exhaust gases per unit of time, contact area between the heat exchanger and the metal of the chimney, the speed of passage of air or water through the device). You can measure the power of an already installed heat exchanger.

Roughly, you should expect that the heat exchanger on the chimney of a solid fuel stove or fireplace will warm up a couple of small radiators, increase the temperature in the garage, or make a room in the attic or a dressing room in a bathhouse warmer.

Construction of a potbelly stove

Storing your car in a warm garage during the winter allows you to avoid many problems. Proper engine starting, clean windows, ease of repair, maintenance - all this significantly increases the operating time of the car, preserving health, including the owner. In a warm room, the body is reliably protected from corrosion. Those who like to repair and improve their car themselves know that frosty days make rubber and metal brittle, and repairs are complicated by constant breakage of bolts and bursting of plastic parts. A comfortable temperature helps to avoid these problems.

It is made like this:

- holes are cut in the steel barrel;

- Pipes and fittings are attached to the holes by welding.

The structure of a modern potbelly stove

It is easy to equip the body for these structures; the main thing is the organization of modifications.

Heating using a potbelly stove is allowed - it heats up quickly and gives off heat. It is quite possible to design a stove for heating a garage yourself, provided you have a small welding machine.

Sometimes brick stoves are built in garages, but they will take up a lot of space and will not be able to heat the room faster than a potbelly stove. The name of the device is conditional, because in fact any fuel material can be placed in the structure.

Stove installation

This process is done in the following order:

- First of all, you should assemble the body. This should be done using oven mitts. After checking with the product drawing, perform the final welding of the parts, then move on to the next one. It is undesirable to leave parts on tacks, as they will later become inaccessible. Gaps between parts and lack of penetration of seams must be excluded.

There should be no gaps between the parts in the potbelly stove body

You can check the tightness of welding with chalk and kerasin

A modern potbelly stove with traditional heating can be included in any decor

Preparatory work before assembling the heater

A potbelly stove is a source of increased fire hazard. Therefore, when placing it in a corner of the room or near a wall, you must:

- Hang protective screens on the stove.

- Raise it from the floor, and protect the floor under it near the doors of the firebox and ash pan with tiles or asbestos slabs.

The walls and floor where the potbelly stove is installed must be protected with fireproof materials, and the stove itself must be raised onto a heat-insulating base

- Mark the chimney hole in the wall. Mark its mounting on the external walls.

- Mark the location of the expansion tank.

- Install water lines.

- Select a boiler model.

To make a temporary stove you will need the following tools and materials:

- Bulgarian.

- Electric or gas welding.

- Electric drill and drill bits.

- Tools: pliers, hammer, file, sanding paper, ruler, tap.

- Plumbing: American fittings, nuts for fittings, swivel taps, adapters.

- Sealant or silicone for fittings.

- Alloy steel sheet metal.

The following can be used as a basis for making a furnace:

- Metal barrels with a volume from 20 to 200 liters.

- Car wheels from 2 pcs.

- Propane or carbon dioxide cylinders.

- Thick-walled metal pipes with a diameter from 150 to 350 mm.

- Metal water flasks for 20, 30 or 40 l.

One of the most popular solutions for making a potbelly stove with your own hands is to remake an old gas cylinder

If the specified materials are at hand, it means that 2/3 of the design of the future stove is already ready. All that remains is to assemble everything into a single device.

We select available material for the manufacture of the device. We take into account that an aluminum recuperator requires twice as much material as a copper one due to its thermal conductivity properties. To install a furnace with a heat exchanger 500 mm high, you will need:

- Copper or aluminum tube with a diameter of 16 mm and a length of 50 m.

- Gas cylinder or compressed gas cylinder.

- Chimney pipe with a diameter of 150–210 mm.

Step-by-step instructions for making a temporary shed with a boiler:

- We cut off the gas cylinder. We weld the legs.

First, you need to cut off the top of the gas cylinder

- We cut a hole for the chimney with a diameter of 150–210 mm.

- We make holes for the grate with a diameter of 30 mm (24–25 pcs.) in the lower part of the cylinder. The air flow through the combustion chamber must correspond to the diameter of the chimney.

Holes are made in the bottom of the cylinder to remove ash and create draft

- We bend the metal sheet and weld it to the bottom or to the legs. This is how we form the ash pit. If the room allows, you can make a box for collecting ash and place it under the stove.

We weld a metal box for the ash pan to the surface where the holes are drilled.

- We make the oven door. Solder the handle to the lid. We attach the canopy. Attach the lid to the firebox. There is no need for an additional air duct; air flow through the grate holes is sufficient.

For fuel combustion there is enough air that will flow through the grate holes

- We carefully wind the heat exchanger tube (copper or aluminum) onto the chimney pipe. To prevent it from springing, it should be soldered through one turn to the chimney. To do this we will use welding.

- Having finished assembling the heat exchanger, we attach adapters with taps to the ends of the tubes using fittings. On the lower branch pipe we install a tee with a swivel valve for draining and filling water into the heat exchanger.

- We carry out hydraulic tests. You should fill the resulting system with water and test it under pressure of 4–6 atmospheres. Excessive pressure allows you to test the strength of all components, connections and check for leaks.

What is a potbelly stove with a water circuit: the advantages and disadvantages of a popular stove

A brick stove with water heating warms up the premises both due to the hot structure (like a conventional stove) and the coolant circulating in the system. Water is usually used as a coolant.

The design of the furnace includes a metal element designed to heat the coolant. In fact, it is a heating boiler to which pipes are connected. The boiler is installed near the firebox.

Such stoves are actually universal; they are suitable for outbuildings and multi-storey country houses.

You can make a fireplace stove with water heating by simply installing a glass door. Such a stove will become not only an important functional element, but also a stylish part of the interior of the house.

But when working with such a furnace, you must comply with a number of requirements:

- the operation of the stove must be constantly monitored, firewood and (or) coal must be added in a timely manner, and the ash pan must be cleaned;

- It is advisable to use the stove only in winter. It should not be used for cooking in summer, since a lot of energy will be spent on the heating system, which is not necessary in warm weather;

- you need to regularly check the condition of chimneys;

- Due to the high temperature, the heat exchanger may burn out over time; replacing it will require partial disassembly of the stove.

To make the simplest heat exchanger, you can use sheet steel. Such a heat exchanger is easy to clean from ash, but is not capable of heating large areas. Tubular models have higher efficiency and are suitable for large buildings.

In the photo of water-heated furnaces you can clearly see the various design options for heat exchangers.

Important information for your safety

The second possible danger after carbon monoxide poisoning is a garage fire. There are always flammable materials here, including the contents of the car's fuel tank. Neglect of safety measures is fraught not only with the loss of your garage and your beloved horse, but also with a serious lawsuit from neighbors in the parking lot.

For these reasons, we consider it useful to remind you of the basic rules:

Think about the fact that it would be a good idea to install the simplest smoke detectors in this room.

Where to use a homemade furnace for mining

Since during the combustion process engine oil, especially used one, does not emit the most pleasant odor, and from a health point of view it is not very useful, it is better not to use stoves of this kind in residential premises. If there is no other way out, high-quality removal of combustion products is mandatory.

Typically, stoves are installed in non-residential premises - utility rooms, garages, sheds, workshops, and so on - where constant heating is not required, but only warming up the air for a relatively short time.

Due to the fact that even the simplest designs of such a “garage stove” make it possible to regulate the intensity of fuel combustion, it is possible to ensure either an economical mode of its use and gradual heating of the premises, or increased consumption with very fast heating of the air volume.