Variants of the Tichelman scheme

With the correct construction of the Tichelman scheme, the heating system assumes the creation of identical conditions for the operation of the radiator. This applies to pressure drops, despite the fact that radiators have equal surface areas, and, consequently, an equal level of heat transfer. To draw diagrams correctly, you need to practice for some time.

The door can be bypassed in several ways: the pipe can be laid on top. When choosing this option, please note that the area above the door must be equipped with an automatic air vent: this will not allow air to accumulate. The appearance of the room suffers. Also, the air vent may leak from time to time, which is quite impractical.

Variants of the Tichelman scheme:

- Option in a one-story house. The pipe can be laid below the floor level. But this can be inconvenient if the flooring has already been done.

- Scheme for two floors. According to the scheme, the entire system is tied together, not individual floors. The supply and return of main pipes having a diameter of 20 mm are carried out. And radiators are already connected to them using a 16 mm tube.

- Trim for three floors. One piping is performed for all floors. The risers have a diameter of 25 mm, supply and return are 20 mm, the pipe for the outlet to the radiators is 16 mm.

If possible, it is better to connect each floor separately, while connecting an individual pump for each. It should be taken into account that the use of one pump if it breaks down can lead to the entire heating system failing at once. The Tichelman scheme can be used for heating installations in all types of premises. It involves uniform heating of the radiators, and it is quite easy to install if the circuit is drawn up correctly.

The main advantages of a single-pipe heating system

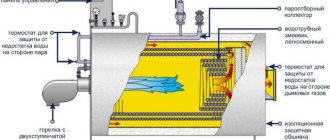

Single-pipe system diagram

The described heating system has several significant advantages:

- The ability to transport heated coolant around the entire perimeter of a residential building in one circle through heating pipes. A two-pipe system can do this in only two or even three times;

- The ability to organize a heating system below the floor level and under the entrance doors, which greatly simplifies organizational and repair work;

- The presence of only one pipe with coolant leads to large savings in the construction budget;

- Possibility of fairly simple control over the heating of all radiators together and separately.

These qualities of a single-pipe heating system make it possible to create a high-quality and reliable heating system in multi-storey buildings.

Acceleration manifold

Despite all the positive aspects of this type of heating systems, it is worth considering one difficulty in their operation.

The single-pipe heating system of a one-story house works rather poorly without the use of a pump, which will facilitate the proper circulation of coolant through the pipe and radiators. In order to organize the correct and reliable operation of such a system, it is necessary to install an acceleration manifold.

This determines the constant temperature of the coolant in each radiator and the noise level, which is inevitable when using water heating systems.

If this heating system is installed in a two-story building, there is no need to install an acceleration manifold. Due to the fact that the heating pipe is located quite high, which helps to create high natural pressure, the use of accelerating pumps and a manifold is practically not required.

Traditionally used heating schemes

- Single-pipe. The coolant circulates through one pipe without the use of pumps. On the main line, radiator batteries are connected in series; from the very last, the cooled medium (“return”) is returned to the boiler through a pipe. The system is simple to implement and economical due to the need for fewer pipes. But the parallel movement of flows leads to a gradual cooling of the water; as a result, the media arrives at the radiators located at the end of the series chain significantly cooled. This effect increases with increasing number of radiator sections. Therefore, in rooms located near the boiler it will be excessively hot, and in remote ones it will be cold. To increase heat transfer, the number of sections in the batteries is increased, different pipe diameters are installed, additional control valves are installed, and each radiator is equipped with bypasses.

- Two-pipe. Each radiator battery is connected in parallel to the direct supply of hot coolant and the “return” pipes. That is, each device is equipped with an individual return outlet. With the simultaneous discharge of cooled water into the common circuit, the coolant is returned to the boiler for heating. But at the same time, the heating of heating devices gradually decreases as they move away from the heat supply sources. The radiator, located first in the network, receives the hottest water and is the first to return the coolant to the “return” circuit, and the radiator located at the end receives the coolant last with a lower heating temperature and is also the last to return water to the return circuit. In practice, in the first device the circulation of hot water is the best, and in the last the worst. It is worth noting the increased price of such systems compared to single-pipe systems.

Both schemes are justified for small areas, but are ineffective for extended networks.

An improved two-pipe heating scheme is the Tichelman heating scheme. When choosing a specific system, the determining factors are the availability of financial capabilities and the ability to provide the heating system with equipment that has the optimal required characteristics.

Heating using electrode boilers

Electrode heating works by ionizing water. The process produces ions with positive and negative charges. The particles approach the electrode plates, and free energy is generated as a result of contact. It is released during boiler operation, which leads to heating of the water. Since the current strength and its direction are not constant and can change direction, particles do not settle on the heating plates.

Types of water heating

Electrode boiler

What are the positive aspects of such heating:

- The efficiency is quite high;

- there is no need to adjust the temperature manually;

- cost-effective financing for heating;

- high heat transfer;

- possibility to change the heater;

- with low energy consumption, the room warms up quickly enough, since the heat transfer rate is high;

- low cost of installation and assembly work;

- not necessarily close to gas pipelines.

What is Tichelman's loop

The Tichelman loop (also called a “passing circuit”) is a heating system pipe routing diagram. This scheme simultaneously combines the advantages of two common schemes: Leningrad and two-pipe, while having additional advantages.

Compared with a two-pipe scheme, when using a Tichelman loop there is no need to install expensive control systems. Heating devices work like one large radiator. The coolant flow is the same throughout the entire heating circuit. There are no narrowing pipes and dead-end radiators, where the flow is worst. The disadvantage compared to a two-pipe heating scheme is that the entire branch must be made with a large-diameter pipe, which can greatly affect the cost of the entire system as a whole.

If we compare it with the Leningrad (single-pipe) scheme, the advantage is that the coolant will not pass through the pipe past the radiator. The Leningrad circuit is very demanding in terms of circuit design and installation. If you are not highly skilled in performing either the first or the second, it will be impossible to force water to pass through the heating device; it will pass through the pipe. The radiator will remain slightly warm. In addition, in the Leningrad scheme, the first radiators in terms of water flow will be hotter than the next ones. Since the water will reach them already cooled. The disadvantage of the Tichelman loop compared to the Leningrad loop is that the pipe flow rate almost doubles.

Of the general advantages, I would like to note that such a scheme is difficult to unbalance. The conditions for coolant movement are almost ideal, which also has a positive effect on the operation of the heat generator (be it a boiler, solar systems or something else).

The main disadvantage of the associated heating scheme is certain requirements for the room. In practice, it is not always possible to organize a circular movement of the coolant. Doorways, architectural features, etc. may interfere. In addition, it can only be used for horizontal wiring; for vertical wiring, the Tichelman loop is not applicable.

Nuances of a three-pipe heating system

It is very important to design the correct heating system, since it determines the warmth and comfort in the house during the entire cold period, which in our country is characterized by severity. A heating system with a coolant in the form of water can be one-pipe, two-pipe, three-pipe or even four-pipe. The Tichelman system is often called a three-pipe system.

The Tichelman scheme is classified as a type of two-pipe system, which is distinguished by a reversible type and a return heating system.

A three-pipe system is qualitatively different from a two-pipe system, but does not reach the level of a four-pipe system. Such a system can be called a compromise: its distinguishing feature is flexibility and affordable cost when compared with the costs of installing a four-pipe system. Installing a three-pipe system is the most optimal and economical option.

Nuances and characteristics of the system:

- Easy to use. The system works very simply if you first understand the principle of its operation.

- The automatic control process ensures that the coolant and its flow rate remain constant for each consumer.

- The system can be used to equip buildings of any type.

- To operate, the system does not require the installation and use of check valves: it works thanks to a circulating pump.

Three-pipe heating systems can be open or closed. Closed systems require continuous operation and circulation of the coolant to the heat source and to the heating source. Open systems are characterized by inequality. After the network water is poured out, the water comes into contact with the atmosphere. The open system can be replenished anywhere.

System Description

In professional circles, the Tichelman loop is called a two-pipe heating system with a parallel movement of the coolant. This name fully reflects the essence and principle of operation; the distinctive features are best seen against the background of a two-pipe system with reverse flow of coolant, which is familiar to almost everyone.

Let's imagine a radiator network deployed in a straight row. In the classical scheme, the heating unit is located at the beginning of this row, from which two pipes follow along the entire network for supplying hot and returning cold coolant, respectively. Moreover, each radiator is a kind of shunt, therefore, the greater the distance of the heating device from the thermal unit, the higher the hydraulic resistance in its connection loop.

If we roll a row of radiators into a ring, then both of its edges will be adjacent to the thermal unit. In this case, it is much more profitable to make sure that the return pipeline does not direct the coolant back to the boiler room, but continues to follow further along the chain, that is, along with the supply. In other words, the supply pipe follows from the heating unit and ends at the outer radiator, in turn, the return pipe originates from the first radiator and is directed to the boiler room. The same principle can be implemented even if the radiators are located linearly in space, simply from the point where the outermost radiator is inserted into the return line, the pipe turns around to return the cooled coolant. In this case, in a certain area the heating system will be three-pipe, as the Tichelman loop is also sometimes called.

But why do we need such complications? If you carefully study the diagram, you will find that the sum of the lengths of the supply and return pipelines for each radiator is the same. Hence the conclusion: the hydraulic resistance of each individual connection loop is equivalent to the remaining sections, that is, the system simply does not need balancing.

Tichelman loop. Associated heating system. Schemes, calculation and selection of diameters.Diagram of the associated heating system, called the Tichelman loop.

Figure: Tichelman loop diagram in a private house.

The circuit is called passing, because the movement of the supply and return coolant moves in the same direction. That is, they move along the same path. This is a heating system with associated movement of coolant.

More about the program

Where did the name Tichelmann loop come from?

Such a circuit was invented and discovered by the German engineer Albert Tichelmann (1861-1926). In 1901, this chain was named the Tichelman loop in honor of Albert Tichelman. Unfortunately, there is no detailed biography. The idea of this circuit, in many opinions, is an improvement of the two-pipe dead-end system, which has the disadvantages of remoteness of consumers from the beginning of the main pipes, which leads to a decrease in pressure and costs for consumers. A two-pipe dead-end can be converted into a passing one (Tichelman loop) by adding a third pipeline. This will be discussed below about the three-pipe system.

Is there any merit to the Tichelman loop?

The Tichelman loop does not have the great advantages that many people talk about. You will be convinced of this when you read the entire article.

The advantage that is advertised on the Internet is that radiators do not need to balance costs. However, this statement is wrong! To understand this, read the entire article.

The Tichelmann loop can be called a three-pipe system

In some cases, such a circuit is called a three-pipe, when the circuit looks like this:

Figure: Tichelman three-pipe loop.

There are three pipelines under the radiators. Such a three-pipe turns out to be economically unprofitable in terms of materials, installation and takes up more space under the radiators. Therefore, a three-pipe is not made, and a two-pipe dead-end one is made in its place.

The associated heating system is more suitable in cases where there are radiators around the entire perimeter of the house.

Figure: Two-pipe associated heating system for a two-story house. Two Tichelman loops.

But running pipes around the perimeter can be problematic due to the entrance or balcony door. Stairs are also in the way.

Therefore, most often, if there are doors around the perimeter, then they make a two-pipe dead-end one.

Why is the Tichelman loop so remarkable?

Unlike a two-pipe dead-end circuit, in such a circuit the sum of the lengths of the supply and return pipes to each radiator is equal to one value. This can be calculated in the diagram:

For example, suppose that the radiators are 1 meter apart from each other. Then, to each radiator, the sum of the lengths of the supply and return pipes will be equal to 11 meters.

1 radiator = 1 + 10 = 11 m.

2 radiators = 2 + 9 = 11 m.

3 radiators = 3 + 8 = 11 m.

And so on.

The Tichelman loop, in contrast to the two-pipe dead-end loop, gives the erroneous idea that such a circuit does not need to balance the flow rates between the radiators, because each radiator has the same sum of the lengths of the supply and return pipes. And it turns out that supposedly the radiators are in the same hydraulic conditions. However, this misconception has received wide publicity among the population and plumbers. And Tichelman circuits with poorly heating medium radiators continue to appear.

What prevents the Tichelman loop from being an ideal heating system?

Why doesn't the Tichelman loop heat up?

Each radiator in the Tichelman loop circuit is a circuit bypass for another radiator, just as in a two-pipe dead-end heating system. It is easier for the coolant to flow through the radiator closest to the boiler than through one further away from the boiler. The flow in the Tichelman loop reverses through radiators with low hydraulic resistance. Therefore, it is so important to create artificial hydraulic resistance to radiator branches.

What conditions must be observed in the Tichelman loop in order for medium radiators to heat well?

Each radiator branch must have a hydraulic resistance of 0.5-1 Kvs. This resistance can be produced by a thermostatic or balancing valve, which is placed on the radiator line. As a rule, when savings are made on thermostatic and balancing valves (that is, they are not installed), then each radiator branch begins to have low hydraulic resistance, which is comparable to what would happen if you simply connected the supply and return with a pipe (Roughly made a bypass).

Note:

For gravity heating systems with natural circulation, radiator branches do not need to create artificial resistance. Because due to the natural pressure of the coolant, the radiator branch itself influences its flow rate.

The Tichelman loop can be used without a pump, but only with large diameters, as is done for gravity heating systems with natural circulation. And to calculate the diameters, the heating system simulator program will help you: Read more about the program

Economic difference between the Tichelman loop (passing) and the Two-pipe dead-end?

The cost of an associated heating system may be more expensive than a two-pipe dead-end one. Because two two-pipe dead-end ones can be installed along the perimeter. And the diameter of the pipeline will be smaller, because the flow rate will be half less.

Indeed, calculations and practice show that the associated heating system (Tichelman loop) is more expensive due to its large diameters.

Prices were calculated for materials from 7 radiators around the perimeter of the house with a polypropylene pipe. A Tichelman loop and a two-pipe dead-end loop with two wings around the perimeter were used. Prices taken from the manufacturer Valtec. All Valtec material.

When using a polypropylene pipe in a two-pipe dead-end heating system with seven radiators, we saved 1,200 rubles compared to the Tichelman loop.

The prices for materials from 7 radiators around the perimeter of the house with a metal-plastic pipe were also calculated. A Tichelman loop and a two-pipe dead-end loop with two wings around the perimeter were used. Prices taken from the manufacturer Valtec. All Valtec material.

When using a metal-plastic pipe, in a two-pipe dead-end heating system with seven radiators, we saved 2,646 rubles in relation to the Tichelman loop.

By the way, in some cases you can save on balancing valves if you use a 16mm pipe with a thermostatic valve on the radiator branch. Thermal valve resistance and 16mm pipe increase the hydraulic resistance. In this case, you need to test it in a simulator program.

The Tichelman loop requires tees of a non-standard sequence of diameters. For example, 32x20x25mm, which you may not find on the market. Metal-plastic pipes have more types of tee transitions than polypropylene pipes.

If we think about the pressure drop of the entire circuit, then the two-pipe dead-end circuit turned out to be less than the associated one (Tichelman loop). The Tichelman loop was 0.9 m.w.st. Two-pipe dead-end 0.6 m.v.st.

The inflated myth that the Tichelmann loop does not need to balance radiators has been completely destroyed! And the benefit of such a chain becomes useless. It is possible to run two two-pipe dead-end heating systems with a smaller diameter around the perimeter.

There are some considerations that the larger diameter replaces two small diameter pipes. But calculations based on cross-sections of diameters show that it is more profitable to take a small diameter than a large one. That is, in relation to the section of the internal diameter, it turns out that a small internal section costs less (not by much). And this argument is not in favor of the Tichelman loop.

There is another feature of hydraulics that in a large diameter there is less pressure loss at the same speeds of coolant movement. This is proven by formulas for calculating pressure losses. It turns out that with a larger diameter we can get more coolant flow. But the game is not worth the candle if the budget of a private home is low. Conducted an experimental calculation of a pipe 10 meters long at a speed of 0.62 m/sec. received a difference in pressure loss from 0.32 to 0.51 m.w.st. That is, by doubling the diameter cross-section, we will get a flow rate of 130% more. That is, the increase in consumption will not be twice as large, but 2.3 times as large. The increase in flow rate is due precisely to the fact that in larger pipeline diameters there are fewer pressure losses relative to the cross-sectional area of the diameter. Of course, these data will depend on the conditions of diameters, pressure losses and coolant speed. This effect will be different for each case. Therefore, you should not immediately switch to larger diameters; you need to test each individual case in the chain.

To calculate the heating system circuit, it is necessary to divide into small pipe diameters and distribute more pipes of small diameters than large ones. On larger diameters, tees and fittings for transitions to other diameters are more expensive. Well, the more pipes, the more installation work.

Installation of the Tichelman loop

Installation of a Tichelman loop is not much different from a two-pipe dead-end heating system. But the tees are not standard. For example, 32x20x25mm. Such tees are difficult to find on the market. If you can’t find them, then buy adapters for certain diameters. Polypropylene fittings are much cheaper than metal-plastic pipes. Therefore, for metal-plastic it will be an expensive pleasure.

What diameters to choose in the Tichelman loop?

The diameters in the Tichelman loop are not an easy task, as is the choice of diameters in a two-pipe dead-end heating system. The principle for choosing diameters depends on flow rates and pressure losses in the pipeline.

Below you will see how diameters are selected.

Bad Tichelmann loop circuits

Medium radiators will work poorly if there is no artificial hydraulic resistance on the radiator branches. Artificial resistance is created by balancing or thermostatic valves. Which have a throughput of 0.5 - 1.1 Kvs.

Pressure heating system with ball valves and 20 mm polypropylene pipe.

You cannot do this on ball valves:

This radiator branch has low hydraulic resistance. It will consume a lot of fuel and there will be little left for other radiators.

A circuit for 5 radiators with a 25mm PP main pipe was tested.

Radiator costs are not the same. The third radiator has the lowest flow rate. This is due to the fact that there are ball valves on the radiator branches.

If you add thermostatic valves to the circuit, the costs become more equally divided:

The picture is already better! But the diameters can be reduced in some places and save on this. For example, there are up to 4 radiators in the supply line and 2 radiators in the return line.

If we try to leave PP20mm on the entire highway, we will get the following costs.

If we used a thermal valve or any regulating device at 2 Kvs, then a change in diameters would have to be done!

Because if someone opens the tap completely, it will prevent other radiators from working normally. There are control valves for radiators at 5 Kvs. Well, if you are going to tighten the bottom valve to reduce the throughput, then do this kind of adjustment. Of course, it would be better to use closed balancing valves that cannot be adjusted by unauthorized people.

In order to improve the distribution of costs among 5 radiators using control valves with higher throughput, it is necessary to use PP32, PP25 and PP20 pipes.

Good Tichelmann loop chains

Diameter selection criteria:

The choice of diameters for the Tichelman loop was selected based on a chain drop of a maximum of 1 m.v.st. The temperature difference of the radiators is 20 degrees. The inlet temperature is 90 degrees. The difference in output power between radiators does not exceed 200 W. The difference in temperature differences between radiators does not exceed 5 degrees.

Note:

The indicated diameters do not apply to low temperature heating systems. For low-temperature systems, it is necessary to reduce the temperature difference to 10 degrees and this requires a doubling of the flow rate.

I prepared Tichelman loop chains for 5 and 7 radiators for metal-plastic and polypropylene pipes.

5 radiators polypropylene pipe, Kvs = 0.5.

5 radiators metal-plastic pipe, Kvs = 0.5.

7 radiators polypropylene pipe, Kvs = 0.5.

This chain uses 32mm PP. If you install a balancing valve on radiators 1 and 7, you can change the pipe from PP32 to PP26 mm. It is necessary to tighten the balancing valves on radiators 1 and 7.

7 radiators metal-plastic pipe, Kvs = 0.5.

Tests on the selection of diameters were carried out in the heating system simulator program.

More information about the simulator program

The program is used to test heating systems before installation on site. It is also possible to test existing heating systems to improve the performance of the existing heating system.

If you need diameter calculations for your heating system for 10 radiators, then apply for calculation services here: Order a calculation service

Calculation of the Tichelmann loop

As in a two-pipe dead-end heating system, the diameters also have to be selected based on the flow rate and pressure loss of the coolant. The Tichelman loop is a complex circuit, and the mathematical calculation becomes very complicated.

If in a two-pipe dead-end circuit the equation looks simpler, then for a Tichelman loop the circuit equation looks like this:

More details about this calculation are described in the video course on heating calculations here: Video course on heating calculations

How to set up a Tichelman loop? How to set up a secondary heating system?

As a rule, the Tichelman loop has conditions when the middle radiators do not heat well; in this case, as in a dead-end pipe, we clamp the balancing valves on the radiators located closer to the boiler. The closer the radiators are to the boiler, the tighter we clamp them.

conclusions

The Tichelman loop heating system is more expensive, but not much. It is possible that it will be possible to meet approximately the same price as with a two-pipe dead-end.

The associated wiring of the heating system is complicated by the search for tees with diameters in a certain sequence; you will have to look for unique tees if there are 7 or more radiators.

The Tichelman loop needs to balance the flow rates between the radiators.

Diameter transitions in the Tichelman loop on main lines can be done or even necessary if there are conditions when this must be done.

Unfortunately, the Tichelman loop system in heating is extremely rare. And that’s why there are so many rumors and speculations about her. And it is not surprising, because it does not have particularly strong advantages compared to a two-pipe dead-end heating system.

Only the Tichelman loop in a private house has become most widespread, because the owners of their houses received misinformation that such a circuit supposedly does not need balancing of radiators.

Tichelman loop cons:

It turns out more expensive.

Structurally, it is difficult to pass pipes around the entire perimeter. The doors are in the way.

It is difficult to find tees with diameters of a certain sequence on the market. 32x20x25mm.

Reviews of the Tichelman loop

Quite a few clients come to me who have problems warming up medium-sized radiators in a Tichelman loop.

Therefore, reviews are usually not encouraging. Customers complain about the Tichelman loop. Above I explained why this happens and how to make the middle radiators work in the Tichelman loop circuit. Like

| Share |

| Comments (+) [ Read / Add ] |

Tichelman loop. Associated heating system. Schemes, calculation and selection of diameters. Gravity heating spider scheme Acceleration loop in the Gravity heating system of KMS tees Tichelman loop - It is forbidden to do it! Ideal condensing boiler connection diagram and operating principle

Tichelman loop - reliable heating for large houses, how to make it

If such a circuit is formed as a closed ring, then both edges become as close as possible to the heating device and the return flow pipeline is not directed to the boiler compartment, but continues further along the chain. In this case, the Tichelman heating scheme requires extending the supply pipeline from the heating device to the last radiator, while the return line goes along the line from the first battery and ends in the boiler compartment.

The scheme is also implemented in the case of a linear arrangement of heating radiators. In this situation, the return flow pipe must be deployed in the insertion area of the last battery and the cooled coolant will return to the heating device. It turns out that in a certain section of the main line the system turns into a two-pipe system, which is why the Tichelman loop is also called a 2-pipe distribution.

On a note! In terms of the total length, the supply and return pipelines for each radiator are equivalent, so balancing the heating system when laying out the Tichelman circuit is not required. Due to the identical thermal power of the batteries, the design ensures uniform heat supply to the radiators at any distance from the heating device. It is not recommended to use the Tichelman loop in small houses; here it is more convenient to equip a dead-end heating system. Increased consumption of materials is not always better, so the Tichelman system is rarely used in a two-story house.

The exception is a highway with radiators placed around the perimeter of the building. We will have to lay another line to return the coolant to the heating device. If the loop is lengthened, moved away from the heater, the cross-section of the pipes is increased, or a powerful circulation pump is selected, otherwise the system will not be able to operate at full capacity.

Naturally, in the process of designing a heating system diagram in a specific architectural object, it is necessary to decide what the diameter of the pipes in the structure should be. In this case, the calculation of general heat and power indicators is assumed. This must be done first, since otherwise the installation of heating will be difficult. So, in the process of determining the diameter of the pipes, we calculate the power of the structure.

To reduce coolant costs in the area where the first batteries are connected, the diameter of the pipeline should be reduced, this will help maintain water pressure in subsequent sections. The diameter is reduced only according to preliminary calculations, otherwise radiators located at a considerable distance from the heating device will not receive a sufficient amount of coolant.

Basic operating principles

Connecting the battery

The main difference between a single-pipe heating system and a two-pipe heating system, which come with bottom or top wiring, is the fact that a single-pipe system does not have a return pipe.

One-pipe heating systems can be used for heating both one-story and two-story houses. Such a system has one undeniable advantage. The distribution of pipes with coolant can be placed under the floor, which has a rather favorable effect on the appearance of the living space and simplifies finishing work.

With this type of arrangement of heating pipes, do not forget about thermal insulation.

Pipes located under the floor must be hidden in a special thermal insulation material. This will help save the maximum amount of thermal energy in the radiators, and most importantly, prevent the destructive heating of some materials that are used as floor coverings.

The procedure for performing installation work

The work consists of the following operations:

- Boiler installation. The required minimum room height for its placement is 2.5 m, the permissible volume of the room is 8 cubic meters. m. The required power of the equipment is determined by calculation (examples are given in special reference publications). Approximately for heating 10 square meters. m requires a power of 1 kW.

- Hangment of radiator sections. The use of biometric products in private homes is recommended. After selecting the required number of radiators, their location is marked (usually under window openings) and secured using special brackets.

- Extension of the associated heating system line. It is optimal to use metal-plastic pipes that successfully withstand high temperatures, are durable and easy to install. The main pipelines (supply and return) are from 20 to 26 mm and 16 mm for connecting radiators.

- Installation of a circulation pump. Mounted on the return pipe near the boiler. The insertion is carried out through a bypass with 3 taps. It is necessary to install a special filter in front of the pump, which will significantly increase the service life of the device.

- Installation of an expansion tank and elements ensuring the safe operation of the equipment. For a heating system with a passing coolant movement, only membrane expansion tanks are selected. Safety group elements are supplied with the boiler.

To line doorways with a main line in utility rooms and utility rooms, it is allowed to install pipes directly above the door. In this place, to prevent air accumulation, automatic air vents must be installed. In residential areas, pipes can be laid under a door in the body of the floor or bypassing an obstacle using a third pipe.

Tichelman’s scheme for two-story houses provides for a certain technology. Pipe distribution is carried out with tying the entire building, and not each floor separately. It is recommended to install one circulation pump on each floor, maintaining equal lengths of return and supply pipelines for each radiator separately in accordance with the basic conditions of the associated two-pipe heating system. If you install one pump, which is quite acceptable, then if it fails, the heating system in the entire building will shut down.

Many experts consider it expedient to install a common riser on two floors with separate piping on each floor. This will make it possible to take into account the difference in heat loss on each floor with the selection of pipe diameters and the number of required sections in radiator batteries.

A separate associated heating circuit on the floors will greatly simplify the setup of the system and allow for optimal balancing of the heating of the entire building. But to obtain the desired effect, it is necessary to insert a balancing crane into the travel circuit for each of the two floors. The taps can be placed side by side directly next to the boiler.

Inverter heating

Heating systems powered by electricity have many positive characteristics. The ease of installation of such equipment is that electricity is available in any building. In order to install inverter heating at home, you do not need to obtain permits. Also, the hyperinverter heating system saves space. Pay attention to the price. The cost of inverter heating equipment is significantly lower than other heating systems. The boiler can be replaced with an inverter, it is much cheaper.

How does DIY inverter heating work? Electricity enters the boiler through the heating element. Take care to protect equipment from damage and insulate the building to minimize heat loss. The operating principle of an inverter boiler is such that it constantly produces an induction current. In the event of a power outage, the boiler can operate on battery power. The boiler consists of two parts - the magnetic part and the heat exchanger.

Components of an inverter boiler

Why is an inverter boiler so good? Due to the fact that it does not have a heating element in its structure, this makes it more practical to use. Due to the fact that a pump is built into the system, the energy carrier warms up faster. There are no great requirements for fuel selection.

The operating principle is the same as that of an open dependent heating system, since the heating elements do not come into contact with various media.

However, do not forget that with all the positive characteristics, you can also find disadvantages. An inverter boiler costs much more than a heating element. Also, the boiler itself is quite large and is not suitable for rooms with a small area. To set the set temperature or reduce the indicators, you need to build an automatic control system into the boiler.

Pros of the scheme

More and more owners of private houses are deciding to install heating systems according to the Tichelman scheme. This is not surprising; it has quite a number of advantages:

Probably the most important advantage of this method is that such a heating system allows all heating devices to work as efficiently as possible. For example, the supply and return lines are connected together, going in the same direction of the radiator chain, the heat transfer of each subsequent radiator decreases, the latter may generally remain cold; The pipes run along two separate circuits in the same direction, the efficiency of the radiators becomes noticeably higher, continuing to decrease; Thanks to the Tichelman loop, radiators are able to operate at 100%; The system is adaptive in nature; small and large premises for domestic or industrial purposes are suitable for installation; Each radiator provides the same amount of heat, so the room will warm up evenly; The method is simple to implement, has no complicated steps, it is only important to follow the technology; There is the possibility of installing additional heating devices; Since the radiators are already balanced, there is no need to waste time on balancing them for uniform heating; installation of the system does not require the purchase of any additional elements; Heating installed according to the Tichelman scheme will last a very long time.

Schematic diagram of Tichelman heating

Opinion of country house owners about the system

According to most owners of country real estate, this scheme is indeed very effective - the Tichelman loop.

This system has received simply excellent reviews. If it is properly designed and assembled, a very comfortable microclimate is established in the house. At the same time, the system equipment itself rarely breaks down and lasts a long time. Not only the owners of residential buildings, but also the owners of dachas speak well of the Tichelman loop. The heating system in such buildings is often used irregularly during the cold season. If the wiring is done according to a dead-end circuit, when the boiler is turned on, the rooms are heated extremely unevenly. With a passing system, such problems, of course, do not arise. But assembling heating according to such a scheme is really more expensive than using a dead-end one.

Algorithm for performing installation work

The installation of a two-pipe associated heating system is carried out in accordance with a certain algorithm, where the initial stage is the selection of pipe diameters, and the final stage is the installation of a circulator pump.

Calculation of pipeline diameter

There is a scientifically based method of calculation. The cross-section of the pipe is selected based on the volume of coolant passing through the pipe per unit time. The calculation starts from the distant radiator using the formula:

G=3600×Q/(c×Δt), (1)

where: G – water consumption for heating the house (kg/h);

Q is the thermal power required for heating (kW);

c – heat capacity of water (4.187 kJ/kg×°C);

Δt is the temperature difference between the hot and cold coolant, taken equal to 20 °C.

Next, calculate the cross-section of the pipes using the formula:

S=GV/(3600×v), (2)

where: S is the cross-sectional area of the pipe (m2);

GV – volumetric water flow (m3/h);

v is the speed of water movement, is in the range of 0.3−0.7 m/s.

The resulting figure is the cross-section; based on it, the internal diameter of the pipeline is selected.

This calculation is carried out for all radiators up to the boiler.

When calculating, you can also rely on the table of the dependence of the internal diameter of the pipe on the thermal load.

Table of dependence of the internal diameter of the pipe on the thermal load

The following guidelines can be taken into account:

- For heat losses of up to 15 kW (150 sq. m.) of area, pipes with a diameter of 20 mm are suitable.

- For losses from 15 to 27 kW (up to 250 square meters), pipes with a diameter of at least 25 mm will be required.

Carrying out calculations using the given formulas or hydraulic tables is a difficult task for the homeowner, so you can rely on the recommended pipe diameters.

The diameter of the pipeline must be the same throughout its entire length to ensure stable operation of the batteries. The recommended minimum internal diameter of pipes is 20 mm.

The following conditions must be met:

- Place pipes under the floor covering to avoid high-rise contours. If this is not possible, then you need to take into account the configuration of the house and strive as much as possible for the same height of pipe laying.

- Pipe material is metal-plastic or polypropylene reinforced with aluminum foil. Such pipes are stronger and will last a long time.

- Radiators are installed bimetallic or steel with a bottom connection system. Such batteries have higher hydraulic resistance, which balances the system. The power of the radiators should be the same throughout the entire area of the house.

- Each battery is equipped with a balancing valve on the return line. It is advisable to install thermostats.

Boiler installation

The room where the boiler is installed must have a height of at least 2.5 m. The volume of the room is recommended from 8 cubic meters. The hot water boiler must be selected depending on the area of the heated house. Boiler power for heating is 10 kW. m is equal to 1 kW. Based on this, the power for the entire system is selected.

The boiler piping consists of a set of shut-off valves; it is installed in several places:

- On the make-up pipe.

- On both sides of the pump.

- At the expansion tank.

- On the pipes coming from the boiler.

Mainline pulling

When installing the associated heating system distribution line, the following must be taken into account:

- The outlet branch of the main line must be located below the supply branch.

- The heat supply and heat removal pipes must be parallel to each other.

- The expansion tank must be installed above the heating boiler.

- Valves for draining water must be installed on the connecting radiators. It is recommended to install a thermostatic head on each radiator to ensure a comfortable temperature.

- When laying the pipeline, right angles are excluded to avoid the occurrence of air locks in the system.

- The expansion tank must be installed in a heated room.

- All diameters of pipes, fittings and taps must match each other. You cannot install pipes of different diameters in an attempt to save money. The water pressure in the system will be disrupted.

Installing a circulation pump

It is unreasonable to rely on natural circulation, since there are 10 or more batteries in the associated heating system. Gravity will not be able to work without forced pressure. The circulation pump is installed on the return branch near the boiler. The pump is installed using a bypass and three valves. It is recommended to install a filter.

The associated heating system is installed in one-story and two-story buildings. In two-story buildings, during installation you need to take into account some nuances:

- A circulation pump is installed on each floor. If a breakdown occurs on one floor, the heating will work fully on the other.

- For each floor it is recommended to install according to a separate scheme.

Three-pipe register

Heating registers are heating devices made of smooth-walled pipes that are connected to each other by welding, gas or electric. The pipes are located parallel to each other and are connected by additional transverse pipes through which the coolant flows. This design can also be called connecting a number of radiators.

Scheme of operation of an open heating system.

Such registers are installed not only in large industrial premises, but also in ordinary apartments, private houses and country cottages.

At the same time, designers took note of this design and began to install it not only horizontally, but also vertically, thus achieving a non-standard and original appearance.

For this, a selection of pipes of different diameters and unusual decoration methods are used. By covering them with decorative elements, you can get a very beautiful decoration for any room.

There are other options: coil three-pipe registers are also made, so there is plenty to get creative with and choose from.

Heating two-pipe floor-by-floor system: features of arranging a private house

As the name implies, the two-pipe heating system of a two-story house consists of two main pipelines supplying batteries and other heaters from the boiler.

One pipeline contains hot water, which heats the radiators, and the second contains cold water from the radiators, which flows back into the gas boiler to heat a private house.

A single-pipe heating system for a two-story house is just as effective as a two-pipe one.

You can give several examples to understand how effective the use of a hot water line without return is:

- Heating speed and high coolant efficiency.

- Economical. When using a two-pipe heating system, it is possible to easily control the air temperature in the building, achieving the required level of comfort.

- Possibility of choosing the most optimal heating device scheme.

Diagrams of a two-pipe heating system for a two-story house

Scheme of a horizontal two-pipe manifold heating system.

A one-pipe heating system for a two-story house, like a two-pipe one, provides for the installation of radiators and pipelines according to several main schemes.

Each of these schemes, naturally, has its own advantages and features, which would be worth considering:

- Beam circuit with distributor. This diagram of a two-pipe heating system for a two-story house is widespread, and its popularity lies in the personal installation of the coolant outlet and supply. Pipe installation is often done directly into the floor.

- Among the advantages of this scheme: preservation of the composition of the interior style, the most effective heating control, adjustment of the coolant supply.

- The sequential scheme for supplying coolant is very popular among owners of small two-story country houses due to its low material consumption.

- This scheme involves sequentially connecting return and supply pipes to each heating battery (the usual one-pipe heating scheme of a two-story house is very similar to it).

- Thanks to the use of a sequential two-pipe heating circuit, the price of the device is reduced, and it becomes possible to install an individual thermal regulator on each radiator.

Two-pipe heating systems of a two-story private house: modernization of wiring

Heating diagram for a two-story house.

- Due to the characteristics of each individual two-story house, property owners often modify the installed heating themselves.

- This is very practical and convenient, since installation instructions are not always standardized and sometimes do not make it possible to achieve high operating efficiency of heating equipment.

- It should be noted that many videos and photos on the Internet show that the greatest demand among country home owners is to install a pump and expansion tank in a two-pipe heating system.

Scheme of a two-pipe water heating system with natural circulation.

Thanks to such upgrades, it is possible to increase work productivity, efficiency, and also reduce the cost of heating the coolant:

- Installation of the expansion tank. This device must be placed almost at the highest point of the house - for example, in the attic of cottages.

- Thanks to such a tank, the coolant will circulate freely in the heating main without creating excess pressure;

- Recommendation: it is advisable to install a large volume tank “with a reserve”, as this will help ensure constant circulation of the required volume of coolant.

- Pump installation. Heating for a modern three- or two-story country house with natural circulation (gravity heating) is a rather outdated option.

- Today, installing a special pump helps increase productivity.

Inserting the return line directly into the pipeline of a special pump makes it possible to significantly speed up heating to the optimal temperature, saving money on the purchase of fuel.

The coolant, moreover, circulates much faster with the pump, accordingly, thanks to this there will always be an optimal temperature in the house, including on the second floor.

Calculation of the required number of registers in the house

For an accurate calculation, you need to take into account several factors, thanks to which you can find out how many registers are needed to heat your home. It is advisable to do this in advance so as not to waste money on buying unnecessary material. Therefore, you need to pay attention to the following:

- wall thickness;

- the exact number of windows and doors;

- the material from which the building is constructed;

- presence of a basement floor;

- roof insulation;

- climatic conditions of the area.

When making calculations, it is worth considering that one linear meter of pipe, the diameter of which is 60 mm, heats one square meter of a room with a ceiling height of up to 3 m. In addition, you need to correctly decide on the choice of pipe diameter. Typically, pipes with a diameter of 32 mm are considered the most ideal option.

System calculation: pipe diameter

Of course, drawing up a detailed project is what the Tichelmann loop heating installation first requires.

In this case, the system is calculated in the usual manner. In order to determine the required pipe diameter, you must first calculate the required thermal power of the system. This can be done using the formula Q = (V * Δt * K), where V is the volume of the house, Δt is the difference in temperature indoors and outdoors, K is the heat loss coefficient. The last parameter depends on the degree of insulation of the task. Heat loss coefficient depending on the degree of insulation of the building

| Thermal insulation degree | Coefficient |

| No thermal insulation (or minimal) | 3-4 |

| Brick cladding | 2-2.9 |

| Average level of thermal insulation | 1-1.9 |

| High-quality insulation, use of plastic windows and modern entrance doors | 0.6-0.9 |

Next, you need to determine the speed of movement of the coolant in the lines. The range of values for the optimal indicator in this case is between 0.36 and 0.7 m/s. All data obtained should ultimately be inserted into a special table of pipe sizes. Most often, metal-plastic with a diameter of 26 mm is purchased for the return and supply lines in such systems. Radiators are connected with 16 mm sections.

Volume of water in the system

Of course, in order for the Tichelman loop heating system to work efficiently, before installing it, you should also calculate the required coolant flow. To determine this parameter, you must first calculate the heat loss of the building. This can be done using the formula G = S * 1 / Po * (Tv - Tn)k. Here Po is the heat transfer resistance, Tv and Tn are the air temperature outside and in the house, k is the reduction factor. The first and last indicators are determined from tables depending on the design features of the building. Actually, the coolant flow itself is calculated using the formula Q = G/(c*(T1-T2)), where:

- c is the specific heat capacity of water (4200),

- T1 is its return temperature,

- T2 - in the supply pipe.

The last two parameters are determined taking into account the nonlinearity of heat transfer from radiators. Ultimately, the difference between their values should be approximately 15-20 C.

In what cases is it advisable to install

Since assembling a passing heating system is more expensive than a conventional dead-end heating system, it is advisable to use it only in large houses with a significant number of radiators. That is, where balancing has a significant impact on the operation of the circulation pump.

Also, the need to assemble such a system comes into question in cases where pipes, due to layout features, cannot be routed along the perimeter of the room. In this case, you have to make an expensive three-pipe system, running the return line in a long loop. And this is usually expensive financially.

Hydraulic calculation

This circuit requires calculating the power of the circulation pump depending on the length of the line.

An important component of the circuit is a hydraulic pump that creates pressure on the supply and vacuum on the return path. The calculation data demonstrate that the values of both parameters decrease as the distance from the pump increases in the direction of coolant movement. If you measure the data on a hundred-meter pipe, it turns out that when removed by 10 m, the supply pressure will be 90% of the nominal value, and the reverse vacuum will be 5%. With a range of 20 m, these parameters will be equal to 75% and 20%, respectively, and the drop on the radiator element in both cases will be 95%. At a distance of 50-60 m, the numbers shift to the middle (45 and 40, 40 and 45, respectively), and the decline on the radiator is 85%. With further distance from the pump, the proportions continue to change towards increasing vacuum; the pressure reduction at a distance of 70 m will be 90%, and at 80 m and more – 95%. Thus, in the middle part the pressure loss will be slightly greater than at the beginning and end. Proportionally changing indicators make it possible to maintain approximately equal radiator pressure drops.

With correct installation, no differences in the cross-section of the main pipe and the same height of the radiators, the system functions uninterruptedly. The power of the batteries involved will be equal to each other.

Pipes and pumps for associated circuit

Reinforced polypropylene with a diameter of 2 cm for heating an area over 150 square meters.

m Since buildings in the private sector are characterized by a compact layout and the absence of long main routes to heating, high hydraulic resistance is uncharacteristic for such systems. To determine what diameter pipelines should have, you can use a table describing the relationship of this parameter with the required energy.

Two-pipe system

In small rooms (150 m2 or less), heat loss does not exceed 15 kW. In this case, it is recommended to choose products with an internal diameter of 2 cm and connect a 25-40 pump. In structures that heat large areas, where 15-30 kW is spent, an indicator of 25 mm is used in main tracks. For loop configurations and branches it is slightly reduced. To connect the radiator elements and supply to the last of them, use a minimum parameter value of 16 mm. A 25-60 pump is suitable for this installation.

Special programs

Of course, you can calculate the Tichelmann loop heating system manually. But it’s better to use a special program. All that needs to be done in this case is to enter the data requested by the software into the form. In most cases, such software, unfortunately, is sold for money. However, some developers provide demo versions of it or offer free versions with limited functionality, which may well be enough to calculate the heating system of an ordinary country house.

Installation features: when balancing is needed

As already mentioned, the Tichelman loop does not require adjustment of the amount of coolant passing through the radiators. But only when radiators of the same power are installed in the building. However, in large houses such a heating system assembly scheme is rarely used. For example, weak radiators are usually installed in the boiler room and other utility rooms, while more powerful models are installed in living rooms. Of course, all these batteries will need different ducts. If the coolant flow is calculated for weak radiators, it will not be enough for powerful ones. With reverse circuits, hydraulic noise will begin to appear in small batteries. To prevent this from happening, balancing valves are installed.